Astec Advanced Power Systems

UM6C75AA

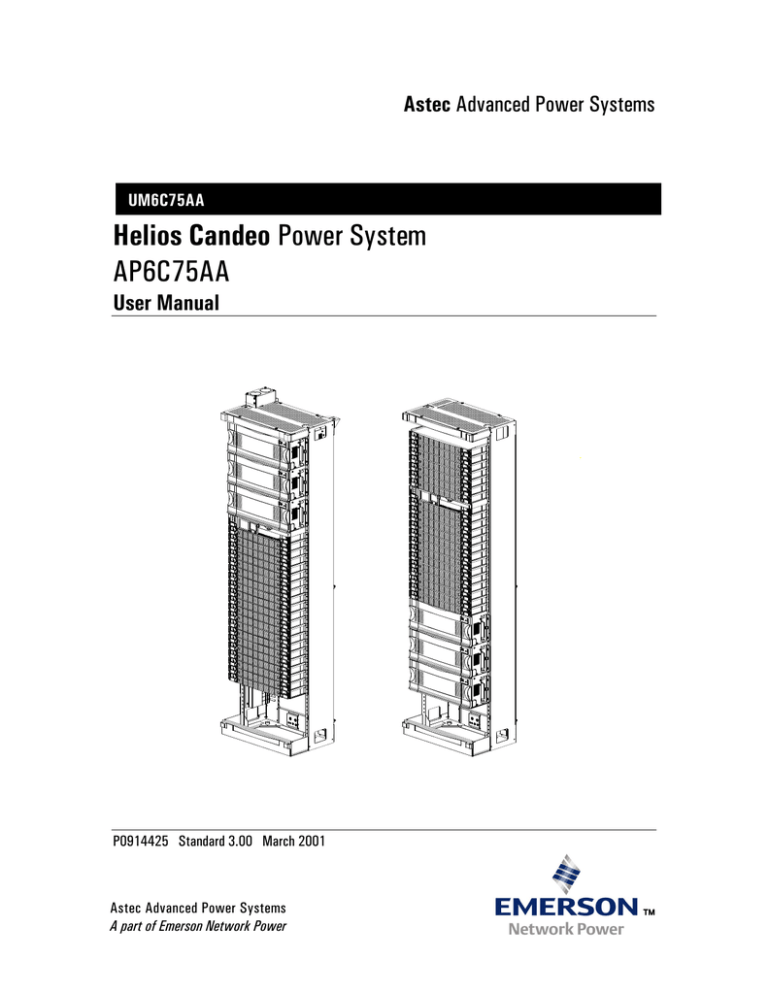

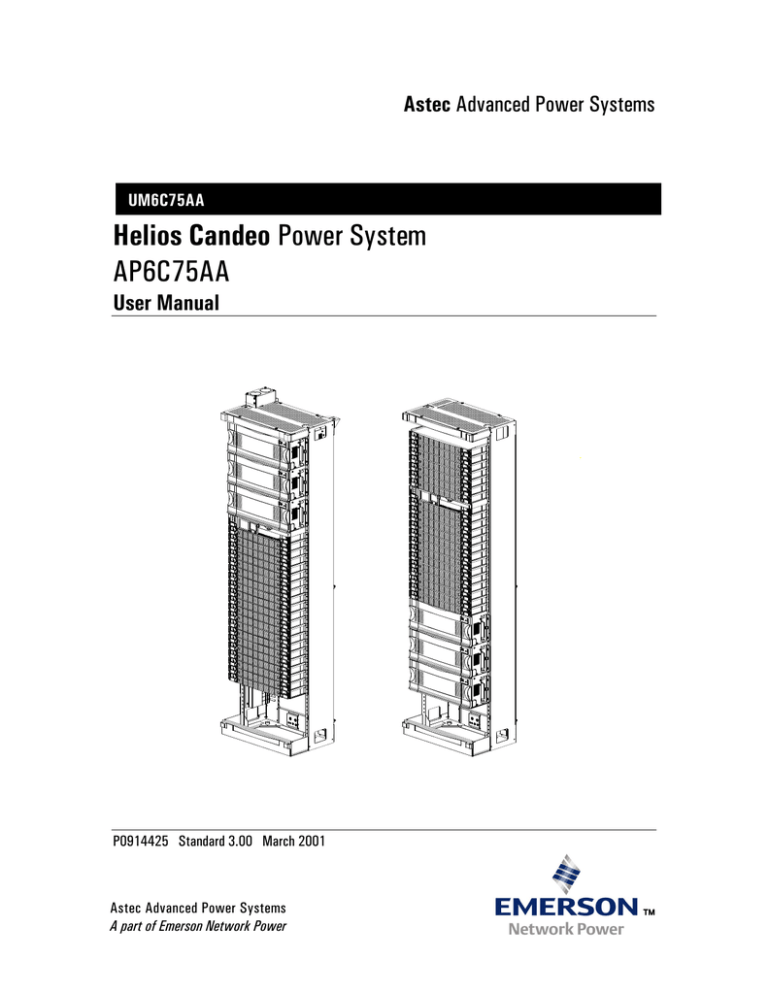

Helios Candeo Power System

AP6C75AA

User Manual

P0914425 Standard 3.00 March 2001

Astec Advanced Power Systems

A part of Emerson Network Power

Astec Advanced Power Systems

Helios Candeo Power System

AP6C75AA

User Manual

Manual Number : UM6C75AA

Manual Status : Standard

Manual Issue : 3.0

Release Date : March 2001

P0914425

Copyright 2001 Astec Advanced Power Systems Ltd

All Rights Reserved

Published in Canada

PROPRIETARY INFORMATION

The information contained in this manual is the property of Astec Advanced Power Systems Ltd and is subject to change

without notice. Astec Advanced Power System Ltd reserves the right to make changes in design or components as progress in

engineering and manufacturing may warrant. Except as specifically authorized in writing by Astec Advanced Power Systems

Ltd, the holder of this manual shall keep all information contained herein confidential and shall protect same, in whole or in

part, from disclosure and dissemination to all third parties, and use the same for installation, start-up, operation, and

maintenance purposes only. Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate this equipment.

Astec Advanced Power Systems

A part of Emerson Network Power

Helios Candeo is a trademark of Astec International Ltd. The Emerson logo is a trademark and service mark of Emerson Electric Co.

Helios Candeo Power System

AP6C75AA User Manual

5

Publication history

March 2001

Standard Issue 3.0. Software upgrade to version 1.2 e.

Modification of the start-up screen, when the system is

initializing. In the Communication Ports screen, the DNS

address field is blocked, to prevent using a wrong DNS

address. New views of the frames and backbones. New

examples of configurations of the modules in the frames.

Battery polarity changed in Figure 1. CANFAR connections

removed on all modules. New procedure for the software

upgrade when using Explorer and Netscape. Additional

information on the configuration of breakers and the

mounting space of each module. New default password for

the supervisor privilege and information on the temporary

password for engineer privilege. ( ECN : 102-25123 ).

February 2001

Standard Issue 2.0. BLVD limitations for the Battery

Connection Modules ( section 2.3.3 ). Utilization of a foil

shield Ethernet cable (section 3.2.4. Change of default

passwords ( sections 4.1.3 and 4.1.4 ). Preventing alarm

triggering when removing the temperature probes (sections

3.4.5 and 4.2.8 ). Details to install double-pole clip of 60 A

capacity ( section 3.5.5 ). ( ECN : 102-24873 ).

January 2001

Standard Issue 1.0 ( ECN : 102-24873 ).

Helios Candeo Power System

AP6C75AA User Manual

6 Publication history

This page is left blank intentionally.

