High-Tech Reheating and Special Application Furnaces

advertisement

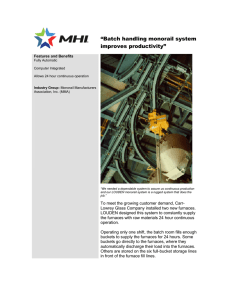

High-Tech Reheating and Special Application Furnaces A complete line of furnace equipment implementing proven innovative technologies TENOVA is a worldwide supplier of advanced technologies, products and engineering services for the metals and mining & minerals industries. I II Tenova is a worldwide supplier of advanced technologies, products and engineering services for the metals and mining & minerals industries providing innovative integrated solutions. Combined process and automation know-how enhance the value delivered to the customers. Tenova is committed to develop its technology in the areas of greatest significance for the future of the industries it serves: product quality, energy saving and environmental sustainability. Tenova Italimpianti is the leading global supplier of reheating equipment for steel and copper, melting/holding furnaces for aluminum, and other industrial furnaces for special applications. It employs its outstanding innovation, experience and know-how to offer complete, state-of-the-art, environment-friendly furnace systems and related combustion systems operating with any kind of fuel. Global Presence Tenova Italimpianti is a leading integrated supplier with operating companies in Europe, China, South Korea, India and the USA and production facilities in India and Vietnam. Present on all the world’s key markets, Tenova Italimpianti provides technological support and closely serves its customers. Tenova Italimpianti is supported by the synergies and worldwide presence of Tenova’s global network of operating companies with solid local roots, who provide unique solutions through an integrated, multi-business organization. This global approach enables Tenova companies to keep in close contact with customers, to provide engineering capabilities aligned with local standards and to guarantee real-time responsiveness. Austria Belgium Bulgaria Canada Calgary, Toronto, Vancouver Mexico Mexico D.f., Monterrey USA Denver, Pittsburgh, Yalesville Brazil Chile Peru 2 Belo Horizonte Santiago Lima Wien Liege France Germany Italy Poland Sofia Lyon Dortmund, Essen, Lauchhammer, Leipzig, Stuttgart Genoa, Milan, Varese Katowice, Swiebodzin Sweden Lidköping South Africa Johannesburg China India Kazakhstan Beijing, Chongqing, Shanghai, Tanggu, Tianjin Bangalore, Chennai, Kolkata, Mumbai Russia South Korea Thailand Uzbekistan Astana Moscow Seoul Bangkok Taschkent Vietnam Ho Chi Minh City Australia Brisbane, Perth, Sydney Indonesia Jakarta Heritage As a leader in reheating furnaces, Tenova Italimpianti draws on the longstanding experience and know-how of: Italimpianti, an Italian engineering company founded in Genoa in 1957. A leading integrated supplier of technology and turnkey industrial plants, Italimpianti specialized in reheating furnaces and related thermal equipment. Through its R&D work and technological innovation, it became a benchmark player on the market. Core, based in the USA, is a leading provider of industrial furnaces and related equipment. The company has established itself as a source for advanced technology and reliable deliveries. Offering fully integrated operational capabilities, Core is the main supplier of large reheating furnaces on the NAFTA market. Hypertherm, based in Mumbai, specializes in the design and supply of industrial furnaces. The company focuses mainly on the SAARC market, where its impressive expertise is supported by numerous installations in the Country and abroad. Envita, based in Incheon, South Korea, specializes in the design and supply of industrial furnaces and related equipment. The company has developed proprietary technologies for aluminum equipment intended primarily for the automotive sector, thus becoming the preferred supplier of well-known brands in Korea and in the West. With more than 4,000 furnace installations, Tenova Italimpianti is the name behind some of the largest, most technologically advanced and most efficient reheating furnace plants in the world. 3 Business 4 Tenova Italimpianti designs and installs a wide variety of ferrous and nonferrous reheating furnaces for long and flat products covering a full range of requirements, from traditional applications to thin slab and direct rolling. Its expertise also covers furnaces for petroleum coke, carbon products and direct reduced iron, as well as metal reclamation and waste oxide recycling, aluminum melting, holding and heat treatment furnaces the thermal section of processing lines, pots and related accessories for GI/GL lines, pollution abatement facilities (RTO and scrubbers) and air knives. Tenova Italimpianti’s success is based on its acknowledged ability to develop reheating furnaces providing outstanding efficiency and reliability, excellent temperature uniformity, fully automatic operation, and low product variability. Tenova Italimpianti excels at delivering highquality furnace product lines to meet the exacting installation and schedule requirements of the customer. 