Submicro-pillars and holes from the depth

advertisement

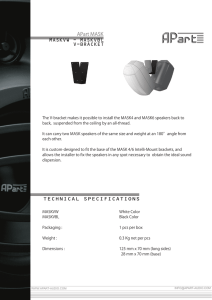

Submicro-pillars and holes from the depth-wise Talbot images of a conical phase mask In-Ho Lee, Seung Chul Park, and Sin-Doo Lee* School of Electrical Engineering, Seoul National University, Kwanak P.O. Box 34, Seoul 151-600, South Korea * sidlee@plaza.snu.ac.kr Abstract: We construct two-dimensional arrays of submicro-pillars and holes from the depth-wise Talbot images of a conical phase mask in a photoactive layer prepared on a quartz substrate. In contrast to the conventional Talbot lithography employing only one image in the photoactive layer, two images of the phase mask are produced in a depthwise manner such that the pillar patterns are in the primary image plane while the hole patterns in the secondary image plane according to the penetration depth of the exposure energy. The conical symmetry plays a critical role in producing the covariant patterns of the phase mask in the photoactive layer through the suppression of higher orders of diffraction. Our two image-type approach is simple and versatile for producing different kinds of periodic structures for photonic applications and surface engineering on a micrometer-to-nanometer scale. ©2015 Optical Society of America OCIS codes: (050.1940) Diffraction; (070.6760) Talbot and self-imaging effects; (110.5220) Photolithography; (220.4241) Nanostructure fabrication. References and links 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Y. Akahane, T. Asano, B.-S. Song, and S. Noda, “High-Q photonic nanocavity in a two-dimensional photonic crystal,” Nature 425(6961), 944–947 (2003). J. Dintinger, S. Klein, and T. W. Ebbesen, “Molecule–surface plasmon interactions in hole arrays: enhanced absorption, refractive index changes, and all‐optical switching,” Adv. Mater. 18(10), 1267–1270 (2006). Y. Alaverdyan, B. Sepúlveda, L. Eurenius, E. Olsson, and M. Käll, “Optical antennas based on coupled nanoholes in thin metal films,” Nat. Phys. 3(12), 884–889 (2007). V. M. Shalaev, “Optical negative-index metamaterials,” Nat. Photonics 1(1), 41–48 (2007). T. H. Reilly III, J. van de Lagemaat, R. C. Tenent, A. J. Morfa, and K. L. Rowlen, “Surface-plasmon enhanced transparent electrodes in organic photovoltaics,” Appl. Phys. Lett. 92(24), 243304 (2008). K. Saxena, V. Jain, and D. S. Mehta, “A review on the light extraction techniques in organic electroluminescent devices,” Opt. Mater. 32(1), 221–233 (2009). S. Liu, J. Wang, Y. Divayana, K. Dev, S. Tan, H. Demir, and X. Sun, “An efficient non-Lambertian organic light-emitting diode using imprinted submicron-size zinc oxide pillar arrays,” Appl. Phys. Lett. 102(5), 053305 (2013). G. Mariani, A. C. Scofield, C.-H. Hung, and D. L. Huffaker, “GaAs nanopillar-array solar cells employing in situ surface passivation,” Nat. Commun. 4, 1497 (2013). A. K. Geim, S. V. Dubonos, I. V. Grigorieva, K. S. Novoselov, A. A. Zhukov, and S. Y. Shapoval, “Microfabricated adhesive mimicking gecko foot-hair,” Nat. Mater. 2(7), 461–463 (2003). N. A. Patankar, “Mimicking the lotus effect: influence of double roughness structures and slender pillars,” Langmuir 20(19), 8209–8213 (2004). M. Ma and R. M. Hill, “Superhydrophobic surfaces,” Curr. Opin. Colloid Interface Sci. 11(4), 193–202 (2006). A. Dousse, L. Lanco, J. Suffczyński, E. Semenova, A. Miard, A. Lemaître, I. Sagnes, C. Roblin, J. Bloch, and P. Senellart, “Controlled light-matter coupling for a single quantum dot embedded in a pillar microcavity using farfield optical lithography,” Phys. Rev. Lett. 101(26), 267404 (2008). H. Lee, B. P. Lee, and P. B. Messersmith, “A reversible wet/dry adhesive inspired by mussels and geckos,” Nature 448(7151), 338–341 (2007). X.-M. Li, D. Reinhoudt, and M. Crego-Calama, “What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces,” Chem. Soc. Rev. 36(8), 1350–1368 (2007). F. M. Huang, N. Zheludev, Y. Chen, and F. Javier Garcia de Abajo, “Focusing of light by a nanohole array,” Appl. Phys. Lett. 90(9), 091119 (2007). C. Genet and T. W. Ebbesen, “Light in tiny holes,” Nature 445(7123), 39–46 (2007). #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25866 17. R. Gordon, D. Sinton, K. L. Kavanagh, and A. G. Brolo, “A new generation of sensors based on extraordinary optical transmission,” Acc. Chem. Res. 41(8), 1049–1057 (2008). 