DL8000

Product Data Sheet

D301255X012

June 2016

DL8000 Preset

The DL8000 Preset is a rugged electronic preset that

provides precise custody transfer batches for petroleum,

industrial chemicals, and other products. It accepts

volumetric and mass inputs from turbine, Coriolis,

ultrasonic, or other flow measurement devices using single

or linearized meter factors. (Pulse-generating meters are

recommended for improved valve closure accuracy.)

Temperature Compensation

The DL8000 can accept an input from an Analog Input or

RTD device. It then calculates a temperature volume

correction factor in accordance with the following

standards:

Hydrocarbon Standards

The DL8000 also performs density, temperature, and

pressure corrections using the latest standards and

accurately calculates delivered volumes at standard

conditions (60°F, 15°C, 20°C, or user-selectable) using

double precision math. The DL8000 can control and blend

up to four products sequentially or simultaneously (ratio

blending). It can control up to 10 additives through metered

injection, and can store up to 30 recipes for blending.

Density Correction

The DL8000 accepts density signals as a frequency, 4–20

mA, or through a communications device. It accepts inputs

from a flowing density meter (such as a Micro Motion

frequency densitometer or a Micro Motion Coriolis meter).

The DL8000 corrects observed density to standard

conditions and calculates the temperature and pressure

volume correction factors.

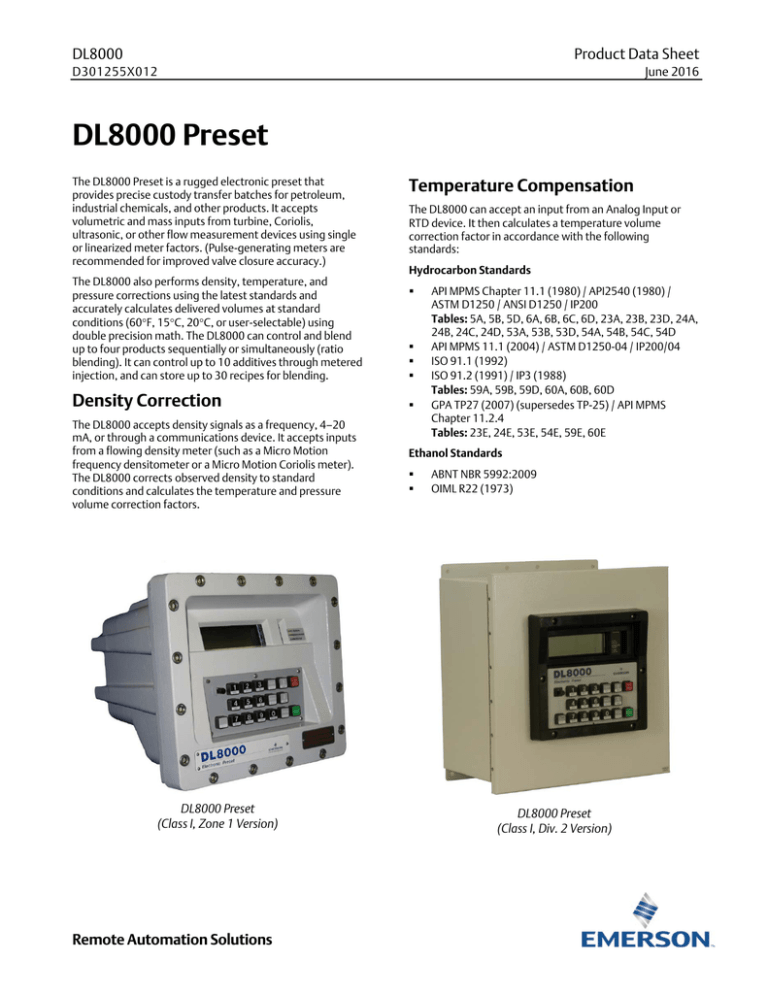

DL8000 Preset

(Class I, Zone 1 Version)

