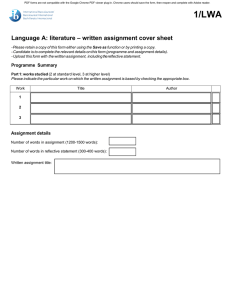

BOEING 737 Classic

advertisement

BOEING 737 Classic -100 / -200 / -300 / -400 / -500 The Green Trailing Edge Flap Ballscrews “The UMBRAGroup ballscrew assemblies were developed to improve the performance and service life of the trailing edge flap ballscrew assemblies, and to incorporate the advance materials and design similar to the ballscrew assemblies installed on Model 777 airplanes. The UMBRAGroup ballscrew assemblies incorporate a new Cronidur 30 induction hardened stainless steel, with load carrying silicon nitrite ceramic balls and Cronidur 30 stainless steel balls as spacers. These new ballscrew assemblies have shown improvement in wear resistance during in-service use. The Cronidur 30 Stainless steel material used for the screw component of the new UMBRAGroup ballscrew assemblies offers improvements in corrosion protection compared to the existing carbon steel ballscrews, without the need of chrome plating.” [Extracted from: Boeing Service Letter 737-SL-27-108-F] No Chrome Plating Means Better Performance A typical chrome plated ballscrew (shown) has been removed from an aircraft after approximately 18,000 FC. Copper Sulphate has been applied to areas of high wear for inspection and analysis. The chrome plate has already worn through to the base material and corrosion has further deteriorated the screw thread radii beyond the allowable limits of the specifications. The screw is Beyond Economical Repair (BER) and will be scrapped and replaced. Chrome break down is the single most prevalent reason for an airline to overhaul or replace their flap ballscrews. Two things happen when the chrome wears through: 1) There is a dramatic increase in wear as the remaining chrome is abraded, and 2) corrosion attacks the base metal as it becomes exposed to the elements. Both conditions combined have a rapid and adverse effect on the ballscrews efficiency, backlash and structural integrity. The Cronidur 30, on the right, has attained more than 75,000 FC. The unique combination of advanced metallurgical technology used for both the ballscrew and ballnut, combined with ceramic load balls, at least, provides a contemporary solution to ballscrew wear out, replacement and maintenance. There is no chrome plating to ever wear through. After a full life cycle test accomplished by UMBRAGroup, all parts were still within the original new unit tolerances. All units tested outlasted the projected life of the aircraft without need for removal, repair or overhaul. 2 1 1 A typical chrome plated ballscrew after approssimately 18,000 FC. 2 A Cronidur-30 ballscrew after more than 75,000 FC and still within the original new tolerance. Wing Position A/C Model Boeing P/N Umbra P/N 1&8 -100 -200 10-61312-23 07314P000-01 -300 -400 -500 10-61312-22 07311P000-02 2&7 all models 10-61312-22 07311P000-02 3&5 all models 10-61312-20 07311P000-01 4&5 all models 10-61312-21 07313P000-01 www.umbragroup.it Excellent endurance under Adverse Conditions Ceramic Load Balls Guarantee Low Wear For the sake of fleet maintenance uniformity, the new 737 UMBRAGroup uses the same lubricant as that used on other Boeing 737 flap ballscrews. The new Cronidur 30 steel, however, has a super-fine microstructure which provides the material with an inherent capability for surviving under poor lubrification conditions. The ceramic load ball configuration enhances the ability to endure less than ideal lubrification without damage to the Conventional ballsrews use steel load balls which are constantly wearing against each other and the plated raceways contributing to early failures. Silicon Nitride balls on Cronidur 30 steel have an extremely low wear rate and are able to carry very high loads. They are combined with steel idler balls which preclude friction and wear from ceramic to ceramic contact. Backlash (mm) .30 Backlash .25 .20 Effici .15 Efficiency .10 .05 0 1000 2000 3000 4 Chrome Plat Cronidur-30 ballscrew components. To compare the behavior of a traditional chrome plated ballscrew with a Cronidur 30 unit, UMBRAGroup performed tests on both, under load with No Lubrification. The results of the tests are displayed above graphically. The chrome plated screw did not survive beyond 1000 FC. The step increase in backlash and precipitous decline in efficiency caused the unit to exceed the torque limiter values, and further testing was aborted. The Cronidur 30 ballscrew exhibited no deterioration in efficiency or backlash until 7,000+FC… a 700% increase over a chrome plated ballscrew. Extending Life – reducing costs. There will be no overhaul costs for Cronidur 30 ballscrews, for the estimated life of the aircraft. Current chrome plated ballscrews must be replaced or overhauled two to three times during the same period. with Cronidur 30 ballscrews you will have no costs for replacement ballnuts, screws, components or for the cost of chrome replating. reduced inventory of repair parts needed for overhaul. reduced need for capital equipment to overhaul and test. eliminates requirement to chrome plate with its environmental constraints. UMBRAGroup world leader in Aerospace Ballscrews manufacture is not only committed to providing the best product at the best price at the right time; we strongly believe that a world leader company has to contribute to the world pollution reduction and create a better environment for all mankind. The successful introduction of Cronidur 30 in the last decade has therefore already drastically reduced adverse environmental impact related to Chrome (Cr+ III, Cr+ VI), Cianite (Cn-) and Cadmium (Cd+). So far more than 8000 aircraft (like Boeing-Airbus–Embraer-Bombardier–etc.) are in service with a total of over 20-plus millions of flight hours of service. Considering that standard technology ballscrews would have required complete Chrome and Cadmium stripping and re-plating at least three times during their life cycle, it is clear that this technological innovation by UMBRAGroup has made, and will continue to make a substantial positive contribution in reducing world pollution. UMBRAGroup is proud to be the innovator and manufacturer of GREEN BALLSCREWS and invites you to add your own contribution to a greener planet by selecting UMBRAGroup for your future ballscrews requirements. www.umbragroup.it