18. Y. Liang, W. Peng, R. Hu, and H. Zou, “Extraordinary optical transmission based on subwavelength metallic grating with ellipse walls,” Opt. Express 21(5), 6139–6152 (2013). 19. B. D. Gates, Q. Xu, M. Stewart, D. Ryan, C. G. Willson, and G. M. Whitesides, “New approaches to nanofabrication: molding, printing, and other techniques,” Chem. Rev. 105(4), 1171–1196 (2005). 20. L. Urbanski, A. Isoyan, A. Stein, J. J. Rocca, C. S. Menoni, and M. C. Marconi, “Defect-tolerant extreme ultraviolet nanoscale printing,” Opt. Lett. 37(17), 3633–3635 (2012). 21. W. Li, V. M. Esquiroz, L. Urbanski, D. Patel, C. S. Menoni, M. C. Marconi, A. Stein, W. Chao, and E. H. Anderson, “Defect-free periodic structures using extreme ultraviolet Talbot lithography in a table-top system,” J. Vac. Sci. Technol. B 31, 06F604 (2013). 22. H.-S. Kim, W. Li, S. Danylyuk, W. S. Brocklesby, M. C. Marconi, and L. Juschkin, “Fractional Talbot lithography with extreme ultraviolet light,” Opt. Lett. 39(24), 6969–6972 (2014). 23. H. H. Solak and Y. Ekinci, “Achromatic spatial frequency multiplication: a method for production of nanometerscale periodic structures,” J. Vac. Sci. Technol. B 23(6), 2705–2710 (2005). 24. H. H. Solak, C. Dais, and F. Clube, “Displacement Talbot lithography: a new method for high-resolution patterning of large areas,” Opt. Express 19(11), 10686–10691 (2011). 25. T. Sato, “Talbot effect immersion lithography by self-imaging of very fine grating patterns,” J. Vac. Sci. Technol. B 30(6), 06FG02 (2012). 26. D. Thomae, J. Maaß, O. Sandfuchs, A. Gatto, and R. Brunner, “Flexible mask illumination setup for serial multipatterning in Talbot lithography,” Appl. Opt. 53(9), 1775–1781 (2014). 27. C.-H. Chang, L. Tian, W. R. Hesse, H. Gao, H. J. Choi, J.-G. Kim, M. Siddiqui, and G. Barbastathis, “From twodimensional colloidal self-assembly to three-dimensional nanolithography,” Nano Lett. 11(6), 2533–2537 (2011). 28. T. Y. Jeon, H. C. Jeon, S. Y. Lee, T. S. Shim, J. D. Kwon, S. G. Park, and S. M. Yang, “3D hierarchical architectures prepared by single exposure through a highly durable colloidal phase mask,” Adv. Mater. 26(9), 1422–1426 (2014). 29. L. Li, “New formulation of the Fourier modal method for crossed surface-relief gratings,” J. Opt. Soc. Am. A 14(10), 2758–2767 (1997). 30. E. Noponen and J. Turunen, “Electromagnetic theory of Talbot imaging,” Opt. Commun. 98(1-3), 132–140 (1993). 31. E. B. Grann, M. Varga, and D. A. Pommet, “Optimal design for antireflective tapered two-dimensional subwavelength grating structures,” J. Opt. Soc. Am. A 12(2), 333–339 (1995). 32. M.-H. Wu, C. Park, and G. M. Whitesides, “Generation of submicrometer structures by photolithography using arrays of spherical microlenses,” J. Colloid Interface Sci. 265(2), 304–309 (2003). 33. M. Gaudet, J.-C. Camart, L. Buchaillot, and S. Arscott, “Variation of absorption coefficient and determination of critical dose of SU-8 at 365 nm,” Appl. Phys. Lett. 88(2), 024107 (2006). 34. A. Fallahpour, A. Gagliardi, D. Gentilini, A. Zampetti, F. Santoni, M. A. der Maur, and A. Di Carlo, “Optoelectronic simulation and thickness optimization of energetically disordered organic solar cells,” J. Comput. Electron. 13(4), 933–942 (2014). 35. X. Luo and T. Ishihara, “Subwavelength photolithography based on surface-plasmon polariton resonance,” Opt. Express 12(14), 3055–3065 (2004). 36. F. H. Dill, W. P. Hornberger, P. S. Hauge, and J. M. Shaw, “Characterization of positive photoresist,” IEEE Trans. Electron. Dev. 22(7), 445–452 (1975). 37. J. Cai and L. Qi, “Recent advances in antireflective surfaces based on nanostructure arrays,” Mater. Horiz. 2(1), 37–53 (2015). 38. P. Born, S. Blum, A. Munoz, and T. Kraus, “Role of the meniscus shape in large-area convective particle assembly,” Langmuir 27(14), 8621–8633 (2011). 39. T. W. Odom, J. C. Love, D. B. Wolfe, K. E. Paul, and G. M. Whitesides, “Improved pattern transfer in soft lithography using composite stamps,” Langmuir 18(13), 5314–5320 (2002). 