®

Heat Link

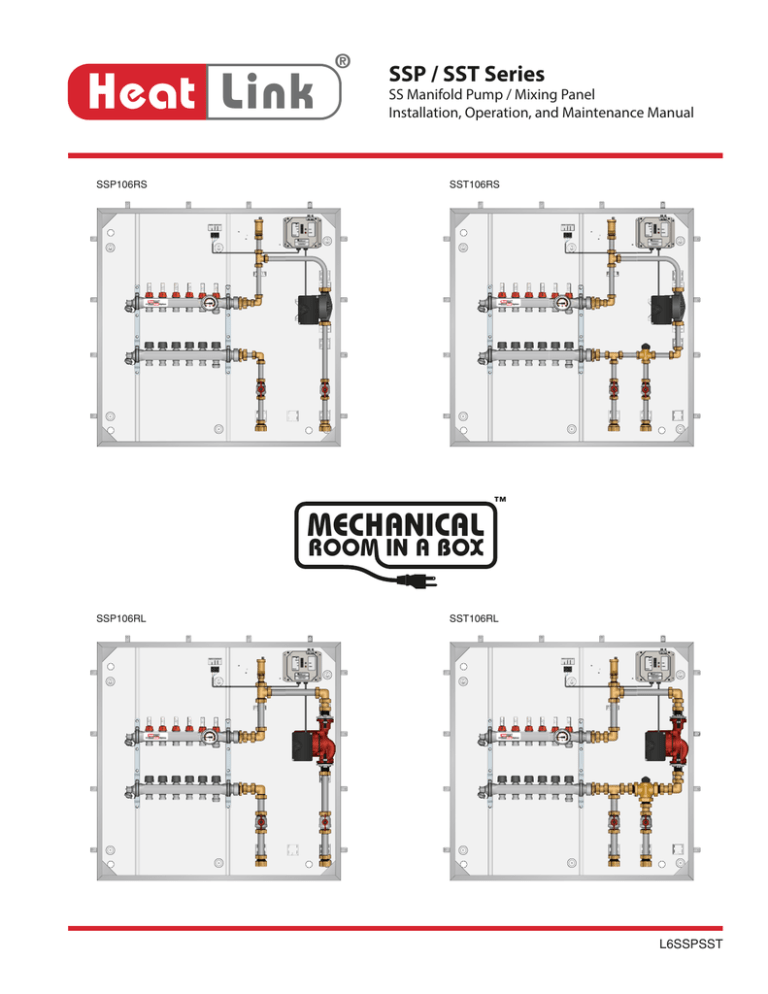

SSP106RS

SSP / SST Series

SS Manifold Pump / Mixing Panel

Installation, Operation, and Maintenance Manual

SST106RS

™

MECHANICAL

ROOM IN A BOX

SSP106RL

SST106RL

L6SSPSST

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Table Of Contents

Warnings........................................................................................................................3

Tools Needed ...............................................................................................................3

Function .........................................................................................................................4

Unpacking.....................................................................................................................5

Panel Components ....................................................................................................6-7

Specifications ...............................................................................................................8

Panel Component Specifications .........................................................................9-16

Valve Adjustments (SST Series only)....................................................................11

Manifold Balancing ....................................................................................................12

Mounting.......................................................................................................................17-18

Piping Hookup ............................................................................................................19-20

Fill and Purge ...............................................................................................................21

Panel Wiring .................................................................................................................22

Panel Control Sequence & Wiring.........................................................................23

Troubleshooting .........................................................................................................24

Maintenance ................................................................................................................25

Application Drawings ...............................................................................................26-27

2

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Warnings

The zone control panel is for indoor use only and must be installed by a qualified installer/service technician. This product

must be installed and operated in strict accordance with the terms set out in this manual and in accordance with the relevant

requirements of the Local Authority Having Jurisdiction. Failure to comply will result in a void of warranty, and may also result

in property damage, serious injury, or death.

Servicing

Prior to commencing installation of this panel it is necessary to read and understand all sections of this manual. The symbols

below are used throughout this document to ensure proper operation of the panel, and your safety. Please pay attention to

these symbols.

Warning

Possible Hazard

Warning

Live Power

Warning

Hot Pipes

Warning

Treated Water

In order to avoid injury or death, switch off the power to the panel prior to

inspecting or making connections to the terminal strip.

Disclaimer

HeatLink Group Inc. shall not be responsible for errors in its brochures or printed materials. HeatLink Group Inc. reserves the

right to alter its products at any time without notice, provided that alterations to products already on order shall not require

material changes in specifications previously agreed upon HeatLink Group Inc. and the Purchaser. All trademarks in this

material are property of the respective companies. HeatLink and the HeatLink logotype are trademarks of HeatLink Group

Inc. All rights reserved.

