TECHNICAL REPORT ON THE ECO RIDGE MINE PROJECT

advertisement

PELE MOUNTAIN RESOURCES INC.

TECHNICAL REPORT ON THE

ECO RIDGE MINE PROJECT,

ELLIOT LAKE, ONTARIO, CANADA

NI 43-101 Report

Qualified Persons:

Jason J. Cox, P.Eng.

Tudorel Ciuculescu, M.Sc., P.Geo.

Kathleen Altman, P.E.

Leo Hwozdyk, P.Eng.

June 20, 2012

ROSCOE POSTLE ASSOCIATES INC.

Report Control Form

Document Title

Technical Report on the Eco Ridge Mine Project, Elliot Lake

Area, Ontario, Canada

Client Name & Address

Pele Mountain Resources Inc.

2200 Yonge Street

Suite 905

Toronto, Ontario M4S 2C6

Document Reference

Project #1826

Issue Date

Lead Author

Final

Version

Status &

Issue No.

June 20, 2012

Jason Cox

Tudorel Ciuculescu

Kathleen A. Altman

Leo Hwozdyk

(Signed)

(Signed)

(Signed)

(Signed)

Peer Reviewer

Deborah McCombe

(Signed)

Project Manager Approval

Jason Cox

(Signed)

Project Director Approval

Richard Lambert

(Signed)

Name

Report Distribution

No. of Copies

Client

RPA Filing

1 (project box)

Roscoe Postle Associates Inc.

55 University Avenue, Suite 501

Toronto, Ontario M5J 2H7

Canada

Tel: +1 416 947 0907

Fax: +1 416 947 0395

mining@rpacan.com

0

www.rpacan.com

TABLE OF CONTENTS

PAGE

1 SUMMARY .................................................................................................................. 1-1 Executive Summary ................................................................................................. 1-1 Technical Summary ............................................................................................... 1-17 2 INTRODUCTION......................................................................................................... 2-1 3 RELIANCE ON OTHER EXPERTS ............................................................................ 3-1 4 PROPERTY DESCRIPTION AND LOCATION ........................................................... 4-1 Licences of Occupation ............................................................................................ 4-5 Royalties and Other Encumbrances......................................................................... 4-5 Permits ..................................................................................................................... 4-5 Environmental Liabilities .......................................................................................... 4-6 5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND

PHYSIOGRAPHY .......................................................................................................... 5-1 6 HISTORY .................................................................................................................... 6-1 7 GEOLOGICAL SETTING AND MINERALIZATION .................................................... 7-1 Regional Geology ..................................................................................................... 7-1 Local Geology .......................................................................................................... 7-5 Property Geology ................................................................................................... 7-12 Mineralization ......................................................................................................... 7-15 Historical Mineralogical Studies ............................................................................. 7-17 Mineralogical Studies on the Eco Ridge Mine Property ......................................... 7-20 Detailed Description of Mineralized Zones ............................................................. 7-23 Discussion of Mineralized Zones............................................................................ 7-27 8 DEPOSIT TYPES........................................................................................................ 8-1 9 EXPLORATION........................................................................................................... 9-1 10 DRILLING................................................................................................................ 10-1 Pele Mountain Drill Programs................................................................................. 10-1 11 SAMPLE PREPARATION, ANALYSES AND SECURITY ...................................... 11-1 Historic Holes ......................................................................................................... 11-4 Pele Mountain Drilling Programs ............................................................................ 11-5 12 DATA VERIFICATION ............................................................................................ 12-1 Drill Hole Collar Surveys ........................................................................................ 12-1 Drill Hole Deviation ................................................................................................. 12-1 Database ................................................................................................................ 12-1 Data Entry .............................................................................................................. 12-2 Database Validation ............................................................................................... 12-3 Pele Mountain QA/QC Monitoring .......................................................................... 12-3 Pele Mountain QA/QC Program 2011 .................................................................... 12-4 Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page i

www.rpacan.com

Independent Sampling by RPA .............................................................................. 12-7 13 MINERAL PROCESSING AND METALLURGICAL TESTING ............................... 13-1 14 MINERAL RESOURCE ESTIMATE ........................................................................ 14-1 Summary ................................................................................................................ 14-1 Mineral Resource Database ................................................................................... 14-2 Geological Interpretation and 3D Solids ................................................................. 14-3 Basic Statistics and Capping of High Assays ......................................................... 14-6 Block Model and Grade Estimation ...................................................................... 14-20 Classification ........................................................................................................ 14-24 Sensitivity Analysis ............................................................................................... 14-27 Comparison with Previous Mineral Resource Estimate ....................................... 14-31 Exploration Potential of Additional Resources on the Property ............................ 14-31 15 MINERAL RESERVE ESTIMATE ........................................................................... 15-1 16 MINING METHODS ................................................................................................ 16-1 Selected Mining Method ......................................................................................... 16-1 Mine Development ................................................................................................. 16-1 Dilution ................................................................................................................... 16-7 Mining Production Rate .......................................................................................... 16-8 Mining Sequence ................................................................................................. 16-10 Support Services .................................................................................................. 16-13 Equipment ............................................................................................................ 16-15 Manpower ............................................................................................................ 16-17 Material Handling Trade-Off Study ....................................................................... 16-22 17 RECOVERY METHODS ......................................................................................... 17-1 18 PROJECT INFRASTRUCTURE ............................................................................. 18-1 19 MARKET STUDIES AND CONTRACTS ................................................................. 19-1 Uranium .................................................................................................................. 19-1 Rare Earths ............................................................................................................ 19-1 Contracts ................................................................................................................ 19-7 20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY

IMPACT........................................................................................................................ 20-1 Introduction ............................................................................................................ 20-1 Permits, Licences and Other Legislative Requirements......................................... 20-2 Environmental Assessment .................................................................................... 20-6 Aquatic Baseline Study ........................................................................................ 20-12 Decommissioning and Closure Planning.............................................................. 20-15 Environmental Risk Assessments ........................................................................ 20-16 Environmental Management Strategies ............................................................... 20-16 Occupational Health and Safety ........................................................................... 20-18 Community Relations ........................................................................................... 20-22 21 CAPITAL AND OPERATING COSTS ..................................................................... 21-1 Capital Costs .......................................................................................................... 21-1 Operating Costs ..................................................................................................... 21-4 Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page ii

www.rpacan.com

22 ECONOMIC ANALYSIS .......................................................................................... 22-1 23 ADJACENT PROPERTIES ..................................................................................... 23-1 24 OTHER RELEVANT DATA AND INFORMATION .................................................. 24-1 25 INTERPRETATION AND CONCLUSIONS ............................................................. 25-1 26 RECOMMENDATIONS ........................................................................................... 26-1 27 REFERENCES........................................................................................................ 27-1 28 DATE AND SIGNATURE PAGE ............................................................................. 28-1 29 CERTIFICATE OF QUALIFIED PERSON .............................................................. 29-1 LIST OF TABLES