UM6C75AA P0914425 Standard 3.0 March 2001

7

Contents

1

General information...........................................................................................13

1.1 Purpose of this manual................................................................................13

1.2 Cautions and Warnings................................................................................13

2

Architecture of the Helios Candeo Power System ..........................................17

2.1 Inside a single frame ...................................................................................17

2.1.1 Basic modules ...................................................................................17

2.1.2 DC and data backbone, and ac rail inside a frame..............................19

2.1.3 Converting a frame into a cabinet......................................................23

2.1.4 AC box, ac duct, ac interface modules and ac rail..............................24

2.2 Adding frames.............................................................................................26

2.2.1 Interframe Linking Kit........................................................................26

2.2.2 Distributed architecture.....................................................................28

2.3 Configurations and limitations.....................................................................29

2.3.1 Engineering notes..............................................................................29

2.3.2 Usable space in the frames................................................................31

2.3.3 Typical configurations.......................................................................33

3

Description of the Helios Candeo Modules ......................................................39

3.1 Helios Candeo Power System specifications................................................39

3.1.1 Regulatory and safety standards.......................................................39

3.1.2 Environmental operating conditions ...................................................39

3.2 System Manager.........................................................................................40

3.2.1 Functions of the System Manager.....................................................40

3.2.2 Status and alarm indicators of the System Manager .........................41

3.2.3 Interfacing to the System Manager ...................................................41

3.2.4 Graphical User Interface....................................................................44

3.3 50 A / –48 V Rectifier Module.....................................................................48

Helios Candeo Power System

AP6C75AA User Manual

8 Contents

3.3.1 Functions of the Rectifier Module......................................................48

3.3.2 Status and alarm indicators of the Rectifier Module ..........................49

3.3.3 Electrical specifications of the Rectifier Module ................................50

3.3.4 Interfacing to the Rectifier Module....................................................52

3.4 Battery Connection Module.........................................................................53

3.4.1 Functions of the Battery Connection Module.....................................53

3.4.2 Electrical specifications of the Battery Connection Module ...............54

3.4.3 Status and alarm indicators of the Battery Connection Module .........55

3.4.4 Battery Low Voltage Disconnect contactor .......................................57

3.4.5 Temperature compensation ...............................................................59

3.5 500 A Distribution Module ..........................................................................61

3.5.1 Functions of the Distribution Module.................................................61

3.5.2 Status and alarm indicators of the Distribution Module .....................62

3.5.3 Electrical specifications of the 500 A Distribution Module.................62

3.5.4 Interfacing to the Distribution Module ...............................................63

3.5.5 Load Low Voltage Disconnect contactor............................................63

4

Start-up and configuration settings .................................................................69

4.1 Quick start-up .............................................................................................69

4.1.1 Initially starting–up from the GUI on the system Manager.................71

4.1.2 Security and log-on privileges ............................................................74

4.1.3 Home page of the GUI .......................................................................75

4.1.4 Communication between the System Manager and a remote PC........80

4.2 Battery management and power system thresholds.....................................84

4.2.1 Battery parameters ...........................................................................84

4.2.2 Battery selection...............................................................................84

4.2.3 Adding a new Battery Connection Module .........................................85

4.2.4 Voltage thresholds settings ...............................................................85

4.2.5 Current thresholds settings ...............................................................86

4.2.6 Voltage boost and charge control settings .........................................86

4.2.7 Battery discharge test settings and results .......................................88

4.2.8 Temperature compensation ...............................................................89

4.3 Alarm triggering and output.........................................................................90

4.3.1 Alarm severity and output ports ........................................................90

4.3.2 Alarm input ports ..............................................................................94

4.3.3 Permanent Audible Cut-off ................................................................96

4.4 Rectifier Sequential Start-up mode..............................................................97

5

Monitoring the modules.....................................................................................99

5.1 Total inventory and mapping .......................................................................99

5.2 Status of the modules ...............................................................................100

UM6C75AA P0914425 Standard 3.0 March 2001

Contents 9

5.2.1

5.2.2

5.2.3

5.2.4

System Manager version, Alarm Input and Output Status................100

Rectifier, Battery Connection and Distribution Modules status ........101

Alarm investigation .........................................................................102

Status and alarms of the modules ...................................................103

6

Maintenance and troubleshooting ................................................................. 105

6.1 Maintenance Switch Enabling ...................................................................105

6.2 Battery maintenance.................................................................................106

6.2.1 Manual Voltage Boost ( Equalize ) to maintain the battery ...............106

6.2.2 Forced Battery Discharge................................................................107

6.3 LED Test and Alarm Relay Test.................................................................109

6.4 Contactor bypassing, test and replacement...............................................110

6.4.1 Manually bypassing the contactor ...................................................110

6.4.2 Electrically opening the contactor in the Battery Connection module111

6.4.3 Replacing the contactor in the Battery Connection Module..............112

6.4.4 Replacing the contactor in the Distribution Module..........................113

6.4.5 Testing a contactor.........................................................................114

6.5 Reset, reconnect and shutdown conditions................................................115

6.5.1 High Voltage Shutdown and Rectifier Reset ....................................115

6.5.2 Low voltage disconnect and Contactor Reconnect...........................115

6.5.3 System Manager screen activation and Reset .................................116

6.6 Replacing the Control Assembly ................................................................117

6.7 Replacing the rectifier Fan Assembly.........................................................119

6.8 Installing the DC link bar between two frames ..........................................120

6.9 Software upgrade .....................................................................................122

6.10 Alarm troubleshooting..............................................................................125

6.10.1 History of the power system ..........................................................125

6.10.2 Summary of set and reset conditions of the alarms ........................126

7

Appendix A : Recommended replacement parts............................................ 131

8

Appendix B : Technical service assistance ................................................... 133

8.1 Local toll-free prefixes...............................................................................133

8.2 Toll-free technical assistance numbers ......................................................134

List of Figures

Figure 1 — Connecting the in-line fuse holder between the sense leads and the

battery ..................................................................................................14

Figure 2 — Helios Candeo Power System modules .......................................................18

Figure 3 — The mounting slide-clamp mechanism.........................................................19

Helios Candeo Power System

AP6C75AA User Manual

10 Contents

Figure 4 — Views of the 84-inch frame with full height backbone, ac rail, dc / data

bus and ac interface module ..................................................................20

Figure 5 — Views of the 84-inch frame with half-height backbone, ac rail, dc / data

bus and ac interface module ..................................................................21

Figure 6 — Views of the 42-inch frame with half-height backbone, ac rail, dc / data

bus and ac interface module ..................................................................22

Figure 7 — The Cabinet Kit ..........................................................................................23

Figure 8 — AC cabling inside the frame and Interframe data link modules cabling ........25

Figure 9 — AC cabling using loose wires and armored cables .......................................26

Figure 10 — The interframe dc link bar between the backbones of two frames............27

Figure 11 — Distributed architecture of the Helios Candeo Power System ...................28

Figure 12 — Block diagram of the Helios Candeo Power System..................................30

Figure 13 — Configuration of a Helios Candeo Power System ( Example 1 ) .................34

Figure 14 — Configuration of a Helios Candeo Power System ( Example 2 ) .................36

Figure 15 — Configuration of a Helios Candeo Power System ( Example 3 ) .................38

Figure 16 — Isometric view of the System Manager ....................................................40

Figure 17 — Block diagram of the System Manager and signals...................................42

Figure 18 —Location of the communication and alarm ports ........................................42

Figure 19 — four typical remote connections to the System Manager..........................45

Figure 20 — Isometric view of the 50 A / –48 V Rectifier Module................................48

Figure 21 — Output power stability of the 50 A / –48 V Rectifier Module....................51

Figure 22 — Block diagram of the 50 A / –48 V Rectifier Module and signals...............52

Figure 23 — Isometric view of the Battery Connection Module ....................................53

Figure 24 — View showing cabling to the Battery Connection Module .........................54

Figure 25 — Front view of the Battery Connection Module ..........................................55

Figure 26 — Block diagram of the Battery Connection Module and signals...................56

Figure 27 — The 1000 A Battery Connection Module ..................................................58

Figure 28 — The 600 A Battery Connection Module and its BLVD contactor................58

Figure 29 — Access to connectors J1 and J2 for the temperature probes....................59

Figure 30 — Location of connectors J1 and J2, contactor kill switch and the

contactor bypass switch .......................................................................60

Figure 31 — View showing an isometric view of the 500 A Distribution Module ..........61

Figure 32 — Block diagram of the 500 A Distribution Module and signals ....................63

Figure 33 — View showing the 500 A Distribution Module without a contactor ...........64

Figure 34 — View showing the 500 A Distribution Module equipped with a

contactor...............................................................................................64

Figure 35 — The Distribution Module with the bypass busbar in the bypass position....65

Figure 36 — Settings for mid-tip or standard circuit breakers.......................................66

Figure 37 — View showing the 500 A Distribution Module with the front panel open...67

Figure 38 — Manually bypassing the contactor..........................................................111

Figure 39 — Replacing the contactor .........................................................................113

UM6C75AA P0914425 Standard 3.0 March 2001

Contents 11

Figure 40 — Replacing a Control Assembly ................................................................118