5 Products Tenova Italimpianti reheating furnaces provide excellent processing quality and productivity for slabs, billets, blooms, beam blanks and rounds. Tenova LOI Italimpianti designs include: • Walking Beam and Walking Hearth Furnaces • Roller Hearth Furnaces for Thin Slab • Pusher Type Furnaces • Rotary Hearth Furnaces • Specialty Furnaces for Calcining Processes and Carbon Products • Furnaces for pipes and quenching systems • Aluminum melting, holding and heat treatment furnaces • Thermal section of processing lines • Pots and related accessories for GI/GL lines and air knives • Pollution abatement facilities (RTO and scrubbers) • Burners • Level 1 and Level 2 Automation 6 Walking Beam and Walking Hearth Furnaces As a long-time player in reheating furnaces, Tenova Italimpianti has installed some of the world’s largest walking beam reheating furnaces. It has designed walking beam furnaces for reheating: • billets • blooms • slabs • thin slabs • beam blanks • pipes and any kind of material, including: • copper • carbon steel • stainless steel • oriented grain steel • titanium • special alloys 7 Roller Hearth Furnaces for Thin Slab 8 Tenova Italimpianti roller hearth furnaces implementing latest-generation direct rolling technology are suitable for slab lengths of 30-50 m and, in special cases, for endless rolling of bar lengths up to 300 m. With a constant focus on critical components such as rollers and burners, Tenova Italimpianti designs outstanding roller hearth furnaces. Milestones include the longest furnace, the furnace with the highest temperature and the first operating furnace with three lines. Pusher Type Furnaces Most of the pusher type furnaces built in the 1970s and 1980s are still in operation today. Modern design techniques and solutions adopted for new furnaces can give fresh life to old plants. New offset skid systems, new hot rider designs, burners with low NOx emissions are some of the advances applied to older furnaces to boost production capacity, improve temperature uniformity, enhance surface quality and save energy. 9 Rotary Hearth Furnaces 10 Tenova Italimpianti is the world’s leading supplier of rotary hearth furnaces for a variety of process applications and product types. Tenova Italimpianti has installed some of the largest-diameter and highestcapacity rotary hearth furnaces in the world. Its rotary hearth furnace technology is adopted for specialized applications including bloom reheating, iron processing and waste reclamation processes. Specialty Furnaces for Calcining Processes and Carbon Products Tenova Italimpianti has developed advanced technologies for petroleum coke and coal rotary hearth calciners used to process lignite, sub-bituminous coal, anthracite, brown coal, formed coke briquettes and many other carbon-based products. Its proprietary rotary hearth calciner provides better product quality and higher product yield than traditional rotary kilns. Tenova Italimpianti deploys its superior carbon-baking process know-how to build furnaces whose superior heating and circulation systems produce the base material for carbon electrodes of the highest quality. With its state-of-the-art combustion technology, waste heat recovery, incineration and process control as well as safety technology, Tenova Italimpianti is the provider of choice for top-quality carbon-baking equipment. 11 Furnaces for Pipes and Quenching Systems 12 Tenova Italimpianti provides reliable processing equipment for pipes. Its innovative quenching systems are designed to meet the strict processing requirements of modern pipe production. Aluminum Melting, Holding and Heat Treatment Furnaces Tenova Italimpianti offers aluminum melting furnaces covering production needs for all applications through Tenova Metals, the new brand name of the Korean company Tenova Envita. Thanks to the quality, reliability, and efficiency of its furnaces and an extremely efficient after-sales department, Tenova Metals has established itself as the key supplier of major producers in the automotive industry such as Hyundai Motors, Kia Motors, GM and others. Different furnace sizes are available, ranging from 0.5 to 5 t/h melting capacity (rapid melting furnaces), with up to 40 t holding capacity. To satisfy customer needs, Tenova Metals is expanding its product portfolio: one new entry is a high-efficiency, high-recovery-rate aluminum chip melting furnace implementing a mechanical recirculation system. Additional products for the aluminum line include state-of-the-art rotary and continuous T-6 aluminum treatment furnaces, fully automated handling systems, low-pressure casting machines and aluminum dosing furnaces with up to 2 t capacity. 13 Thermal section of processing lines 14 Tenova Italimpianti supplies state-of-the-art furnaces for strip processing. Its offer includes continuous furnaces for hot-dip galvanizing including alu-zinc coating, continuous annealing furnaces, paint ovens for color coating lines and thermal sections for vertical bright annealing, as well as horizontal and vertical direct fired sections, indirect heating radiant tube chambers, jet cooling units and after-pot coolers. Tenova Italimpianti thermal sections cover a wide capacity range, from 10 t/h up to 100 t/h. Pots and related accessories for GI/GL Lines and air knives Tenova Italimpianti is a well-established supplier of reliable and efficient induction-heated ceramic pots for galvanizing lines (GI/GL), designed with top-quality components and materials. With its fully automated air knife design, Tenova Italimpianti provides a complete, integrated technology for the thermal section of the galvanizing process. A full selection of maintenance equipment is available, including a sink roll preheating system. 15 Pollution abatement facilities (RTO and scrubbers) 16 Tenova Italimpianti develops regenerative thermal oxidizers (RTO) through Tenova Metals, the new brand name of the Korean company Tenova Envita. The compact design and advanced technology content of the equipment delivers highly efficient levels of volatile organic compound destruction. The multi-chamber RTO unit implements reliable, durable solutions, combined with high energy recovery to minimize maintenance concerns. Burners Burners are the heart of a furnace. Tenova Italimpianti designs and supplies its own in-house advanced burner technology as a component of most reheating furnace projects. Its burners integrate the expertise of its engineering team and advanced combustion research tools. As a specialist in high-performance furnaces, Tenova Italimpianti has developed the Flexytech® burner product line. The new generation of Tenova Italimpianti FlexyTech® flameless burners implements the best available technology on the combustion systems market, to provide dramatic reductions in NOx emissions. Flameless technology is also applied to regenerative burners, to deliver top performance for both NOx emissions reduction and energy savings. 