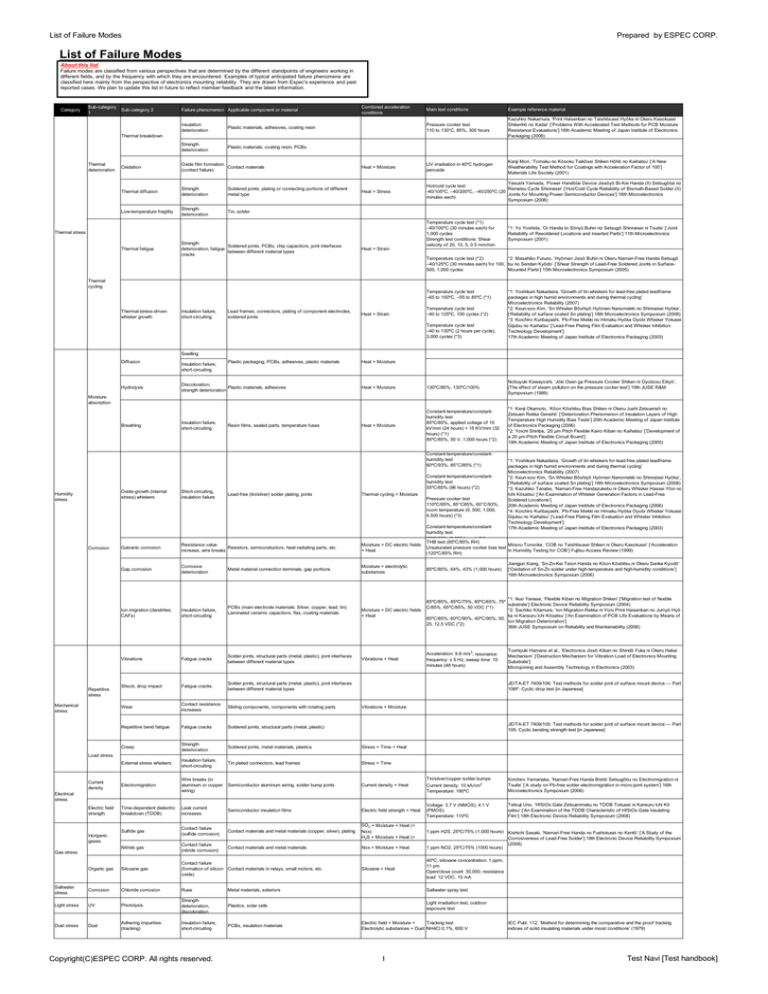

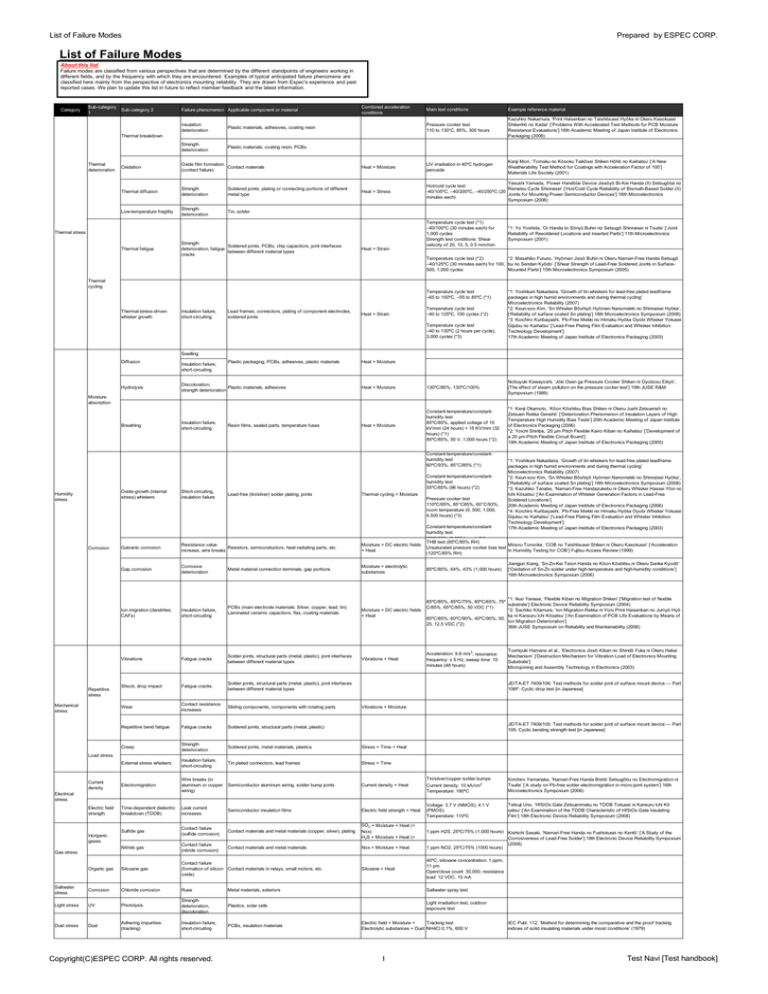

List of Failure Modes

Prepared by ESPEC CORP.