Remote Automation Solutions

API MPMS Chapter 11.1 (1980) / API2540 (1980) /

ASTM D1250 / ANSI D1250 / IP200

Tables: 5A, 5B, 5D, 6A, 6B, 6C, 6D, 23A, 23B, 23D, 24A,

24B, 24C, 24D, 53A, 53B, 53D, 54A, 54B, 54C, 54D

API MPMS 11.1 (2004) / ASTM D1250-04 / IP200/04

ISO 91.1 (1992)

ISO 91.2 (1991) / IP3 (1988)

Tables: 59A, 59B, 59D, 60A, 60B, 60D

GPA TP27 (2007) (supersedes TP-25) / API MPMS

Chapter 11.2.4

Tables: 23E, 24E, 53E, 54E, 59E, 60E

Ethanol Standards

ABNT NBR 5992:2009

OIML R22 (1973)

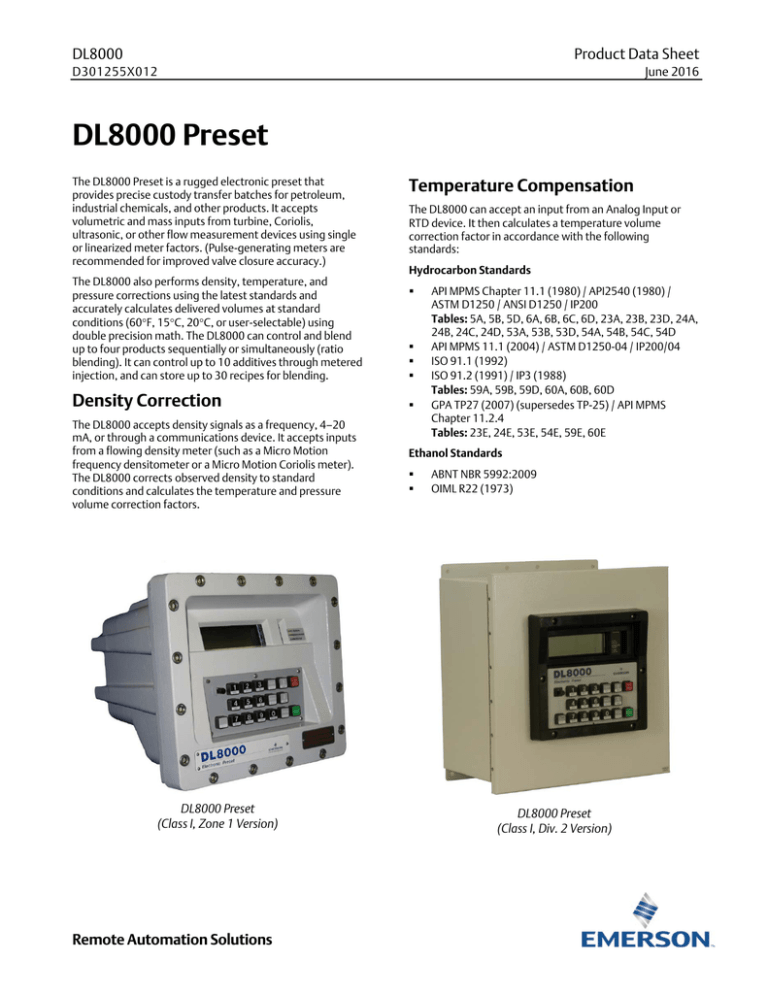

DL8000 Preset

(Class I, Div. 2 Version)

DL8000

June 2016

Pressure Compensation

The DL8000 can accept a 4–20 mA signal from a pressure

transducer and compensate flow calculations for

volumetrics due to pressure in accordance with the

following standards:

API MPMS 11.1 (2004) / ASTM D1250-04 / IP200/04

API MPMS 11.2.1

API MPMS 11.2.2

API MPMS 11.2.1(M)

API MPMS 11.2.2(M)

Pulse Fidelity

The DL8000 monitors dual pulse inputs for integrity in

accordance with the following standards:

ISO 6551-1982 and BS 6439-1983

API Petroleum Measurement Standard, Chapter 5.5,

level B and Institute of Petroleum Standard, IP 252.76,

Part XIII, Section 1, Level B.