Figure 41 — Replacing the rectifier Fan Assembly......................................................119

Figure 42 — Linking with a dc link bar the backbones at the top of two frames

( bottom fed ) ......................................................................................121

List of Tables

Table 1 — AC cabling with an ac channel ....................................................................24

Table 2 — AC cabling with MC or Teck type cable.......................................................24

Table 3 — Dimensions and weight of the modules........................................................31

Table 4 — Mounting space in an 84-inch ( 213.4 cm ) Helios Candeo frame .................32

Table 5 — Mounting space in a 42-inch ( 106.7 cm ) Helios Candeo frame...................32

Table 6 — Typical configuration in one frame ..............................................................33

Table 7 — Typical configuration in two frames ............................................................35

Table 8 — Typical configuration in two frames ............................................................37

Table 9 — Status and alarm indicators of the System Manager ...................................41

Table 10 — Alarm input ports description ....................................................................42

Table 10 — Alarm input ports description ....................................................................43

Table 11 — Alarm output ports description..................................................................43

Table 12 — Ethernet, RS-232 and RS-485 ports and Auxiliary Power Input

Connector on the System Manager........................................................44

Table 13 — Operational and alarm indicators on a 50 A / –48 V Rectifier Module ........49

Table 14 — Electrical specifications of the 50 A / –48 V Rectifier Module...................50

Table 15 — Standards met by the 50 A / –48 V Rectifier Module ................................52

Table 16 — Electrical specifications of the Battery Connection Modules......................54

Table 17 — Alarm indicators on the Battery Connection Module..................................56

Table 18 — Sensing devices of the Battery Connection Module ...................................57

Table 19 — Status and alarm indicators on the 500 A Distribution Module ..................62

Table 20 — Sensing devices of the Distribution Module ...............................................62

Table 21 — Electrical specifications of the 500 A Distribution Module.........................62

Table 22 — Privileges to access the System Manager .................................................74

Table 23 — Alarm input ports to the System Manager.................................................94

Table 24 — Power system alarms, severity, set conditions and reset conditions........126

Table 25 — Replacement parts ..................................................................................131

List of Procedures

Procedure 1 – Remote connection between a PC and the System Manager .................82

Procedure 2 – Manually bypassing the contactor to test it or replace it.....................110

Procedure 3 – Replacing the contactor in the Battery Connection Module..................112

Procedure 4 – Replacing the Control Assembly containing the neuron card ................117

Procedure 5 – Replacing the Fan Assembly................................................................120

Helios Candeo Power System

AP6C75AA User Manual

12 Contents

This page is left blank intentionally.

UM6C75AA P0914425 Standard 3.0 March 2001

13

1 General information

1.1

Purpose of this manual

1.2

Cautions and Warnings

This manual describes the operation and maintenance of the Helios Candeo

Power System ( AP6C75AA ). Please refer to the Helios Candeo Installation

Manual IM6C75AA for the installation procedure.

The following Cautions and Warnings must be observed at all times when

handling and operating the power equipment.

CAUTION

Optimizing the life of the equipment

Make sure there is no obstruction in front of the ventilation

openings that could restrict the flow of air. Leave a space of

at least 6 inches ( 15.24 cm ) between the frame and the

wall.

WARNING

Generator requirements

To select ac generators that will effectively maintain peak

performance and operating characteristics for all Astec

Power Systems, follow the instructions on the partners’

page of the Astec APS web site at www.AstecAPS.com to

access the Engine Alternator Standard specifications. You can

also dial our local 1−800 technical support line listed in

Appendix B of this manual.

Helios Candeo Power System

AP6C75AA User Manual

14 General information

CAUTION

Preventing short circuits between the senses leads

Ensure that the remote sense leads are connected between

pins #1 and #2 of the J1 connector ( on the Battery

Connection Module ), and the BR and –48 V dc battery

terminals respectively. An in-line fuse must be installed at

the battery end of the sense lead ( see Figure 1 ).

Figure 1 — Connecting the in-line fuse holder between the sense leads and the battery

UM6C75AA P0914425 Standard 3.0 March 2001

General information 15

CAUTION

Preventing erratic rectifier output voltage

If battery disconnect units are used, ensure that the Remote

sense leads are connected between the battery disconnect

units and the Helios Candeo Power System, never between

the battery disconnect units and the batteries.

DANGER

Short circuit hazard

Despite the fact that the Helios Candeo Power System is

designed for maximum safety, rectifiers and batteries can

deliver high current if a short to ground occurs. When

working on live equipment, remove all personal jewelry,

use properly insulated tools, and cover any live bus bars

with an insulating sheet of canvas to prevent short circuits

that could be caused by falling tools or parts.

DANGER

Protecting against electrical shocks

The ac cabling of the Helios Candeo Power System, and all

other cabling, must be carried out by qualified personnel

and in conformance with local and national electrical codes.

Input ac voltage to the rectifiers is at a dangerous level.

Ensure that the circuit breakers are locked in the OFF

position in the ac service panel before cabling the power

system.

Dangerous voltages may be present at the output dc

terminals even if the rectifiers are OFF. Use a voltmeter to

verify for the presence of such voltages.

Do not put the circuit breakers to ON until the entire

system has been assembled and you have been instructed to

do so. Verify, and identify with a tag, the proper polarity of

the battery leads before connecting them to the power

system.

Before starting up and configuring the settings, the ac cabling of the Helios

Candeo Power System, and all other cable distribution and battery cabling,

must have been carried out by qualified personnel, as described in Installation

Manual IM6C75AA.

Helios Candeo Power System

AP6C75AA User Manual

16 General information

This page is left blank intentionally.

UM6C75AA P0914425 Standard 3.0 March 2001

17

2 Architecture of the Helios Candeo Power

System

2.1

Inside a single frame

The AP6C75AA Helios Candeo Power System is a positive ground –48 V dc

modular power system that can be expanded from 50 A to 2,000 A ( using

forty 50 A rectifiers ). The design makes installation easy and simple. No

tools are required to start up and set the parameters of the system, and it can

be upgraded while it is live. The modules are plug-in type and can be

removed and relocated anywhere in the frame.

2.1.1 Basic modules

The Helios Candeo modules are mounted in frames that can be converted

into cabinets with a cabinet kit, if so desired.

As illustrated in Figure 2, a basic 50 A Helios Candeo Power System consists

of at least :

•

one Battery Connection Module

•

one Distribution Module

•

one System Manager

•

one 50 A / –48 V Rectifier

A System Manager provides the following functions :

•

automatic system set-up

•

control and monitoring

•

inventory, history of incidents and remote access

Helios Candeo Power System

AP6C75AA User Manual

18 Architecture of the Helios Candeo Power System

Figure 2 — Helios Candeo Power System modules

The mounting mechanism allows the installation of the System Manager and

the Rectifier Modules in a frame without the use of mechanical fasteners. It

includes a rail ( on the equipment frame side ) that captures a sliding bracket.

Two rails are required for each piece of equipment. The equipment is slid

into its final position in the frame on these rails, and locks into position ( see

Figure 3 ).

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 19

Figure 3 — The mounting slide-clamp mechanism

CAUTION

Preventing damage to the locking mechanism

When sliding the System Manager and the Rectifier Module

into the Helios Candeo Power System, the locking latches

must be fully open to prevent damage to the locking

mechanism system ( see Figure 3 ).

2.1.2 DC and data backbone, and ac rail inside a frame

The 84-inch ( 213.4 cm ) frame is equipped with :

• a vertical backbone consisting of

- a dc bus ( battery return and –48 V )

- a data bus

- an Interframe data link module

• a vertical ac rail

It can also be equipped with a half-height backbone when battery strings or

other equipments are located inside the frame.

The 42-inch ( 106.7 cm ) frame must be equipped with a half-height

backbone.

Helios Candeo Power System

AP6C75AA User Manual

20 Architecture of the Helios Candeo Power System

Figure 4 — Views of the 84-inch frame with full height backbone, ac rail, dc / data bus and ac

interface module

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 21

Figure 5 — Views of the 84-inch frame with half-height backbone, ac rail, dc / data bus and ac

interface module

Helios Candeo Power System

AP6C75AA User Manual

22 Architecture of the Helios Candeo Power System

Figure 6 — Views of the 42-inch frame with half-height backbone, ac rail, dc / data bus and ac

interface module

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 23

2.1.3 Converting a frame into a cabinet

The frame can be converted into a cabinet with a Cabinet Kit as illustrated in

Figure 7.