40. L. M. Sanchez-Brea and F. J. Torcal-Milla, “Near-field diffraction of gratings with surface defects,” Appl. Opt. 49(11), 2190–2197 (2010). 1. Introduction Periodic surface structures on a micrometer-to-nanometer scale lead to a wide range of the application fields from photonics [1–4] and optoelectronics [5–8] to surface engineering [9– 11]. For example, two-dimensional (2D) pillars exhibit the optical micro-cavity effect [1, 12], the gecko adhesion [9, 13], and the super-hydrophobicity [11, 14]. Moreover, 2D holes allow a variety of the optical phenomena such as the light focusing effect [15] and the extraordinary optical transmission [16–18]. In fabricating such periodic structures, either different types of photomasks or nanoimprinting stamps are typically required [19]. Recently, the Talbot lithography (TL) has attracted much attention from the defect-tolerant capability [20, 21], the #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25867 high-resolution achieved by the spatial frequency multiplication [22, 23], and the improved depth of field [24] using a simple optical setup [25, 26] for the construction of diverse periodic structures in 2D including lines and dots. Basically, it relies on the generation of only one Talbot image of a phase mask, of which location needs to be precisely controlled using an optical spacer, in a photoactive layer [27, 28]. This single image-type TL often encounters the difficulty of controlling the precise distance between the phase mask and the photoactive layer, suffers from the proper choice of the photoactive material, and limits the flexibility in design. In this work, we demonstrate how 2D arrays of submicrometer-sized pillars and holes can be constructed from the depth-wise Talbot images of a conical phase mask in a photoactive layer. In contrast to the conventional TL where only one image is considered, two types of the images, i.e., the primary image (self-image) and the secondary image, of the phase mask are produced in the photoactive layer in a depth-wise manner according to the exposure energy of ultraviolet light (UV). It is found that for given UV intensity, depending on the penetration depth of the exposure energy in terms of the exposure time, either the pillars or holes of positive photoresist are constructed through a conical phase mask. Numerical simulations based on the rigorous coupled wave analysis (RCWA) [29] agree well with the experimental results for both the primary and the secondary images of the phase mask. Owing to the conical symmetry, higher orders of diffraction are suppressed and the covariant patterns of the phase mask are accordingly produced. 2. Basic concept of two image-type Talbot lithography Figure 1(a) is the schematic illustration of our two image-type TL. Unlike the conventional methods [27, 28], a phase mask is directly placed on a photoactive layer without any optical spacer. The shape of a void pattern in our mask is conical rather than spherical. Here, the refractive indices of the incident medium, the phase mask, and the photoactive layer are denoted as n1 + iκ1, n2 + iκ2, and n3 + iκ3, respectively (i2 = −1). The refractive index of the void pattern is identical to that of the incident medium. The contact plane between the phase mask and the photoactive layer corresponds to the x-y plane and the propagation direction of the incident light into the photoactive layer is taken as the + z direction. As shown in the inset, the conical voids are hexagonally arranged such that the periodicities in the x and y direction are Λx and Λy, respectively. For an incident plane wave with the wavelength of λ, both the primary and secondary images of the phase mask are periodically generated along the + z direction according to the Talbot effect [30]. The periodicity of the image corresponds to the Talbot length, zT. For the case of a phase mask having hexagonal lattices, the Talbot length is given as [27] zT = λ / n3 1 − 1 − [2λ / ( 3n3 Λ x )]2 . (1) In our approach, both the primary and secondary images of the Talbot fields through the phase mask are produced in the photoactive layer in a depth-wise manner. Here, the distances from the