Tools For Installation

• Level

• Screwdriver or power drill

• Flat head bit

• Phillips head bit # 2

• 2 adjustable wrenches (or 2× 30mm wrenches and 2× 40mm wrenches)

• O-ring Lubricant (#79951 or #79952)

3

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Function

This panel can provide mixing (SST series only), distribution, and zoning for a wide variety of hydronic heating applications.

The effectiveness of the system is dependant on the system being designed and installed correctly. Proper consideration

of factors such as BTU loads, outdoor design temperature, indoor design temperature, room set-point temperature(s),

differential fluid temperatures, head loss, flow rates, and transfer capacities of the heat emitters is critical.

Once these factors have been considered and the system requirements determined, these can then be evaluated and

compared to the zone control panel capabilities (refer to pages 6-11).

Note:

4

This panel does not regulate or monitor the operating safety limit temperatures of the fluid leaving the heat source.

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Unpacking

Step 1 Examine carton for any damage that may have occurred during shipping. If damage is visible notify your courier and

supplier immediately.

Step 2 Open the carton by removing the strapping.

Step 3 Remove the cardboard spacers from the carton, then remove the panel from the carton. Lift the panel by the

enclosure, not the cover.

This panel is heavy; 2-3 person lift required.

Step 4 Remove the cover from the panel by unlocking the coin/screwdriver locks. Lift the top of the cover upwards to

disengage the tongues from the slots at the bottom of the panel and then pull the cover off.

Step 5 Verify the following items:

Small pump

• (2) 3⁄4" MBSP x 1" FNPT adapters

• (4) 3⁄4" rubber washers (2 spares)

• (1) 1" rubber washers (1 spares)

Large pump

• (2) 1" MBSP x 1" FNPT adapters

• (6) 1" rubber washers (4 spares)

5

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Panel Components

Part Number

#

Component

SSP1xxRS

SSP1xxRL

SST1xxRS

SST1xxRL

1

Primary Pump

PUMP1558

PUMP2699

PUMP1558

PUMP2699

2

Power Box

PWRB1R2

PWRB1R2

PWRB1R2

PWRB1R2

3

Stainless Steel Manifold

76100 series

76100 series

76100 series

76100 series

Flow Meter Valve Insert (supply)

(0-1.5 US gpm lock nut)

76916

76916

76916

76916

Zone Valve Insert (return)

76911

76911

76911

76911

4

3-way Mixing Valve

n/a

n/a

63716

63725

5

Automatic Air Vent

79932

79932

79932

79932

6

Thermometer

76940

76940

76940

76940

7

SS Manifold Port Caps

77100

77100

77100

77100

8

Hose Bib

–

–

–

–

9

Isolation Ball Valve

–

–

–

–

10

Enclosure

–

–

–

–

11

Cover

–

–

–

–

12

Accessory Pack

ACCSSSML

ACCSSLRG

ACCSSSML

ACCSSLRG

⁄4" Washer

WHTWSH34

WHTWSH34

WHTWSH34

WHTWSH34

1" Washer

NTRWSH1

NTRWSH1

NTRWSH1

NTRWSH1

3

Optional Installed Items

13

SSAPB - Installed Accessory Pressure Bypass

for SS Manifolds

14

15

76936

76936

76936

76936

SSATH - Installed Accessory Thermostatic

Head for Manifold Mixing Panels

n/a

n/a

57094

57094

SSADDC - DDC Actuator Installed on Mixing

Valve

n/a

n/a

56121

56121

71902

71902

71902

71902

77105

77105

77105

77105

Sold Separately

16

Key Lock

⁄2"

1

17

PEX to Manifold Connecters

⁄8"

77119

77119

77119

77119

⁄4"