PAGE

Table 1-1 Pre-Tax Cash Flow Summary ...................................................................... 1-4 Table 1-2 Sensitivity Analysis ...................................................................................... 1-8 Table 1-3 Summary of Mineral Resources – April 16, 2012 ...................................... 1-10 Table 1-4 Proposed Work Program and Estimated Cost ........................................... 1-15 Table 1-5 Overall Capital Cost Estimate .................................................................... 1-25 Table 1-6 Operating Cost Estimate ............................................................................ 1-25 Table 4-1 Schedule of Claims ...................................................................................... 4-1 Table 4-2 Precambrian Agreement Terms ................................................................... 4-3 Table 4-3 May 2007 Agreement Terms ....................................................................... 4-4 Table 5-1 Average Minimum and Maximum Temperatures in the Elliot Lake District .. 5-2 Table 6-1 Historic Drill Hole Summary ......................................................................... 6-5 Table 7-1 Table of Formations in the Region ............................................................... 7-1 Table 7-2 Stratigraphy of the Huronian Supergroup .................................................... 7-2 Table 7-3 Elliot Lake Group, Elliot Lake Area .............................................................. 7-5 Table 7-4 Stratigraphy of Lower Matinenda ................................................................. 7-9 Table 7-5 Stratigraphy of Lower Matinenda (Ryan Member) ..................................... 7-17 Table 7-6 Uranium-Bearing and Associated Heavy Minerals .................................... 7-17 Table 7-7 Uranium Mineralogy of the Main Conglomerate Bed ................................. 7-21 Table 7-8 Uranium Mineralogy of the Basal Conglomerate Bed ................................ 7-22 Table 7-9 Relative Percentage of Individual Rare Earth Elements ............................ 7-29 Table 7-10 Correlation Between Uranium and Rare Earths ....................................... 7-30 Table 12-1 RPA Independent Sampling..................................................................... 12-8 Table 13-1 Preliminary Screening Size Distribution ................................................... 13-2 Table 13-2 Preliminary Screening Size Distribution ................................................... 13-2 Table 13-3 Overall Size Distribution........................................................................... 13-3 Table 13-4 Magnetic Separation Results ................................................................... 13-4 Table 13-5 Flotation Results ...................................................................................... 13-5 Table 13-6 Leaching Results ..................................................................................... 13-6 Table 13-7 Bulk Sample #4 Analyses ........................................................................ 13-6 Table 13-8 Fine Size Fraction Analyses .................................................................... 13-7 Table 13-9 Estimated REO Recoveries ..................................................................... 13-9 Table 14-1 Summary of Mineral Resources – April 16, 2012 .................................... 14-1 Table 14-2 MCB and Hwz Intercepts True Thickness - Descriptive Statistics ........... 14-4 Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page iii

www.rpacan.com

Table 14-3 Rare Earth and Other Elements - MCB Resource Assays Descriptive

Statistics ....................................................................................................................... 14-7 Table 14-4 Rare Earth and Other Elements - HWZ Resource Assays Descriptive

Statistics ....................................................................................................................... 14-8 Table 14-5 Rare Earth and Other Elements - MCB Resource Composites Descriptive

Statistics ..................................................................................................................... 14-10 Table 14-6 Rare Earth and Other Elements - HWZ Resource Composites Descriptive

Statistics ..................................................................................................................... 14-11 Table 14-7 Block Model Setup ................................................................................. 14-20 Table 14-8 Search Strategy Parameters.................................................................. 14-20 Table 14-9 Summary of Mineral Resources – April 16, 2012 .................................. 14-25 Table 14-10 Mineral Resource Estimate - April 16, 2012 - Rare Earth Oxides and

Related Oxides........................................................................................................... 14-26 Table 14-11 Indicated Resource – Tonnage And TREO% Grade at Various NSR Cutoff Values ................................................................................................................... 14-28 Table 14-12 Inferred Resource – Tonnage and Treo% Grade at Various NSR Cut-off

Values ........................................................................................................................ 14-28 Table 14-13 Mineral Resource Comparison – 2007 to 2012 ................................... 14-31 Table 14-14 Historic Drill Holes Not Included in the 2012 Resource Estimate ........ 14-32 Table 14-15 Historic Drill Holes Demonstrating the Down-Dip Potential of the Main

Conglomerate Bed ..................................................................................................... 14-33 Table 14-16 Historic Drilling Results from the Pecors Lake Block ........................... 14-34 Table 16-1 Equipment Optimum Production Capacities ............................................ 16-9 Table 16-2 Effective Production Rates..................................................................... 16-10 Table 16-3 Air Volume Requirements ...................................................................... 16-13 Table 16-4 Mine Equipment Summary ..................................................................... 16-16 Table 16-5 Manpower Requirements ....................................................................... 16-18 Table 17-1 Conceptual Design Criteria ...................................................................... 17-5 Table 17-2 Conceptual Mass Balance ....................................................................... 17-6 Table 19-1 Distribution of Rare Earths by Source – China ........................................ 19-3 Table 19-2 Rare Earth Supply – 2008 & 2010 ........................................................... 19-4 Table 19-3 REO Forecast Prices vs. Current Spot Prices ......................................... 19-6 Table 21-1 Overall Capital Cost Estimate .................................................................. 21-1 Table 21-2 Mine Capital Cost Estimate ...................................................................... 21-2 Table 21-3 Initial process Capital Cost Estimate ....................................................... 21-3 Table 21-4 Total Operating Cost Estimate ................................................................. 21-4 Table 21-5 Mine Operating Cost Estimate ................................................................. 21-5 Table 21-6 Process Operating Cost Estimate ............................................................ 21-6 Table 22-1 Pre-Tax Cash Flow Summary .................................................................. 22-3 Table 22-2 Sensitivity Analysis .................................................................................. 22-6 Table 25-1 Summary of Mineral Resources – April 16, 2012 .................................... 25-2 Table 26-1 Proposed Work Program and Estimated Cost ......................................... 26-2 LIST OF FIGURES

PAGE

Figure 1-1 Sensitivity Analysis ..................................................................................... 1-7 Figure 1-2 Project Schedule....................................................................................... 1-16 Figure 4-1 Location Map .............................................................................................. 4-7 Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page iv

www.rpacan.com

Figure 4-2 Land Tenure Map ....................................................................................... 4-8 Figure 7-1 Regional Geology ....................................................................................... 7-4 Figure 7-2 Property Geology ...................................................................................... 7-10 Figure 7-3 Location of the Mineralized Channels....................................................... 7-11 Figure 7-4 Property Geology ...................................................................................... 7-14 Figure 7-5 Typical Cross Section Through the Adit Block .......................................... 7-25 Figure 7-6 Variation in Uranium Concentration in the Main Conglomerate Bed ........ 7-26 Figure 10-1 Location of the Historic Drill Holes .......................................................... 10-3 Figure 10-2 Location of Pele Mountain Drill Holes ..................................................... 10-4 Figure 12-1 Blank Samples ........................................................................................ 12-5 Figure 12-2 Certified Reference Materials Samples .................................................. 12-6 Figure 12-3 Field Sample Duplicates ......................................................................... 12-7 Figure 14-1 MCB Intercepts True Width Histogram (n=238)...................................... 14-5 Figure 14-2 HWZ Intercepts True Width Histogram (n=130) ..................................... 14-6 Figure 14-3 U3O8, Dy, and Nd Assay Histograms - MCB and HWZ........................... 14-9 Figure 14-4 U3O8, Dy, and Nd Composite Histograms - MCB and HWZ ................. 14-12 Figure 14-5 MCB intercepts Variography for U3O8, Nd, and Dy ............................... 14-15 Figure 14-6 HWZ intercepts Variography for U3O8, Nd, and Dy............................... 14-16 Figure 14-7 U3O8 Composites Grade Contours in MCB .......................................... 14-17 Figure 14-8 Nd Composites Grade Contours in MCB .............................................. 14-18 Figure 14-9 Dy Composites Grade Contours in MCB .............................................. 14-19 Figure 14-10 Resource Blocks in MCB .................................................................... 14-22 Figure 14-11 Resource Blocks in HWZ .................................................................... 14-23 Figure 14-12 Grade –Tonnage Curves of Indicated Resource ................................ 14-29 Figure 14-13 Grade –Tonnage Curves of Inferred Resource .................................. 14-30 Figure 14-14 Historic Drill Holes with Mineralized Intersections Outside the Mineral

