PCB設計的基本觀念 - 電力電子與運動控制實驗室

advertisement

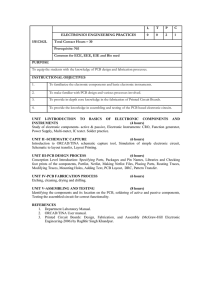

台灣新竹‧交通大學‧電機與控制工程研究所‧808實驗室 電源系統與晶片、數位電源、馬達控制驅動晶片、單晶片DSP/FPGA控制 Lab-808: Power Electronic Systems & Chips Lab., NCTU, Taiwan http://pemclab.cn.nctu.edu.tw/ PCB設計原理與佈局原則 鄒應嶼 教授 國立交通大學 電機與控制工程系 2007年1月1日 Lab808: 電力電子系統與晶片實驗室 Power Electronic Systems & Chips, NCTU, TAIWAN LAB808 NCTU 台灣新竹•交通大學•電機與控制工程研究所 1/26 Contents 1. 2. 3. 4. 5. 6. 7. 8. Introduction Introduction to EMI/EMC EMI Regulations Review of Basic Theory Electromagnetic Interference EMI Reduction Techniques Fundamentals of PCB Design Guide Lines for PCB Design for EMC Compliance Power Distribution and Grounding Techniques PCB Design for High-Frequency Signal Traces Techniques Analog and Digital Signal Traces Back Plane and Terminals 9. PCB Design Procedure 2/26 Power Electronic Systems & Chips Lab., NCTU, Taiwan Introduction 電力電子系統與晶片實驗室 Power Electronic Systems & Chips Lab. 交通大學 • 電機與控制工程研究所 3/26 1. Introduction 高速數位電子時代 (Giga Hertz Microelectronics) 類比與數位混合信號IC的發展趨勢(Mixed-Signal IC) 高頻電源時代 (Mega Hertz Power Electronics) On-Board AC-DC and DC-DC Converters Development of High-Density Packaging Technology Development of Multi-Chip IC Modules PCB佈局設計將成為未來電子科技發展的關鍵技術 PCB佈局設計是高級電子工程師必須具備的專業技術 4/26 PCB Design: EMI & SI? What is the Problem? 不同應用的電路板,所處理電子信號的目的與方式也不盡相同,通常 其差異相當大,因此,雖然PCB電磁干擾與信號完整性的原理是相同 的,但針對不同的應用,就必須採用正確的設計方法。 5/26 From Schematics to PCB Layout Where is the fastest current changing loop? Where is the fastest voltage changing node? 6/26 Hierarchical Structure of an Electronic System LSI裸晶粒 系統 主機板 配線 主機板 基板 FC、WB、TAB等 主機板 基板 IC封裝 CSP 主機板 ㄧ般的印刷線路板 基板上配線 L/S = 100m IC封裝 單機能零件等 連接器等 封裝 (BGA、PGA、QFP、 SOP等) (印刷電路板) MCM (印刷電路板) FC、WB、 TAB等 BGA, CSP, MCM 主機板 (印刷電路板) 封裝內配線 L/S = 25m IC晶片 晶片內配線 L/S = 0.18m 連接器 電晶體 電晶體 背板 (Back Board) 機器組裝 7/26 Interconnection of Electronic Systems … Power Supply (a) IC內的連線 (b) PCB的連線 (c) 電子系統的連線 Interconnections CAN NOT be neglected! The characteristics of the current flowing through the interconnection is a major concerned in the design of the interconnection! PCB design is an art of connections! 8/26 Architecture of a PCB System System Topology: Needs to be converted into an equivalent electrical circuit model de-coupling cap at edge of package chipset ASIC I/O card Core signals I/O #2 I/O #1 Microprocessor de-coupling cap “away” from pkg power plane outlines PCB Design Rule No. 1: Top-Down Systematic Architecture Design 9/26 Construction of an Electronic System Conducted emissions of a SPS without EMI filter p. m e T UBP as. UPC e m … CAN bus UPSFE Power/Data Power UDR Data JINF UHVD UTE UFE Control bus HV SPS UHVG 10/26 Development of High-Speed Digital Systems 3.2 GHz 30A Dynamic Current, ICC Operating Voltage Multi-Core 12A 5V 500Mhz Clock Frequency 4A 3.3V 1A 0.5A 0.1A 166Mhz 2.5V 90Mhz Package Technology 1.8V 25Mhz 4.77Mhz 1980 DIP 0.9V 8Mhz 1985 1987 QFP 1990 PGA 1995 BGA 2000 COB/FC 2005 2010 OLGA 11/26 Development Trend of IC Packaging Technology Density Conventional CSP Wafer Level CSP QFP BGA 1970 1980 1990 2000 12/26 PCB Design Flow Limited countermeasures after completion of design/prototype Problem causes at evaluation stage No care about art work Design Schematic design Layout design A handful of technical people work for EMC Prototype PCB pattern design Manufacture of PCB Evaluation Packaging Estimation System verification Mass production Problem causes Reiteration Turn back as problem causes Long TAT 13/26 Improvement of PCB Design Flow Execute fundamental counter measures and solve all problems at schematic/layout stage Design Schematic design Prototype Layout design PCB pattern design Manufacture of PCB Packaging Evaluation Estimation System verification Mass production Floor planning Solve the problem at design step All steps can be proceed smoothly Complete design without any reiteration 14/26 Improvement Opportunity to Cost Most important design process Cost EMI measurement at first design stage can realize better effect with low cost. Schematic design Layout design PCB pattern design Improvement opportunity Manufacture Packaging of PCB Estimation System Mass verification production 15/26 EMC & SI: Driving Force to the Future Smaller Time to Market Technology EMC Faster & Cheaper SI & PI Signal Integrity Regulations More Efficient 16/26 PCB Layout Concept for EMC Compliance Design Analog circuits rarely work correctly unless engineering effort is expended to solve EMI and layout problems. Sooner or later (or now!), the engineer needs to learn to deal with EMI Practical engineering approaches: figure out where are the significant EMI sources figure out where the EMI is going (EMI victim) figure out where the EMI is coupling (Coupling path) engineer the circuit layout to mitigate EMI problems Build a layout that can be understood and analyzed! 