77122

77122

77122

77122

5

3

11

16

6

17

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

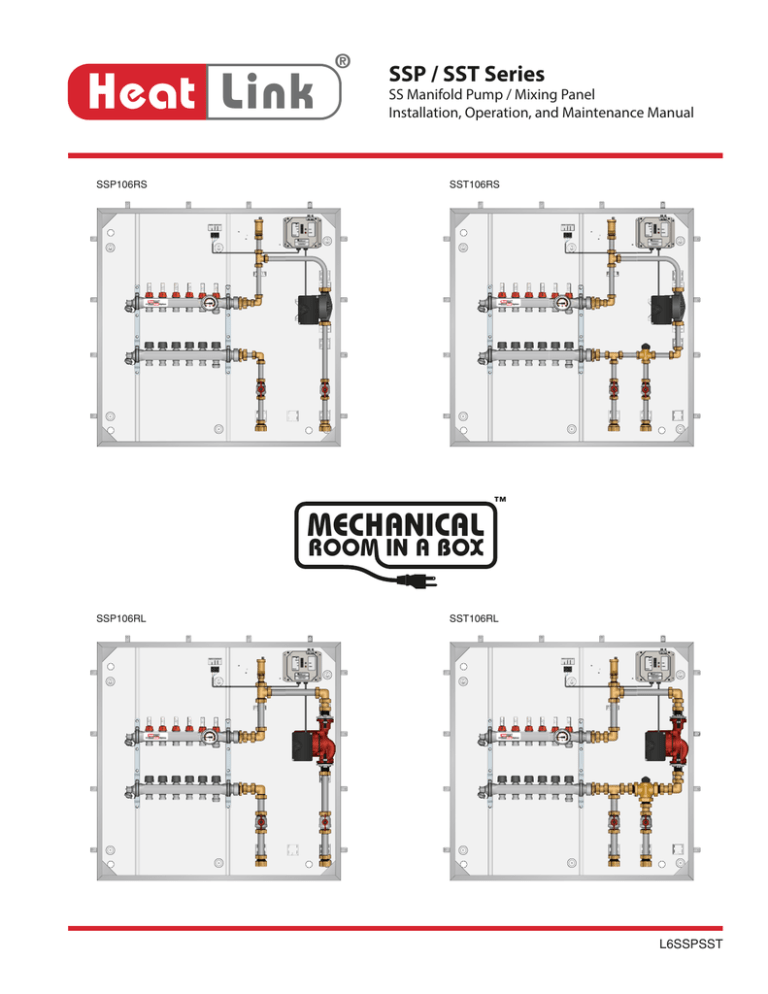

SSP106RS shown

SST106RS shown with SSATH

5

10

5

10

2

6

8

6

3

8

1

3

7

1

7

3

8

9

4

7

9

12

SSP106RL shown with SSAPB

10

14

3

8

7

2

9

9

SSP & SST small pump

accessory pack

SST106RL shown with SSADDC

5

10

2

5

6

2

6

13

3

8

1

3

7

1

7

15

3

8

8

7

9

3

7

9

12

4

9

9

SSP & SST large pump

accessory pack

7

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Specifications

SSP Series - SS Manifold Pump Panels

SSP104RS

Dimensions

Weight

Nominal panel output

Nominal flow

Nominal pressure drop outside of

panel

Max ambient temperature

Max water temperature

Circulator

Power supply:

pre-wired on system controller

Auxiliary terminal

Piping

Piping connections

Enclosure

SSP106RS SSP104RL SSP106RL SSP108RS SSP110RS SSP108RL SSP110RL

36-3⁄4"H × 37-1⁄2"W × 5-7⁄8"D

36-3⁄4"H × 49-1⁄8"W × 5-7⁄8"D

62 lbs.

64 lbs.

68 lbs.

70 lbs.

109 lbs.

111 lbs.

115 lbs.

117 lbs.

45,000

61,000

62,000

87,000

76,000

111,000

88,000

132,000

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

4.5 US gpm 6.1 US gpm 6.2 US gpm 8.7 US gpm 7.6 US gpm 11.1 US gpm 8.8 US gpm 13.2 US gpm

@ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT

based on 250' loops of 1⁄2" tubing

120°F

180°F

Non-ferrous, Grundfos

Ferrous, Grundfos

Non-ferrous, Grundfos

Ferrous, Grundfos

UPS15-58RU

UPS26-99FC

UPS15-58RU

UPS26-99FC

110 V(ac);

110 V(ac);

110 V(ac);

110 V(ac);

max. current 2A

max. current 3A

max. current 2A

max. current 3A

Yes, dry contacts, 1×2 terminal strip, screw type, max. load 1.5A

3

3

⁄4" 304SS tubing

1" 304SS tubing

⁄4" 304SS tubing

1" 304SS tubing

1" FNPT

Galvanized steel, visible parts are satin coated steel.

SST Series - SS Manifold Mixing Panels

SST104RS

Dimensions

Weight

Nominal panel output

Nominal flow

Nominal pressure drop outside of

panel

Max ambient temperature

Max water temperature

Circulator

Power supply:

pre-wired on system controller

Auxiliary terminal

Temperature control method

Mix Valve Cv

Piping

Piping connections

Enclosure

8

SST106RS SST104RL SST106RL SST108RS SST110RS SST108RL SST110RL

36-3⁄4"H × 37-1⁄2"W × 5-7⁄8"D

36-3⁄4"H × 49-1⁄8"W × 5-7⁄8"D

65 lbs.

