ATEX / IEC Terminology

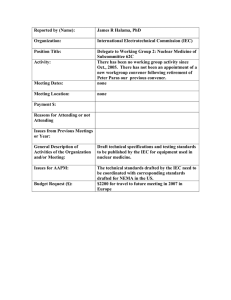

advertisement

ATEX / IEC Terminology SB568 ATEX / IEC Motor Terminology Alleinshutz Alleinshutz defines the certification of flameproof motor and protection device together. In the IEC world the most common protection device is a thermistor and relay that is set to switch off the motor in case of overheating before any danger of explosion can occur, unlike North America where the practice is to use a thermostat. Ambient Temperature Ambient temperature is the temperature that surrounds the motor. Ambient is always based on nameplate KW. It is common practice to reduce the nameplate KW to accommodate the higher ambient. Altitude IEC identifies 1,000 meters as standard where NEMA would be 3,300 feet. NEMA defines a maximum altitude of 16,500 feet; IEC defines a maximum altitude of 4,000 meters. IEC 34-16.3.5 specifications assume that reduced cooling will occur as a result of higher altitude and is compensated by a reduction of the maximum ambient temperature per the table below: Altitude In Meters 1000 2000 3000 4000 Temperature (C) Class of Insulation F 40 30 19 9 B 40 32 24 16 H 40 28 15 3 ATEX 95 This directive sets out the essential health and safety requirements (EHSR) for equipment and protection systems intended for use in potentially explosive atmospheres. Refer to ATEX Directives definition for additional comments. ATEX 137 ATEX Directive 137 is actually an addendum to ATEC Directive 95. ATEX Directive 95 describes the construction of equipment intended for installation and use in potentially explosive atmospheres and ATEX Directive 137 describes how these areas should be classified into hazardous areas and how work can be performed safely in these areas. ATEX Directives ATEX is an abbreviation for the French “ATmosphere EXplosible” and is used as a synonym for the two European directives related to explosion hazard in atmospheric conditions. ATEX 95 Directive specifies the construction of equipment and protection systems intended for use in potentially explosive atmospheres. ATEX 137 Directive specifies to the use of equipment and protection systems intended for use in potentially explosive atmospheres. ATEX Group Two groups are referred to in the ATEX 95 Directive: Group I and Group II. Both groups are further subdivided into categories. These categories indicate whether a device or protective system can be deployed in a possible explosive atmosphere with gas (G), mist, with dust (D) or with gas and dust (GD). SB568, 11/13 1 ATEX / IEC Motor Terminology Group I Comprises equipment intended for use in the underground parts of mines and to those parts of surface installations of such mines likely to be exposed to combustible dust. Category M1 Products of this category are required to remain functional for safety reasons when an explosive atmosphere is present and is characterized by integrated explosion protection measures functioning in such a way that: In the event of failure of one integrated measure, at least a second means of protection provides for a sufficient level of safety, or In the event of two faults occurring independently of each other, a sufficient level of safety is ensured. Category M2 These products are intended to be de-energized in the event of an explosive atmosphere. Group II Comprises equipment intended for use in other places likely to become endangered by explosive atmospheres. Category 1 Comprises products designed to be capable of remaining within its operational parameters, stated by the manufacturer, and ensuring a very high level of protection for its intended use in areas in which explosive atmospheres caused by mixtures of air and gases, vapors, mists of air/dusts mixtures are highly likely to occur and are present continuously, for long periods of time or frequently. Category 2 Comprises products designed to be capable of remaining with their operational parameters, stated by the manufacturer, and based on a high level of protection for their intended use, in areas in which explosive atmospheres caused by mixtures of air and gases, vapors, mists or air/dust mixtures are likely to occur. Category 3 Comprises products designed to be capable of keeping within its operational parameters, stated by the manufacturer, and based upon a normal level of protection for its intended use, considering areas in which explosive atmospheres, mists or air/dust mixtures are unlikely to occur and if they do occur, do so infrequently and for a short period of time only. Atmosphere The environmental atmosphere and prevailing conditions at the workplace are a major determinant for the installation methods of equipment and the choice of materials to be used. It is, therefore, a prerequisite to classify the areas with potential gas and