contact plane (z = 0) to the mid-planes of the primary and the secondary images are denoted by dM1 and dM2, respectively, and the distance between the two mid-planes is simply one half of Talbot length (zT/2). Figures 1(b) and 1(c) show the intensity patterns of the Talbot fields in the mid-planes of the primary and secondary images. Owing to the conical symmetry in the phase mask which is known to suppress higher orders of diffraction [31], the intensity patterns are covariant with the phase mask. Note that non-covariant patterns, for example, rings and hollow posts, are produced for the case of a conventional phase mask having spherical voids [27, 32]. In the covariant case, the two intensity patterns are reciprocal to each other in shape. Depending on #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25868 the choice of either the primary or the secondary image formed in the photoactive layer in a depth-wise manner, microstructures of either pillars or holes can be constructed. Fig. 1. (a) Schematic illustration of our two image-type Talbot lithography using an incident plane wave with the wavelength of λ. Here, n1 + iκ1, n2 + iκ2, and n3 + iκ3 denote the refractive indices of the incident medium, the phase mask, and the photoactive layer. Here, dM1 and dM2 denote the distances from the contact plane (z = 0) to the mid- planes of the primary and secondary images generated by the Talbot fields. The inset represents the unit cell of the phase mask whose periodicities in the x and y directions are Λx and Λy, respectively. (b) The primary image and (c) the secondary image located at z = dM1 and z = dM2, respectively. In two image-type TL, defining the penetration depth (δp) as the distance from the contact surface (z = 0) at which the exposure energy decays to become the activation energy (Ea) for photoreaction of a photoactive material [33], δp plays a critical role in producing either only the primary image or both the primary and secondary images (pillars and holes) in the photoactive layer in a depth-wise manner. Here, Ea represents the minimum energy needed for the generation of the image patterns in the photoactive layer. For example, Ea for SU-8 (MicroChem), one of most widely used photoactive materials, is 49.4 mJcm−2 at the wavelength of 365 nm [33]. In our case, the magnitude of δp is simply controlled by means of the exposure time (tex) for given intensity (I) of the incident light. Note that δp depends on the material parameters, such as Ea and the absorption coefficient of the photoactive layer, and it satisfies the requirement of Ea = tex I(z = δp). Since the exposure intensity in the photoactive layer decays along the + z direction, δp becomes large with increasing the exposure time. This implies that for a relatively short exposure time, only the primary image is available while for a long exposure time, the secondary image can be generated. In general, the depth-wise intensity profiles of the Talbot fields do not exactly follow the Beer-Lambert law due to the interference among different diffraction orders [34]. Numerical simulations in the RCWA are performed to examine the depth-wise image patterns of the conical mask in the photoactive layer for given exposure intensity. The simulation results are discussed along with the experimental results for submicro-pillars and holes. 3. Numerical simulations for intensity patterns of Talbot fields We first carried out full three-dimensional numerical simulations for the intensity patterns of the Talbot fields generated from a conical phase mask in the RCWA [29]. Suppose that unpolarized UV light at the wavelength of 365 nm is incident onto the phase mask as shown in Fig. 1(a). For numerical simulations, the refractive indices of the incident medium and the conical voids (n1 + iκ1) were taken to be identical to the refractive index of air (1.00 + 0.00i) as in the typical TL case. The refractive index (n2 + iκ2) of the phase mask of polydimethylsiloxane (PDMS) giving the high optical transmittance and the conformal contact with a photoactive layer [28, 32], was 1.41 + 0.00i. For the photoactive layer, the real part of the refractive index #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25869 (n3) was 1.70, being in the range of the refractive indices of typical photoresists [35], while the imaginary part (the extinction coefficient of κ3) was set to be 0.0358 which is significantly larger than those for most of photoresists [36]. This large extinction coefficient facilitates to enhance the intensity contrast between the primary and the secondary images according to the exposure time. The conical phase mask used in our study was fabricated through the colloidal lithography based on an array of colloidal particles of submicrometers [37]. Figure 2 shows the crosssectional view of the conical phase mask where both the diameter (D) and the depth (H) of each conical void are 300 nm. The periodicity in the x direction (Λx) is 500 nm. Since the conical voids are hexagonally periodic, the periodicity in the y direction (Λy) is accordingly 500 3 nm. Fig. 2. (a) The simulation results for the time-averaged intensity patterns of the Talbot fields in the x-z plane upon the incidence of the unpolarized plane wave with the wavelength of λ. Here, Λx denotes the periodicity in the x direction and D and H represent the diameter and the height of the conical void, respectively. The mid-plane and the bottom plane of the primary image (or the secondary image) are represented as dM1 and dB1 (or dM2 and dB2), respectively. (b) The time-averaged intensity patterns at z = dM1 (the mid-plane) of the primary image and (c) those at z = dM2 (the mid-plane) of the secondary image along the black solid lines in (a). The rectangles enclosed by dotted lines in (b) and (c) correspond to the unit cell of a phase mask. The normalized intensity patterns were shown in the color-coded representation. Using the refractive indices and the geometrical parameters mentioned above, the timeaveraged intensity patterns of the Talbot fields in the x-z plane, calculated numerically in the RCWA, are presented in Fig. 2(a). The normalized intensity patterns were shown in the colorcoded representation. In principle, the primary and the secondary images are periodically repeated along the z direction. The Talbot length is about 1600 nm which is consistent with the theoretical value of 1632 nm obtained from Eq. (1) under no optical loss in the photoactive layer. The estimated values of the distances of the relevant planes for the primary and secondary images are dM1 = 120 nm, dB1 = 239 nm, dM2 = 920 nm, and dB2 = 1114 nm. The values of dB1 and dB2 were chosen such that at z = dB1 and z = dB2, for each case, the ratio of the minimum intensity to the maximum intensity is 1/2 to ensure the optimum intensity contrast. Accordingly, dM1 = dB1/2 and dM2 = dM1 + zT/2 in the + z direction. Note that from the practical point of view, the ratio of the maximum intensity to the minimum intensity, giving 0.5, is a more meaningful parameter in the photolithography rather than the magnitude of the intensity itself. This corresponds to the plane at z = dM2. For the purpose of constructing pillars from the primary image, the penetration depth δp should be the same as dB1 = 239 nm while for holes from the secondary image, it should be dB2 = 1114 nm. #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25870 Figures 2(b) and 2(c) show the simulation results for the time-averaged intensity patterns obtained in the mid-planes of the primary and the secondary images produced from the conical phase mask. The normalized intensity patterns were shown in the color-coded representation. The rectangles enclosed by dotted lines correspond to the unit cell of a phase mask. In the mid-plane, the intensity patterns of the primary image are nearly reciprocal to those of the secondary image although the values for the full width at the half maximum (FWHM) are different. The FWHM of the intensity dip in the primary image and that of the intensity peak in the secondary image are 315 nm and 250 nm, respectively. As discussed earlier, the covariant patterns of the phase mask are produced for either pillars or holes depending on the choice of the depth-wise Talbot images. 