67 lbs.

71 lbs.

73 lbs.

114 lbs.

116 lbs.

120 lbs.

122 lbs.

57,000

45,000

77,000

49,000

93,000

52,000

104,000

37,000

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

Btu/h

3.7 US gpm 5.7 US gpm 4.5 US gpm 7.7 US gpm 4.9 US gpm 9.3 US gpm 5.2 US gpm 10.4 US gpm

@ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT @ 20°F ΔT

based on 250' loops of 1⁄2" tubing

120°F

180°F

Non-ferrous, Grundfos

Ferrous, Grundfos

Non-ferrous, Grundfos

Ferrous, Grundfos

UPS15-58RU

UPS26-99FC

UPS15-58RU

UPS26-99FC

110 V(ac);

110 V(ac);

110 V(ac);

110 V(ac);

max. current 2A

max. current 3A

max. current 2A

max. current 3A

Yes, dry contacts, 1×2 terminal strip, screw type, max. load 1.5A

1

1

⁄2" 3-Way

1" 3-Way

⁄2" 3-Way

1" 3-Way

2.9

5.3

2.9

5.3

3

3

⁄4" 304SS tubing

1" 304SS tubing

⁄4" 304SS tubing

1" 304SS tubing

1" FNPT

Galvanized steel, visible parts are satin coated steel.

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Panel Component Specifications

Power Box

Auxiliary

Contacts

Bypass

OFF

PUMP

ON

POWER

This module provides the required power for all electronic

components on the panel, via the ON/OFF switch. Power box may

not be exactly as shown.

PWRB1R2

CAUTION When wiring

Thermostat to Terminal Strip:

DO NOT CROSS terminals C and R

This will cause damage to 24V

transformer in this powerbox.

Specifications:

• Requires 115V power source.

• Requires a maximum 15A circuit breaker.

Thermometer (76940)

The pipe mounted thermometer reads the supply fluid

temperature.

Specifications:

• Temperature range of 32-210°F (0-100°C).

9

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Circulators

The circulators moves the heated fluid through the hydronic system when there is a call for heat from the thermostat. Factory

set to 3rd speed.

Specifications:

• The following pump curves apply.

UPS15-58CIL2 Pump Curve

20

18

16

Head (feet)

14

12

10

8

6

4

2

0

0

2

4

6

8

10

12

14

16

Flow (gpm)

1st Speed

2nd Speed

3rd Speed

UPS26-99FC Pump Curve

35

30

Type UPS 26-99 FC

115 V 1 PH

60 Hz

20 uF

P 1 (w)

1.30 150

1.50 179

1.80 197

P/N: 52722512 P1

PC: 0939

US

|1/1 (A)

Class F

IMPEDANCE

PROTECTED

99K4

UL

C

US

LISTED

MAX. FlUID

TEMP. 230˚F

FOR INDOOR USE ONLY

U

LISTED L

Head (feet)

25

20

15

99K4

10

5

0

0

5

10

15

20

25

Flow (gpm)

1st Speed

10

2nd Speed

3rd Speed

30

35

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

3-way Mixing Valve (SST Series only)

A

AB

B

A

AB

Three-way mixing valve for fluid temperature control in heating

and cooling systems. Bronze valve body with brass nipples,

protective cap, and stainless spindle with double O-ring seal. Outer

O-ring replaceable without draining of system.

Specifications:

• Material - Housing: Bronze

• Material - Spindle: Stainless steel

• Spindle Sealing: 2 o-rings

Valve open:

A-AB is open

A-AB is closed

B-AB is closed

B-AB is open

Valve Pressure Loss in ft H2O

10

TL

SS

SS

TS

arg

ma

ll

Valve closed:

e

B

1

0.1

0.01

0.1

1

10

50

Flow Rate in US gpm

11

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Stainless Steel Manifold

Specifications:

• Material: Stainless Steel EN 1.4301 (X5CrNi18-10) which is equivalent to SAE 304 (V2A)

• Maximum Trunk Flow Rate: 18 US gpm (4.1 m3/h)

• Maximum Circuit Flow Rate: 1.5 US gpm (0.34 m3/h)

Return Manifold

Primary Balancing.

Black cap for manual shut-off only.

Use drip cap ➀ for balancing.

Supply Manifold

Secondary Balancing (Fine Tuning).

Flow meter balancing adjustment range:

0-1.5 US gpm or 0-5 L/min.

Remove locking cap to adjust flow meter.

