Motor Protection and Monitoring

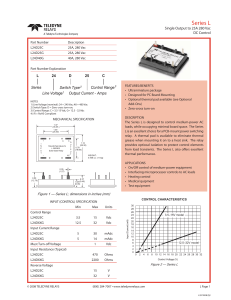

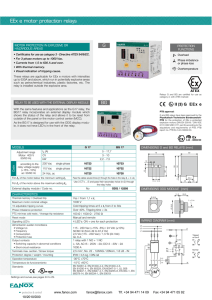

advertisement