Figure 7 — The Cabinet Kit

Note : Do not remove the auxiliary bracket unless it obstructs the

insertion of the cables. If the eyelets are removed, secure the

auxiliary bracket to the frame with two 1-inch long, 5/8-inch

bolts, washers, and lock washers. If the frame is secured with tie

rods refer to Installation Manual IM6C75AA.

Helios Candeo Power System

AP6C75AA User Manual

24 Architecture of the Helios Candeo Power System

2.1.4 AC box, ac duct, ac interface modules and ac rail

There are three ac wiring options :

•

loose wires through conduit into the ac channel ( see Figure 8

and Table 1 )

•

armored cables running inside the frame ( ac channel not

required )

•

armored cables run outside the frame, through knock-outs ( see

Table 2 )

Refer to Installation Manual IM6C75AA for the complete ac cabling

procedures. The ac cables to the rectifiers enter the frame on the left side,

when viewing it from the front, and are run to the ac interface modules.

Most of the cables are run in a built-in ac duct, and the rest outside the frame

when the duct is full ( see Table 2 ). An ac Channel Kit ( P0912455 ) must be

ordered for applications with internal loose wires.

Table 1 — AC cabling with an ac channel

Maximum number of

rectifiers

Cable Type

Size

( AWG # )

20

RW90 6CL-1007-01 ( white )

10

20

RW90 6CL-1007-02 ( black )

10

20

RW90 6CL-1007-04 ( green )

10

Table 2 — AC cabling with MC or Teck type cable

Max. number

of rectifiers

Cable type

model

Typical Squeeze

Connectors

( 90° angle )

Cable numbers

inside the frame

Cable numbers

outside the

frame

24 + 1 redundant

TECK90 7TF1002AJ

T&B 268-C

0-10

11-25

24 + 1 redundant

MC 7XF-1003AJ

T&B 268-C

0-10

11-25

24 + 1 redundant

MC 7A-1002A

T&B 266-C

0-16

17-25

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 25

Figure 8 — AC cabling inside the frame and Interframe data link modules cabling

Helios Candeo Power System

AP6C75AA User Manual

26 Architecture of the Helios Candeo Power System

Figure 9 — AC cabling using loose wires and armored cables

Armored cables run

inside the frame

Loose wires in the

conduit run into the ac

box

2.2

Adding frames

2.2.1 Interframe Linking Kit

To link two frames you must install the Interframe Linking Kit consisting

of :

•

an interframe linking plate ( see Figure 8 )

•

an interframe dc link bar ( see Figure 10 and 11 )

•

an interframe data link cable ( see Figure 8 )

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 27

The interframe linking plate is used to secure two frames together. The

interframe data link cable extends the data bus and is connected between the

interframe data link modules, adjusting the impedance of the data bus.

The interframe dc link bar consists of a horizontal bipolar bus and bracket

assembly. It provides a high current electrical connection ( bridge ) between

vertical bipolar bus bars in two or more adjacent frames. It can be installed in

the “dead space”, located at either the top or the bottom of the frames,

through side openings.

Figure 10 — The interframe dc link bar between the backbones of two frames

DC LINK OF TOP FED CABLED FRAMES WITHOUT ISOLATION COVERS AND WITHOUT SAFETY LINER

DC LINK OF BOTTOM FED CABLED FRAMES WITHOUT ISOLATION COVERS AND WITH A SAFETY LINER

Helios Candeo Power System

AP6C75AA User Manual

28 Architecture of the Helios Candeo Power System

2.2.2 Distributed architecture

In the following example, as the Distribution Modules, Battery Connection

Modules, and Rectifier Modules are populated equally between frames, the

current in the interframe dc link bar is low. The backbone extension through

the interframe dc link bar ensures that the same dc potential exists

throughout the entire system. Although the interframe dc link bar has a

capacity of 1,200 A, there should be practically no current flowing through it

( see Figure 11 ). Each frame should be equipped with its own Battery

Connection Module, Distribution Modules, and Rectifier Modules.

Figure 11 — Distributed architecture of the Helios Candeo Power System

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 29

The rectifier current is measured by adding :

•

battery currents from all the Battery Connection Modules

•

load currents from all the Distribution Modules

The advantages of a distributed architecture are :

• reduced dc cable congestion by spreading the wiring of batteries and

loads amongst several frames

• easier expansion by allowing all types of modules to fit in all frames

( except the System Manager in the first frame )

• expansion to the left or to the right of the first frame

• specific shunt for each module, allowing to measure the current of

each module

2.3

Configurations and limitations

2.3.1 Engineering notes

A single Helios Candeo frame can be equipped with the following ( see

Figure 10 for the typical number of each module type ) :

•

a backbone having a capacity of 1,200 A

•

a data bus that can access a total of 100 modules ( 40 of the same

type )

•

one System Manager ( required only in the first frame )

•

up to twenty-five 50 A / –48 V Rectifier Modules ( one for

redundancy ) with MC or TEK bottom fed ac cables ( one 50 A

rectifier used for redundancy )

•

or up to twenty 50 A / –48 V Rectifiers with free wiring ( one 50 A

rectifier used for redundancy )

•

one 1,000 A Battery Connection Module ( without LVD )

•

only one 600 A Battery Connection Module ( with LVD ) for the

system

•

two Distribution Modules ( 500 A )

Note : Up to forty 50 A / –48 V Rectifiers Modules can be installed in a

Helios Candeo Power System distributed in several frames

Note : The number of rectifiers in a frame is also limited by the size of

the ac cables connected to the rectifiers as described in Table 1

and Table 2.

Helios Candeo Power System

AP6C75AA User Manual

30 Architecture of the Helios Candeo Power System

Figure 12 — Block diagram of the Helios Candeo Power System

DC BUS

FRAME 1

BR

-48V

DATA BUS

AUX. DC POWER IN

SYST EM

MANAGER

( 1 P ER SYSTEM)

EXT COM PORT

DISTRIBUTION

MODULE

( MINIMUM

1 PER FRAME )

TO LOADS

CABINET LAMP

AC INPUT

TO BATTERIES

BATTERY

CONNECTION

MODULE

( 1 PER FRAME )

50 A RECTIFIER

( UP TO 25 )

INTERFRAME DC LINK BAR

DISTRIBUTION

MODULE

( MINIMUM

1 PER FRAME )

TO LOADS

TO BATTERIES

BATTERY

CONNEC TIO N

MODULE

( 1 PER FRAME )

CABINET LAMP

AC INPUT

50 A RECTIFIER

( UP TO 20 )

INTERFRAME DATA LINK

FRAME 2 DAISY-CHAINED

Sufficient numbers of rectifiers have to be installed in a frame to provide

equal current capacity to the loads fed from the same frame. The battery

backup capacity must match the rectifier capacity and current draw from the

loads.

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 31

2.3.2 Usable space in the frames

The space available for modules inside a frame depends on the backbone

used ( full-height or half-height ), if the system is top fed or bottom fed, and

if the Interframe Linking Kit is used. The configurations listed in Table 4 and

Table 5 have been calculated based on the height of the modules as described

in Table 3.

Table 3 — Dimensions and weight of the modules

Modules

Height

( including

rails )

± 0.01 in.

( ± 0.03 cm )

Depth

Width

± 0.02 in.

± 0.02 in.

( ± 0.05 cm ) ( ± 0.05 cm )

Mounting

space

Weight

System

Manager

2.96 in.

( 7.51 cm )

14.70 in.

( 37.34 )

22.62 in.

( 57.45 cm )

3 in.

7.50 lbs ( 3.402 Kg )

Rectifier

Module

2.22 in.

( 5.63 cm )

14.79 in.

( 37.56 cm )

22.62 in.

( 57.45 cm )

2 in.

25.50 lbs ( 11.57 Kg )

Battery

Connection

Module

8.23 in.

( 20.90 cm )

14.75 in.

( 37.46 cm )

23.00 in.

( 58.42 cm )

8 in.

43.00 lbs ( 19.51 kg )

Distribution

Module

8.23 in.

( 20.90 cm )

14.75 in.

( 37.46 cm )

23.00 in.

( 58.42 cm )

8 in.