17/26 Power Electronic Systems & Chips Lab., NCTU, Taiwan Fundamentals of PCB Design 電力電子系統與晶片實驗室 Power Electronic Systems & Chips Lab. 交通大學 • 電機與控制工程研究所 18/26 PCB Design for EMC Compliance Differential mode emissions Common mode emissions Differential mode currents Interplane capacitance Common mode currents Mark I. Montrose, Printed Circuit Board Design for EMC Compliance: A Handbook for Designers, IEEE Press, 1996. 19/26 Fundamental Concepts for PCB Layout 1. EMC considerations for PCB design 2. Hidden characteristics of passive components 3. How and why RF energy is developed within the PCB 4. Magnetic flux and cancellation requirements 5. Routing topology configurations 6. Layer stackup assignment 7. Radial migration 8. Grounding methodologies 9. The need for an optimal return path for RF current 10. Aspect ratios 11. Image planes 12. Partitioning 13. PCB Design to Reduce DM and CM Noises 20/26 Component Characteristic at RF Frequencies Component Low Frequency Behavior High Frequency Behavior Frequency response Wire f Resistor f Capacitor f Inductor f Solid line is low frequency behavior Transformer f Dashed line is high frequency behavior 21/26 Hidden Characteristics of Passive Components 電容不像電容,電感不像電感。 被動元件的高頻特性與低頻特性有著相當大的不同,不可以其低 頻特性估計其高頻行為。 瞭解被動元件的高頻特性,密切的關係著高頻電路的設計與PCB 佈局。 數位電路工程師常犯的的錯誤是,誤以為元件僅有著單一頻率的 特性,因而忽略了被動元件在高頻範圍特性的改變。 『電磁干擾』可以說是『一切沒有畫在電路圖與配線圖上的電路 高頻行為』。因此,必須以高頻等效電路來詮釋或分析高頻電路 的電磁干擾現象,但是由於PCB、導線、與元件在空間上的分佈 不容易建立其高頻等效電路模型,因而使得『電磁干擾』 有如 魔術盒子一般的困擾著工程人員。 『電磁干擾』的基本關鍵仍在於『電路與元件的高頻行為』,瞭 解電路的運作原理與元件的高頻特性,是解決 『電磁干擾』 的 22/26 根本之道。 How and Why RF Energy is Developed within the PCB NOTE: 1. For frequencies greater than a few kHz, the value of inductive reactance typically exceeds R. Current takes the path of least impedance, Z. Below a few kHz, the path of least impedance is resistive; above a few kHz, the path of least reactance is dominant. Because most circuits operate at frequencies above a few kHz, the belief that current takes the path of least resistance provides an incorrect concept of how RF current flow occurs within a transmission line structure or PCB trace. 2. Each trace has a finite impedance value. Trace inductance is one major reason that RF energy is developed within a PCB. 3. The impedance of free space is 377 ohm. When the impedance of the return path is greater than 377 ohm, free space becomes the return path and is observed as radiated EMI. 23/26 Characteristic Impedance of Free Space The characteristic impedance of free space, also called the Zo of free space, is an expression of the relationship between the electric-field and magnetic-field intensities in an electromagnetic field (EM field) propagating through a vacuum. The Zo of free space, like characteristic impedance in general, is expressed in ohms, and is theoretically independent of wavelength. It is considered a physical constant. Zo μ0 377 ( 120 ) Ohm ε0 0 = 4 x 10-7 [H/m]; permeability of free space (Henrys/m) 0 = 8.85 x 10-12 [F/m]; permittivity of free space (Farads/m) 24/26 Frequency Representation of a Closed-Loop Circuit Complete circuit with a ground return path. Circuit works as designed. E Low frequency representation AC or DC current return path If a low-impedance, direct line path from load to source does not exist, such as a slot in a ground plane, RF currents cannot return to the source to satisfy the circuit in an optimal manner. This RF return path will be forced to return through an alternative return path, causing EMI to occur. Equivalent circuit with a poor RF return current structure. E High frequency representation RF current return path Break in the RF return path 25/26 Magnetic Flux and Cancellation Requirements Using proper stackup assignment and impedance control for multilayer boards to allow for a RF return image or ground path to exist. Routing a clock trace (high frequency in nature) adjacent to a RF return path, ground plane (multilayer PCB), ground grid, or ground/guard trace (single- and double-sided boards). Capturing magnetic flux created internal to a component's plastic package into the 0V-reference system to reduce component radiation. Reducing RF currents (energy) within traces by reducing the RF drive voltage from clock or frequency generation circuits, for example, Transistor-Transistor Logic (TTL) versus Complimentary Metal Oxide Semiconductor (CMOS). 26/26