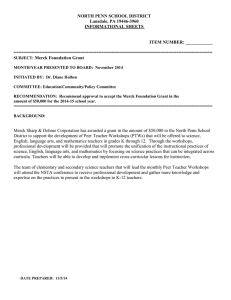

Merck – Living Innovation

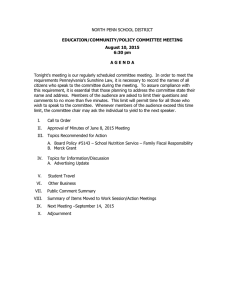

advertisement