dust explosive atmospheres into hazardous areas. The potentially hazardous areas are classified into hazardous areas based on the frequency and duration of the occurrences of an explosive atmosphere. Zone 0, 1 and 2: Areas at risk of gas explosion (where a mixture of air with any combination of flammable gas, fumes or mist is present). Zone 20, 21 and 22: Areas at risk of dust explosion (where a cloud of flammable dust may occur). The lowest number indicates the lowest hazardous area. SB568, 11/13 2 ATEX / IEC Motor Terminology BASEEFA The abbreviation for British Approval Service for Electrical Equipment. BASEEFA is a third party independent testing and certification agency. This is one agency that can be used to obtain third party certification for motors in hazardous areas. B3 Mount Mounting arrangement with the motor base mounted with the shaft in the horizontal plane. Similar to F2 mount in NEMA terminology. B5 Mount Mounting arrangement with the motor flange at the drive end and no base with the shaft in the horizontal plane. This would be close to a NEMA motor with a D-Flange. B14 Mount Mounting arrangement with the motor flange at the drive end and no base with the shaft in the horizontal plane. This would be similar to a NEMA motor with a C-Face. NOTE: IEC only defines two flanges “FF” where the bolt holes are thru-bolts and “FT” which the bolt holes are tapped or threaded. NEMA defines what size D-flange or C-face will be standard on what frame, IEC does not define what size flange will be on what frame and leaves it up to the motor manufacturer to define this to IEC 72 dimensions. A flange is defined by the “FF” or “FT” followed by the bolt circle dimension “M” in millimeters. For example a frame designation would be written as 200L FF280 which defines the FF as thru-bolt hole construction with a 280 mm bolt circle. Cable Gland A cable connection device that is used on a jacketed neoprene cable. The cable gland screws into the motor conduit box and a compression seal bushing fits around the incoming cable, that when compressed, seals around the cable jacket. The result is a liquid or a dust tight connection. Products in this category are required to remain functional for safety reasons when an explosive atmosphere is present and is characterized by integrated explosion protection measure functioning in such a way that: In the event of failure of one integrated measure, at least a second means of protection provides for a sufficient level of safety, or In the event of two faults occurring independently of each other, a sufficient level of safety is ensured. CENELEC The European Committee for Electrotechnical Standardization is a standards writing organization. It was established by the European Union to develop harmonized electrical standards for European countries. CE Mark Conformity European, or CE, is an administrative identification meant to be a reference for trade authorities showing that the identified product satisfies the requirements of the technical harmonization guidelines. Beginning in January 1997 any motor labeled as such requires a manufacturer to have established a technical construction file and be able to issue a Declaration of Conformity upon request that it meets the European Standards for Safety and environmental protection. D-End Abbreviation for drive end bearing. SB568, 11/13 3 ATEX / IEC Motor Terminology DSEAR The Dangerous Substances and Explosive Atmospheres Regulations of 2002) is the United Kingdom’s implementation of the European union-wide ATEX Directive. The intention of the regulation is to reduce the risk of a fatality or serious injury resulting from a “dangerous substance” igniting and potentially exploding. Examples of a “dangerous substance” as defined by SDEAR include sawdust, ethanol vapors and hydrogen gas. The regulation is enforceable by HSE or lower authorities. Design Code IEC has only two definitions for Electrical Design Characteristics, Design N and Design H whereas NEMA has four Designs. Design N is a motor with a normal torque curve similar to a NEMA Design B. Design H is a motor with a high starting torque similar to a NEMA Design C or NEMA Design A. No limit is set for how high of starting torque is required for a motor to be labeled Design H. So if you have a specification calling for a Design H you will need to get a clear understanding of the torque requirements, starting and breakdown torque. NOTE: There is no cross-reference from NEMA Design D to IEC. DIN An abbreviation for Deutsche Industrie Normenasusschvs. DIN is the association in Germany that determines the standards for electrical and other equipment in that country. Directive A directive is a legislative act of the European Union, which requires member states to achieve a particular result without