Meter Factor Linearization

The DL8000 can perform linearization of meter factors and K

factors using up to 12 points to ensure accuracy over the

entire range of flow.

Reporting

The DL8000 generates reports in compliance with NIST

Handbook 44 – 2006 Edition and 2003 Update and NCWM

Publication 14.

Other Features

Archival storage of 200 transactions with up to four

batches each and 450 alarms.

Storage of the last 1000 weights & measures events (in

accordance with NIST Handbook 44).

Integral Weights & Measures switch.

Independent permissive sensing AC power.

Digital valve control with automatic high flow rate

recovery.

Independent temperature compensation methods for

individual products.

Automatically sensing or user-entered values for

thermal expansion and linear equation.

User-entered vapor pressure of light hydrocarbons.

Operations

The DL8000’s user-friendly multi-language display prompts

the operator through the entire loading sequence, assuring

a safe and reliable loading operation. The loading sequence

starts after the operator connects the safety circuits, selects

a recipe, enters a preset quantity, and presses the Start

button. The DL8000 automatically turns on the required

product pumps and additive injection equipment and opens

the digital flow control valves.

2

A low-flow start sequence can be initiated to reduce static

build-up when delivering petroleum products. To keep

loading time to a minimum, the DL8000 automatically

maintains the highest possible flow rate the system can

deliver. When additives are present, the maximum flow rate

is 2700 units/minute. Three different flow profiles for each

recipe provide maximum system flexibility regardless of the

meter size. When certain recipes require small percentages

of one or more components, you can configure the

programmable flow profiles to automatically deliver smallpercentage component(s) only during the high flow stage of

the delivery.

As the end of the batch sequence approaches, the

component streams slow to a pre-defined low-flow/stop

flow rate. The high-speed digital valve control algorithm,

working in conjunction with the linear digital control valve,

ensures a smooth, repeatable, low-flow/final stop without

line shock.

To assure product quality, you can program an automatic

single product line-flush sequence at the end of the delivery

to flush the loading arm with a single base product.

Blend Recipes

Memory allows up to 30 blend recipes. Each recipe has

individual totalizers and is highly configurable, providing

maximum flexibility.

Linearization

Multi-point linearization is programmable with up to 12

points. The DL8000 automatically interpolates between the

12-meter factor setpoints to assure system accuracy over

the required flow ranges.

Vapor Recovery

Measures the amount of returned or recovered vapor during

the loading of light hydrocarbons, and computes the Net

delivered for billing purposes. This feature is available for

mass delivery only and the delivered quantity will be equal

to the preset amount.

In addition, GPA TP-15 allows the DL8000 to calculate and

maintain the back pressure above the vapor pressure during

loading. This reduces vapor pressure loss and emissions.

Metered Additive Injection

Measures and controls the additive amount injected into the

product stream for up to ten additives. The injection site can

be selected as either upstream or downstream, and the

additive amount can be included in total or in addition to

the delivered quantity.

www.EmersonProcess.com/Remote

DL8000

June 2016

DanLoad 6000 Protocol Support

I/O Modules

The DL8000 supports all terminal automation commands

necessary for terminal operation and some for terminal

automation configuration. This allows you to multi-drop

your existing DanLoad 6000s with the DL8000 without

changes to the host.

The DL8000 supports a variety of I/O modules. You can add

up to nine optically isolated I/O modules as needed to

satisfy a wide variety of field I/O requirements. Available

modules include:

Swing Arm Position Detection

The DL8000 allows swing arm safety circuit operation, and

you have the option to select which side (one, two, or both)

is applicable per circuit.

Alarms

The DL8000 offers comprehensive alarms for blending

systems. You can define each alarm action for no action,

display only, close relay contact, stop loading process, or

lock the unit. Built-in programmable alarm conditions are

also user-selectable. You can also configure the reference

base temperature for compensation corrections.