17 Level 1 and Level 2 Automation 18 Tenova Italimpianti provides in-house development of Level 1 and Level 2 automation systems for new furnace installations or for existing system upgrades. The Tenova Flexytech® Level 1 system is a microprocessorbased system (PLC or DCS) interfaced with HMI (Human Machine Interface) state-of-the-art display screens, to provide furnace operators with manual, automatic or Level 2 control of furnace functions and processes. In 1981, Tenova Italimpianti was the first company to utilize on-line mathematical models to automatically control the operating functions of a reheating furnace. These mathematical models have been continuously tested and improved through more than one hundred reheating furnace performance evaluations and are now crucial components of the Tenova Flexytech® Level 2 system. The Flexytech® Level 2 system provides vital furnace performance benefits such as lower specific fuel consumption and improved product temperature uniformity as well as higher mill production rates. Research and Sustainable Development Technological innovation is the main pillar of Tenova Italimpianti competitiveness. Energy savings, environmental protection and product quality are the drivers of its in-house R&D. On-going burner and combustion system developments rank Tenova Italimpianti furnaces among the most technologically advanced installations in the world. Tenova Italimpianti uses an incremental innovation approach based on extensive testing, development of modeling software, metallurgical knowhow and process technology. Involvement in international R&D projects, together with collaboration with customers, are key factors in Tenova Italimpianti product innovation. Thanks to its solid background, Tenova Italimpianti is able to offer the most advanced solutions to meet customer requirements. As the owner of one of the industry’s most prestigious international research centers, Tenova Italimpianti develops cutting-edge combustion technology such as flameless regenerative burners in-house, in its combustion testing facilities. 19 Technical Services Tenova Italimpianti engineering services range from existing equipment upgrades to the design and turnkey installation of integrated systems. Services: • Feasibility Studies • Energy Surveys • Plant Surveys • Equipment Revamps • Complete Project Management • Construction and Start-up Supervision • Training • Maintenance Assistance • Spare Parts • Process Control and Automation Upgrades 20 Quality Tenova Italimpianti is committed to quality and continuous service improvement and follows the best industry practices and standards to meet or exceed customer expectations. Tenova Italimpianti has introduced an excellence path involving a number of companies with ISO 9001 certification in the Business Area and others that plan to obtain certification from primary certifying bodies. 21 Environmental Responsibility 22 Respect for the environment is a core value of Tenova Italimpianti projects. Tenova Italimpianti’s commitment to the environment also takes the form of investment in thermal process simulation models and combustion systems to improve product efficiency and optimize control systems. Focus on People People are vital to success and growth at Tenova Italimpianti. Almost 350 qualified engineers and technicians are the lifeblood of the company network. Outstanding technical and management expertise in every area of activity, a strong customer focus, a passion for innovation and continuous flexibility: these are the features that distinguish Tenova Italimpianti professionals. With their different nationalities and varied operating experience, Tenova Italimpianti specialists execute projects all over the world. Their multicultural backgrounds equip them to take on new challenges i n any location. Tenova Italimpianti enhances and optimizes the talents of the individual for the good of the team and the benefit of the customer. By supervising every stage of professional growth and providing on-going knowledge and skills training, Tenova Italimpianti guarantees the expertise of its people. 23 Tenova ITALIMPIANTI Tenova S.p.A. Via Albareto, 31 16153 Genoa - Italy Phone +39 010 6054807 Fax +39 010 6054741 tenovaitalimpianti@tenova.com Tenova Tenova East Europe LLC Ul. Gruzinskij val, dom 10, stroenie 4 123557 Moscow Russia Phone/Fax +7 495 995 95 07 temos@tenova.com Tenova Hypertherm Pvt Ltd 2093, Oberoi Garden Estates Chandivli, Andheri (E) Mumbai 400 072 - India Phone +91 22 66810200 Fax +91 22 2847 7703 tenovahypertherm@tenova.com Tenova Representative Office for CIS Ul. Gruzinskij val, dom 10, stroenie 4 123557 Moscow Russia Phone/Fax +7 495 995 95 07 temos@tenova.com Tenova METALS Tenova Core Inc Cherrington Corporate Center 100 Corporate Center Drive Coraopolis, PA 15108-3185 - USA Phone +1 412 262 2240 Fax +1 412 262 2055 core@tenova.com Tenova Envita Co Ltd 7-21 Songdo-dong, Yeonsoo-gu Incheon - Korea Phone +82 32 851 6212 Fax +82 32 816 6460 envita@tenova.com www.tenova.com 26 TECHINT GROUP Printed by Quadrifolio-Signum, December 2013 Tenova Industrial Technologies (Beijing) Co Ltd 1700 Air China Plaza 36 Xiaoyun Lu Beijing 100027 - China Phone +86 10-8447 5656 Fax +86 10-8447 5858 titb@tenova.com