Please note:

Do not use tools to adjust flow

meters. (Damage to the flow meter

will occur, and will not be covered

under warranty).

1

CCW = open

CW = close

CCW = open

Balancing Notes:

Return : Use for primary balancing purposes and manual shut-off. Use drip cap

to adjust the return manifold.➀➁

Caution: Opening the return valve too far will result in removing

the valve stem.

Supply : Use for secondary balancing / fine tuning the flow rate. Remove

locking cap to adjust the flow meter by hand, do not use tools.

Balancing Method 1:

Valve setting or flow characteristic

known (pre-balancing)

1. Fully open supply valve (flow

meter) [factory open].

2. Close return valve completely

[factory open].

3. Open return valve the number of

turns as per heatloss calculation or

friction head graph.

4. After all valves are set, field

adjustments may be necessary.

12

Balancing Method 2:

Only flow rate known

1. Ensure all supply valves are open

[factory open].

2. Ensure all return valves are open

(remove black cap).

3. Use the return valve to adjust flow

to desired setting (flow meter).

4. Valves adjusted first may need to

be re-adjusted once all other loops

have been set.

CW = close

1

2

Notes:

• Hose bib thread is an ASME thread.➁

• After fill procedure: the drip cap ➀ should be

placed back on to the hose bib ➁.

• Pipe to manifold connectors sold separately.

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Stainless Steel Manifold # of turns from closed position

0.25

30 (90)

0.5

0.75

1

1.5

2

3.5

10 (30)

Pressure Drop in ft H2O (kPa)

5 (15)

1 (3)

0.5 (1.5)

0.1 (0.3)

0.05 (0.15)

0.01 (0.03)

0.01

(0.04)

0.05

(0.19)

0.1

(0.38)

0.5

(1.89)

1

(3.78)

3

(11.36)

Mass Flow Rate in US gpm (L/min)

Working loop flow ranges from 0.1 to 1.25 US gpm (0.38 to 4.7 L/m) for floor heating and from 1.5 to 2.5 US gpm (5.7 to 9.5

L/m) for snowmelting. Pressure drop must be closely checked when water flow is beyond the upper working range.

13

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

SSADDC - Optional DDC Actuator Installed on Mixing Valve

(#56121; SST Series only)

These actuators allow for additional room temperature control in

conjunction with a direct digital control system.

Specifications:

• Operating Voltage: 24 V(ac), 50/60Hz

• Control Voltage: 0-10 V(dc), RE = 100kΩ

• Power Consumption: 2 VA

• Max. Current: max. 250 mA for max. 2 min

• Type: Normally Closed

• Opening and Closing Time: 3 min

• Protection Class: IP 54

• Force: 100 N ± 5%

• Cable Length: 1 m / 3.28 ft (removable)

• Standards / Listings: CE

Sample Wiring Diagram

Red +

0-10V DC

Blue 0

24V~ AC

Black -

Travel (mm)

4

3

Valve travel=0

2

1

Range beyond valve travel

Valve adapter rim

0

14

1

2

3

4

5

6

7

UST in V

active control voltage range

8

9

10

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Assembly

Screw the valve adapter onto the valve and hand tighten.

Align the actuator and push down until it snaps it into place.

Make all necessary electrical connections according to the

diagram.

Standby

After the voltage has been removed for 20 min. the actuator

is still in a standby mode. The valve is closed, however when

a voltage is applied again the actuator can respond rapidly.

Signal Noise

The actuator reacts only to voltages starting from 1V DC to

avoid reaction to signal noise.

“First open” function

The actuator is delivered in an open position. When power

is applied, the calibration process cancels the first open

function, ie. the actuator is ready for operation in ~6 min.

Automatic calibration

When voltage is first applied and approx. twice each day the

actuator performs a calibration process, in order to adjust

itself to the valve. During this process the actuator opens and

closes completely, and important points are stored. During

this process the control voltage is ignored. If the results

deviate then the calibration is repeated. After calibrating

itself the actuator response is proportional to the applied

voltage.

Adaption check

After releasing the first open function and commissioning,

the adaption between the valve and the actuator can be

inspected. When no voltage is applied, the function indicator

should be elevated slightly. It should not be flush with the

body nor should the indicator region be visible.

Function indicator

The current operating status can be seen at the function

indicator.

Disassembly

Press down on the lower front cover button and pull up the

actuator. Do not use force to open the body.

To prevent removal of the

actuator from its mount

simply remove the front

cover.