Alternating Current Input/Output (AC I/O)

Advance Pulse Module (APM) with densitometer

processing

Analog Inputs (AI)

Analog Outputs (AO)

Discrete Inputs (DI)

Discrete Outputs (DO)

Discrete Output Relay (DOR)

HART Input/Output (a maximum of 5 modules)

Pulse Inputs (PI) – High or Low speed

RTD Inputs (RTD)

Note:

CE approved I/O configurations are shown in the

Approvals section of the specifications table.

Data Security

Product Options

Data is secured with a 4-digit user-defined access code. All

calibration data is secured with the access code and a wiresealable mechanical security switch that is integrally

mounted in the DL8000 keypad.

The DL8000 product options consist of a Class I, Zone 1

flameproof version and a Class I, Division 2 Type 4 version.

Both versions contain the same keypad and display.

Data Communications

The DL8000 has three built-in communication ports. The

unit can support up to three additional ports (via optional

communications cards) for a total of six ports. The built-in

communication ports are:

Local Operator Interface (RS-232D) – LOI.

Ethernet – Comm1.

EIA-232 (RS-232) – Comm2.

The Local Operator Interface (LOI) port’s standard RJ-45

connector provides an EIA-232 (RS-232D) link between the

CPU and a PC. Use ROCLINK™ 800 Configuration software to

configure the CPU, extract data, and monitor its operation.

All DL8000 ports support Modbus slave protocol; master

protocol is supported on all but the LOI and Ethernet ports.

Communications Modules

You can install up to three additional communication

modules in the DL8000 to provide ports for communicating

with a host computer or other devices. The DL8000

accommodates the following module types, in any

combination:

EIA-232 (RS-232).

EIA-422/EIA-485 (RS-422/RS-485).

Dial-up modem.

www.EmersonProcess.com/Remote

The Class I, Zone 1 version includes a cast aluminum casing

with sixteen stainless steel front cover bolts (M10 – 1.5

metric) that secure the lid to the housing. With the front

cover bolts removed, the lid hinges down to reveal the

electronic compartment. It is flame-proof (in accordance

with Class I, Zone 1, Groups IIB) and weatherproof (rated

IP66). The viewing window in the enclosure lid is made from

non-glare glass.

The Class I, Division 2 version includes a 14 gauge stainless

steel box with 12 gauge stainless steel mounting flanges.

The door is made of .090 inch thick aluminum and is secured

to the box via a stainless steel piano hinge and two stainless

steel spring latches. The latches include features for

padlocking or installing wire seals. The assembly includes a

door stop that locks the door in position at approximately

120 degrees from the closed position. The viewing window

in the enclosure door is made from scratch / UV resistant

polycarbonate/acrylic blend (PC/PMMA). The keypad bezel

is mounted to the front of the door and is made from UV

resistant polycarbonate. The assembly is rated by CSA as a

Type 4 enclosure.

The operator keypad is the same for both versions and

provides 18 rugged, Hall-effect push keys which are

impervious to chemicals commonly associated with

petroleum applications. A sealable Weights & Measures

switch provides security to flow measurement parameters.

3

DL8000

June 2016

The liquid crystal display (LCD) is the same for both versions

and provides an 8-line by 40-column message area for

operator interface. The display uses a photo sensor and

temperature sensor which can be set to automatically adjust

contrast and backlighting for optimal viewing.

Light-emitting diodes (LEDs) display the status of alarms,

operating mode, and permissive powers. LEDs are located to

the right of the display on both versions.

Measurement Canada

Measurement Canada is available for the DL8000. The

Measurement Canada version of the DL8000 consists of a

CPU loaded with a Measurement Canada-approved

firmware, a power module, and 9 communications and/or

I/O modules housed in either cast aluminum casing or

stainless steel box with keypad and LCD display.