Resource .................................................................................................................... 14-36 Figure 14-15 Location of the Exploration Targets .................................................... 14-37 Figure 16-1 Site Layout .............................................................................................. 16-2 Figure 16-2 Mine PLan............................................................................................... 16-5 Figure 16-3 Panel Plan .............................................................................................. 16-6 Figure 16-4 Mining Sequence Section ..................................................................... 16-11 Figure 16-5 Stope Development Section ................................................................. 16-12 Figure 16-6 Stope Drilling Section ........................................................................... 16-19 Figure 16-7 Tramming Section................................................................................. 16-20 Figure 16-8 Hauling Section..................................................................................... 16-21 Figure 17-1 Process Flow Sheet ................................................................................ 17-7 Figure 19-1 Chinese Rare Earth Export Quotas by Year (Thousands of Tons) ......... 19-4 Figure 22-1 Sensitivity Analysis ................................................................................. 22-5 Figure 24-1 Project Schedule..................................................................................... 24-2 Figure 26-1 Project Schedule..................................................................................... 26-3 Figure 26-2 Preliminary Proposed Drill Hole Location for Indicated and Inferred

Tonnage Targets 2012 Program .................................................................................. 26-4 Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page v

www.rpacan.com

1 SUMMARY

EXECUTIVE SUMMARY

INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by Pele Mountain Resources Inc.

(Pele Mountain), to carry out a Preliminary Economic Assessment (PEA) on the Eco

Ridge Mine Project (the Project), located in Elliot Lake, Ontario. The purpose of this

report is to update the Project economics with results of work completed since the

previous PEA in August 2011 (the “2011 PEA”). This updated PEA features an updated

resource estimate and a base case scenario for production that focuses on mining the

relatively higher-grade main conglomerate bed, and uses a conventional milling

approach for processing which achieves materially higher recoveries for rare earths and

uranium.

Pele Mountain is a Canadian resource exploration and development company focused

on the sustainable development of its 100%-owned Eco Ridge Mine Rare Earths and

Uranium Project (Eco Ridge or the Project). Pele Mountain is a reporting issuer in

Ontario, British Columbia, and Alberta, and its common shares are listed on the TSX

Venture Exchange and also trade on the OTCQX. Pele Mountain has also entered into

an agreement to purchase the Simon Rare Earth Claims in Mountain Pass, California.

Currently, the major asset associated with the Project is a stratabound zone of rare earth

oxide (REO) and uranium oxide (U3O8) mineralization.

Rare earth elements (REE) are divided into two groups:

1. The Light Rare Earth Elements (LREE) or cerics, comprising of La, Ce, Pr, and

Nd.

2. The Heavy Rare Earth Elements (HREE) or yttrics, comprising of Y, Eu, Gd, Tb,

Dy, Ho, Er, Tm, Yb, Lu, and Sm. Scandium, while not a rare earth, has been

included with the HREE for purposes of this report.

LREO and HREO refer to oxides of light and heavy rare earth elements respectively. In

this document, TREO (Total Rare Earth Oxides) refers to LREOs and HREOs

collectively.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-1

www.rpacan.com

PEA-level work on the Project is based on the development of an underground mining

operation ramping up to 9,000 tonnes per day (tpd), with the recovery of REO and U3O8.

The 2011 PEA was based on processing via underground bioleaching and surface heap

leaching, while this update is based on conventional milling and acid baking. Materially

higher recoveries of REO and U3O8, based on recent testwork, proved to outweigh

associated capital and operating cost increases, providing for more robust economic

results.

ECONOMIC ANALYSIS

A Pre-Tax Cash Flow Projection has been generated from the Life of Mine (LOM)

production schedule and capital and operating cost estimates, and is summarized in

Table 1-1. A summary of the key criteria is provided below.

PRODUCTION

Production quantities total 34.6 Mt, at grades of 0.040% U3O8 and 1,455 ppm

TREO, over a mine life of 11 years.

o

The Main Conglomerate Bed (MCB) zone totals 31.0 Mt grading

0.043% U3O8 and 1,544 ppm TREO

o

The Hangingwall Zone (HWZ) totals 3.6 Mt grading 0.017% U3O8 and

1,017 ppm TREO

Underground mining using room and pillar mining methods, with all

development in ore.

Two years of pre-production development with mill commissioning and limited

production commencing in the second year.

Production rate ramping up to a nominal 9,000 tpd in Year 1.

Processing by crushing and grinding, magnetic separation, froth flotation,

acid baking and water leaching, solid/liquid separation, high density sludge

(HDS) removal, and recovery of the valuable elements by solvent extraction

and precipitation.

The proposed processing method produces yellow cake and a mixed rare

earths carbonate concentrate.

Uranium recovery of 90% (assumption, based on historical operations in the

area).

Rare earths recoveries by individual oxide, based on preliminary bench scale

testwork. LREOs average 89% recovery, while HREOs average 75%

recovery.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-2

www.rpacan.com

Mine life production of 27.5 million pounds of U3O8 and 44.1 million kg of

TREO.

Production of a strategically significant combination of rare earths forecast to

remain in supply deficit, with 85% of Project revenue from heavy REO,

neodymium oxide (Nd2O3) and U3O8.

REVENUE

Exchange rate US$1.00 = C$1.00.

Uranium price of US$70 per pound U3O8.

Rare earth prices by individual oxide, with a basket price of US$78 per kg.

o Net of costs for separating the rare earth concentrate into individual

oxides – C$30 per kg for HREOs and C$10 per kg for LREOs.

LREOs consist of CeO2, La2O3, Nd2O3 and Pr6O11 while HREOs consist of

Sm2O3, Eu2O3, Gd2O3, Sc2O3, Y2O3, Yb2O3, Dy2O3, Er2O3, Ho2O3, Lu2O3,

Tb4O7 and Tm2O3.

NSR royalty of 0.75%.

Average net revenue (NSR unit value) of $154 per tonne.

Uranium provides 36% of revenue, and rare earths provide 64%.

HREO make up slightly over 50% of the rare earths revenue.

Revenue is recognized at the time of production.

Initial capital of C$563 million (first two years), includes contingency of $108

million.

Mine life capital totals C$670 million.

Unit operating costs of $71.33 per tonne.

