WASTEMASTER

A Product of Hard Work

Machines dedicated to waste and recycling

materials rehandling

Over 25 machines purpose designed for waste and recycling applications and built to thrive in

the tough, often extreme conditions so common in this industry. The JCB Wastemaster range

is the widest of its kind available and combines the legendary JCB build quality, reliability and

versatility with unique features for specialist applications. Whether you’re working with paper,

wood, metal, tyres, glass, green waste, cars, batteries or fridges, our machines offer the

performance power and productivity you need to operate efficiently and profitably.

MACHINES DEDICATED TO THE WASTE INDUSTRY

Additional protection features have been added for operator safety, particularly important

in harsh environments that often feature airborne fibres and pollutants, and to minimise

costly damage to your investment that can be caused by falling material and restricted sites.

The Wastemaster range is comprised of larger machines for bulk handling and shifting,

such as tracked and wheeled excavators, wheeled loading shovels and Loadalls down to

more compact machines that are ideal for loading/unloading and more general site duties,

including, compact Loadalls, Teletruks and skid steer loaders. In addition is the TM310

Wastemaster, a telescopic handler with an articulated chassis providing extra manoeuvrability.

At the heart of every single one of these Wastemasters is our understanding of the issues

you face. From the hazards of handling dangerous, awkward or bulky materials to the

pressures of forthcoming legislation, we are continually developing new solutions to meet

your needs.

Operator protection

and productivity

Screen and roof guards protect against falling material

Air conditioning eliminates the need to open

windows keeping pollutants out

Carbon cab and optional P3 filters result in a

clean-air cab environment

Superb comfort and low in-cab noise levels encourage

more operator productivity

Incredible controllability, including AMS, servo controls and cushion

control, enables real precision work

No one understands the harsh, dangerous environments operators in

waste industries need to work in, day in day out, better than you. And no

one goes further to ensuring the operator stays protected, comfortable and

productive than JCB.

The fully enclosed cab on a JCB Wastemaster is a protective shell that helps

to keep out any airborne dust or debris, particularly when rehandling paper,

green or municipal waste, or compost; prevents acid splash problems

associated with processing used batteries; and protects the operator from

falling debris, an unavoidable hazard when you’re dealing with glass, end of

life vehicles, metals, wood... any waste material.

Specific protective features, each of which you will find on Wastemaster

machines where they are needed most, include full screen and roof guards

to shield against falling debris. Air conditioning means there is no need to

open the windows to achieve the most comfortable working conditions,

while a carbon cab filter keeps out dust and pollutants. Where particles in

the air are a particular problem, you may also be able to opt for a P3 filter

which offers even higher filtration and protection.

The safety of your operators is, of course, your prime consideration. But

Wastemaster machines also go a long way to keeping operator fatigue at

bay for superb productivity and increased earning potential. So you will find

ergonomic control layouts, suspension and deluxe air suspension seats,

climate control and cab heaters, an enhanced Advanced Management

System and cushion control on our excavators, the JCB Smooth Ride

System which smoothes out jolts and bumps, not to mention automotivestyle interiors.

It all goes a long way to giving your operators the day-long comfort and

precise control they need in such arduous, specialist applications.

WASTEMASTER | Operator protection and productivity

Machine protection

and safety

Underbelly guarding prevents hazardous material from

getting up inside the machine

Light guards, screen guards and trash guards help to protect

the body of the machine

Additional working lights and chevrons improve on-site

safety and operation

A choice of tyre options maximise machine uptime

Additional air filtration protects the engine in dusty,

fibrous environments

No machines are more robust or better equipped to take the blows

of the most extreme rehandling and recycling environments than JCB

Wastemasters. Not only do these machines, like all JCBs, have the integral

strength and durability required in waste and recycling applications – we

have also developed a special package of features to protect your machine

and your investment.

First of all, to prevent material like paper and plastic, which can be a fire

hazard, from getting up inside the machine, many of the Wastemaster

machines feature underbelly guarding, including fuel-tank protection. Robots

and Teletruks also boast front wheel motor protection which prevents

materials like twine from getting tangled and damaging the machine.