List of Failure Modes

About this list

Failure modes are classified from various perspectives that are determined by the different standpoints of engineers working in

different fields, and by the frequency with which they are encountered. Examples of typical anticipated failure phenomena are

classified here mainly from the perspective of electronics mounting reliability. They are drawn from Espec's experience and past

reported cases. We plan to update this list in future to reflect member feedback and the latest information.

Category

Sub-category

1

Sub-category 2

Failure phenomenon Applicable component or material

Insulation

deterioration

Plastic materials, adhesives, coating resin

Strength

deterioration

Plastic materials, coating resin, PCBs

Combined acceleration

conditions

Main test conditions

Example reference material

Pressure cooker test

110 to 130ºC, 85%, 300 hours

Kazuhiro Nakamura, 'Print Haisenban no Taishitsusei Hyōka ni Okeru Kasokusei

Shikenhō no Kadai’ [‘Problems With Accelerated Test Methods for PCB Moisture

Resistance Evaluations’] 16th Academic Meeting of Japan Institute of Electronics

Packaging (2008)

Kanji Mori, ‘Tomaku no Kōsoku Taikōsei Shiken Hōhō no Kaihatsu’ [‘A New

Weatherability Test Method for Coatings with Acceleration Factor of 100’]

Materials Life Society (2001)

Thermal breakdown

Thermal

deterioration

Oxidation

Oxide film formation

Contact materials

(contact failure)

Heat + Moisture

UV irradiation in 40ºC hydrogen

peroxide

Thermal diffusion

Strength

deterioration

Soldered joints, plating or connecting portions of different

metal type

Heat + Stress

Yasushi Yamada, ‘Power Handōtai Device Jissōyō Bi-Kei Handa (II) Setsugōtai no

Hot/cold cycle test:

Reinetsu Cycle Shinraisei’ [‘Hot/Cold Cycle Reliability of Bismuth-Based Solder (II)

-40/105ºC, –40/200ºC, –40/250ºC (20

Joints for Mounting Power Semiconductor Devices’] 16th Microelectronics

minutes each)

Symposium (2006)

Low-temperature fragility

Strength

deterioration

Tin, solder

Thermal stress

Thermal fatigue

Strength

Soldered joints, PCBs, chip capacitors, joint interfaces

deterioration, fatigue

between different material types

cracks

Heat + Strain

Temperature cycle test (*1)

–40/100ºC (30 minutes each) for

1,000 cycles

Strength test conditions: Shear

velocity of 20, 10, 5, 0.5 mm/min

*1: Yo Yoshida, ‘Oi Handa to Sōnyū Buhin no Setsugō Shinraisei ni Tsuite’ [‘Joint

Reliability of Resoldered Locations and Inserted Parts’] 11th Microelectronics

Symposium (2001)

*2: Masahiko Furuno, ‘Hyōmen Jissō Buhin ni Okeru Namari-Free Handa Setsugō

Temperature cycle test (*2)

–40/125ºC (30 minutes each) for 100, bu no Sendan Kyōdo’ [‘Shear Strength of Lead-Free Soldered Joints in SurfaceMounted Parts’] 15th Microelectronics Symposium (2005)

500, 1,000 cycles

Thermal

cycling

Temperature cycle test

–65 to 150ºC, –55 to 85ºC (*1)

Thermal-stress-driven

whisker growth

Insulation failure,

short-circuiting

Lead frames, connectors, plating of component electrodes,

soldered joints

Heat + Strain

Temperature cycle test

–40 to 125ºC, 100 cycles (*2)

Temperature cycle test

–40 to 130ºC (2 hours per cycle),

3,000 cycles (*3)

*1: Yoshikuni Nakadaira, 'Growth of tin whiskers for lead-free plated leadframe

packages in high humid environments and during thermal cycling'

Microelectronics Reliability (2007)

*2: Keun-soo Kim, ‘Sn Whisker Bōshiyō Hyōmen Nanomekki no Shinraisei Hyōka’,

[‘Reliability of surface coated Sn plating’] 18th Microelectronics Symposium (2008)

*3: Koichiro Kuribayashi, ‘Pb-Free Mekki no Himaku Hyōka Oyobi Whisker Yokusei

Gijutsu no Kaihatsu’ [‘Lead-Free Plating Film Evaluation and Whisker Inhibition

Technology Development’]