45.00 lbs ( 20.41 kg )

Frame full-height ( 84 in. )

199.3 lbs ( 90.4 kg )

Frame half-height ( 42 in. )

131.2 lbs ( 59.5 kg )

1200 A Copper Backbone Kit – full-height

116.6 lbs ( 52.9 kg )

1200 A Copper Backbone Kit – half-height

63.3 lbs ( 28.7 kg )

Cabinet and Door Kit

82.7 lbs ( 37.5 kg )

Free Standing Earthquake Bracing Kit

19.4 lbs ( 8.8 kg )

AC Channel Kit – full-height

40.6 lbs ( 18.4 kg )

Note : The height of each module is greater than the mounting space

because the rails of each module slide into the rails of the modules

located above and below it. The height of each module without

taking the rails into consideration is listed in the mounting space

column of Table 3.

Helios Candeo Power System

AP6C75AA User Manual

32 Architecture of the Helios Candeo Power System

Table 4 — Mounting space in an 84-inch ( 213.4 cm ) Helios Candeo frame

Full-height backbone mounting space

Top fed

Bottom fed

77 inches ( 195.6 cm ) without an Interframe Linking kit

67 inches ( 170.2 cm ) without an Interframe Linking kit

77 inches ( 195.6 cm ) with an Interframe Linking kit

67 inches ( 170.2 cm ) with an Interframe Linking kit

Typical configuration of modules in the first frame with full-height backbone

1 Battery Connection Module

8 in.

24 Rectifier Modules

48 in.

2 Distribution Modules

16 in.

1 System Manager

3 in.

1 System Manager

3 in.

1 Distribution Module

8 in.

25 Rectifier Modules

( 1 is redundant )

50 in.

1 Battery Connection Module

8 in.

Half-height backbone mounting space

Top fed

Bottom fed

31 inches ( 78.7 cm ) without an Interframe Linking kit

29 inches ( 73.7 cm ) with an Interframe Linking kit ( top )

Typical configuration of modules in the first frame with half-height backbone

1 Battery Connection Module

8 in.

5 Rectifier Modules

10 in.

1 Distribution Module

8 in.

1 System Manager

3 in.

1 System Manager

3 in.

1 Distribution Module

8 in.

6 Rectifier Modules

12 in.

1 Battery Connection Module

8 in.

Table 5 — Mounting space in a 42-inch ( 106.7 cm ) Helios Candeo frame

Half-height mounting backbone space

Top fed

Bottom fed

31 inches ( 78.7 cm ) without an Interframe Linking kit

29 inches ( 73.7 cm ) with an Interframe Linking kit

26 inches ( 66.0 cm ) with or without an Interframe Linking

kit

Typical configuration of modules in the first frame with half-height backbone

1 Battery Connection Module

8 in.

3 Rectifier Modules

6 in.

1 Distribution Module

8 in.

1 System Manager

3 in.

1 System Manager

3 in.

1 Distribution Module

8 in.

5 or 6 Rectifier Modules

10 or

12 in.

1 Battery Connection Module

8 in.

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 33

2.3.3 Typical configurations

The three following examples illustrate typical configurations of the Helios

Candeo Power System. In each example, the concept of distributed

architecture must be respected. The space required to support the projected

load in the frames must be evaluated ( leaving space for additional rectifiers

and batteries if necessary ).

Example 1 ( see Figure 13 )

System requirements : an initial load of 700 A, a battery reserve of eight

hours, and for the future, a distribution load of 800 A.

Configuration of the modules in one frame :

• fifteen 50 A Rectifier Modules to feed the initial 700 A load

• total capacity of 875 A in the two 500 A Distribution Modules :

− ten 60 A circuit breakers and one 25 A circuit breaker

− five 30 A circuit breakers and four 25 A circuit breakers

• one System Manager

• one 1,000 A ( no BLVD contactor ) Battery Connection Module

• one frame

• sufficient batteries for the 700 A load

Note : Only one 600 A Battery Connection Module ( always equipped

with a BLVD contactor ) can be used in a Power System, even

with many frames. When two Battery Connection Modules and

more are used, no BLVD should be used in any module.

Table 6 — Typical configuration in one frame

Top fed frame 1

( 77 inches of mounting space )

Qty

Description

Space used

1

1,000 A Battery Connection Module x 8 inches

8 inches

2

500 A Distribution Modules x 8 inches

16 inches

1

System Manager x 3 inches

3 inches

50 A Rectifier Modules x 2 inches

30 inches

14+1

Total space occupied

57 inches

Helios Candeo Power System

AP6C75AA User Manual

34 Architecture of the Helios Candeo Power System

Figure 13 — Configuration of a Helios Candeo Power System ( Example 1 )

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 35

Example 2 ( see Figure 14 )

System requirements : a load of 1,900 A and a battery reserve. This

configuration is well distributed between the two frames ( see Figure 14 ).

Configuration of the modules in two frames :

• total capacity of 2,375 A in four 500 A Distribution Modules :

− eighteen 30 A, one 60 A and one 25 A circuit breaker

− six 100 A, one 10 A and one 15 A circuit breaker

− four 150 A, five 5 A

− ten 50 A circuit breakers

• two 1,000 A Battery Connection Modules without BLVD

contactors ( one by frame )

• forty 50 A rectifiers ( twenty in each frame )

• sufficient batteries for the 1,900 A

Table 7 — Typical configuration in two frames

Top fed Frame 1

( 77 inches mounting space )

Loose wires in the ac channel

Top fed Frame 2

( 77 inches mounting space )

Loose wires in the ac channel

Qty

Description

Space

used

Qty

Description

Space used

1

1000 A Battery

Connection Module x

8 inches

8 inches

1

1000 A Battery

Connection Module x

8 inches

8 inches

( without a BLVD

contactor )

( without a BLVD

contactor )

2

500 A Distribution

Modules x 8 inches

16 inches

1

System Manager x

3 inches

3 inches

19+1

Rectifier Modules x

2 inches

40 inches

Total space occupied

67 inches

2

500 A Distribution

Modules x 8 inches

16 inches

No System Manager

required

19 +1

Rectifier Modules x

2 inches

Total space occupied

40 inches

67 inches

Note : Only one 600 A Battery Connection Module ( always equipped

with a BLVD contactor ) can be used in a Power System, even

with many frames. When two Battery Connection Modules and

more are used, no BLVD should be used in any module.

Helios Candeo Power System

AP6C75AA User Manual

36 Architecture of the Helios Candeo Power System

Figure 14 — Configuration of a Helios Candeo Power System ( Example 2 )

UM6C75AA P0914425 Standard 3.0 March 2001

Architecture of the Helios Candeo Power System 37

Example 3 ( see Figure 15 )

System requirements : a load of 1,500 A and a battery reserve. This

configuration is well distributed between the two frames ( see Figure 15 ).

Configuration of the modules in two frames :

• total capacity of 1,875 A in three 500 A Distribution Modules :

− eighteen 30 A, one 60 A and one 25 A circuit breaker

− six 100 A, one 10 A and one 15 A circuit breaker

− four 150 A, five 5 A circuit breakers

• two 1,000 A Battery Connection Modules without BLVD

contactors ( one by frame )

• thirty-two 50 A rectifiers

• sufficient batteries for the 1,500 A

Table 8 — Typical configuration in two frames

Top fed Frame 1

( 77 inches mounting space )

Top fed Frame 2

( 77 inches mounting space )

With teck cables

Loose wires in the ac channel

Qty

Description

Space

used

Qty

Description

Space used

1

1000 A Battery

Connection Module x

8 inches

8 inches

1

1000 A Battery

Connection Module x

8 inches

8 inches

( without a BLVD

contactor )

( without a BLVD

contactor )

2

500 A Distribution

Modules x 8 inches

16 inches

1

System Manager x

3 inches

3 inches

24 +1

Rectifier Modules x

2 inches

50 inches

Total space occupied

77 inches

1

500 A Distribution

Modules x 8 inches

8 inches

No System Manager

required

6+ 1

Rectifier Modules x

2 inches

Total space occupied

22 inches

38 inches

Note : Only one 600 A Battery Connection Module ( always equipped

with a BLVD contactor ) can be used in a Power System, even

with many frames. When two Battery Connection Modules and

more are used, no BLVD should be used in any module.

