Case study

SHARC PDC Bit and PowerDrive Archer RSS Save

Operator USD 9.8 Million Offshore Australia

Precise directional control reduces sidetracking improves borehole quality

Challenge

Drill high dogleg borehole with PDC and

RSS drilling system, reduce the BHA’s

tendency to drop inclination through the

unconsolidated reservoir sand offshore

Australia.

Solution

Use IDEAS* drillbit design to modify a

standard SHARC* PDC bit by optimizing

the drillbit blade count, cutting structure

exposure, and nozzle configuration, and

pair it with a PowerDrive Archer* RSS to

accomplish the operator’s objectives.

Result

The SHARC bit and PowerDrive Archer

RSS to consistently held inclination

through the drop zone and drilled horizontally in a high ROP environment. It

marked the first time a PDC and RSS were

combined with this result. Increased directional control reduced sidetracking and

improved wellbore quality. This enabled

a quick screen deployment saving the

operator USD 9.8 million.

High-build rate RSS with systemmatched PDC bit required

The operator is using extended reach

horizontal drilling techniques to develop

lower Cretaceous oil reserves offshore

Australia. During the initial phases of the

drilling campaign, the operator was forced to

construct a 9½-in section with a bent angle

positive displacement motor (PDM) drive

system to deliver the dogleg requirements

and effectively geosteer in the reservoir. PDM

drilling proved costly and time consuming,

resulting in poor and tortuous borehole, which

limited horizontal reach. The operator experimented with two different rotary steerable

systems with limited success. The major issue

was the inability of a standard dogleg RSS to

maintain wellbore trajectory drilling through a

drop zone composed of unconsolidated reservoir sand. This required expensive sidetracking

to correct wellbore trajectory, a conventional

PDM BHA or both to reach TD. In some cases,

another trip was needed to continue drilling

with a RSS. Rollercone tungsten carbide insert

(TCI) drill bits were used because of rig torque

delivery limitations, but a three year design

initiative resulted in several new TCI footage

and ROP records.

Drilling strategy: Phase III

Before launching Phase III development, a

team of well construction professionals brainstormed specific drilling operations to determine areas for potential improvement. The

plan was to design a drilling system that would

provide precise trajectory control and the

capability to drill the drop zone without sidetracking or tripping for a BHA change out. The

team concluded that the PowerDrive Archer’s

RSS high build-rate capability could solve a

multitude of application issues associated with

PDM drilling systems. The PowerDrive Archer

dogleg capability would enable it to cross drop

zones and steer through obstacles that proved

difficult for standard RSS.

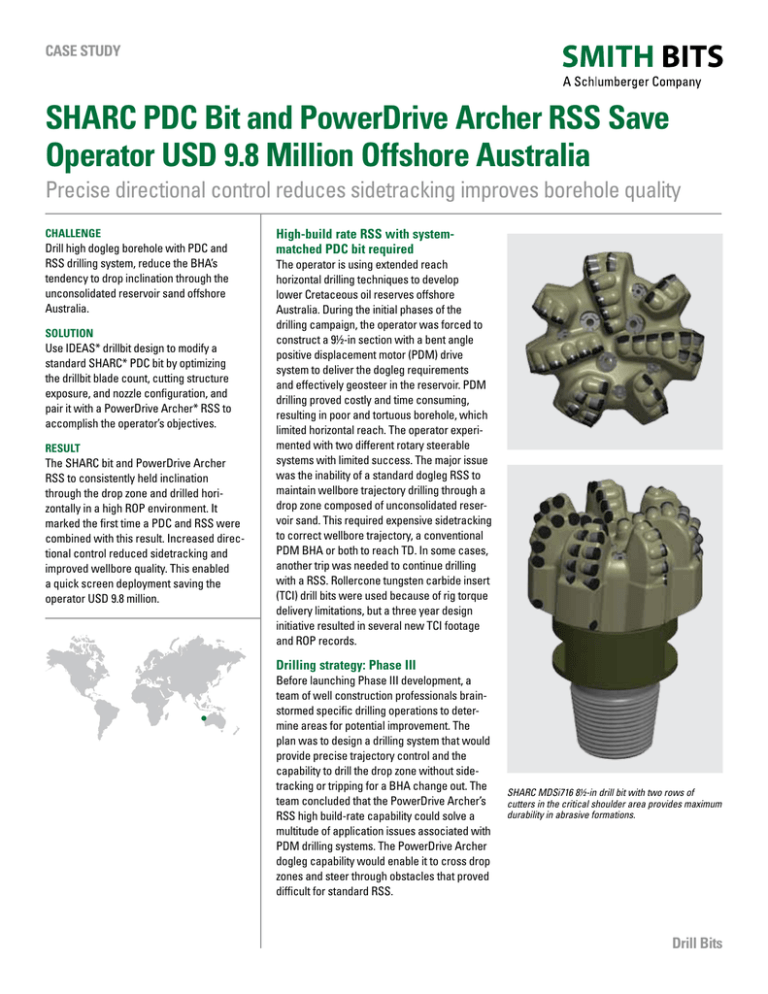

SHARC MDSi716 8½-in drill bit with two rows of

cutters in the critical shoulder area provides maximum

durability in abrasive formations.