To protect against damage to the body of the machine, where necessary

Wastemasters feature light guards, screen guards and trash guards, and a

strong steel lower door. For safe working in the dark and inside buildings,

there is a choice of front and rear working light options, a roof-mounted

beacon and Wastemaster branding that features highly visible chevron

markings. Plus to help avoid knocks on site, machines can be fitted with a

range of mirrors, a choice of reverse alarms and even reversing cameras.

Another vulnerable area can be the tyres. That’s why we offer a range of

special tyre options to keep you moving even when sharp glass and bits of

metal or plastic are a constant hazard. Additional air filtration for the engine

and cab ensure reliability in dusty, fibrous environments, while reverse fans

keep machine cooling in check and wide core radiators allow small particles

to pass through rather than blocking the system.

These really are tough machines that can stand up to, and thrive, in the

toughest environments.

WASTEMASTER | Machine protection and safety

Machine performance

and productivity

Worklights mean longer working hours are possible

Limited slip differentials give extra traction in challenging ground conditions

JCB Smooth Ride System keeps more of the load in the bucket

Automatic greasing options reduce maintenance tasks

and ensure machine longevity

AMS features diagnostic tools for easier servicing

When your operator and machine are so incredibly well protected, all you

need to concentrate on is getting the job done as efficiently and effectively

as possible. JCB Wastemasters are designed with exactly that in mind,

with specialist work equipment and machine features to help you get the

maximum output from your machine.

In addition to the machine and operator protection specifically on Wastemaster

machines, which of course is also of benefit when it comes to performance

and productivity, we have introduced, where relevant: worklights for longer

operating hours, quickhitches for enhanced versatility, limited slip differentials

for added traction in difficult ground conditions, a choice of tyres to suit the

application, the JCB Smooth Ride System to keep more of the load in the

bucket, and much, much more.

On our Wastemaster excavators you will also be given the option of a fixed

raised or hydraulically raised cab to provide a clear view into containers,

vital for waste operations. And a dipper stroke limiter which allows you to

set a maximum height allowing you to use the machines in buildings without

worrying about the possibility of damaging ceilings.

Just as vital to machine output as specific working equipment are features

to ensure you the maximum uptime. So you’ll find that the serviceability of

these machines is second to none. Service intervals of 500 hours, true

ground-level servicing with daily checks grouped together, engine sump

drain kits and automatic greasing all help make life much easier. Plus on

some machines there is the extra diagnostic power of the Advanced

Management System.

Add a huge range of specialist attachments, such as sorting grapples, selector

grabs and bale clamps, and you have machines that get the job done... and

keep on getting it done.

WASTEMASTER | Machine performance and productivity

Tracked excavators

Choice of standard mono, TAB or specialist boom and dipper

combinations (on selected machines)

Optional fixed or hydraulically raised cabs gives an

excellent view into containers

Various hydraulic circuits allow operation of specialist attachments

Wide core radiator gives efficient, trouble-free cooling

Additional air filtration for cab and engine enhances machine and

operator protection in fibrous environments

We have taken some of our most popular models from our 1- to 46-tonne

range of tracked excavators and suitably specified them to Wastemaster

standards. The result is the perfect solution for numerous industry applications.

Excavators are the ideal machines for picking and sorting incoming

material in a recycling facility. The fitment of a rotating selector grab aids

material picking, or a 4- or 5-tine orange peel grab can be used for bulk

loading or stockpiling.

If you need to work in confined areas, maybe up against the wall of a

recycling hall or in a skip hire yard, you need the zero tailswing design of the

8080. Whatever the conditions or space restrictions, with this machine the

operator can be confident there will be no danger of tailswing interference,

leaving him free to concentrate 100% on rehandling.

All Wastemaster models are fitted with an Advanced Management System

(AMS) which continually checks all the main operating parameters of the

machine, including water and oil temperatures, pressures and air filter

condition, and informs the operator of any potential problems. The AMS

also offers full diagnostic support for the service engineer, resulting in quicker

diagnosis and turnaround.

Fixed or hydraulic raised cabs can be fitted to the larger tracked excavator

models improving operator visibility to the work area. Plus, specialist rigs

such as the materials or scrap handler units can also be fitted where the

application dictate, giving greater reach and performance.