Notes

If the power supply cable is damaged, it must be replaced by

the manufacturer or its service agent or a similarly qualified

person in order to avoid a hazard. A contact separation of

at least 3 mm in all poles must be incorporated in the fixed

wiring. Ensure the power supply is isolated via a safety

transformer. The actuator is not protected against valve leaks.

15

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

SSATH - Optional Installed Accessory Thermostatic Head (#57094;

SST Series only)

Sensing Bulb

Used as injection control for HeatLink® zone valves. Senses 0.4°F (0.2°C)

supply water change. Takes 15 minutes to close from full open.

Specifications:

• Temperature Setting Range: 96-150°F (36-66°C)

• Sensor: Liquid filled contact sensor

• Type: Normally closed

Capillary

Setting arrow

Notes: Do not use any tools when installing the thermostatic head

onto the zone valve! Hand tighten only!

Do not kink capillary when installing the head!! Doing so

will render the capillary unusable.

SSAPB - Optional Installed Accessory Pressure Bypass (#76937)

Adjustable pressure bypass valve kit for 76100 and 76200 series

stainless steel manifolds. This valve prevents a steep rise of the

pump head and maintains flow at a stable rate. Also ensures only

required amount of circulating water is used for hydronic systems.

Specifications:

• Adjustment Range: 0.05 - 0.5 bar (1.67 - 16.73 ft H2O)

16

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Mounting

Step 1

Use a screwdriver or similar thin tool through the hole to bend the mounting tabs out 90 degrees

from the enclosure.

Step 2

If electrical wiring will be coming from the top, remove the appropriate knockouts.

26-7/16"

20-7/16"

14-9/16"

7/8" O.D.

10-1/16"

3-3/4"

36"

38-1/16"

32-1/16"

14-9/16"

7/8" O.D.

10-1/16"

3-3/4"

47-5/8"

Step 3

Build a 2×6 supporting frame where the panel is to be mounted.

The panel should be mounted at least 12" above the floor.

17

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Mounting continued

Step 3

Lift and place the panel onto the supporting frame.

This panel is heavy; 2-3 person lift required.

Step 4

Complete the supporting frame by adding a top plate.

Be sure to drill corresponding holes in the top plate if any

knockouts were removed.

Step 5

Secure the panel in place by putting screws into each of the

mounting tabs.

Note: Panel contents are not shown in the diagrams.

18

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Piping Hookup

Step 1

Before making any connections, identify the

required connections to and from the panel.

Adapters are 3⁄4" M BSPP × 1" FNPT or 1" M BSPP ×

1" FNPT, and must use the supplied adapters and

rubber washers.

Step 2

Connect all adapters.

1. Connect MNPT adapter E to copper pipe or

tubing F .

2. Screw supplied M × FNPT adapter D onto E

using appropriate thread sealant.

3. Take assembly D E F and place rubber

washer C on flat surface of D .

4. Without disturbing rubber washer C , place

assembly against flanged stainless steel pipe

B .

5. Slide nut A over adapter D and finger

tighten nut. Then, tighten the nut (using two

40mm wrenches for 1" adapters or 30mm

wrenches for 3⁄4" adapters), taking care not to

overtighten the nut, as this will damage the

rubber washer.

SST106RL shown

Floor Supply

Floor Return

Primary

Return

Primary

Supply

A

B

C

D

E

F

Do not overtighten brass nuts!

Note: Use precautions when soldering or applying heat within 16" of the panel.

19

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Piping Hookup continued

Step 3

Connect all tubing to manifold adapters. (77100 series connectors sold separately)

1. Lubricate the inside of the manifold port with silicone o-ring lubricant (#79952 sold separately).

2. Cut the PEX tubing at a 90˚ angle.

3. Place the Nut and Split Ring Ferrule onto the PEX tubing.

Method A

5. Push the Brass Insert onto the PEX tubing as far as it will go.

6. Push the PEX tubing with Brass Insert as far as it will go into the manifold module. Ensure the o-ring is clean and

take care not to pinch it.

Method B

5. Push Brass Insert as far as it will go into the manifold. Ensure the o-ring is clean and take care not to pinch it.

6. Push PEX tubing onto the Brass Insert as far as it will go.

7. Use a wrench to tighten the nut.

90°

Brass Insert with

O-ring

Split Ring Ferrule

Nut

20

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

SSP Series

Fill And Purge

The following steps are recommended in order to fill the panel

with water and purge entrained air once piping is completed,

and before activation of the panel.

E

The discharged system fluid from the fill and purge

process is not for consumption or washing.

C

D

F

A

Note:

Additional purging steps may be required for the rest of

the hydronic system.

Note:

Isolation and drain valves are not included with the

panel, but are necessary to properly fill and purge the

panel, and to isolate the panel for service.

