steni - Vink

advertisement

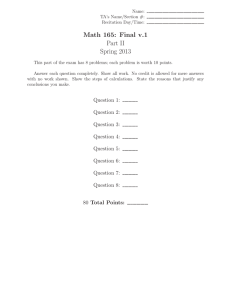

® steni interior Interiorsystem 2003/1809 Highly flexible dimensions, form and colour. steni effect interior panels are glassreinforced polymer composite sheets with a super smooth surface of electronhardened acrylic resin (100% pure and solvent free). steni effect panels are: 100% water resistant and can stand submerged in water without either swelling or damaging their laminated surface. Hygienic, easy to keep clean and do not encourage bacterial growth. Highly resistant to chemicals (see chemical resistance table on p. 4). Very frost resistant (retains 90% of its mechanical strength from -50 to +80 degrees C). Robust and impact resistant and very suitable in exposed positions (breakage & practically zero) Very flexible as regards both format and colour. (36 standard colours or special colours if required). Environmentally friendly, chemically neutral and can be recirculated (see environmental information). The steni effect interior panel has been developed in Norway and is the direct result of close to 40 years market experience and ongoing product development. The unique properties of steni effect product are the answer to those demands and requirements that can only be satisfied by an interior cladding of superior physical and aesthetic quality. steni effect panels are therefore supplied under one of the market´s best product guarantees. This is the assurance we give you. steni® interior The complete interiorsystem The steni effect interior system is a complete system of extrusions specially developed for installing steni effect interior panels. With the help of natural anodised aluminium extrusions and UV and chemicals resistant packing seals it is possible to assemble aesthetically satisfying, functional and hygienic cladding elements of superior quality that are perfect in every detail. If so desired, or required, the aluminium extrusions can be supplied with a polyester powder lacquered finish. The steni interior system can be supplied for watertight assembly and is then especially suitable for: The food industry, meat conditioning and food processing. Aquaculture, fishfarming, fish processing. Cooling plants, refrigeration plants, defrosting industry. Workshops, car wash halls, engineering industry. Hospitals, laboratories, sterile rooms. Schools, sports centres, swimming baths. Domestic bathrooms, public washrooms, shower installations. Refer to the ERECTION INSTRUCTIONS for the steni interior system, for technical details and a listing of the different extrusion and packing seal variants. ® steni interior Technical data – steni effect type 6 (Extract from the Technical Manual) End extrusion/ top extrusion (AP) Specification detail: Max. width Standard width1 Max lenght Standard length – Thickness – Weight – Density – Temperature coefficient – Temperature resistance – Fire class2 – Water absorbtion after 24 hrs. – Moisture/dimensional deviation – Frost resistance, no damage Vertical connector extrusion (VP) Type: 4 6 Value: Unit: 1195 mm 595 (582) and 1195 (1182) mm 3500 mm 3000 (3020) mm ca. 5,5 ±0,6 mm ca. 10,5 kg/m2 1.880 kg/m2 0,026 mm/mK 0,0074 m2K/W In 1 (In 2) – 0,2 % mm/%RF 5,2 X 10-6 >300 cykle Norm: NBI (-20° – +65°C) NBI NS 3919, lic. no 338 ISO/R 62-158 NT BUILD 113 NB! Resistance to chemicals of the steni effect panel. (Extract from the Technical Manual). Chemical environment: Concentration: Acetone 100% Acetic acid 100% Acetic acid 5% Phosphoric acid 20–30% Chlorine (household) – Formic acid (used in silage prodn.) 48% Lactic acid 5% Hydrochloric acid 15% Synthetic detergents – Water (test with boiling water on surface) at +100°C Water (submerged in) 3.000 hrs at +20°C White spirit – Durability3: No visible damage No visible damage Surface matted No visible damage No visible damage No visible damage No visible damage No visible damage No visible damage No visible damage No visible damage No visible damage ) Values quoted in brackets apply to interior panels adapted to the steni interior systems (c/c 1200/600 mm horizontal module minus an 18 mm joint segment for the extrusion). 1 ) Values in brackets apply to steni effect type 4. 2 Bottom extrusion/ horizontal connector extrusion (HP) Dolny (HP) 3 ) Where no other informations is given, tests are based on the surface of a panel being exposed to the chemical for one week. The steni group are engaged in product development on a continuing basis and reserve the right to change the product concept, product range and product specifications without prior notice. The steni effect interior panel is available in two thicknesses - type 4 and 6. Please refer to the ERECTION INSTRUCTIONS for the steni interior system and to our product listing. Do not hesitate to contact us for further information. Please contact us for further information! CALL - FAX - E-MAIL - WRITE! www.steni.com steni