dictating the means of achieving that result. It can be distinguished from regulations which are self-executing and do not require any implementing measures. Directive 94/9/EC The European Union directive to protect people from explosion risk in areas with an explosive atmosphere. Refer to ATEX 95 and ATEX Directives and Definitions, for additional comments. DNV DNV is an abbreviation for Det Norske Veritas. DNV is a Commercial Marine Specification Organization that is similar to and competes with American Bureau for Shipping (ABS). DNV commercial marine specifications do not require that an IEC motor meet the specifications although you will see DNV most commonly used with IEC motors. Dust Ignitionproof Dust ingnitionproof motors are used in atmospheres where combustible dust is present. Duty Cycle The duty cycle types are indicated by the symbols S1 through S9 according to IEC34.1. See the table below. Duty Type S1 S2 SB568, 11/13 Short Description Continuous Duty Explanation Operation at constant load of sufficient duration for thermal equilibrium to be reached. - Similar to the NEMA definition of Continuous Duty. Operation at constant lad during a given time, less than that required to reach thermal equilibrium, followed by a rest and de-energized period to established motors ambient level. Similar to NEMA 15 minute or 30 minute duty motors. Short-Time Duty 4 ATEX / IEC Motor Terminology S3 Intermittent Duty without influence of running-up period S4 Intermittent Duty with influence of running-up period Intermittent Duty with influence of running-up period and electrical braking Continuous Operation Periodic Duty S5 S6 S7 A sequence of identical duty cycles each including a period of operation at constant load and a rest and de-energized period. The starting current does not significantly affect the temperature rise. Same as S3 but with each cycle including a significant period of starting. Same as S4, but with each cycle, including a period of rapid electric braking. A sequence of identical duty cycles, each cycle consisting of a period of operation at constant load and a period of operation at no-load. There is no rest and de-energized period. Same as S6 with each cycle including a period of starting and a period of electric braking. As S6 with each cycle, including a period of starting and a period of electric braking. Effective Ignition Source Effective ignition source is a term defined in the European ATEX Directive as an event which, in combination with sufficient oxygen and fuel in gas, mist, vapor or dust form, can cause an explosion. Methane, hydrogen or coal dust are examples of possible fuels. Effective ignition sources are lightning strikes, open flames, mechanically generated impact sparks, mechanically generated friction sparks, electric sparks, high surface temperatures, electrostatic discharge, radiation and adiabatic compression. Enclosure The enclosure field in IEC is a combination of the IP (Inherent Protection) and IC (Inherent Cooling) codes. Each number in the IP code or the IC code stands for a different degree of protection. The first number in the IP code refers to contact with live or moving parts inside the enclosure and the ingress of solid objects entering the motor. The second number has to do with degree of protection or ingress of liquids into the motor enclosure. NOTE: IEC defines the IP codes by type enclosure of product in different sections. IEC 34-5 applies to motors or rotating products. IP Code per IEC 34-5 First Numeral 0 1 2 3 4 5 6 SB568, 11/13 Degree Protection Protection of Persons Ingress of Solids No special protection No protection Protection of large surface of body (e.g. a No ingress of solid objects larger than 50 hand) mm diameter Prevention of contact by finger No ingress of solid objects larger than 12 mm diameter Does not apply to rotating machines Does not apply to rotating machines Objects of thickness greater than 1 mm No ingress of solid objects larger than 1 mm, excluding ventilation openings and drain holes Complete protection No amounts of dust that interferes with satisfactory operation of the motor. Does not apply to rotating machines Does not apply to rotating machines 5 ATEX / IEC Motor Terminology Second Numeral 0 1 2 3 4 5 6 7 8 Degree of Protection No special protection Vertically falling drops shall have no harmful effect Drops falling at any angle up to 15 from vertical shall have no harmful effect. A spray falling at any angle up to 60 from vertical shall have no harmful effect. A splash from any direction shall have no harmful effect. Liquid projected by a nozzle from any direction shall have no harmful effect. Water from heavy seas or powerful water jets shall not enter in harmful amounts. When machine is immersed for the time and depth stated