COSTS

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-3

TABLE 1-1 PRE-TAX CASH FLOW SUMMARY

Pele Mountain Resources Inc. – Eco Ridge Mine Project

Year -2

Units

Inputs

Year -1

Year 1

Year 2

Year 3

Year 4

Year 5

Year 6

Year 7

Year 8

Year 9

Year 10

Year 11

Year 12

Year 13

Total

MINING

Ore Mined

34,550

000s tonnes

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Uranium Grade

CeO2 Grade

La2O3 Grade

Nd2O3 Grade

Pr6O11 Grade

Sm2O3 Grade

Eu2O3 Grade

Gd2O3 Grade

Sc2O3 Grade

Y2O3 Grade

Yb2O3 Grade

Dy2O3 Grade

Er2O3 Grade

Ho2O3 Grade

Lu2O3 Grade

Tb4O7 Grade

Tm2O3 Grade

Th Grade

LREO Grade

HREO Grade

Total REO Grade

0.040%

%U3O8

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

Oxide Factors

1.23

1.17

1.17

1.21

1.16

1.16

1.15

1.53

1.27

1.14

1.15

1.14

1.15

1.14

1.18

1.14

1.14

657.05

346.12

210.56

65.49

36.34

2.05

24.30

7.12

71.39

5.04

15.54

6.48

2.62

0.69

3.36

0.88

338.14

1,279.23

175.80

1,455.03

229

318

3,287

3,284

3,284

3,283

3,278

3,279

3,253

3,280

3,282

3,279

1,214

-

0.048%

0.058%

0.058%

0.052%

0.044%

0.045%

0.045%

0.036%

0.036%

0.037%

0.032%

0.020%

0.018%

0.000%

758.70

395.72

248.58

77.66

42.32

2.41

27.83

5.91

85.32

5.88

18.43

7.59

3.08

0.76

3.90

1.00

398.19

1,481

204

1,685

881.29

464.47

283.77

88.46

48.89

2.62

32.73

6.36

96.21

6.93

21.31

8.95

3.59

0.91

4.52

1.18

428.55

1,718

234

1,952

900.46

472.81

289.64

90.71

50.08

2.70

33.88

6.49

98.87

7.09

21.92

9.22

3.69

0.93

4.69

1.21

451.49

1,754

241

1,994

784.53

415.51

256.07

79.60

43.91

2.36

29.05

6.25

87.46

6.20

19.14

7.98

3.18

0.82

4.01

1.05

389.40

1,536

211

1,747

677.01

355.06

222.51

69.06

38.24

2.25

25.45

6.28

77.30

5.35

16.73

6.88

2.77

0.70

3.57

0.91

360.63

1,324

186

1,510

759.61

401.86

240.41

75.12

41.67

2.16

27.86

7.78

77.93

5.58

17.36

7.20

2.90

0.77

3.79

0.98

345.06

1,477

196

1,673

718.66

381.27

229.30

71.28

39.49

2.12

26.02

6.50

74.84

5.45

16.37

6.88

2.77

0.74

3.55

0.93

348.42

1,401

186

1,586

680.21

358.22

218.13

68.24

37.60

2.07

24.49

6.00

70.74

5.09

15.47

6.43

2.57

0.69

3.38

0.86

322.34

1,325

175

1,500

658.74

351.36

209.09

65.50

35.93

2.07

24.07

6.85

71.15

4.92

15.20

6.36

2.59

0.71

3.29

0.90

339.23

1,285

174

1,459

464.09

241.90

152.27

46.79

27.35

1.83

19.49

9.85

61.01

4.33

13.32

5.56

2.26

0.61

2.86

0.76

330.19

905

149

1,054

512.57

267.86

163.22

49.56

28.11

1.77

19.35

6.79

57.29

3.96

12.37

5.16

2.17

0.58

2.70

0.73

292.97

993

141

1,134

462.46

241.41

141.33

43.90

24.10

1.40

15.87

9.29

45.15

3.06

9.38

3.97

1.64

0.47

2.13

0.57

232.66

889

117

1,006

448.10

234.52

139.47

43.90

23.34

1.20

14.52

5.07

40.85

2.67

8.41

3.44

1.36

0.38

1.90

0.45

218.42

866

104

970

-

PROCESSING

Ore to Processing

34,550

%U3O8

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

0.040%

657.05

346.12

210.56

65.49

36.34

2.05

24.30

7.12

71.39

5.04

15.54

6.48

2.62

0.69

3.36

0.88

338.14

1,304

179

1,483

Recovery U3O8

Recovery CeO2

Recovery La2O3

Recovery Nd2O3

Recovery Pr6O11

Recovery Sm2O3

Recovery Eu2O3

Recovery Gd2O3

Recovery Sc2O3

Recovery Y2O3

Recovery Yb2O3

Recovery Dy2O3

Recovery Er2O3

Recovery Ho2O3

Recovery Lu2O3

Recovery Tb4O7

Recovery Tm2O3

Recovery Th

%

%

%

%

%

%

%

%

%

%

%

%

%

%

%

%

%

%

Recovered U3O8

Recovered CeO2

Recovered La2O3

Recovered Nd2O3

Recovered Pr6O11

Recovered Sm2O3

Recovered Eu2O3

Recovered Gd2O3

Recovered Sc2O3

Recovered Y2O3

Recovered Yb2O3

Recovered Dy2O3

Recovered Er2O3

Recovered Ho2O3

Recovered Lu2O3

Recovered Tb4O7

Recovered Tm2O3

Recovered Th

Recovered LREO

Recovered HREO

Total REOs

000 lbs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 kgs

000 lbs

3,287

3,284

3,284

3,283

3,278

3,279

3,253

3,280

3,282

3,279

1,214

-

0.054%

829.93

435.66

269.03

83.94

46.14

2.53

30.68

6.17

91.65

6.49

20.10

8.38

3.38

0.85

4.26

1.11

415.83

3,199

439

3,637

546

0.058%

900.46

472.81

289.64

90.71

50.08

2.70

33.88

6.49

98.87

7.09

21.92

9.22

3.69

0.93

4.69

1.21

451.49

1,754

241

1,994

0.052%

784.53

415.51

256.07

79.60

43.91

2.36

29.05

6.25

87.46

6.20

19.14

7.98

3.18

0.82

4.01

1.05

389.40

1,536

211

1,747

0.044%

677.01

355.06

222.51

69.06

38.24

2.25

25.45

6.28

77.30

5.35

16.73

6.88

2.77

0.70

3.57

0.91

360.63

1,324

186

1,510

0.045%

759.61

401.86

240.41

75.12

41.67

2.16

27.86

7.78

77.93

5.58

17.36

7.20

2.90

0.77

3.79

0.98

345.06

1,477

196

1,673

0.045%

718.66

381.27

229.30

71.28

39.49

2.12

26.02

6.50

74.84

5.45

16.37

6.88

2.77

0.74

3.55

0.93

348.42

1,401

186

1,586

0.036%

680.21

358.22

218.13

68.24

37.60

2.07

24.49

6.00

70.74

5.09

15.47

6.43

2.57

0.69

3.38

0.86

322.34

1,325

175

1,500

0.036%

658.74

351.36

209.09

65.50

35.93

2.07

24.07

6.85

71.15

4.92

15.20

6.36

2.59

0.71

3.29

0.90

339.23

1,285

174

1,459

0.037%

464.09

241.90

152.27

46.79

27.35

1.83

19.49

9.85

61.01

4.33

13.32

5.56

2.26

0.61

2.86

0.76

330.19

905

149

1,054