Helios Candeo Power System

AP6C75AA User Manual

38 Architecture of the Helios Candeo Power System

Figure 15 — Configuration of a Helios Candeo Power System ( Example 3 )

UM6C75AA P0914425 Standard 3.0 March 2001

39

3 Description of the Helios Candeo Modules

3.1

Helios Candeo Power System specifications

3.1.1 Regulatory and safety standards

The Helios Candeo Power System complies to the following standards:

Safety :

UL-1801

EN 61204

VDE

Grounding :

Telcordia TR-NWT-000295

General :

CE

Telcordia GR-1089-CORE

Telcordia TR-NWT-000154

Electromagnetic Compliance ( EMC ):

FCC Part 15, Subpart B, Class B with foil shielded Ethernet cable

EN 300 386-2

General:

NEBS Level 3 ( pending )

3.1.2 Environmental operating conditions

During normal operation, the Helios Candeo Power System can be subjected

to the following conditions without sustaining damage :

Temperature : 0 to 40°C and 50°C for a short period

Humidity : 5% to 95 % RH ( non-condensing )

Altitude : standard performance from –300 ft ( -91.44 m ) to 7,000 ft

( 2133.6 m ) and derating from 7,000 ft ( 2133.6 m ) to 13,000 ft

( 3962.4 m )

Helios Candeo Power System

AP6C75AA User Manual

40 Description of the Helios Candeo modules

3.2

System Manager

3.2.1 Functions of the System Manager

Figure 16 — Isometric view of the System Manager

The System Manager ( see Figure 16 ) monitors the voltage, the current and

the alarms of the power system, and it monitors and sets the Rectifier

modules. The main functions of the System Manager are :

•

automatic set-up and adjustment of float voltage and charge current

•

setting of the optional Low Voltage Disconnect

•

temperature compensation, discharge tests, charge control and

equalize of the batteries

•

sequential start and current share of the rectifiers

•

statistical history of faults and inventory mapping

•

connections to Ethernet and serial ports

•

configuration of the alarm thresholds and I / O ports

•

programmable control of output dry-C contacts

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 41

The System Manager has a local database of up to 200 different battery

specification records and configuration settings. An updated version of the

files can be loaded. However, the user can customize the configuration

settings.

3.2.2 Status and alarm indicators of the System Manager

The red, yellow and green LED pathfinders indicate ( only one at a time ) the

status of the System Manager ( see Figure 16 ). The alarms are classified as

critical, major and minor. The alarm status and definitions are described in

Table 9.

Table 9 — Status and alarm indicators of the System Manager

Indicator

Description

Critical

Critical alarm

Major

Major alarm

Minor

Minor alarm

RED triangle pathfinder

System Manager failed or is initializing

YELLOW circle pathfinder

System Manager is in an abnormal condition

GREEN rectangle pathfinder

System Manager is in a normal condition

3.2.3 Interfacing to the System Manager

The –48 V dc operating voltage is supplied to the DC bus from either :

• one battery supply input ( –48 V dc, BR )

• one auxiliary back-up power on J4 ( –48 V dc, BR )

The available communication ports ( see Figure 18 ) are :

• RS-232, RS-485, Ethernet RJ45

• optional modem ( external )

Note : Use shielded cables to the Ethernet, RS-232 and RS-485 connections

and 16-26 stranded wires to the input and output ports.

There are six alarm input ports ( see Figure 17 ) :

• Aux 1, Aux 2, Aux 3 ( user defined )

• Generator on, Generator overload, System shutdown

There are eight alarm output ports equipped with C-relay contacts ( see

Figure 17 ). The input and output port connections described in Table 10

and Table 11 are programmed and monitored by using the Alarms Severity and

Output pages of the GUI.

Helios Candeo Power System

AP6C75AA User Manual

42 Description of the Helios Candeo modules

Figure 17 — Block diagram of the System Manager and signals

Figure 18 —Location of the communication and alarm ports

AUX POWER IN

1 AND 2 ( J4 )

IN PUT PORTS

1 TO 6 ( J7 )

ETHERNET PORT ( J5 )

UM6C75AA P0914425 Standard 3.0 March 2001

OUTPUT PORTS

1 TO 8 ( J8 )

COM1 PORT ( J2 )

RS-232 D -SUB 9 FEMALE CONNECTOR

COM2 PO RT ( J3 )

RS-485 D-SUB 9 FEMALE CONNEC TOR

C ANFAR D-SUB 9

FEMALE C ONNECTOR ( J6 )

Description of the Helios Candeo modules 43

Table 10 — Alarm input ports description

Pin no.

Input port number

Alarm description

Alarm level

J7-1

Input port 1 +

Minor ( default )

J7-2

Input port 1 –

Auxiliary input 1

( programmable )

J7-3

Input port 2 +

Minor ( default )

J7-4

Input port 2 –

Auxiliary input 2

( programmable )

J7-5

Input port 3 +

Minor ( default )

J7-6

Input port 3 –

Auxiliary input 3

( programmable )

J7-7

Input port 4 +

Generator on ( fixed )

Minor ( fixed )

J7-8

Input port 4 –

J7-9

Input port 5 +

Generator overload ( fixed )

Major ( fixed )

J7-10

Input port 5 –

J7-11

Input port 6 +

System shutdown ( fixed )

Major ( fixed )

J7-12

Input port 6 –

Note : If –48 V is applied between J7-11 and J7-12 the power system will shut

down ( a supervisor privilege is required to modify the Input port 6

parameters ).

Table 11 — Alarm output ports description

Pin no.

Output port number

Pin no.

Output port number

J8-1

Output port 1 ( NC )

J8-13

Output port 5 ( NC )

J8-2

Output port 1 ( COM )

J8-14

Output port 5 ( COM )

J8-3

Output port 1 ( NO )

J8-15

Output port 5 ( NO )

J8-4

Output port 2 ( NC )

J8-16

Output port 6 ( NC )

J8-5

Output port 2 ( COM )

J8-17

Output port 6 ( COM )

J8-6

Output port 2 ( NO )

J8-18

Output port 6 ( NO )

J8-7

Output port 3 ( NC )

J8-19

Output port 7 ( NC )

J8-8

Output port 3 ( COM )

J8-20

Output port 7 ( COM )

J8-9

Output port 3 ( NO )

J8-21

Output port 7 ( NO )

J8-10

Output port 4 ( NC )

J8-22

Output port 8 ( NC )

J8-11

Output port 4 ( COM )

J8-23

Output port 8 ( COM )

J8-12

Output port 4 ( NO )

J8-24

Output port 8 ( NO )

Helios Candeo Power System

AP6C75AA User Manual

44 Description of the Helios Candeo modules

Table 12 — Ethernet, RS-232 and RS-485 ports and Auxiliary Power Input

Connector on the System Manager

Pin Number

Ethernet Port J5

RS-232 Port J2

RS-485 Port J3

( Ethernet )

( COM1 )

( COM2 )

1

TX+

DCD

SIRIN

2

TX-

RXD

SIROUT

3

RX+

TXD

GND

4

NC

DTR

GND

5

NC

GND

TXD+

6

RX-

DSR

TXD-

7

NC

RTS

RX+

8

NC

CTS

RX-

9

N/A

RI

GND ( through

100 Ω )

Pin Number

Auxiliary Power Input Connector J4

1

Battery Return

2

–48 V

3.2.4 Graphical User Interface

GUI in the System Manager

A liquid crystal display ( LCD ) screen displays the information processed

through the Graphical User Interface ( GUI ) in the System Manager. It

allows operation, administration, maintenance and provisioning activities

through the System Manager. The different icons and menus are selected by

sliding a finger over the touch pad to move an arrow cursor. When the arrow

cursor moves over an active element, it changes into a hand showing a direct

link to a specific page. Taping on the item selected with a finger ( or pushing

the left button located below the touch pad ) accesses the function page

selected. ( The right button is used to set the contrast of the screen. )

Note : The LCD screen has an energy saver, which is enabled after one

hour of inactivity. The screen is activated by tapping on the touch

pad with a finger ( or pushing the left button located below the

touch pad ).

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 45

PC remote access to the System Manager

Figure 19 — four typical remote connections to the System Manager

Helios Candeo Power System

AP6C75AA User Manual

46 Description of the Helios Candeo modules

The System Manager can be accessed through an Ethernet RJ45 connector

by a remote personal computer ( use a foil shield Ethernet cable ). A LAN

access through an Ethernet port or a direct access through an RS232 modem

connection is required. To establish a remote connection you need Java Plugin and Netscape or Explorer. The procedure for establishing this connection is

described in the "Start-up and configuration section" of this manual.

The Home page has a Menu, a pop-up window of active alarms, and it displays

the float voltage, the total load current, the total current from the rectifiers,

and the battery current.