Step 1

Ensure the panel is not powered.

Step 2

SST Series only - Adjust the mixing valve G so that it

is fully open (i.e. cap removed). If a DDC actuator or

Thermostatic Head is installed, it must be removed.

Step 3

Fully close valves A , B , and C . Fully close all supply

E and all return F manifold valves.

Fully open valve D .

Step 4

Attach a purge hose (not included) to

the main supply line. Open valve B .

D

SST Series

. Pressurize

E

C

Step 5

Open the first return manifold valve F . Open the first

supply manifold valve E . Watch the hose in the pail

until you observe a steady stream of water (no air or

spitting). Close the first return manifold valve F .

Step 6

Repeat Step 5 for each loop until all loops are filled

with water, and air is purged from pipes.

Step 7

Purging is complete when there is no more air and/or

spitting. Close valve D then valve B .

Step 8

Remove hose from drain valve

Step 9

Check for leaks at connections. If any leaks are found

use a back-up wrench and carefully tighten until leak

stops. Do not overtighten.

Step 10

SST Series only - Redjust the mixing valve G to

provide a proper mixed fluid temperature to the

hydronic system (see page 11). If a DDC actuator or

Thermostatic Head was removed, reinstall it.

D

B

D

G

F

A

B

.

21

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Panel Wiring

Note: Terminal headers are removable to make wiring connections easier.

Thermostat Wiring

• 24V low voltage power may be supplied to the thermostat. Wiring of thermostat

should be done by qualified electrician and should meet local codes and

jurisdictions. Wiring to the terminal strip requires 18 gauge 4 wire.

2-Wire Thermostat

(battery only or non-electric)

Signal

C

AUX

3-Wire Thermostat

(HeatLink thermostats)

Jumper to

Dry Contact

W R

24 V

AUX

24 V

C

24 V

W R

24 V

Signal

24 V

Signal

• Do not exceed 2VA.

• Do not cross terminals C and R – this will damage the Power Box.

W R

C

AUX

4-Wire Thermostat

(with dry contact signal)

Other Terminals

Auxiliary Contacts

The auxiliary contact set is dry, meaning no supply of power is present at the terminal. The maximum

allowable load is 1.5A. The auxiliary dry contact located on the terminal is to switch another device

(ie. the heat source) when there is a call for heat from any zone.

110V Power

110V power wiring should be done by qualified electrician and should meet local codes and

jurisdictions.

Field Wiring

To Thermostat

To Heat Source

Contacts

W R C

Thermostat

Connection

Auxiliary

Contacts

BYPASS

OFF

PUMP

ON

PB2R1

POWER

CAUTION When wiring

Thermostat to Terminal Strip:

DO NOT CROSS terminals C and R

This will cause damage to 24V

transformer in this powerbox.

Field Wiring

Ground

Neutral

Live

22

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Panel Control Sequence

1.

When power is provided to the 110V terminals connected to the power module 1 , and the 3-way switch is placed in the

“ON” position the red LED will be lit, indicating that the panel is powered with 110V.

2.

The Bypass function for the 3-way switch is for troubleshooting purposes only. Only switch to the Bypass position if

the red and green LED’s on the power module do not light up during a call for heat. Please refer to the troubleshooting

section of the manual for further details.

3.

When the thermostat calls for heat, its internal 24V contacts close, the auxiliary terminals close, and the pump turns on.

4.

SST panels only - As the circulator

on the user settings (page 11).

5.

When the requirements of the thermostat are met, the internal contacts of the thermostat open, the auxiliary contacts

open, and the circulator stops.

2

moves fluid through the panel the mixing valve adjusts the fluid temperature based

Field Wiring

To Thermostat

To Heat Source

Contacts

W R C

Thermostat

Connection

Auxiliary

Contacts

1

BYPASS

OFF

PUMP

ON

PB2R1

POWER

CAUTION When wiring

Thermostat to Terminal Strip:

DO NOT CROSS terminals C and R

This will cause damage to 24V

transformer in this powerbox.

Field Wiring

Ground

Neutral

Live

2

23

®

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Heat Link

www.heatlink.com

Troubleshooting

Problem

Check / Verify

Possible Cause

Low Temperature Within Room

Misplacement of thermostat location within

room.

Make sure thermostat is not being influenced

by an additional heat source, such as lighting

or air duct.

Low temperature setting of the thermostat.

Adjust the temperature setting on thermostat.

The system fails to turn on if the thermostat is

set to high setting

Thermostat may be out of calibration or

defective. Replace thermostat.