Measurement Canada approves the following firmware and

user program versions:

4

DL8000 firmware version 2.31

Liquid Calcs version 2.31

Transaction History version 2.33

Printer version 2.31

Additives version 2.30

Batching version 2.34

Keypad Display Version 2.34

www.EmersonProcess.com/Remote

DL8000

June 2016

DL8000 Common Specifications

Processor

Type

32-bit microprocessor based on the Motorola MPC862 Quad Integrated Communications

Controller (PowerQUICC™) PowerPC processor running at 65 MHz

Memory

Boot Flash

256 KB for system initialization and diagnostics

Flash

16 MB for firmware image

SRAM

2 MB for historical data logs and configuration

Battery Backup

Synchronous DRAM

User-replaceable

Type

Sanyo 3 V CR2430 lithium

Normal use life

10 years while power is applied to unit

Backup life

1 year minimum while maintaining SRAM and RTC

data and no power is applied to unit

Shelf life

10 years (jumper disengaged)

32 MB for firmware execution and execution memory

Time Functions

Clock Type

32 KHz crystal oscillator with regulated supply, battery-backed, Year/Month/Day and

Hour/Minute/Second

Clock Accuracy

0.01%

Watchdog Timer

Hardware monitor expires after 3 seconds and resets the processor

Communications

On Board

EIA-232 (RS-232)

Port

Ethernet Port

LOI Port

Modules (optional)

EIA-232 (RS-232)

Module

EIA-422/485

(RS-422/485)

Module

www.EmersonProcess.com/Remote

Type

Single

Maximum Data

Rate

115.2 k bps

10BASE-T twisted pair. IEEE multi-segment 10 MB/second baseband

Ethernet.

Maximum

Segment

100 m (330 ft).

Type

EIA-232D (RS-232D) Standard

Maximum Data

Rate

115.2 k bps

Type

Single

Maximum Data

Rate

115.2 k bps

Type

Single

Maximum Data

Rate

115.2 k bps

5

DL8000

June 2016

Dial-Up Modem

Module

Note:

Type

Single

Maximum Data

Rate

115.2 k bps

For more information about optional communications modules, refer to Technical

Specifications ROC800:COM.

Inputs/Outputs

On Board

Modules (optional)

Board Temperature

Accuracy

1% typical, 2% maximum

Voltage Monitor

Accuracy

0.75% typical, 1% maximum

Analog Input-12

4 channels, 12 bits of resolution. For more information, refer to

Technical Specifications ROC800:AI.

Analog Input-16

4 channels, 16 bits of resolution. For more information, refer to

Technical Specifications ROC800:AI.

Alternating Current

I/O

6 channels. For more information, refer to Technical Specifications

ROC800:ACIO.

Advance Pulse

Module

4 channels, 4 single or 2 dual (one configurable as a densitometer

input and one as a pulse output). For more information, refer to

Technical Specifications ROC800:APM.

Analog Output

4 channels. For more information, refer to Technical Specifications

ROC800:AO.

Discrete Input

8 channels. For more information, refer to Technical Specifications

ROC800:DI.

Discrete Output

5 channels. For more information, refer to Technical Specifications

ROC800:DO.

Discrete Output

Relay

5 channels. For more information, refer to Technical Specifications

ROC800:DOR.

HART Input/Output

4 channels, each capable of communications with up to 5 HART

devices (when in input multi-drop mode). Supports up to 5 HART

modules in slots 1-5. For more information, refer to Product Data Sheet

ROC800:HART2.

Pulse Input

2 channels, user-selectable high speed or low speed per channel. For

more information, refer to Technical Specifications ROC800:PI.

RTD Input

2 channels. For more information, refer to Technical Specifications

ROC800:RTD.

Power

Requirements

115 to 240 V ac (+ 10%/– 15%), 50 to 60 Hz, 1-phase 30-watt nominal

Physical

Keypad

18 rugged, Hall-effect push keys which are impervious to chemicals commonly associated

with petroleum applications. A sealable Weights & Measures switch is incorporated into the

front panel to provide security to flow measurement parameters.