0.032%

512.57

267.86

163.22

49.56

28.11

1.77

19.35

6.79

57.29

3.96

12.37

5.16

2.17

0.58

2.70

0.73

292.97

993

141

1,134

0.020%

462.46

241.41

141.33

43.90

24.10

1.40

15.87

9.29

45.15

3.06

9.38

3.97

1.64

0.47

2.13

0.57

232.66

889

117

1,006

0.018%

448.10

234.52

139.47

43.90

23.34

1.20

14.52

5.07

40.85

2.67

8.41

3.44

1.36

0.38

1.90

0.45

218.42

866

104

970

0.000%

-

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

Recovery

90%

90%

88%

89%

89%

85%

79%

81%

61%

76%

71%

75%

74%

71%

74%

78%

74%

80%

44,942

23,227

14,210

4,425

2,355

123

1,496

331

4,127

272

882

364

142

39

200

49

20,605

86,804

10,381

97,185

27,491

20,386

10,535

6,446

2,007

1,068

56

678

150

1,872

123

400

165

64

18

91

22

9,346

39,374

4,709

44,083

97,185

583

407

210

130

41

21

1

14

2

38

3

8

3

1

0

2

0

182

788

94

882

3,776

2,658

1,369

843

264

140

7

90

13

247

17

54

22

9

2

12

3

1,187

5,135

615

5,750

3,413

2,314

1,202

745

232

123

6

77

13

218

14

47

19

7

2

10

3

1,023

4,493

539

5,033

2,855

1,997

1,027

647

201

107

6

68

13

193

12

41

17

6

2

9

2

948

3,873

475

4,348

2,960

2,240

1,162

699

219

116

6

74

16

194

13

42

17

7

2

10

2

906

4,320

499

4,819

2,926

2,115

1,101

666

207

110

5

69

13

186

13

40

17

6

2

9

2

914

4,089

473

4,562

2,374

2,003

1,035

634

198

105

5

65

12

176

12

38

16

6

2

9

2

846

3,870

447

4,317

2,350

1,925

1,007

603

189

99

5

63

14

176

11

37

15

6

2

8

2

883

3,723

439

4,162

2,422

1,367

699

443

136

76

5

52

20

152

10

33

13

5

1

7

2

867

2,645

376

3,021

2,111

1,511

774

475

144

79

5

51

14

143

9

30

13

5

1

7

2

769

2,904

358

3,262

1,298

1,362

697

411

128

67

4

42

19

112

7

23

10

4

1

5

1

610

2,597

295

2,893

423

489

251

150

47

24

1

14

4

38

2

8

3

1

0

2

0

212

937

98

1,034

www.rpacan.com

Rev. 0 Page 1-4

000s tonnes

Uranium Grade

CeO2 Grade

La2O3 Grade

Nd2O3 Grade

Pr6O11 Grade

Sm2O3 Grade

Eu2O3 Grade

Gd2O3 Grade

Sc2O3 Grade

Y2O3 Grade

Yb2O3 Grade

Dy2O3 Grade

Er2O3 Grade

Ho2O3 Grade

Lu2O3 Grade

Tb4O7 Grade

Tm2O3 Grade

Th Grade

LREO Grade

HREO Grade

Total REO Grade

Head Grade

Year -2

Inputs

Units

Year -1

Year 1

Year 2

Year 3

Year 4

Year 5

Year 6

Year 7

Year 8

Year 9

Year 10

Year 11

Year 12

Year 13

Total

REVENUE

Gross Revenue

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

U3O8

CeO2

La2O3

Nd2O3

Pr6O11

Sm2O3

Eu2O3

Gd2O3

Sc2O3

Y2O3

Yb2O3

Dy2O3

Er2O3

Ho2O3

Lu2O3

Tb4O7

Tm2O3

Sub-Total LREOs

Sub-Total HREOs

Sub-Total REOs

Total Gross Revenue

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

US$ '000s

Exchange Rate

1 US$=C$

REO Basket Price

Gross Revenue

C$ '000s

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

70

18

20

175

140

80

2,900

150

3,000

150

90

1,450

195

1,200

2,200

3,000

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

$

1,924,376

366,941

210,708

1,127,993

280,988

85,468

162,090

101,756

450,732

280,814

11,094

579,933

32,232

21,280

199,912

67,163

1,986,631

1,992,474

3,979,104

5,903,481

$

$

90

5,903,481

$40,804

$7,331

$4,195

$22,795

$5,696

$1,717

$3,168

$2,032

$6,183

$5,702

$226

$11,867

$659

$0

$412

$4,011

$1,338

$40,017

$37,314

$77,332

$118,135

1.00

1.00

$

$264,346

$47,837

$27,381

$147,601

$37,023

$11,205

$20,336

$13,494

$39,129

$36,995

$1,485

$77,812

$4,359

$0

$2,713

$26,563

$8,775

$259,842

$242,867

$502,710

$767,055

1.00

$238,883

$41,649

$24,045

$130,398

$32,465

$9,819

$17,761

$11,564

$37,632

$32,705

$1,297

$67,894

$3,771

$0

$2,401

$22,688

$7,656

$228,557

$215,188

$443,745

$682,628

1.00

$199,859

$35,940

$20,546

$113,305

$28,166

$8,550

$16,910

$10,130

$37,786

$28,903

$1,121

$59,341

$3,250

$0

$2,037

$20,192

$6,616

$197,956

$194,836

$392,793

$592,652

1.00

$207,172

$40,312

$23,248

$122,384

$30,629

$9,313

$16,224

$11,085

$46,831

$29,128

$1,168

$61,555

$3,403

$0

$2,242

$21,453

$7,105

$216,573

$209,508

$426,081

$633,253

1.00

$204,808

$38,074

$22,019

$116,529

$29,011

$8,812

$15,900

$10,338

$39,028

$27,927

$1,137

$57,958

$3,245

$0

$2,165

$20,061

$6,726

$205,633

$193,297

$398,930

$603,737

1.00

$166,176

$36,052

$20,697

$110,900

$27,785

$8,394

$15,539

$9,732

$36,075

$26,408

$1,062

$54,786

$3,032

$0

$2,007

$19,069

$6,255

$195,434

$182,360

$377,795

$543,971

1.00

$164,503

$34,642

$20,142

$105,473

$26,464

$7,959

$15,390

$9,492

$40,831

$26,352

$1,019

$53,410

$2,976

$0

$2,061

$18,458

$6,492

$186,720

$184,439

$371,159

$535,663

1.00

$169,567

$24,608

$13,982

$77,447

$19,060

$6,108

$13,747

$7,749

$59,251

$22,787

$906

$47,190

$2,623

$0

$1,767

$16,160

$5,530

$135,096

$183,816

$318,912

$488,478

1.00

$147,739

$27,192

$15,490

$83,056

$20,198

$6,282

$13,282

$7,696

$40,852

$21,406

$828

$43,866

$2,439

$0

$1,692

$15,264

$5,312

$145,935

$158,917

$304,853

$452,592

1.00

$90,895

$24,511

$13,948

$71,853

$17,874

$5,379

$10,506

$6,307

$55,851

$16,856

$638

$33,230

$1,873