in test conditions, harmful amounts of water shall not enter. When machine is immersed to the pressure agreed on between manufacturer and customer for an indefinite time, harmful amounts of water shall not enter. A letter “S”, “M” or “W” may follow the second numeral of the IP code. “S” indicates that the machine was tested against the ingress of liquids with the machine not running. “M” indicates that the machine was tested against the ingress of liquid with the machine running. If neither “S” nor “M” is used, the machine was tested both running and not running. “W” indicates a weather-protected machine. This protection is that under prescribed conditions; rain, snow and airborne particles will not enter the machine in harmful amounts. First Numeral 0 1 2 3 4 5 6 7 8 9 Second Numeral 0 1 2 3 4 5 6 7 8 IC Code per IEC 34-6 Method of Cooling Free Circulation Inlet pipe ventilation Outlet pipe ventilated Inlet and Outlet pipe ventilated Frame Surface Cooled Integral mounted heat exchanger Machine mounted heat exchanger Integral heat exchanger transferring heat to a piped in medium Machine mounted heat exchanger transferring heat to a piped in medium Separately mounted heat exchanger transferring heat to a piped in medium Source of Power to Circulate Coolant Free Convection Self Circulate Integral component mounted on separate shaft Dependent component mounted on the machine (not used) Integral independent component Independent component mounted on machine Independent and separate device or coolant system pressure Relative displacement Enclosure Conversation Table IEC Enclosure NEMA Enclosure ODP IP23IC01 TENV IP54IC40 TEFC IP54IC41 TEAO IP54IC48 SB568, 11/13 6 ATEX / IEC Motor Terminology EN Euronorm (EN) is a standards writing organization. EX Mark The EX mark is the European Commission mark for products approved for hazardous areas. EX d The EXd type of protection is the only type of protection based on containment of the explosion. The electrical components that could ignite an explosive atmosphere are located inside an enclosure which can withstand the pressure of an explosion of the explosive mixture which has formed inside due to the penetration of a flammable gas or vapor. The enclosure must also prevent the transmission of the explosion to the explosive atmosphere surrounding the enclosure (flameproof). EX de The EX de protection is a combination of “d” flameproof protection and “e” protection. EX e The EX e protection applies to the electrical equipment which does not product arcs, sparks or hazardous temperatures under normal operation (non-sparking construction). EX nA The EX nA type of protection applies to the “non-sparking” requirement, i.e. equipment which does not provide arcs, sparking or hazardous temperatures under normal operation. EX tD The EX tD type of protection is based on the protection by an enclosure which is sealed to the penetration of dust and limits the surface temperature. Explosive Atmosphere An explosive atmosphere is defined as a mixture of dangerous substances with air, in the form of gases, vapors, mist or dust in which, after ignition has occurred, combustion spreads to the unburned mixture. Atmospheric conditions are commonly referred to as ambient temperatures and pressures. Temperatures of -20°C to 40°C and pressures of 0.8 to 1.1 bar. Flameproof – Type of Protection “d” Since flammable gases and vapors are expected inside an enclosure, the equipment must be capable of withstanding an explosion caused by sparking contacts of devices, high temperatures or an electrical fault. The enclosure is designed so hot gases generated during an internal explosion are cooled below the ignition temperature of the surrounding flammable atmosphere as they escape through the joints of the unit. In addition, the external surfaces of the enclosure must not become hot enough to ignite the surrounding atmosphere due to heat energy within the unit. This heat energy may be the result of normal operation of heat-producing equipment, or the result of an electrical arc to the enclosure from an arcing ground fault. Safety factors are applied to all testing of this type of enclosure to ensure the unit will not rupture as a result of an internal explosion. Frame The IEC specification 72 uses metric frame measurements. An IEC frame 112S or 112M or 112L denotes a 112 mm shaft height. The S, M, or L stands for Small, Medium, and Long. NOTE: IEC frames 280K and 280H are not defined by IEC specification 72 but are recognized and used throughout the IEC industry. SB568, 11/13 7 ATEX / IEC Motor Terminology IEC Frame 71M 80M 90S 90L 100S 100L 112S 112M 112L 132S 132M 132L 160S 160M 160L 180S 180M 180L 200S 200M 200L 225S 225M 225L 250S 250M 250L 280S 280M 280K 280H “H” Shaft Height in mm 71 80 90 90 100 100 112 112 