Display

A single, 8-line by 40-column super-twist LCD display. Status LEDs identifying alarm,

permission power, and operational mode (Auto or Manual).

6

www.EmersonProcess.com/Remote

DL8000

June 2016

Wiring

Size 12 to 22 AWG for terminal blocks

Environmental

Temperature

Operating

–20°C to +65°C (–4°F to +149°F)

Certified by NMI

–25°C to +55°C (–4°F to +131°F)

Note:

Storage

(non-operating)

Class I, Zone 1 version only

–30°C to +80°C (–22°F to +176°F)

Relative Humidity

5 to 95 percent (non-condensing)

Radiated/Conducted Immunity

Meets requirements of IEC 61326 Electrical Equipment for use in industrial locations

Class I, Zone 1 Version Specifications

Physical

Construction

Cast aluminum enclosure with sixteen stainless steel front cover bolts

Dimensions

Height

330 mm (13 inches)

Width

355 mm (14 inches)

Depth

366 mm (14.4 inches)

Weight

34 kg (75 pounds)

Wiring Access

Center

50 mm (2 in.) female NPSM; normally used for all DC signal (meter pulse, RTD,

analog, communication, or status/control) cabling

Left

25 mm (1 in.) female NPSM; normally used for AC power input and AC

status/control signals

Right

25 mm (1 in.) female NPSM; normally used for meter pulse, RTD,

communication, or analog signals when separate signal routing is required

CSA CUS

Certified by CSA as Models W40161 and W40209 per CSA certification number

1859870

Approvals

Product Markings for

Hazardous Locations

Product Markings: Ex d IIB T6, AEx d IIB T6 (-40°C ≤ T ≤ 65°C ), IP66

Class I, Zone 1, Groups IIB flame-proof

Evaluated per Approval

Standards

www.EmersonProcess.com/Remote

ANSI/IEC 60529:2004

ANSI/UL 60079-0-2005

ANSI/UL 60079-1-2005

CAN/CSA-C22.2 No 0-M91

CAN/CSA-C22.2 No 94-M91

CAN/CSA-C22.2 No. 60079-0-07

CAN/CSA-C22.2 No. 60079-1-07

CAN/CSA-60529:05

CSA Std C22.2 No 142-M1987

CSA Std C22.2 No 213-M1987

UL 50 (11th Ed.)

UL 916 (3rd Ed.)

UL 1604 (3rd Ed.)

7

DL8000

June 2016

CE / ATEX

Certified by IEC IECExas Model W40176 per certification number IECEx SIR

08.0019

Certified by Sira as Model W40176 per certification number SIRA 08ATEX1063

Product Markings: Ex d IIB T6 (-40°C ≤ T ≤ 65°C), IP66

II 2 G

Note:

0081

Temperature range for LCD Display is -20°C ≤T ≤65°C

Evaluated per Approval

Standards

Product Marking for

Metrology

Measurement

(Industry)

Canada

Certified by Measurement Canada as DL8000.

Approval No.: AV-2426C

NTEP

Certified by NTEP as Model W40161 per certificate number 08-056A1

Evaluated per Approval

Standards

NMi

(MID Standards)

Valid I/O Configurations for MID Approval:

To maintain CE approval, you can only use the following I/O modules

connected to the valid I/O types as shown in the table below.

Review the corresponding certificates to ensure full compliance.

I/O Modules

I/O Type 1

I/O Type 2

AI-12

Pressure

Density

DI

Feedback Signals

RS 485

Communication

RTD

Temperature

DO

Control Signals

APM

Pulse In (level B)

HART

Temperature

AC I/O

Control Signals

(output)

Evaluated per Approval

Standards

8

NIST Handbook 44 (2010)

NCWM Publication 14 (2010)

Certified by NMi as DL8000 per certificate number TC7661 revision 1

Miscellaneous Approvals

IEC 60079-0 : 20ll ed. 6

IEC 60079-l :2O07-04 ed. 6

EN 60079-0:2012

EN 60079-1:2007

Feedback Signals

(input)

OIML R117-1 Edition 2007 (E)