$0

$1,374

$12,029

$4,136

$128,185

$148,179

$276,364

$367,259

1.00

$29,625

$8,793

$5,017

$26,253

$6,618

$1,929

$3,328

$2,136

$11,284

$5,647

$207

$11,025

$600

$0

$410

$3,964

$1,223

$46,680

$41,751

$88,432

$118,057

1.00

88 $

$118,135

87 $

$767,055

88 $

$682,628

90 $

$592,652

88 $

$633,253

87 $

$603,737

88 $

$543,971

89 $

$535,663

106 $

$488,478

93 $

$452,592

96 $

$367,259

86

$118,057

$7,880

$2,825

$10,705

12 $

13.8%

$51,346

$18,453

$69,799

12 $

13.9%

$44,931

$16,182

$61,113

12 $

13.8%

$38,726

$14,254

$52,980

12 $

13.5%

$43,201

$14,981

$58,181

12 $

13.7%

$40,893

$14,178

$55,071

12 $

13.8%

$38,699

$13,404

$52,103

12 $

13.8%

$37,234

$13,171

$50,405

12 $

13.6%

$26,449

$11,292

$37,741

12 $

11.8%

$29,040

$10,736

$39,776

12 $

13.0%

$25,974

$8,860

$34,833

12 $

12.6%

$9,366

$2,928

$12,294

12

13.9%

Offsite Concentrate Costs

LREOs

HREOs

Total

C$ '000s

C$ '000s

C$ '000s

C$/kg

% of Gross

$

$

10.00

30.00

$

$

$

$

393,737

141,264

535,002

12

13.4%

$

Net Revenue

Uranium

Rare Earths

Total Net Revenue

C$ '000s

C$ '000s

C$ '000s

$

$

$

1,924,376

3,444,103

5,368,479

$40,804

$66,627

$107,431

$264,346

$432,911

$697,256

$238,883

$382,632

$621,515

$199,859

$339,813

$539,672

$207,172

$367,900

$575,072

$204,808

$343,858

$548,666

$166,176

$325,691

$491,867

$164,503

$320,755

$485,258

$169,567

$281,171

$450,737

$147,739

$265,077

$412,816

$90,895

$241,531

$332,425

$29,625

$76,137

$105,762

NSR Royalty

NSR Royalty

Total Royalty Paid

C$ '000s

C$ '000s

C$ '000s

0.75% $

0.00% $

$

40,264

40,264

$806

$0

$806

$5,229

$0

$5,229

$4,661

$0

$4,661

$4,048

$0

$4,048

$4,313

$0

$4,313

$4,115

$0

$4,115

$3,689

$0

$3,689

$3,639

$0

$3,639

$3,381

$0

$3,381

$3,096

$0

$3,096

$2,493

$0

$2,493

$793

$0

$793

Net Smelter Return

$106,625

$195

$692,027

$211

$616,854

$188

$535,625

$163

$570,759

$174

$544,551

$166

$488,178

$149

$481,618

$148

$447,357

$136

$409,720

$125

$329,932

$101

$104,969

$86

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

$41.52

$26.31

$3.50

$71.33

C$ '000s

C$/t

$

OPERATING COSTS

Mining

Processing

G&A

Total Opex Per Tonne Milled

C$/t mined

C$/t milled

C$/t milled

C$/t milled

$

$

$

$

42.64

26.31

3.44

72.40

Mining

Processing

G&A

Total Operating Cost

C$ '000s

C$ '000s

C$ '000s

C$ '000s

$

$

$

$

1,473,308

909,013

119,013

2,501,334

$28,519

$0

$0

$28,519

$32,959

$14,378

$0

$47,336

$136,462

$86,472

$11,503

$234,438

$136,365

$86,410

$11,495

$234,270

$136,359

$86,407

$11,495

$234,260

$136,320

$86,382

$11,491

$234,193

$136,085

$86,233

$11,472

$233,790

$136,144

$86,270

$11,476

$233,891

$135,080

$85,597

$11,387

$232,064

$136,200

$86,306

$11,481

$233,987

$136,266

$86,348

$11,487

$234,101

$136,143

$86,270

$11,476

$233,889

$50,405

$31,940

$4,249

$86,594

Operating Margin

C$ '000s

$

2,826,882

-$28,519

$59,288

$457,589

$382,583

$301,365

$336,566

$310,761

$254,288

$249,554

$213,370

$175,619

$96,043

$18,375

$0

$0

$86,420

$7,300

$165,366

$33,926

$20,215

$3,000

$47,620

$35,000

$30,909

$7,300

$82,683

$16,963

$10,107

$3,000

$10,000

$17,000

$30,276

$9,404

$5,963

$6,977

$2,891

41.52

26.31

3.50

C$ '000s

C$ '000s

C$ '000s

C$ '000s

C$ '000s

C$ '000s

C$ '000s

C$ '000s

$86,802

$7,300

$165,366

$33,926

$20,215

$3,000

$47,620

C$ '000s

C$ '000s

C$ '000s

$12,000

$67,561

$35,000

$12,000

$67,561

$35,000

$6,000

$33,781

$17,500

$6,000

$33,781

$17,500

C$ '000s

C$ '000s

C$ '000s

30%

25%

$89,210

$18,396

$562,843

$46,150

$9,227

$290,620

$43,060

$9,169

$272,224

C$ '000s

C$ '000s

C$ '000s

$24,000

$22,000

$667,013

$3,000

$3,000

$3,000

$3,000

$290,620

$272,224

$19,404

$8,963

$26,389

$5,891

$3,000

$3,000

$2,000

$5,000

$3,000

$2,000

$11,523

$3,000

$3,000

$6,000

$3,000

$2,000

$5,000

$2,000

$2,000

$8,000

$8,000

$2,000

$2,000

$1,000

$1,000

PRE-TAX CASHFLOW

Pre-Tax Cash Flow

Cumulative

C$ '000s

C$ '000s

$2,159,868

-$319,139

-$319,139

-$212,935

-$532,074

$438,185

-$93,889

$373,620

$279,731

$274,976

$554,706

$330,675

$885,381

$307,761

$1,193,142

$249,288

$1,442,430

$238,031

$1,680,462

$207,370

$1,887,831

$170,619

$2,058,450

$94,043

$2,152,493

$10,375

$2,162,868

-$2,000

$2,160,868

-$1,000

$2,159,868

PROJECT ECONOMICS

Pre-Tax IRR

Pre-Tax NPV

Pre-Tax NPV

Pre-Tax NPV

C$ '000s

C$ '000s

C$ '000s

Sustaining Capital

Site Decomissioning and Monitoring

Total Capital Cost

5%

7.5%

10%

50%

$1,475,351

$1,226,684

$1,022,820

$82,683

$16,963

$10,107

$14,685

$8,000

$16,412

$6,523

$10,000

www.rpacan.com

Rev. 0 Page 1-5

CAPITAL COSTS

Directs

Mining

Process Site Development

Acid Baking Plant

Uranium Extraction Plant

Y & REE Plant

Water Treatment Plant

Tailings

Site infrastructure

Indirects

Mine Indirects

Process Indirects

Construction Indirects

Contingency

Process Contingency

Mining & Other Contingency

Total Initial Capital

$

$

$

5,328,215

$154

www.rpacan.com

CASH FLOW RESULTS

The cash flow analysis in this report has been carried out on a pre-tax basis.