112 132 132 132 160 160 160 180 180 180 200 200 200 225 225 225 250 250 250 280 280 280 280 Nearest NEMA Frame 48 56 56 56 140 140 180 180 180 210 210 210 250 250 250 280 280 280 320 320 320 360 360 360 400 400 400 444 445 447 449 Hazardous Area Hazardous areas are defined as premises, buildings or parts of the where fire or explosion hazards may exist due to the presence of flammable gases or vapors, flammable liquids, combustible dusts or easily ignitable fibers or flyings. IEC defines the classification of hazardous areas into three zones, according to degree of hazard. Where ignitable concentrations of flammable gases, vapors or liquids are present Zone 0 continuously or for long periods of time under normal operating conditions. Where ignitable concentrations of flammable gases, vapors or liquids are likely to Zone 1 exist under normal operating conditions. Where ignitable concentrations of flammable gases, vapors or liquids are not likely to Zone 2 exist under normal operating conditions. NOTE: An IEC document recommends that no rotating apparatus should be located in a Zone 0 area. IEC defines Classification of Gases: IEC uses a Group code as a location code and an Alpha Code as a Gas Type: Group I - Coal Mines Group II - Other Industries SB568, 11/13 8 ATEX / IEC Motor Terminology IEC A B C NEC Group D Group C Groups A, B IEC Designation Flameproof - noted as (EXd) Pressurized – noted as (EXp) Increased Safety – noted as (Exe) Gas Examples Gasoline, Methane, Natural Gas Ethyl, Ether Acetylene, Hydrogen USA & Canada Equivalent UL /CSA listed Explosion Proof UL/CSA listed Purged Non-Sparking motor with: 1. Permissible temperature rise reduced by 10C for all insulation types. 2. Maximum rotor temperature limited to 300C during starting. NOTE: There is no direct US equivalent to an Exe motor. Division II motor - Internal and external surfaces of the motor must not exceed 200C or the gas ignition temperature, whichever is less. Non-Sparking – noted as (Exn) Temperature Classification Ignition temperature is the minimum temperature of a surface at which an explosive atmosphere ignites. Flammable vapors and gases can e classified into temperature classes according to their ignition temperature. The maximum temperature of a piece of equipment must always be lower than the ignition temperature if the gas/air mixture or vapor/air mixture in which it is placed. Equipment shall be marked to show the operating temperature or temperature class referenced to a +40°C ambient. The temperature class (T-Code) is indicated on the manufacturer’s nameplate and is based on the table below. Maximum Temperature NEC T-Codes Degrees C 450 T1 300 T2 280 T2A 260 T2B 230 T2C 215 T2D 200 T3 180 T3A 165 T3B 160 T3C 135 T4 120 T4A 100 T5 85 T6 NOTE: Both IEC and NEC assume 40C ambient. IEC T-Codes T1 T2 T3 T4 T5 T6 IC Code Abbreviation for International Cooling designation system concerning methods of cooling. Refers to standard IEC 34-6. Also see definition for Enclosure. IEC International Electrotechnical Commission (IEC) is an organization founded in 1906 for the purpose of coordination and unification of National standards on electrotechnology. Over 40 countries worldwide participate in IEC standards. SB568, 11/13 9 ATEX / IEC Motor Terminology IECEx The objective of the IECEx scheme is to facilitate international trade in electrical equipment intended for use in explosive atmospheres. Increased Safety – Type of Protection “e” A type of protection applied to electrical and under specified product arcs or sparks in normal service and under specified abnormal conditions, in which additional measures are applied so as to give increased security against the possibility of excessive temperatures and of occurring of arcs and sparks. IP Code IP Codes is an abbreviation for classification of degrees of protection provided by enclosures of rotating machines. Also see definition for Enclosure. Insulation IEC standards define the maximum allowable temperature rise by class of insulation. See the table below for the insulation class and respective rises in degree C: Class of Insulation A E B F H Rise by Resistance in C NEMA @ 1.0 SF 60 80 105 125 IEC 60 75 80 100 125 NEMA @ 1.15 SF 70 90 115 - NEMA allows additional 5C for non-ventilated and encapsulated motors (10C for class H non-ventilated) where IEC has no such allowance. NEMA ties rise to Service Factor and makes allowance for 1.15 SF. In the IEC world the term “Service Factor” has no meaning. Everything in the IEC terminology is evaluated at nameplate KW. kW Rating IEC uses KW or kilowatts to denote power vs. NEMA using HP or horsepower. The IEC standard KW rating and the approximate corresponding NEMA horsepower is provide for reference purposes only. The formula is: KW = HP X .746 kW HP kW HP .25 1/3 18.5 25 .37 ½ 22 30 .55 ¾ 30 40 .75 1 37 50 1.1 1½ 45 60 1.5 2 55 75 2.2 3 75 100 3 4 90 125 4 5 110 150 5.5 7.5 132 175 7.5 10 150 200 11 15 186 250 15 20 224 300 Lead Labels A NEMA motor normally identifies the leads as T1, T2, T3 whereas IEC motors use U, V, W. SB568, 11/13 10 ATEX / IEC Motor Terminology Marking All equipment and protective systems must be marked legibly and indelibly with the following minimum information: Name and address of the manufacturer CE marking, if involved, the identification number or the notified body Designation of series or type Serial number, if any Year of construction The community mark The equipment group and the category For Group II, the letter “G” (concerning explosive atmospheres caused by gases, vapors or mists) and the letter “D” (concerning explosive atmosphere cased by dust) Metric Frame The frame measurement is a decimal system covered under IEC specification 72. An IEC frame 112S or 112M or 112L denotes a 112 mm shaft height and is denoted on a dimensional drawing as “H.” The S, M or L stands for Small, Medium or Long. N Is referred to as speed, revolutions per minute and is a standard marking on a nameplate. NEMA Abbreviation for National Electrical Manufacturers Association. Non-explosive Atmosphere An atmosphere with no explosive components. Power Factor On an IEC nameplate it is expressed as the Cosine (Cos ) which is a definition of Power Factor. Power Factor is a measurement for the time phase difference between the voltage and current in an AC circuit. It is represented by the cosine of the angle of this phase difference. S Code This code defines the motor duty cycle. Also see definition for Duty. Temperature Class (gas atmospheres) Electrical motors are classified into six classes according to the maximum surface temperatures. Terminal Box Power leads are run separately from the control leads therefore it is common to have all thermistors, space heaters etc… in an auxiliary conduit box with it’s own terminal strip. Many times IEC motors supply terminal connections via terminal blocks or strips. This is not required by the IEC specifications but is a common industry standard. NOTE: When a specification refers to “leads are eft to dangle,” this means the leads are not connected to a terminal block or strip. Most European inspectors consider the motor incomplete if there are no terminal blocks in the conduit box. V1 Mounting Mounting arrangement with the motor flange at the drive end and no base. The shaft is in the vertical plane with the drive end down. SB568, 11/13 11 ATEX / IEC Motor Terminology V3 Mounting Mounting arrangement with the motor flange at the drive end and no base. The shaft is in the vertical plane with the drive end up. Voltage Common Voltage Combinations IEC @ 50HZ NEMA @ 60HZ 190 230 190/380 230/460 380 460 400 575 415 - Wye-Delta Starting Wye-Delta is a connection that is used to reduce the inrush current and torque of a polyphase motor. In the IEC world it is an industry practice that all motors 160 frames and larger come set up for Wye-Delta connection. This is not required by IEC specifications, therefore it is common that 160 frame and up conduit boxes will have two lead entry holes, one for the Wye connection cable and one for the Delta connection where the actual reconnect is done back at the starter. Zone Classification The user of the hazardous duty equipment has the responsibility to classify the areas in which explosive atmospheres may be present into zones and to ensure that the minimum organizational and technical requirements of the directive are observed. Zone 0 An area in which an explosive mixture of gases or vapors is continuously present or present for long periods. Equivalent to the North American classification system Class I Division I (gases). Zone 1 An area in which an explosive mixture is likely to occur in normal operation. Equivalent to the North American classification system Class I Division 2 (gases). Zone 2 An area in which an explosive mixture is not likely to occur in normal operation and if it occurs, it will exist only for a short time. Equivalent to the North American classification system Class I Division 2 (gases). Zone 20 An area in which an explosive mixture is continuously present or present for long periods. Equivalent to the North American classification system Class II Division 1 (dusts). Zone 21 An area in which an explosive mixture is likely to occur in normal operation. Equivalent to the North American classification system Class II Division 1 (dusts). Zone 22 An area in which an explosive mixture is not likely to occur in normal operation and if it occurs, it will exist only for a short time. Equivalent to the North American classification system Class II Division 2 (dusts). SB568, 11/13 12