WASTEMASTER | Tracked excavators

Wheeled excavators

Choice of standard mono, TAB or specialist boom and dipper

combinations (on selected machines)

Optional fixed or hydraulically raised cabs gives an

excellent view into containers

Various hydraulic circuits allow operation of specialist attachments

Wide core radiator gives efficient, trouble-free cooling

Additional air filtration for cab and engine enhances machine and

operator protection in fibrous environments

Proven reliability, specialist features and extra guards make JS Wastemaster

wheeled excavators extremely popular in waste rehandling industries. A

choice of fixed raised or hydraulically raised cabs give the operator an

unimpaired view into containers, hoppers or waste bulkers. There is also a

wide choice of boom and dipper options including mono, TAB or specialist

materials or scrap handling rigs.

Take the 25 tonne materials handler as an example. This robust workhorse

is purpose-designed for the toughest of all re-handling environments. It

offers nearly 12m of reach and four stabilisers for reassuring stability, while

solid tyres protect against punctures resulting in maximum uptime.

The range of specialist attachments for these machines makes them an

even more versatile investment. So for instance, fitted with a selector grab

you’ll find that a wheeled excavator is an effective machine for picking and

sorting incoming material. Fitted with an orange peel grab, the machine

becomes a bulk loader.

Add a compaction wheel to help maximise loads in containers and you will

achieve compaction rates of up to three or four times, subject to material,

reducing necessary movements and costs to the operation.

The mobility of a wheeled excavator enables the machine to quickly move

around a working site and fitted with a quickhitch, the machine could be

picking and sorting one minute and compacting material in bins the next.

All the machines in the JS Wastemaster wheeled range feature powerful,

turbocharged Tier 3 Isuzu engines, renowned for reliability, durability and

fuel efficiency, with low noise and gas emissions. They also boast an

enhanced Advanced Management System (AMS) which puts you in total

control of extra power and precision.

WASTEMASTER | Wheeled excavators

Wheeled loading

shovels

Large capacity standard or hi-tip refuse buckets mean

more material shifted in less time

Optional limited slip differentials add to already

superb traction or effortless climbing

JCB Smooth Ride System option keeps more of

the load in the bucket

Best-in-class super-high-lift arms give superb reach

and clearance when loading high-sided bulkers

4-ram geometry on HT models and the largest cab

on the market ensure excellent visibility

JCB Wastemaster wheeled loading shovels are some of the most robust

and reliable machines available. With the traction and brute power you

need to get waste right to the top of stockpiles and the large capacity refuse

buckets – some with top grabs to ensure good material capacity and

retention – to make small work of big loads, these machines are indispensable

in recycling and rehandling operations the world over.

The sturdy design is of course common to all JCB wheeled loaders.

Wastemaster models add extra guarding for the cab and lighting, also

including underbelly guarding for added protection of the driveline and

transmission, limited slip differentials are available for even greater traction

and heavy-duty, puncture-resistant tyres help minimise downtime in harsh

waste applications.

The optional JCB Smooth Ride System makes life more comfortable for

the operator and helps to keep the load in the bucket, whilst reversing

alarms and reversing cameras, not forgetting a flashing beacon and high

visibility chevrons, ensure the machine is safe and highly visible on site.

Optional high-lift and super high-lift loader arms or hi-tip buckets give

additional reach and plenty of clearance for effortless loading of high sided

bulkers. Plus, 4-ram geometry on HT models and a fully glazed cab ensure

excellent visibility.

With operator comfort firmly in mind, JCB wheeled loaders boast

the largest cab on the market, with features like servo controls, low

noise levels and additional air filtration and air conditioning. The

sophisticated Electronic Monitoring System continually monitors the

machine throughout long, arduous days and immediately reports any

potential problems to the operator.

Additional air filtration, not only for the cab but also for the engine, combined

with wide core radiators and reversing fans, ensure maximum cooling is

maintained in these extremely dusty environments.

