Dynex Directional Control Valves

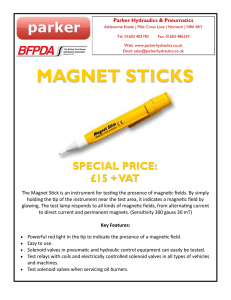

advertisement