17th Academic Meeting of Japan Institute of Electronics Packaging (2003)

Swelling

Diffusion

Hydrolysis

Insulation failure,

short-circuiting

Plastic packaging, PCBs, adhesives, plastic materials

Discoloration,

Plastic materials, adhesives

strength deterioration

Heat + Moisture

Heat + Moisture

130ºC/85%, 130ºC/100%

Nobuyuki Kawayoshi, ‘Jōki Osen ga Pressure Cooker Shiken ni Oyobosu Eikyō’,

[The effect of steam pollution on the pressure cocker test’] 19th JUSE R&M

Symposium (1989)

Heat + Moisture

Constant-temperature/constanthumidity test

85ºC/85%, applied voltage of 10

kV/mm (24 hours) + 15 KV/mm (32

hours) (*1)

85ºC/85%, 50 V, 1,000 hours (*2)

*1: Kenji Okamoto, ‘Kōon Kōshitsu Bias Shiken ni Okeru Jushi Zetsuensō no

Zetsuen Rekka Genshō’ [‘Deterioration Phenomenon of Insulation Layers of High

Temperature High Humidity Bias Tests’] 20th Academic Meeting of Japan Institute

of Electronics Packaging (2006)

*2: Yoichi Shinba, ’20 μm Pitch Flexible Kairo Kiban no Kaihatsu’ [’Development of

a 20 μm-Pitch Flexible Circuit Board’]

19th Academic Meeting of Japan Institute of Electronics Packaging (2005)

Moisture

absorption

Breathing

Insulation failure,

short-circuiting

Resin films, sealed parts, temperature fuses

Constant-temperature/constanthumidity test

60ºC/93%, 85°C/85% (*1)

Oxide-growth (internal

stress) whiskers

Humidity

stress

Corrosion

Lead-free (tin/silver) solder plating, joints

Thermal cycling + Moisture

Pressure cooker test

110ºC/85%, 85°C85%, 60°C/93%,

room temperature (0, 500, 1,000,

4,500 hours) (*3)

Constant-temperature/constanthumidity test

85ºC/85% (3 000 h

) (*4)

THB test (85ºC/85% RH)

Minoru Tomoike, ‘COB no Taishitsusei Shiken ni Okeru Kasokusei’ [‘Acceleration

Unsaturated pressure cooker bias test

In Humidity Testing for COB’] Fujitsu Access Review (1999)

(120ºC/85% RH)

Galvanic corrosion

Resistance value

Resistors, semiconductors, heat-radiating parts, etc.

increase, wire breaks

Moisture + DC electric fields

+ Heat

Gap corrosion

Corrosive

deterioration

Moisture + electrolytic

substances

85ºC/85%, 64%, 43% (1,000 hours)

Moisture + DC electric fields

+ Heat

*1: Ikuo Yanase, ‘Flexible Kiban no Migration Shiken’ [‘Migration test of flexible

85ºC/85%, 85ºC/75%, 85ºC/65%, 75º

substrate’] Electronic Device Reliability Symposium (2004)

C/85%, 65ºC/85%, 50 VDC (*1)

*2: Sachiko Kitamura, ‘Ion Migration Rekka ni Yoru Print Haisenban no Jumyō Hyō

ka ni Kansuru Ichi Kōsatsu’ [‘An Examination of PCB Life Evaluations by Means of

85ºC/85%, 60ºC/90%, 40ºC/90%; 50,

Ion Migration Deterioration’]

25, 12.5 VDC (*2)

36th JUSE Symposium on Reliability and Maintainability (2006)

Vibrations + Heat

Acceleration: 9.8 m/s2; resonance

frequency: ± 5 Hz; sweep time: 10

minutes (48 hours)

Metal material connection terminals, gap portions

PCBs (main electrode materials: Silver, copper, lead, tin)

Laminated ceramic capacitors, flax, coating materials

Jiangjun Xiang, ‘Sn-Zn-Kei Teion Handa no Kōon Kōshitsu ni Okeru Sanka Kyodō’

[‘Oxidation of Sn-Zn solder under high-temperature and high-humidity conditions’]

16th Microelectronics Symposium (2006)

Ion migration (dendrites,

CAFs)

Insulation failure,

short-circuiting

Vibrations

Fatigue cracks

Solder joints, structural parts (metal, plastic), joint interfaces

between different material types

Shock, drop impact

Fatigue cracks

Solder joints, structural parts (metal, plastic), joint interfaces

between different material types

Wear

Contact resistance

increases

Sliding components, components with rotating parts

Repetitive bend fatigue

Fatigue cracks

Soldered joints, structural parts (metal, plastic)