STATUS OF

OPERATION

POWER SYSTEM

VOLTAGE

The status of operation of the system is also displayed to the right of the

power system voltage on the Home page with one of the following statuses :

•

Sequential start in progress

•

Charging is being limited

•

Voltage boost in progress

•

Temperature compensated

•

Alarm relay test in progress

•

Float

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 47

To view the menu list, slide the cursor to the Menu and tap on the touch pad

of the System Manager to open the menu. If a remote PC is used to access

the System Manager, slide the mouse to select the Menu, and click on it to

open it.

For more detailed information about navigating from the Home page,

accessing the Menu, and using the icons on the lower bar of the Graphical

User Interface, see the “Start-up and configuration settings” section of this

User Manual.

Helios Candeo Power System

AP6C75AA User Manual

48 Description of the Helios Candeo modules

3.3

50 A / –48 V Rectifier Module

3.3.1 Functions of the Rectifier Module

The Helios Candeo 50 A Rectifier Module ( see Figure 20 ) provides isolated,

filtered and regulated dc power from a single-phase ac source, to feed the

load and charge a positive grounded battery. The nominal output is

adjustable within a range of –42 V to –58 V to float a 23-cell or 24-cell

battery string. The ac input is protected by an ac breaker and the dc output is

protected by a replaceable fuse.

Figure 20 — Isometric view of the 50 A / –48 V Rectifier Module

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 49

At start-up, the operating parameters of the rectifiers are controlled by the

System Manager, and no adjustments are required at the rectifier level. The

parameters of the rectifiers are measured and sent through the data bus to

the System Manager. These parameters are : current, alarm conditions, serial

number, internal temperature, and derating status. The default operating

parameters of the Rectifier Module allow the rectifier to operate normally

without a System Manager.

3.3.2 Status and alarm indicators of the Rectifier Module

Pathfinders, located on the face of the Rectifier Module, indicate ( one at a

time ) its status ( see Figure 20 and Figure 22 ). The operational and alarm

indicators on a 50 A / –48 V Rectifier Module are listed in Table 13.

Table 13 — Operational and alarm indicators on a 50 A / –48 V Rectifier Module

Indicator

Description

FAN ( RED rectangle )

Fan alarm

Pathfinder ( RED triangle )

• rectifier failed, is not in sequential start and

the Temporary Release status is Off

• ac failed

• high voltage shutdown

• dc fuse opened

• thermal shutdown

• fan failed

Pathfinder ( YELLOW circle )

Abnormal condition :

• high temperature

• power derating

• temporary release status is On

• sequential status in progress

Pathfinder ( GREEN rectangle )

Rectifier operating normally

Helios Candeo Power System

AP6C75AA User Manual

50 Description of the Helios Candeo modules

3.3.3 Electrical specifications of the Rectifier Module

Table 14 — Electrical specifications of the 50 A / –48 V Rectifier Module

Input voltage :

Single phase nominal 208 / 240 V ac at 45-65 Hz

Range : 80 to 300 V ac with reduced output power outside

the normal operating range ( see Figure 21)

Absolute maximum : 300 V ac

High voltage inhibit > 295 V ac

High voltage shutdown reset > 283 V ac

Input current :

Nominal : 14.5 A at 208 V ac input if the dc output is 50 A

at –54.5 V dc

Recommended ac

service input :

Two poles / 30 A, ac circuit breaker

Output voltage :

Float : –42 V to –58 V dc

High voltage shutdown : –59.0 V dc ± 0.75 V

Output current :

50 A

Input protection :

Two poles / 25 A circuit breaker open both lines

Output protection :

70 A fuse, output current limited between 50 A and 55 A

( factory set )

Output voltage

regulation :

Automatic regulation within the selected value

± 0.5% for all load conditions and within the specified

input voltage, frequency, at ambient temperature

• ± 1% for any combinations of specified input, output and

environmental conditions

Efficiency :

Efficiency is better than 92% at a nominal input voltage of

230 V ac for an output load of 20 A to 50 A

Power factor :

Power factor better than 0.99 for an input voltage from :

• 176 V to 265 V ac for an output load of 20 A to 50 A

Total harmonic

distortion :

Less than 5% for an input voltage of 187 V to 240 V ac

Operating

conditions :

Ambient temperature : 0 °C to 65 °C ( see Figure 21 )

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 51

Figure 21 — Output power stability of the 50 A / –48 V Rectifier Module

Note : The temperature inside the rectifier is usually 5°C higher than the

ambient temperature

Helios Candeo Power System

AP6C75AA User Manual

52 Description of the Helios Candeo modules

The Rectifier Module complies with the following standards.

Table 15 — Standards met by the 50 A / –48 V Rectifier Module

Safety standards :

Electromagnetic

compatibility ( EMC ) :

General standards :

UL-1950

VDE ( safety requirement similar to UL )

Safety and EMI compliance : CE mark

Grounding standard : CSA 22.2 ( #0.7 )

EN 60950 ( before IEC-950 )

US : FCC, Part 15, Subpart B, Class B

EN 55022 / CISPR22 Class B

EN 300 386-2

Design to meet GR-1089-CORE ( emission Class B )

Telcordia Technologies GR-947-CORE ( for rectifiers )

3.3.4 Interfacing to the Rectifier Module

Figure 22 — Block diagram of the 50 A / –48 V Rectifier Module and signals

DC BUS

P1

TB1

L1 1

AC INPUT

CONNECTOR

L2

2

GND

3

2

1

CO NTROL

AND

INTERFACE

YELLO W

FAN RE D

FAIL G REEN

PATHFINDERS

UM6C75AA P0914425 Standard 3.0 March 2001

DATA

INTERFA CE

Description of the Helios Candeo modules 53

3.4

Battery Connection Module

3.4.1 Functions of the Battery Connection Module

The Battery Connection Module allows the connection of battery strings ( or

other dc power reserve ) to the Helios Candeo Power System. Each module

has a total capacity of 600 A ( with a BLVD contactor ) or 1,000 A ( with no

BLVD contactor ). The Battery Connection Module provides operation

status indication on the pathfinders, and also sends alarm signals on the data

bus to the System Manager.

Note : Only one 600 A Battery Connection Module ( always equipped

with a BLVD contactor ) can be used in a Power System, even

with many frames. When two Battery Connection Modules and

more are used, no BLVD should be used in any module.

Figure 23 — Isometric view of the Battery Connection Module

The Battery Connection Module can be mounted at the top or at the bottom

of a Helios Candeo frame. The front panel of the module can be completely

removed to access the –48 V dc and the battery return bus bars ( BR ) of the

module. Up to six pairs of 750 kcmil cables can be attached back-to-back to

the bus bars. ( See Figure 24. )

Helios Candeo Power System

AP6C75AA User Manual

54 Description of the Helios Candeo modules

Figure 24 — View showing cabling to the Battery Connection Module

3.4.2 Electrical specifications of the Battery Connection Module

Table 16 — Electrical specifications of the Battery Connection Modules

Battery string connections

Maximum : twelve cables

Busbar capacity

600 A ( with contactor )

Input voltage range

Input current

1000 A ( with no contactor )

40 V to 60 V

60 mA

The location of the fuse alarm, pathfinder of the Battery Connection Module,

monitoring jacks for the voltage between the sense leads, and the contactor

bypass switch are shown in Figure 25.

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 55

Figure 25 — Front view of the Battery Connection Module

3.4.3 Status and alarm indicators of the Battery Connection Module

The operational and alarm indicators located on the front panel of the

Battery Connection Module are described in Table 17.

Helios Candeo Power System

AP6C75AA User Manual

56 Description of the Helios Candeo modules

Table 17 — Alarm indicators on the Battery Connection Module

Indicator

Description

FA ( RED rectangle )

Fuse alarm for internal or external fuse alarm

Pathfinder ( RED triangle )

Battery Connection Module failed

Pathfinder ( YELLOW circle )

Abnormal condition :

• contactor opened

• bypass switch activated

• mechanical bypass installed

• contactor kill switch activated

• no communication with the System Manager

Pathfinder ( GREEN rectangle )

Battery Connection Module in normal condition

The functions of the Battery Connection Module and its signals are described

in Table 18 and in Figure 26.

Figure 26 — Block diagram of the Battery Connection Module and signals

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 57

Table 18 — Sensing devices of the Battery Connection Module

Test points ( jacks )

Voltage ( + and – ) and current shunt ( + and – ) :

50 mV for 2,500 A measured at the sense leads

connected to the battery.