Drill Bits

MD interval other bit, m

MDSi716LKUBPXX

(4-6-BT-A-X-I-CT-TD)

MDSi716LKUBPXX

(4-5-BT-A-X-In-ER-TW)

MDSi716LKUBPXX

(2-6-BT-S-X-2-ER-TD)

MDSi716LKUBPXX

(3-5-BT-S-X-In-CT-BHA)

MDSi716LKUBPXX

(2-6-BT-S-X-IN-CT-DTF)

MDSi716LKUBPXX

(8-7-RO-C-X-2-BT-TD)

MDSi716LKUBPXX

(3-6-WT-A-X-1-BT-PR)

MDSi716LKUBPXX

(1-7-BT-S-X-I-CT-TD)

MDSi616LBPX

(3-3-CT-A-X-IN-BT-TD)

MDSi716LKUBPXX

(1-5-BT-S-X-1-LT-PR)

MDSi716LKUBPXX

(1-3-CT-S-X-I-NO-TD)

MDSi716LKUBPXX

(4-4-CT-A-X-IN-ER-TD)

9 ½-in Other PDC

(1-6-BT-S-E-I-ER-TD)

9 ½-in MDi616LABPXC

(1-1-CT-S-X-I-ER-BHA)

MD interval Smith Bits, m

On-bottom ROP, m/h

90

2000

Interval Drilled (m)

100

2200

80

2400

70

2600

60

2800

50

3000

3200

3400

3600

3800

Average meterage

drilled per run with

PDC on RSS 1 =

98m, with poor

directional control

4000

40

Average meterage

drilled per run with PDC

on RSS 2 = 371m, with

poor directional control

4200

30

ROP (m/h on bottom)

1800

9½-in Other PDC

(2-4-BT-S-X-I-NO-BHA)

Other PDC

(0-1-CT-S-X-I-NO-TD)

MDi616CTPX

(1-1-BT-A-X-I-ER-BHA)

1600

MDi616CTPX

(1-1-PN-N-X-I-ER-BHA)

Case study: SHARC PDC drill bit and PowerDrive Archer RSS improve directional control, Australia.

20

Average meterage drilled per run with PDC

on PowerDrive Archer = 970m

10

0

4400

Phase I

Phase II

Phase III

Evolution of project from Phase I to Phase III showing 10x increase in meterage per run with SHARC MDSi716 and PowerDrive Archer drilling system

The solution would provide all the traditional advantages of using RSS

including enhanced wellbore quality, better hole cleaning and more

effective geosteering in the reservoir. However, the new BHA would

require a system matched PDC bit with proper blade count and cutter

configuration to ensure optimal directional response and drillstring

stability. Other changes included a switch to water based mud, a reduction in hole size to 8½-in and rig modifications to provide the required

torque to efficiently drive the SHARC high-abrasion-resistance PDC drill

bit and bottom hole assembly.

Engineering assessment

Since most of the offsets were drilled with a rollercone and PDM

assembly, only six applicable PDC/RSS runs were available for

analysis. A dull grading exercise revealed bit body erosion caused by

cuttings recirculation and vibration induced cutter chipping. Any new

PDC design would need to address these issues. Relying on limited

data could prove problematic and force the operator into a trial and

error approach to develop a matched PDC bit. To avoid field trials,

designers used IDEAS drillbit design platform to evaluate several

different PDC cutting structures in a virtual environment that matched

the operator’s application to determine which base design offered the

best combination of directional responsiveness, high ROP potential,

and stability for the directional profile and formations to be drilled.

Over 200 simulations were run, after which iterative changes were

made to the bit resulting in the final 8½-in SHARC MDSi716LKUBPXX

design. Specific modifications include:

■■

diamond-impregnated depth-of-cut control feature to reduce

torsional vibration/ensure blade top durability

■■

CFD* modified hydraulic layout to mitigate cuttings recirculation

■■

high-erosion resistant matrix bit body

■■

modified gauge pad length with diamond protection

Integrated tool solution produces win-win scenario

The application of the IDEAS designed SHARC bit on a

PowerDrive Archer RSS successfully delivered the required directional work on the two wells/five laterals and consistently corrected

inclination even while drilling the extreme drop zones where ROP

reached 300 m/h. This was also the first time the PowerDrive Archer

RSS was used in deepwater to geosteer horizontally in a high-ROP

application rather than just for its ability to drill short radius borehole.

The improved directional control and well placement capabilities

eliminated the need for drop zone correction sidetracking. The BHA

delivered a smooth high-quality wellbore significantly reducing the

time required to run openhole sand screens. This increased operational efficiency saved the operator USD 9.8 million.

www.slb.com/SHARC

*­ Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2011 Schlumberger. All rights reserved. 11-BT-0087