WASTEMASTER | Wheeled loading shovels

Telemaster

Combination of telescopic handler and articulated chassis equals

superb materials handling and manoeuvrability

Fully integrated JCB driveline gives power, economy,

low noise levels and durability

Variflo hydraulics give increased flow and efficiency

Large cab and central seating position provide

superb all-round visibility

Special Wastemaster package of features tailors the machine to

more arduous waste rehandling applications

The TM310 has all the attributes of a telescopic handler but with the

articulated steering of a wheeled loader. It offers over 3-tonne lift capacity

to a full height of over 5 metres, with a load capacity of over 2 cubic metres

for typical waste material. All combined with the superb manoeuvrability

you need in often-restricted rehandling operations.

The performance of this machine in waste applications is incredible. First,

we’ve installed the four-cylinder turbo JCB Dieselmax Tier 3 engine. Part

of a fully integrated JCB driveline, this provides excellent power, economy,

low noise levels and durability. Four-wheel drive is permanently engaged

and the Powershift transmission features selectable operating modes and

auto-shifting, enhancing machine versatility.

Second are the variflo hydraulics which use a single piston pump with flowon-demand variable output for superb machine efficiency and increased

flow. And then there is the proportional control of auxiliary services which

gives you finer control when operating attachments.

A large cab with a central seating position results in truly outstanding all-round

visibility. This is enhanced by a deeper glazed area, a one-piece windscreen

giving clear forward vision over the low boom pivot, and a narrow pillar

between the windscreen and full-width roof keeping potential blind spots at

loading height to a minimum.

The standard TM310 machine is an impressive machine and that’s before

you add the special, additional Wastemaster features. In a package similar to

that designed for our wheeled loaders, the TM310 benefits from a cab

heater, suspension seat, underbelly guarding, front light guards, aspirator air

cleaner, reverse travel alarm, heavy-duty battery and engine sump drain kit,

all as standard. Optional extras include limited slip differentials for extra

traction, the Smooth Ride System to keep the load in the bucket at ground

level or height, additional worklights and more.

WASTEMASTER | Telemaster

Loadalls

Smallest Loadall provides access to closed-top

containers and restricted plants

Full-size models offer ground-level and high-reach capabilities for

stockpiling waste and loading high bulkers

A bucket with top grab ensures excellent load retention

3- to 4-tonne lift capacity and up to 7 metres lift height means these

machines can tackle most handling tasks

Additional Wastemaster features include extra

guarding and full air conditioning

The JCB Wastemaster range of Loadalls begins with our compact models.

Similar in size to a small saloon car, these useful little machines are capable

of accessing closed-top containers and restricted plants or ELV stations. They

can offer nearly 3 tonnes of lift capacity and over 5 metres of lift height, plus

a standard quickhitch lets you easily change from forks and rotator to a barrel

clamp for example, rehandling drums of fluids, oils and lubricants, ideal for

ELV applications.

With their heavy-duty construction, 3- to 4-tonne lift capacity and up to 7

metres lift height, full-sized Wastemaster Loadalls are robust enough to

thrive in the toughest conditions. Their ground-level and high-reach

capabilities are ideal for stockpiling waste and loading high bulkers. Complete

with forks or buckets they also work effectively with rotators for emptying

stillages, while a bucket with top grab ensures excellent load retention to

maximise productivity.

In essence, Wastemaster Loadalls are the perfect balance between dedicated

ability and instant versatility. They have a proven track record for multi-tasking

in civic amenity sites or materials recycling facilities, while in composting

operations or in transfer stations they also make effective use of specialist

refuse or recycling buckets and grabs. Yet their inherent versatility means they

can also undertake general duties such as collecting refuse, compacting and

pallet handling.

A superb combination of all-round visibility, low-effort control and impressive

reach performance, Wastemaster models also offer additional features like

extra guarding, air conditioning and all sorts of optional extras making them

top of the list for customers looking for value for money.

WASTEMASTER | LOADALLS

Teletruk

Ability to lift up to 3.5-tonne loads lets you load

more into trucks and containers at one time

Forward reach can reduce need for loading space by

up to 50% and can load from one side

Turning radius under 3 metres aids performance in tight areas

Unique telescopic loader arm results in superb visibility, reach and

freelift capabilities without restriction

111° of tilt for the forks help keep awkward loads

securely on the forks during transit

JCB Teletruks are unique in that, unlike any other counterbalanced forklift,

they offer genuine forward reach.

