Mr Jönsson and his colleague Mikael Jortby,

who deals with machine tool mechanical

issues, both use ballbar systems daily to test a

large variety of CNC machine tools, including

small VMCs, 5-axis machines and large boring

machines.

Scania chassis parts are made on machines calibrated by

NC Service

Their customers include machine tool

manufacturers such as KMT, a leading

manufacturer of waterjet machine tools and

end users such as SKF (bearings), Scania

(commercial trucks) and LKAB mining.

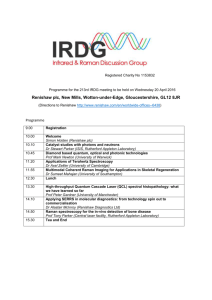

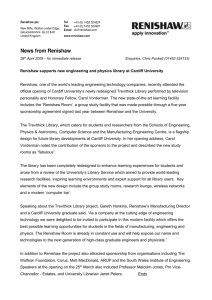

Peter Jönsson receives a QC20-W kit from Ben Taylor, Assistant Chief Executive of Renishaw, at EMO 2009, Milan

Case study

Peter Jönsson, Managing Director of NC

Service, Gothenburg, Sweden, has used

the Renishaw QC10 ballbar (and Renishaw

laser calibration systems) for years, and is

convinced of the benefits, but is

delighted to take delivery of the new

QC20-W wireless ballbar. As he comments,

“QC10 has been one of our most important

tools, and 100% reliable, since

2004 – we will continue to use it for some

jobs. However, most machines must be

run with the doors shut, and with large test

radii on bridge machines the cable can

become a problem – QC20 makes it much

easier. I’m also looking forward to using

the ‘volumetric analysis’ function.”

IN414

Wireless QC20-W ballbar loses cable

and gains support

LKAB operates one of the worlds largest iron

ore mines within the Arctic Circle and runs its

own machine shop to provide support for its 24/7

operations, critical in such a remote location.

Despite only having QC20-W for a few weeks,

Mr Jönsson explains his initial impressions,

“We have used QC20 on customer machines

for several jobs now and what might seem like a

simple change over QC10, the move to wireless

data transmission, makes a significant difference.

Previously when we set-up a test on a machine

with QC10 we often find problems routing the

cable through the guarding - machines should

always be run with the doors shut. QC20 has

solved another problem we’ve always had with

using QC10 on large bridge machines. In this

case we use the largest diameter test, with a

600mm radius, and with QC10 it was very difficult

to stop the cable tangling.”

The change to QC20-W has been seamless for

NC Service, as Mr Jönsson adds, “QC20 uses

new Ballbar 20 software, which accepts data

captured using both QC20 and QC10, so we can

continue to compare the latest test with historical

data. We have also found that the support from

the Renishaw engineers has been excellent

ever since we first purchased QC10 and the

XL-80 laser calibration system, now in setting up

the new Bluetooth connection and training us in

the new software.”

Mr Jönsson is keen to start using the new

‘volumetric diagnostics’ function, which can

only be used with data gathered with Ballbar 20

software. The user selects 3 test files from the

X-Y, X-Z and Y-Z planes, which are displayed

on a single page. The new analysis finds overall

maximum and minimum circularity values to

give ‘sphericity’ and also shows individual test

circularity results.

NC service supports LKAB mining at one of Europes largest

and most important mines

A typical annual CNC machine testing service

would involve Mr Jortby checking and correcting

for any major mechanical issues, then

Mr Jönsson using the Renishaw XL-80 laser

calibration system to comprehensively map and

compensate for positioning errors, followed by

benchmark tests with QC20-W ballbar in all

3 planes.

www.renishaw.com/calibration

This page is intentionally left blank

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0) 1453 524524

F +44 (0) 1453 524901

Euk@renishaw.com

www.renishaw.com

About Renishaw

Renishaw worldwide

Renishaw is an established

world leader in engineering

technologies, with a strong

history of innovation in product

development and manufacturing.

Since its formation in 1973, the

company has supplied leadingedge products that increase

process productivity, improve

product quality and deliver costeffective automation solutions.

Australia

Italy

Spain

T +61 3 9521 0922

E australia@renishaw.com

T +39 011 966 10 52

E italy@renishaw.com

T +34 93 663 34 20

E spain@renishaw.com

Austria

Japan

Sweden

T +43 2236 379790

E austria@renishaw.com

T +81 3 5366 5316

E japan@renishaw.com

T +46 8 584 90 880

E sweden@renishaw.com

Brazil

Malaysia

Switzerland

T +55 11 4195 2866

E brazil@renishaw.com

T +60 3 5631 4420

E malaysia@renishaw.com

T +41 55 415 50 60

E switzerland@renishaw.com

Canada

The Netherlands

Taiwan

T +1 905 828 0104

E canada@renishaw.com

T +31 76 543 11 00

E benelux@renishaw.com

T +886 4 2473 3177

E taiwan@renishaw.com

The People’s Republic of China

Poland

Thailand

T +86 21 6180 6416

E china@renishaw.com

T +48 22 577 11 80

E poland@renishaw.com

T +66 2 746 9811

E thailand@renishaw.com

Czech Republic

Russia

Turkey

T +420 548 216 553

E czech@renishaw.com

T +7 495 231 16 77

E russia@renishaw.com

T +90 216 380 92 40

E turkiye@renishaw.com

France

Singapore

UK (Head Office)

T +33 1 64 61 84 84

E france@renishaw.com

T +65 6897 5466

E singapore@renishaw.com

T +44 1453 524524

E uk@renishaw.com

Germany

Slovenia

USA

T +49 7127 9810

E germany@renishaw.com

T +386 1 527 2100

E mail@rls.si

T +1 847 286 9953

E usa@renishaw.com

Hong Kong

South Korea

For all other countries

T +852 2753 0638

E hongkong@renishaw.com

T +82 2 2108 2830

E southkorea@renishaw.com

T +44 1453 524524

E international@renishaw.com

A worldwide network of subsidiary

companies and distributors

provides exceptional service and

support for its customers.

Products include:

• Dental CAD/CAM scanning

and milling systems.

• Encoder systems for high

accuracy linear, angle and

rotary position feedback.

• Laser and ballbar systems for

performance measurement

and calibration of machines.

• Medical devices for

neurosurgical applications.

• Probe systems and software

for job set-up, tool setting and

inspection on CNC machine

tools.

• Raman spectroscopy systems

for non-destructive material

analysis.

• Sensor systems and software

for measurement on CMMs

(co-ordinate measuring

machines).

• Styli for CMM and machine

tool probe applications.

Hungary

T +36 23 502 183

E hungary@renishaw.com

India

T +91 80 6623 6000

E india@renishaw.com

Indonesia

T +62 21 2550 2467

E indonesia@renishaw.com

Israel

T +972 4 953 6595

E israel@renishaw.com

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

© 2011 Renishaw plc. All rights reserved.

Renishaw reserves the right to change specifications without notice

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other countries.

apply innovation, Productive Process Pyramid, Productive Process Patterns, Productivity+, AxiSet, Rengage, Trigger Logic, ToolWise,

Sprint, MicroHole, PassiveSeal and SwarfStop are trademarks of Renishaw plc.

All other brand names and product names used in this document are trade names, service marks, trademarks or registered trademarks of

their respective owners.

*H-5650-3133-01

Part no. H-5650-3133-01-A