4. Fabrication processes of conical phase mask and samples Based on our concept of two image-type TL, we describe the fabrication processes of the conical phase mask for 2D arrays of submicro-pillars and holes. As shown in Fig. 3(a), the master mold for the conical phase mask was first prepared through reactive ion etching using an array of colloidal particles as an etching mask as in the case for biomimetic anti-reflective coatings [37]. A quartz wafer used as a substrate was cleaned by immersion in a piranha solution (sulfuric acid: hydrogen peroxide = 3: 1) for 1 hour at 120 °C to produce a hydrophilic surface and then rinsed with de-ionized water. The substrate was dried in a nitrogen stream before being used. A monolayer of polystyrene (PS) nanospheres (3500A; Duke scientific) of 500 nm in diameter was prepared on the substrate by the convective selfassembly method as described elsewhere [38]. The image in Fig. 3(b) taken with a scanning electron microscope (SEM) (S-4800; Hitachi) shows the uniform monolayer of the hexagonally close-packed nanospheres. Using the array of the PS nanospheres as an etching mask, reactive ion etching was performed with a plasma etcher (Plasmalab 80 Plus; Oxford instruments) with CF4 of 50 sccm at the RF power of 150 W under the pressure of 0.05 torr for 13 min. The SEM image in Fig. 3(c) shows the resultant hexagonal array of the submicrocones produced by gradual etching. Both the diameter and the height of each cone were about 300 nm. The magnified SEM image shown in the inset of Fig. 3(c) clearly shows the conical shape of a single pattern. The final step is to construct the conical phase mask of the PDMS (Sylgard 184; Dow Corning) having the refractive index of 1.41 + 0.00i by replica molding of the master mold. For minimizing the adhesion of the cured PDMS to the master mold, the master mold was treated with a solution of dimethyledichlorosilane (Sigma Aldrich) with the concentration of 5 wt.% in dichloromethane (Sigma Aldrich) and placed in a vacuum chamber for 2 hours for silanization. After being rinsed with dichloromethane and ethanol in sequence, the master mold was used for the pattern transfer onto the bilayer of the PDMS described elsewhere [39]. In fact, the outmost surface of the phase mask was formed with a hard PDMS (h-PDMS; Gelest) layer with a high elastic modulus. This results in only small distortions of the conical voids in our case. Owing to the oligomers of the PDMS in the outmost surface, the adhesion between the phase mask and the photoactive layer naturally produces the conformal contact, meaning that no gap is present in contact between them. After being cured for 2 hours at 120°C, the PDMS plate with an array of the conical voids was detached from the master mold and used for the conical phase mask. In the two-image TL employing the conical phase mask fabricated above, for the purpose of reducing the reflection, antireflective polymer (BARLi-2; AZ Electronic Materials) was spin-coated on a glass substrate at 3000 rpm for 30 s. A photoactive material of a positive photoresist (AZ 1512; AZ Electronic Materials), having the refractive index of 1.70 + 0.0358i (at the wavelength of 365 nm), was prepared on the top of the antireflective polymer layer at the spinning rate of 4000 rpm for 30 s and subsequently soft-baked at 95 °C for 60 s. The thickness of the photoresist was about 1200 nm, being comparable to dB2 (1114 nm). Note that the extinction coefficient of AZ 1512 is relatively large in comparison to those of most photoresists. The conical phase mask was then placed on the photoresist layer in conformal #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25871 contact. The photoresist layer was exposed to UV light with the central wavelength of 365 nm through the phase mask in a standard UV exposure system (MA-6; Karl-Suss) at the lamp power of 16 mWcm−2. The exposure time was varied from 4 s to 12 s at the interval of 1 s to vary the penetration depth δp for the image plane. After being exposed, all the samples were developed in a developer (AZ-300 MIF; AZ electronic materials) for 45 s, rinsed with deionized water, and dried with a nitrogen stream. The samples were observed using the SEM and an atomic force microscope (AFM) (XE-150; PSIA) in a non-contact mode. The radius and the cone angle of the tip (PPP-NCHR; Nanosensors) used in the AFM measurement were 10 nm and 20°, respectively. Fig. 3. (a) Schematic illustration of the fabrication steps of a conical phase mask. (b) The image of a monolayer taken with a scanning electron microscope (SEM). (c) The SEM image of hexagonal array of submicro-cones. The inset in (c) shows the magnified SEM image of the single cone. 5. 