Considering the Project on a stand-alone basis, the undiscounted pre-tax cash flow

totals C$2.1 billion over the mine life and simple payback occurs 1.5 years after the start

of commercial production. The internal rate of return (IRR) is 50% and the net present

value (NPV) is as follows:

C$1.5 billion at a 5% discount rate

C$1.2 billion at a 7.5% discount rate

C$1.0 billion at a 10% discount rate

The economic analysis contained in this report is based, in part, on Inferred Resources,

and is preliminary in nature.

Inferred Resources are considered too geologically

speculative to have mining and economic considerations applied to them and to be

categorized as Mineral Reserves. There is no certainty that economic forecasts on

which this Preliminary Economic Assessment is based will be realized.

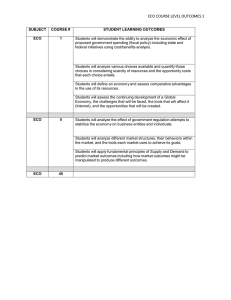

SENSITIVITY ANALYSIS

Sensitivity analyses were performed for uranium price, REO prices, operating cost,

capital cost, uranium recovery, and rare earth recoveries. The sensitivity analyses on

IRR and NPV at a discount rate of 10% indicate that the Project economics are most

heavily influenced by the recovery and market price of REEs. The Project economics

are also heavily influenced by the operating cost.

These sensitivities focus on rare earth oxides, which provide approximately 64% of the

base case revenue whereas uranium provides approximately 36% of the base case

revenue. The recent price history for rare earths covers a wide range, including order-ofmagnitude increases within 2011. The rare earths price sensitivity is based on results at

a conservative long-term forecast ($30/kg basket price), the base case ($90/kg basket

price), and current prices ($103/kg basket price). Note that these basket prices relate to

gross revenue, before charges for separation are applied.

Figure 1-1 and Table 1-2 summarize the results of the sensitivity analyses.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-6

www.rpacan.com

FIGURE 1-1 SENSITIVITY ANALYSIS

$2,000,000 NPV @ 10% ('000s)

$1,600,000 REE Recovery

$1,200,000 U3O8 Recovery

REE Price

$800,000 U3O8 Price

Operating Costs

$400,000 Capital Costs

$0 ‐40%

‐30%

‐20%

‐10%

0%

10%

20%

30%

40%

Factor of Change

Note: U3O8 recovery has the same slope as U3O8 price.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-7

www.rpacan.com

TABLE 1-2 SENSITIVITY ANALYSIS

Pele Mountain Resources Inc. – Eco Ridge Mine Project

Factor

0.72

0.86

1

1.14

1.29

U3O8 Market Price

U3O8 Price (US$/lb)

NPV (C$ millions)

50

728

60

875

70

1,022

80

1,171

90

1,319

IRR (%)

35%

45%

50%

57%

60%

Factor

0.33

0.66

1

1.14

REO Basket Price

REO Price (US$/kg)

NPV (C$ millions)

30

(381)

60

324

90

1,022

103

1,316

IRR (%)

NA

26%

50%

59%

Operating Cost Per Tonne Milled

Opex (C$/t)

NPV (C$ millions)

IRR (%)

Factor

0.8

0.9

1

1.1

1.2

Factor

0.8

0.9

1

1.1

1.2

Factor

0.85

0.925

1

1.075

1.15

58

65

71

80

87

1,278

1,151

1,022

895

767

Capital Cost

Capex (C$ millions)

NPV (C$ millions)

534

600

667

734

800

1,132

1,077

1,022

968

914

Recovery - REE

Average Recovery

NPV (C$ millions)

68%

751

74%

887

79%

1,022

85%

1,159

90%

1,295

58%

54%

50%

46%

42%

IRR (%)

63%

56%

50%

46%

41%

IRR (%)

42%

46%

50%

54%

58%

EXTENDED MINE LIFE SENSITIVITY

The MCB is known to persist to the north of the current resource model, as indicated by

historical drilling. RPA examined the effect of extending the mine life to include an

additional 50 Mt of production from the MCB, resulting in a mine life of 25 years.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-8

www.rpacan.com

The undiscounted pre-tax cash flow for the extended mine life sensitivity totals C$6.5

billion with an IRR of 51%. The net present value (NPV) is as follows:

C$3.2 billion at a 5% discount rate

C$2.3 billion at a 7.5% discount rate

C$1.7 billion at a 10% discount rate

Given the long mine life, RPA also looked at a higher production rate for this extended

mine life sensitivity, increasing production from 9,000 tpd to 12,000 tpd while using the

same mining method. A summary of the key inputs and criteria in developing the 12,000

tpd option is illustrated below.

LOM of 20 years

Higher capital costs for larger operation:

o Initial capital cost of C$661 million

o Total capital cost of C$838 million

Lower operating costs of C$69 per tonne of ore mined,

The undiscounted pre-tax cash flow in this case totals C$6.6 billion. The IRR is 53% and

the NPV is as follows:

C$3.6 billion at a 5% discount rate

C$2.7 billion at a 7.5% discount rate

C$2.1 billion at a 10% discount rate

CONCLUSIONS

In RPA’s opinion, the PEA indicates that positive economic results can be obtained for

the Eco Ridge Mine Project, in a scenario that includes room and pillar mining, and

uranium and rare earth recovery by conventional milling.

The Base Case LOM plan for the Project indicates that 34.6 Mt, at average grades of

0.040% U3O8 and 1,455 g/t TREO, will be mined over 11 years at a nominal production

rate of 9,000 tpd. Uranium production is projected to total 27.5 million pounds, and REO

production is projected to total 44.1 million kilograms.

The Project has good potential for increasing the base case mine life.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Technical Report NI 43-101 – June 20, 2012

Rev. 0 Page 1-9

www.rpacan.com

Specific conclusions by area of the PEA are as follows.

GEOLOGY AND RESOURCES

Rare earth and uranium mineralization on the Eco Ridge property is hosted primarily by

the Main Conglomerate Bed (MCB) and the Hangingwall Zone (HWZ) located within the

Ryan Member of the Mississagi Quartzite.

On average, the MCB is 2.7 m thick and dips consistently at an average of -21o north.

The HWZ, located immediately above the MCB, is defined by economic limits. The

current Mineral Resource estimate is listed in Table 1-3.

TABLE 1-3 SUMMARY OF MINERAL RESOURCES – APRIL 16, 2012

Pele Mountain Resources Inc. – Eco Ridge Mine Project

Tonnes

U3O8

U3O8

LREO

HREO

TREO

TREO

(000)

(%)

(000 lbs)

(ppm)

(ppm)

(ppm)

(000 lbs)

MCB

20,514

0.045

20,447

1,426

193

1,618

73,184

HWZ

28,223

0.012

7,214

733

88

821

51,111

Total

48,737

0.026

27,661

1,025

132

1,157

124,295

MCB

16,906

0.043

15,940

1,279

183

1,463

54,515

HWZ

20,956

0.013

5,822

713

95

808

37,329

Total

37,863

0.026

21,762

966

134

1,100

91,843

Zone &

Classification

Indicated

Inferred

Notes:

1.