The electronic actuator fails to open during a

call for heat

The electronic actuator may be improperly

seated or may be defective. Replace if

necessary.

Low supply mixed fluid temperature.

Adjust the power box to the appropriate

setting.

Wiring from heat source to panel.

Check that the wiring is done properly. Consult

qualified electrician prior to alteration of wiring

between heat source and panel.

Output of heat source is unable to meet

demand of heating system.

Compare output of heat source to the

requirements of the heating system.

The red and green LED’s on the power module The zone valve controller may be defective or

do not light up during a call for heat.

there is no power being supplied to the panel

or the power module is not on. If this is so,

switch the power module to Bypass mode.

The green LED will be lit, indicating that the

panel is powered with 110V and the pump will

run. This will provide constant circulation so

long as there is still 110V power to the panel.

High Temperature Within Room

24

Circulator is not on during a call for heat. (Use

a stethoscope or similar device to verify)

The power box or circulator may be defective.

When zone valves are installed outside the

panel a qualified electrician should verify 24V

power is supplied to the thermostats and

actuator. The power module only supplies

enough power for a thermostat; any external

actuators must be powered from an external

24V transformer.

The 24V transformer may have failed. If this

so, switch the power module to Bypass mode.

This will provide constant circulation so long

as there is still 110V power to the panel. Prior

to Bypass mode selection, any zone valves

must be opened manually to avoid deadheading of the circulator.

Check current setting of the thermostat.

Adjust the temperature setting on thermostat

to a lower setting.

High supply mixed fluid temperature.

Adjust the Thermostatic Mixing Valve to the

appropriate settings.

Installed electronic actuators remain open

after the thermostat is satisfied.

An obstruction inside the zone valve is not

allowing the actuator to fully close or the

thermostat is still calling for heat.

Bypass may be on.

Check that the Power switch on the power box

is in the “ON” position.

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

Maintenance

Yearly maintenance should be done on the panel prior to each heating season to ensure the efficient and accurate operation

of the panel.

Complete the following check list:

• Raise all thermostats to cause a call for heat within the system. Verify that the circulator starts, via a stethoscope or

similar device.

• Confirm that the Auxiliary Contacts close.

• If applicable, verify that each zone valve opens during the call for heat – the actuator should be warm to the touch, the

LED will light up (on 5620x models) and the white indicator should rise from the top of the actuator.

• Return all thermostats to a desirable setting.

You are now ready for another heating season with HeatLink.

25

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

SSP Series Manifold Pump Panels

SSP Series

For all of these models, primary piping

with circulator must have no pressure

differential between panel primary supply

and return, i.e. close tees.

Heat

Source

(e.g. boiler or

heat exchanger)

Notes:

A) This drawing is for illustrative purposes only. It is not intended to be used as a wiring or piping diagram.

Not all required components are shown. Local codes, regulations, and authorities have final jurisdiction.

26

®

Heat Link

www.heatlink.com

Installation, Operation, and Maintenance

SSP / SST – SS Manifold Pump / Mixing Panels

SST Series Manifold Mixing Panels

SST Series

For all of these models, primary piping

with circulator must have no pressure

differential between panel primary supply

and return, i.e. close tees.

Heat

Source

(e.g. boiler or

heat exchanger)

Notes:

A) This drawing is for illustrative purposes only. It is not intended to be used as a wiring or piping diagram.

Not all required components are shown. Local codes, regulations, and authorities have final jurisdiction.

27

Canada

Manufactured & distributed by HeatLink Group Inc.

Head Office:

4603E - 13th Street N.E.

Calgary, Alberta, T2E 6M3

Eastern Canada Distribution Center:

2810 Argentia Road, Units 5-7

Mississauga, Ontario, L5N 8L2

Toll Free: 1-800-661-5332

Fax: 1-866-450-1155

China

Distributed by Cathay-Links International

Phone: 852-25693213

Fax: 852-25359271

Ireland

Distributed by Jamoni Ltd.

Phone: 057 - 932 4062

Fax: 057 - 932 4063

Freephone: 1800-311338

México

Distributed by Distribuidora Caisa S.A. de C.V.

Phone: (52-55) 3300-4400

Fax: (52-55) 3300-4406

United States

Distributed by HeatLink Group Inc.

USA Distribution Center:

1000 - 100th Street SW, Suite B

Byron Center, MI, 49315

Toll Free: 1-800-661-5332

Fax: 1-800-869-6098

www.heatlink.com

HeatLink, the HeatLink logo, and “Mechanical Room in a Box” logo are either registered

trademarks or trademarks of HeatLink Group Inc.

August 1, 2013

Printed in Canada

© HeatLink Group Inc.