2D arrays of submicro-pillars and holes by two-image TL Figures 4(a) and 4(b) show the SEM images of the 2D arrays of submicrometer-sized pillars and holes constructed by the two-image TL employing the conical phase mask for different exposure times of 5 s and 8 s, respectively. The pillars and holes were well-defined as shown in the AFM images together with the morphological profiles in two insets of Figs. 4(a) and 4(b), respectively. The covariant patterns of pillars and holes from the depth-wise Talbot images of the phase mask with hexagonal lattices were clearly seen in Figs. 4(a) and 4(b), respectively. This is consistent with the intensity patterns shown in Figs. 2(b) and 2(c). From the line profiles along the red dashed lines in the insets, the diameter (dp) and the height (hp) of a pillar were measured to be 350 nm and 200 nm, respectively. For a hole, the diameter (dh) and the depth (hh) were 280 nm and 50 nm, respectively. The measured values of the diameters of the pillar and the hole are comparable to the theoretical FWHM values (315 nm for pillar and 250 nm for hole) in Figs. 2(b) and 2(c). In fact, for the holes, both the diameter and the depth by the secondary image are expected to increase with increasing the exposure energy or the penetration depth into the secondary image layer of about 900 nm. The discrepancy between the experimental results and the numerical simulations may be attributed to the imperfection of the conical phase mask and the non-negligible elastic deformation in conformal contact with the substrate, both of which result in the distortions of the Talbot #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25872 fields, particularly, in far field region [40]. In our two image-type TL, the exposure time (either 5 s for pillars or 8 s for holes) is the key parameter to determine one of two images (either the primary image or the secondary) for given exposure intensity. As expected from the relationship of Ea = tex I(z = δp), the pillars were produced for a short exposure time (5 s) while the holes were for a long exposure time (8 s). Fig. 4. The SEM images of 2D arrays of submicrometer-sized structures under the exposure times of (a) 5 s and (b) 8 s. Insets show the corresponding AFM images together with the line profiles along the red dashed lines. Here, dp and hp in (a) denote the diameter and the height of a pillar, respectively. The diameter and the depth of a hole are denoted by dh and hh in (b), respectively. 6. Concluding remarks We demonstrated two-image type TL which enables to generate the depth-wise Talbot images of a phase mask in a photoactive layer according to the exposure time for given exposure intensity of the UV light. Using a conical phase mask, 2D arrays of submicro-pillars and holes were constructed from the primary image and the secondary image, depending on the penetration depth of the exposure energy into the photoactive layer, respectively. The conical symmetry was found to play a critical role in producing the covariant patterns of the phase mask in the photoactive layer through the suppression of higher orders of diffraction. The experimental results for the submicro-pillars and holes were in good agreement with the numerical simulations based on the RCWA method. Our two image-type TL will be useful for constructing diverse functional microstructures down to a nanometer scale in the areas of photonics and optoelectronics. Acknowledgment This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. 2011-0028422). #246375 © 2015 OSA Received 20 Jul 2015; revised 17 Sep 2015; accepted 20 Sep 2015; published 23 Sep 2015 5 Oct 2015 | Vol. 23, No. 20 | DOI:10.1364/OE.23.025866 | OPTICS EXPRESS 25873