2.

3.

4.

5.

6.

CIM definitions were followed for Mineral Resources.

Mineral Resources were estimated at a cut-off value of $100 per tonne for the MCB, and $50 per

tonne for the HWZ. Values were calculated based on prices and recoveries of uranium and rare

earths, net of off-site rare earth separation costs.

Mineral Resources were estimated using an average uranium price of US$70 per lb U3O8, a rare

earth “basket price” of $78 per kg (net of separation charges), and a C$:US$ exchange rate of

1.00:1.00.

A minimum mining thickness of 1.8 m was used for the MCB.

Light Rare Earth Oxides include La2O3, CeO2, Pr6O11, and Nd2O3.

Heavy Rare Earth Oxides include Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3, Ho2O3, Er2O3, Tm2O3,

Yb2O3, Y2O3, and Lu2O3. Sc2O3 is also included in HREO, as it occurs in low concentrations and

carries high unit values like an HREO.

Historic drilling has intersected the MCB to the west, to the east, and down-dip from the

current Mineral Resource. A target for further exploration was estimated for these areas,

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Rev. 0 Page 1-10

Technical Report NI 43-101 – June 20, 2012

www.rpacan.com

consisting of a further 40 Mt to 60 Mt, grading from 0.030% to 0.050% U3O8,

accompanied by 0.12% to 0.18% TREO for the MCB.

The potential quantities and grades of the exploration targets are conceptual in nature

and there has been insufficient drilling to define a Mineral Resource. It is uncertain if

further exploration will result in the definition of a mineral resource in these areas.

MINING

The MCB is correlated with the “Pardee Reef” in the Nordic Channel. This reef was

mined at the adjacent Nordic and Stanleigh mines operated by Rio Algom between 1957

and 1996.

A number of mining methods have been assessed by RPA and others for extraction of

the MCB mineralization. The selected mining method was room and pillar, with both

development and production contained within the mineralized zone. The development

and production tonnage will be loaded into trucks and transported to surface for

processing.

Although the MCB average mining thickness is 2.7 m, in RPA’s opinion, the deposit will

support a high production rate. The lateral extents are such that multiple accesses from

surface are feasible, providing many independent workplaces.

The use of conveyors instead of haul trucks for material handling, while not included in

the base case, may provide economic advantages, and is worth consideration in future

studies.

Particular attention should be paid to impacts on grade distribution in

production schedules for each option, as there may be less flexibility with conveyors,

offsetting the cost advantage that they provide.

In RPA’s opinion, conveyors may also provide operational advantages that are difficult to

quantify economically at this stage of the Project, including better mine ventilation,

reduced traffic on the ramps, and easier material handling as the mine extends at depth.

Geotechnical and hydrogeological assumptions are supported by historic operations in

Elliot Lake, however, require confirmation by data collection and analysis at the Project.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Rev. 0 Page 1-11

Technical Report NI 43-101 – June 20, 2012

www.rpacan.com

PROCESSING AND METALLURGY

Historically, mining and processing operations have been carried out in the Elliot Lake

area, but not on the Eco Ridge Mine property. The major portion of the ore mined was

processed through a conventional uranium processing plant, with some production from

underground leaching on run-of-mine ore. Yttrium oxide and rare earth oxides were also

recovered at the Denison Mine in the past, as by-products of the uranium production.

RPA has observed that the metallurgical program supporting the current Project

flowsheet has been dynamic, involving changes in pursuit of potential improvements on

relatively short notice.

The unit operations within the process flowsheet have been

tested at various times, using different metallurgical samples, which is not unusual at the

PEA stage of project development. The testwork to date has focused on optimizing rare

earths recoveries, and although the overall uranium recovery assumption has not been

verified by testwork, it is typical of that achieved in historical operations. The assumed

recovery is supported by excellent results achieved for uranium in the acid bake unit

operation. RPA made a number of assumptions in assembling the various testwork

results into a coherent overall recovery for each element.

The data used for the PEA is preliminary in nature and, therefore, indicative of the

results that may be expected after a more rigorous and thorough program of

metallurgical testing is conducted. The actual results achieved in the long term may vary

significantly if a plant is ultimately constructed and operated, particularly since the

current design is based on many assumptions.

That being said, the processes that have been tested are not optimized and, based on

that observation, it is reasonable to expect that the results may also be better.

ENVIRONMENT

Preliminary baseline aquatic and terrestrial environmental studies have been performed

and no environmental problems have been identified to date. In order to identify all

potential environmental risks pertaining to the Project, Human Health and Ecological

Risk Assessments will need to be conducted during the Environmental Assessment (EA)

process. The assessments will be completed in full matrices, with the highest ranking

environmental risks being identified along with corresponding abatement strategies listed

in table format. Because of the extensive documented experience in the Elliot Lake

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Rev. 0 Page 1-12

Technical Report NI 43-101 – June 20, 2012

www.rpacan.com

mining camp with uranium mine operations and decommissioning, it is expected that all

significant risks can be effectively managed.

MARKETS

Uranium

A uranium price of US$70/lb U3O8 has been used in this PEA, based on independent

metal price forecasts from banks and financial institutions. RPA notes that the price

used in the PEA, while slightly above the long term price for U3O8, is within the range of

medium- to long-term forecasts.

Rare Earths

The market for rare earth products is currently relatively small but growing rapidly for

certain rare earths. Public information on price forecasts and sales terms are difficult to

obtain and vary within a wide range. Current prices are tracked by sources such as

Asian Metal and Metal-PagesTM, based on transactions.

Recent history shows international rare earth market prices growing at an

unprecedented rate since China cut export quotas by approximately 40% in 2011.

China’s overwhelming control on the rare earth supply chain, from upstream mining to

downstream processing and end-user products, is likely to remain intact on all but a few

materials through 2016. Rare earth prices are expected to remain volatile in the short

term.

A small number of REE producers outside of China are likely to be in operation by the

time the Eco Ridge Mine Project is developed. This is expected to saturate the market

for LREO such as lanthanum and cerium, however, demand for high-value HREO (such

as dysprosium) is expected to grow, and supply is expected to remain in deficit.

Price forecasting in this environment is difficult, and certain to contain wide margins of

error.

RPA selected rare earth prices within a range of available forecasts. Prices for certain

elements are higher than current prices, and for others, lower, however the average

basket price is approximately 13% lower than Q2 2012 prices.

Pele Mountain Resources Inc. – Eco Ridge Mine Project, Project #1826

Rev. 0 Page 1-13

Technical Report NI 43-101 – June 20, 2012

www.rpacan.com

RPA considers these rare earths prices to be appropriate for a PEA-level study,

however, we note that the recent market volatility introduces considerably more

uncertainty than a comparable base or precious metals project.

RECOMMENDATIONS

RPA recommends that Pele Mountain continue collecting data to support the feasibility

and licensing process, and move on to more advanced engineering studies.