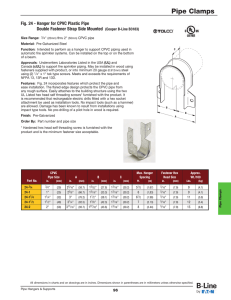

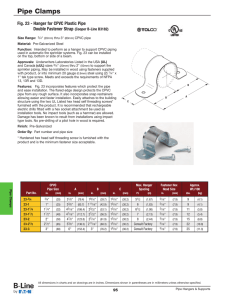

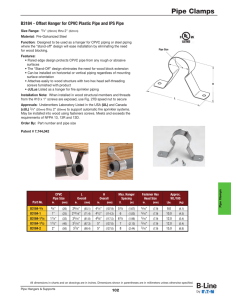

ChemDrain - Charlotte Pipe

advertisement