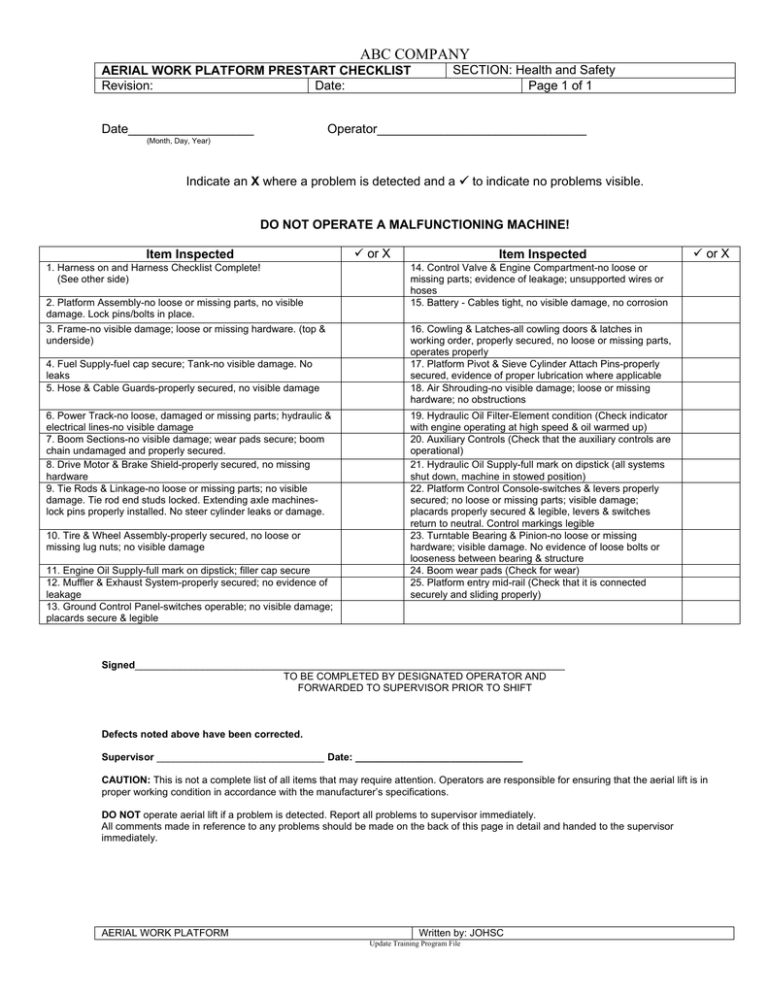

ABC COMPANY

advertisement

ABC COMPANY AERIAL WORK PLATFORM PRESTART CHECKLIST Revision: Date: Date__________________ SECTION: Health and Safety Page 1 of 1 Operator______________________________ (Month, Day, Year) Indicate an X where a problem is detected and a 9 to indicate no problems visible. DO NOT OPERATE A MALFUNCTIONING MACHINE! Item Inspected 1. Harness on and Harness Checklist Complete! (See other side) 2. Platform Assembly-no loose or missing parts, no visible damage. Lock pins/bolts in place. 3. Frame-no visible damage; loose or missing hardware. (top & underside) 4. Fuel Supply-fuel cap secure; Tank-no visible damage. No leaks 5. Hose & Cable Guards-properly secured, no visible damage 6. Power Track-no loose, damaged or missing parts; hydraulic & electrical lines-no visible damage 7. Boom Sections-no visible damage; wear pads secure; boom chain undamaged and properly secured. 8. Drive Motor & Brake Shield-properly secured, no missing hardware 9. Tie Rods & Linkage-no loose or missing parts; no visible damage. Tie rod end studs locked. Extending axle machineslock pins properly installed. No steer cylinder leaks or damage. 10. Tire & Wheel Assembly-properly secured, no loose or missing lug nuts; no visible damage 11. Engine Oil Supply-full mark on dipstick; filler cap secure 12. Muffler & Exhaust System-properly secured; no evidence of leakage 13. Ground Control Panel-switches operable; no visible damage; placards secure & legible 9 or X Item Inspected 9 or X 14. Control Valve & Engine Compartment-no loose or missing parts; evidence of leakage; unsupported wires or hoses 15. Battery - Cables tight, no visible damage, no corrosion 16. Cowling & Latches-all cowling doors & latches in working order, properly secured, no loose or missing parts, operates properly 17. Platform Pivot & Sieve Cylinder Attach Pins-properly secured, evidence of proper lubrication where applicable 18. Air Shrouding-no visible damage; loose or missing hardware; no obstructions 19. Hydraulic Oil Filter-Element condition (Check indicator with engine operating at high speed & oil warmed up) 20. Auxiliary Controls (Check that the auxiliary controls are operational) 21. Hydraulic Oil Supply-full mark on dipstick (all systems shut down, machine in stowed position) 22. Platform Control Console-switches & levers properly secured; no loose or missing parts; visible damage; placards properly secured & legible, levers & switches return to neutral. Control markings legible 23. Turntable Bearing & Pinion-no loose or missing hardware; visible damage. No evidence of loose bolts or looseness between bearing & structure 24. Boom wear pads (Check for wear) 25. Platform entry mid-rail (Check that it is connected securely and sliding properly) Signed_____________________________________________________________________________ TO BE COMPLETED BY DESIGNATED OPERATOR AND FORWARDED TO SUPERVISOR PRIOR TO SHIFT Defects noted above have been corrected. Supervisor ______________________________ Date: ______________________________ CAUTION: This is not a complete list of all items that may require attention. Operators are responsible for ensuring that the aerial lift is in proper working condition in accordance with the manufacturer’s specifications. DO NOT operate aerial lift if a problem is detected. Report all problems to supervisor immediately. All comments made in reference to any problems should be made on the back of this page in detail and handed to the supervisor immediately. AERIAL WORK PLATFORM Written by: JOHSC Update Training Program File