Creep

Strength

deterioration

Soldered joints, metal materials, plastics

Stress + Time + Heat

External stress whiskers

Insulation failure,

short-circuiting

Tin plated connectors, lead frames

Stress + Time

Current

density

Electromigration

Wire breaks (in

aluminum or copper

wiring)

Semiconductor aluminum wiring, solder bump joints

Current density + Heat

Tin/silver/copper solder bumps

Current density: 10 kA/cm2

Temperature: 180ºC

Kimihiro Yamanaka, ‘Namari-Free Handa Bishō Setsugōbu no Electromigration ni

Tsuite’ [‘A study on Pb-free solder electromigration in micro-joint system’] 16th

Microelectronics Symposium (2006)

Electric field

strength

Time-dependent dielectric

breakdown (TDDB)

Leak current

increases

Semiconductor insulation films

Electric field strength + Heat

Voltage: 3.7 V (NMOS), 4.1 V

(PMOS)

Temperature: 110ºC

Tetsuji Uno, ‘HfSiOx Gate Zetsuenmaku no TDDB Tokusei ni Kansuru Ichi Kō

satsu’ [‘An Examination of the TDDB Characteristic of HfSiOx Gate Insulating

Film’] 18th Electronic Device Reliability Symposium (2008)

Sulfide gas

Contact failure

(sulfide corrosion)

Contact materials and metal materials (copper, silver), plating

SO2 + Moisture + Heat (+

Nox)

H2S + Moisture + Heat (+

Nitride gas

Contact failure

(nitride corrosion)

Contact materials and metal materials

Nox + Moisture + Heat

Organic gas

Siloxane gas

Contact failure

(formation of silicon Contact materials in relays, small motors, etc.

oxide)

Corrosion

Chloride corrosion

Ruse

Metal materials, exteriors

Saltwater spray test

Plastics, solar cells

Light irradiation test, outdoor

exposure test

PCBs, insulation materials

Repetitive

stress

Mechanical

stress

Load stress

Electrical

stress

Inorganic

gases

Gas stress

Saltwater

stress

Short-circuiting,

insulation failure

Constant-temperature/constanthumidity test

55ºC/85% (96 hours) (*2)

*1: Yoshikuni Nakadaira, ‘Growth of tin whiskers for lead-free plated leadframe

packages in high humid environments and during thermal cycling’

Microelectronics Reliability (2007)

*2: Keun-soo Kim, ‘Sn Whisker Bōshiyō Hyōmen Nanomekki no Shinraisei Hyōka’,

[‘Reliability of surface coated Sn plating’] 18th Microelectronics Symposium (2008)

*3: Kazuhiko Tanabe, ‘Namari-Free Handazukebu ni Okeru Whisker Hassei Yōin no

Ichi Kōsatsu’ [‘An Examination of Whisker Generation Factors in Lead-Free

Soldered Locations’]

20th Academic Meeting of Japan Institute of Electronics Packaging (2006)

*4: Koichiro Kuribayashi, ‘Pb-Free Mekki no Himaku Hyōka Oyobi Whisker Yokusei

Gijutsu no Kaihatsu’ [‘Lead-Free Plating Film Evaluation and Whisker Inhibition

Technology Development’]

17th Academic Meeting of Japan Institute of Electronics Packaging (2003)

Light stress

UV

Photolysis

Strength

deterioration,

discoloration

Dust stress

Dust

Adhering impurities

(tracking)

Insulation failure,

short-circuiting

Copyright(C)ESPEC CORP. All rights reserved.

Toshiyuki Hamano et al., ‘Electronics Jissō Kiban no Shindō Fuka ni Okeru Hakai

Mechanism’ [‘Destruction Mechanism for Vibration Load of Electronics Mounting

Substrate’]

Microjoining and Assembly Technology in Electronics (2003)

JEITA-ET 7409/106: Test methods for solder joint of surface mount device — Part

106F: Cyclic drop test [in Japanese]

Vibrations + Moisture

JEITA-ET 7409/105: Test methods for solder joint of surface mount device — Part

105: Cyclic bending strength test [in Japanese]

Siloxane + Heat

1 ppm H2S, 25ºC/75% (1,000 hours) Kishichi Sasaki, ‘Namari-Free Handa no Fushokusei no Kentō’ [‘A Study of the

Corrosiveness of Lead-Free Solder’] 18th Electronic Device Reliability Symposium

(2008)

1 ppm NO2, 25ºC/75% (1000 hours)

40ºC; siloxane concentration: 1 ppm,

11 pm

Open/close count: 30,000; resistance

load: 12 VDC, 10 mA

Electric field + Moisture +

Tracking test

Electrolytic substances + Dust NH4Cl 0.1%, 600 V

1

IEC Publ. 112, ‘Method for determining the comparative and the proof tracking

indices of solid insulating materials under moist conditions’ (1979)

Test Navi [Test handbook]