Their ability to lift up to 3.5-tonne loads to the 2 metres forward reach

allows you to load more into trucks and containers at one time, as well as

enabling easy and safe positioning of cars into depollution rigs. The forward

reach can reduce the need for loading space by up to 50%, plus it eliminates

the need for turning trailers to gain access to the other side. A turning radius

under 3 metres further aids the ability to perform in tight areas.

All of this makes the Wastemaster Teletruk ideally suited to kerbside recycling,

scrap rehandling and materials handling functions. The versatility of these

machines is increased even further with a whole host of attachments,

including a bale clamp, a variety of forks and buckets, a 360° rotator for quick

and simple unloading, and much more. You can also opt for twin wheels too

for extra stability in tougher conditions such as ELV applications.

The Teletruk’s unique telescopic loader arm rather than a typical forklift mast

results in superb visibility for the operator. It is safer on site too, with clear

visibility when loads are down low. No mast enables some models to access

in and out of closed-top containers without the interference you get with a

conventional mast, and once inside freelift capability is a distinct advantage.

The Teletruk also offers 111° of tilt for the forks, ideal for keeping heavy,

awkward loads securely on the forks during transit, and can be fitted with a

left/right 360° rotator for precise balancing of loads or for tipping containers

full of frag.

WASTEMASTER | Teletruk

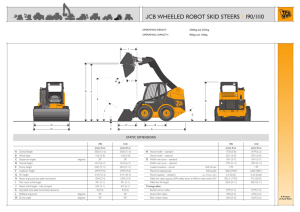

Skid steer loaders

Ability to lift up to 3.5-tonne loads lets you load more

into trucks and containers at one time

Forward reach can reduce need for loading space by up to

50% and can load from one side

Turning radius under 3 metres aids performance in tight areas

Unique telescopic loader arm results in superb visibility,

reach and freelift capabilities without restriction

111° of tilt for the forks help keep awkward loads

securely on the forks during transit

Most waste and recycling operations are hampered by extremely confined

sites and therefore welcome machines with compact dimensions and good

manoeuvr­ability. Enter the JCB Wastemaster skid steer loaders.

With direction changes achievable within the machine length, these machines

nip around restricted sites with ease. Their compact dimensions mean they

are at home inside and out, and are even able to access closed containers.

The unique single tower on these machines also vastly improves visibility

even in the tightest areas allowing the operator to see his colleagues and

any obstacles in good time.

The single-arm design, an industry first when we introduced it, provides the

operator with the safest way of accessing the cab, doing away with the need

to climb over awkward attachments or stillages. Plus, a single chain case is

designed onto the right side of the machine, eliminating the left-hand chain

case and making for even safer cab access.

Inside the cab, you will find an ergonomic layout and an easy-to-use,

operator friendly machine. Excellent controllability, including a choice of

three industry-recognised control patterns to suit your preference, puts

you in total charge. Additional operator and cab protection can be assured

with the fitment of a front screen or metal protection bars.

Punctures are obviously a concern in waste applications and therefore JCB

Wastemaster skid steer loaders are available with a selection of wheels and

tyres offering increased puncture protection. Machine protection is offered

by the fitment of wrap-round rear bars protecting the rear door and the

engine compartment from on-site damage.

Plus, skid steers can also be fitted with attachments, such as a bucket or

forks with a top clamp to help load retention, or a sweeper collector to

keep everything tidy.

WASTEMASTER | Skid steer loaders

A few words about JCB

A groundbreaking, class-leading

family business with a commitment

to supporting our customers and

protecting the environment

A family company on a global scale. JCB is no ordinary company.

From the dreams of one man, Joseph Cyril Bamford, we have grown into

the world’s largest privately owned construction company by volume.

Since 1945, the same attention to detail, passion for progress and family

spirit has taken us from strength to strength.

Nowadays JCB operates across all five continents, manufacturing at 17

factories in the UK, Brazil, Germany, China, North America and India.

With 1,500 dealerships and depots selling and supporting our products

in over 150 countries, we are one of the top three manufacturers of

construction equipment with some of the finest engineering facilities in

the world.