Contactor bypass switch

Forced closure of the contactor.

Contactor kill switch inputs

Shorting pins 3 and 5 of J1 forces the opening of

the contactor.

External fuse alarm

User installed on J1

Temperature probe 1 inputs

Measures the temperature of the battery

Temperature probe 2 inputs

Measures the ambient temperature

Remote sense leads

Regulation of the float voltage ( see Figure 30 ).

3.4.4 Battery Low Voltage Disconnect contactor

The 1,000 A Battery Connection Module has no contactor, while the 600 A

Battery Connection Module is equipped with a contactor, which can be :

• opened automatically by the System Manager at low voltage and

reconnected automatically at a set voltage

• closed manually through a bypass switch ( located on the Battery

Connection Module ) for maintenance purposes.

• opened manually by an external contactor kill switch ( overrides all

software commands from the System Manager )

The contactor bypass switch overrides all software commands coming from

the System Manager. The contactor kill switch inputs can be used to

disconnect the battery in critical situations. To access it, and connect the

contactor kill switch according to your needs, you must loosen the captive

screw and open the hinged plate ( see Figure 29 ).

To manually bypass the contactor, the bypass busbar must be placed in an

upper horizontal position. This must be done to replace the contactor or

when the bypass switch, for any reason, cannot be used.

Note 1 : For evident security reasons ( lightning and restricted access ), the

contactor kill switch must not be installed outside a building.

Note 2 : The contactor kill switch on the Battery Connection Module must

be the only one used. Non-linked Helios Candeo Power Systems,

each having a System Manager, must have the kill switch of their

Battery Connection Modules daisy-chained. Under no

circumstances must a kill switch be connected to a Distribution

Module.

Helios Candeo Power System

AP6C75AA User Manual

58 Description of the Helios Candeo modules

Figure 27 — The 1000 A Battery Connection Module

Note 3 : The contactor is a magnetic latching contactor. Once latched by

applying a manual or electrical force, it will remain in this latched

state ( Opened or Closed ) until unlatched electrically or manually.

Figure 28 — The 600 A Battery Connection Module and its BLVD contactor

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 59

3.4.5 Temperature compensation

The temperature compensation function adjusts the float voltage of the

rectifiers to optimize the charging of VRLA batteries and limit their

oxidation. When temperature Probe 1 is connected, the temperature

compensation function is automatically enabled. Disconnecting probe 1 or

probe 2 generates an alarm if you do not disable the function in the

Temperature compensation screen before disconnecting the probes. The

ambient temperature may be measured by probe 2 ( optional ). The two

probes measure the difference between the temperature of the battery and

the ambient temperature ( see Figure 30 ). A high difference in temperatures

may indicate a thermal runaway of the batteries.

Refer to Installation Manual IM6C75AA for the temperature probe installation

procedures. Use probe 1 to measure the temperature of the post of a battery

located in the middle of the string ; this probe must be connected between

pin #1 and pin #2 of connector J2. The ambient temperature near the

battery is measured by probe 2 connected between pin #3 and pin #4 of the

J2 connector.

Figure 29 — Access to connectors J1 and J2 for the temperature probes

PROBE 2 FOR

AMBIENT

TEMPERATURE

CONNECT THE TEMPERATURE

PROBE TO THE POST OF ONE OF THE

BATTERIES LOCATED IN THE CENTER

OF THE BATTERY STRING

PROBE 1 FOR

BATTERY TEMPERATURE

BATTERY STRINGS

Helios Candeo Power System

AP6C75AA User Manual

60 Description of the Helios Candeo modules

Sense leads connection

•

•

The sense leads can be connected remotely by connecting pins 1 and

2 on J1, respecting polarity, to the + and – terminals as shown in

Figure 1.

The sense leads can be connected locally by connecting pins 1 and 2

on J1, respecting polarity, to the Uninterrupted Battery Supply

connectors marked –48 V and BR ( see Figure 32 ).

Figure 30 — Location of connectors J1 and J2, contactor kill switch and the

contactor bypass switch

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 61

3.5

500 A Distribution Module

3.5.1 Functions of the Distribution Module

The Distribution Module is used to terminate customer loads. Distribution

Modules provide local alarm indications on the module itself, the status of

the breakers or fuses, the current and the low voltage disconnect, and the

alarm signals on the Data bus to the System Manager. The operational and

alarm indicators on the Distribution Module are listed in Table 19 and a

block diagram of its functions and signals are shown in Figure 32.

Figure 31 — View showing an isometric view of the 500 A Distribution Module

Helios Candeo Power System

AP6C75AA User Manual

62 Description of the Helios Candeo modules

3.5.2 Status and alarm indicators of the Distribution Module

Table 19 — Status and alarm indicators on the 500 A Distribution Module

Indicator

Description

FA ( RED rectangle )

Fuse alarm

Pathfinder ( RED triangle )

Distribution Module failed

Pathfinder ( YELLOW circle )

Abnormal condition :

Pathfinder ( GREEN rectangle )

• contactor opened

• bypass switch activated

• mechanical bypass installed

• no communication with the controller

Distribution Module operating normally

Table 20 — Sensing devices of the Distribution Module

Test points

Distribution voltage ( + and – ) and current shunt ( +

and – ) : 50 mV for 2,500 A

Contactor bypass switch

Forced closure of the contactor

3.5.3 Electrical specifications of the 500 A Distribution Module

Table 21 — Electrical specifications of the 500 A Distribution Module

Circuit breakers

Maximum : 20 breakers

Busbar

Capacity : 500 A

Input voltage range

40 V to 60 V

Input current

60 mA

UM6C75AA P0914425 Standard 3.0 March 2001

Capacity : 1 to 150 A

Description of the Helios Candeo modules 63

3.5.4 Interfacing to the Distribution Module

Figure 32 — Block diagram of the 500 A Distribution Module and signals

Note : Under no circumstances must a kill switch be connected to a

Distribution Module.

3.5.5 Load Low Voltage Disconnect contactor

The Distribution Module can be equipped with a 600 A Load Disconnect

contactor. A Distribution Module is shown without a contactor in Figure 33

and equipped with an optional contactor in Figure 34. The contactor can be :

• opened automatically by the System Manager at low voltage and

reconnected automatically at a set voltage

• closed manually by a bypass switch ( located on the Distribution

Module ) for maintenance purposes.

To manually bypass the contactor, reposition the bypass busbar horizontally

( see Figure 35 ). This has to be done when the contactor must be replaced,

or when you want to ensure that the loads will not be disconnected. The

corresponding procedure is described in the "Maintenance and

troubleshooting" chapter of this manual.

Helios Candeo Power System

AP6C75AA User Manual

64 Description of the Helios Candeo modules

Figure 33 — View showing the 500 A Distribution Module without a contactor

Figure 34 — View showing the 500 A Distribution Module equipped with a contactor

UM6C75AA P0914425 Standard 3.0 March 2001

Description of the Helios Candeo modules 65

Figure 35 — The Distribution Module with the bypass busbar in the bypass position

The 500 A Distribution Module can be equipped with ( see Figure 36 and

Figure 37 ) :

• load clips, single or double-pole, one for each breaker or plug-in fuse

• twenty positions for 1 A to 60 A bullet-type single-pole circuit

breakers ( mid-trip and standard trip ) occupying one position ( total

breaker capacity of 625 A )

• ten positions for 65 A to 100 A bullet-type single-pole circuit

breakers ( mid-trip and standard trip ) occupying two positions ( total

breaker capacity of 625 A )

• seven positions for 100 to 150 A double-pole circuit breakers ( midtrip and standard trip ) occupying two positions with an empty space

between two breakers ( total breaker capacity of 625 A )

• any combination of the above

Refer to Installation Manual IM6C75AA for the complete breaker installation

procedures. You must install the jumper in mid-trip or standard position

( J2 ) on the front side of the circuit breaker contact support. The

distribution interconnect cable must also be connected to J1 on the backside

of the circuit breaker contact support.

Note 1 : Leave an empty position on each side of breakers having a

capacity of 65 A and greater, and use the double-position load clip

type.

Helios Candeo Power System

AP6C75AA User Manual

66 Description of the Helios Candeo modules

Note 2 : An angle bracket must be fixed on the Battery Return busbar of

the Battery Connection Module when using a double-pole clip

( 65 A and greater ). See Figure 37.

Note 3 : If the connector J2 is incorrectly positioned, continuous alarms

will be generated.