WELMEC guide 8.8

GOST

Certified by Gosstandart as Models W40176 and W40161 per certification

number 8468248

INMETRO

Certified by INMETRO as Model 40176

NCC 14.2252

Marking: Ex d IIB T6 (-40°C ≤ T ≤ 65°C) Gb IP66

www.EmersonProcess.com/Remote

DL8000

June 2016

Class I, Division 2 Version Specifications

Physical

Construction

14 gauge, painted, stainless steel enclosure with 3 mm (0.12 inches) thick aluminum door

and stainless steel spring catches

Dimensions

Height

432 mm (17 inches)

Width

410 mm (16.14 inches)

Depth

276 mm (10.86 inches)

Weight

16 kg (36 pounds)

Wiring Access

Center

Two 35 mm (1.375 inches) diameter holes for customer supplied 1inch Type 4 rated conduit hub; normally used for I/O. Four additional

center punch locations included to aid customer placement of

additional entries.

Right

35 mm (1.375 inches) diameter hole for customer supplied 1-inch Type

4 rated conduit hub; normally used for AC power input and AC

status/control signals.

CSA CUS

Certified by CSA as Model W40201 per CSA certification number

1859870

Approvals

Product Marking for Hazardous

Locations

Class I, Div. 2, Groups A, B, C, D T4 (-25°C ≤ T ≤ 70°C )

Evaluated per Approval

Standards

CE / ATEX

ANSI/IEC 60529:2004

ANSI/UL 60079-0-2005

ANSI/UL 60079-1-2005

CAN/CSA-C22.2 No 0-M91

CAN/CSA-C22.2 No 94-M91

CAN/CSA-C22.2 No. 60079-0-07

CAN/CSA-C22.2 No. 60079-1-07

CAN/CSA-60529:05

CSA Std C22.2 No 142-M1987

CSA Std C22.2 No 213-M1987

UL 50 (11th Ed.)

UL 916 (3rd Ed.)

UL 1604 (3rd Ed.)

Certified by Sira as Model W40208 per certification number SIRA

11ATEX4040X

Product Markings: Ex nA IIC T4 (-20°C ≤ T ≤ 70°C ) Gc

II 3 GD

Evaluated per Approval

Standards

EN 60079-0:2006

EN 60079-0:2009

EN 60079-15:2005

EN 61241-0:2006

EN 61241:2004

RoHS (China)

Product Markings for Metrology

Measurement

(Industry) Canada

www.EmersonProcess.com/Remote

Certified by Measurement Canada as DL8000.

Approval No.: AV-2426C

9

DL8000

June 2016

NTEP

Certified by NTEP as Model W40201 per certificate number 08-056A1

Evaluated per Approval

Standards

10

NIST Handbook 44 (2010)

NCWM Publication 14 (2010)

www.EmersonProcess.com/Remote

DL8000

June 2016

For customer service and technical support,

visit www.EmersonProcess.com/Remote/Support.

Global Headquarters,

North America, and Latin America:

Emerson Process Management

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.EmersonProcess.com/Remote

Europe:

Emerson Process Management

Remote Automation Solutions

Unit 8, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley UK DY5 1LX

T +44 1384 487200 | F +44 1384 487258

Middle East/Africa:

Emerson Process Management

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Asia-Pacific:

Emerson Process Management

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

T +65 6777 8211| F +65 6777 0947

Remote Automation Solutions

© 2007–2016 Remote Automation Solutions, a business unit of Emerson Process

Management. All rights reserved.

This publication is for informational purposes only. While every effort has been made to ensure

accuracy, this publication shall not be read to include any warranty or guarantee, express or

implied, including as regards the products or services described or their use or applicability.

Remote Automation Solutions (RAS) reserves the right to modify or improve the designs or

specifications of its products at any time without notice. All sales are governed by RAS terms

and conditions which are available upon request. RAS accepts no responsibility for proper

selection, use or maintenance of any product, which remains solely with the purchaser and/or

end-user.