A history of world-class innovation. Our business has always been

driven by innovation, using only the most advanced technology, components

and processes, meticulous design and rigorous testing. In heavy products

this has meant one of our largest investments to date, £40 million, into a

new factory dedicated to producing large excavators. Here, with a team of

industry experts and machine specialists, we’re designing and developing

the heavy machinery of the future.

Sustainability in all we do. As a manufacturer of working machinery,

operating in both established and emerging markets, we accept the

challenge of helping to deliver economic and environmental sustainability.

Product innovations that provide the right solutions to our customers

have been a vital part of our history and will be key to our sustainable

future. But in addition to developing cleaner and more efficient machines,

we have a commitment to ensuring our manufacturing facilities meet the

highest environmental standards.

A commitment to our customers that goes on and on. That’s a fact

we remind ourselves of constantly, and it’s the reason our customers are

at the heart of everything we do. Whatever a customer needs, we make it

our mission to provide world-class support and 100% satisfaction.

At the heart of this is a dedication to minimising machine downtime.

So our state-of-the-art World Parts Centre dispatches more than a million

genuine parts and attachments every week, with an ‘Anywhere in 24

hours’ strategy. Our JCB-trained technicians provide excellent, expert

customer care, whether it’s routine servicing or something more urgent.

And we are constantly looking at new, innovative ways to help you get the

most out of your machine.

JCB | A FEW WORDS

The best back-up in the business

Whether we’re providing you with

support, parts or finance, we aim for

100% satisfaction. It’s all part of our

promise to put you, the customer, first

Wherever you are, we are. Our mission to provide world-class

can benefit your business in many ways, from increasing the security of

support and deliver 100% satisfaction reaches into more than 1,500

your machines to improving fleet utilisation. It can also enable your JCB

dealer depots, spanning 150 countries across five continents. The aim?

dealer to view your machine and guarantee timely servicing of your fleet,

To bring you global expertise at a local level. We truly believe no other

improving uptime.

manufacturer does more to understand the subtle differences between

one region of the world and another. It’s a degree of attention that we

maintain at every level of the company and an assurance to our customers

that wherever they are in the world, JCB will fulfil their needs.

Trust the genuine article. At the heart of the support network is our

impressive World Parts Centre, a state-of-the-art facility operating 24/7 to

dispatch more than a million genuine parts and attachments every week to

our dealers and international distribution centres. Because we understand

the need to minimise downtime, we utilise the latest logistics and

warehouse management systems and have committed to an ‘Anywhere in

24 hours’ strategy.

Keeping you up and running. Just as important as genuine JCB parts

are the people who fit and maintain them. Our JCB-trained technicians in

all of those 1,500-plus dealer depots provide excellent, expert customer

care, whether it’s routine servicing or something more urgent. If there is

an emergency breakdown situation, we need to act fast. This is why all

our dealers operate their own fleets of support vehicles, enabling parts to

That’s why, at JCB, we are committed to offering expert financial advice

and support to help customers maximise their earning potential.

be delivered quickly and fitted expertly, and fulfilling our promise to keep

Finance options* are available for new and used machinery, all part of

our customers working.

our dedication to helping customers preserve their working capital while

Advanced technology. At JCB, we are constantly looking at new,

Manufacturing Facilities

Dealers

Parts Distribution Centres

Maximising earning potential. We grow as our customers grow.

spreading costs in the most effective and tax-efficient way.

innovative ways to help you get the most out of your machine. Our latest

And as well as financial help, we are also happy to offer JCB Insurance.*

development is JCB LiveLink, an advanced telematics system using satellite

We specialise in construction and industrial insurance and in offering

and cellular technology that enables you to better protect your machine

Insurance Premium Finance facilities.

and accurately monitor and improve its performance. Using JCB LiveLink

* Please check individual countries for available services.

JCB | BACK-UP

JCB Sales Limited, Rocester, Staffordshire, United Kingdom ST14 5JP. Tel: +44 (0)1889 590312 Email: salesinfo@jcb.com

Download the very latest information on this product range at: www.jcb.com

©2009 JCB Sales. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB Sales.

JCB reserves the right to change specifications without notice. Illustrations and specifications shown may include optional equipment and accessories. The JCB logo is a registered trademark of J C Bamford Excavators Ltd.

9999/5363 07/10 Issue 2