Engagement in Global Environment Preservation, etc.

advertisement

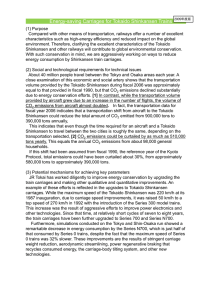

(QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQ 29% Bus Airplane 6% 5% Automobile 52% 7% (passenger-km) 2% Energy 5% 6% consumption 3% CO2 5% emissions 5% 77% 84% 9% 3% Comparison of the Tokaido Shinkansen and Airplane (Tokyo~Osaka) (FY2009) Other Source: Created based on data from Transportation Related Statistics (Ministry of Land, Infrastructure, Transport and Tourism)(Transportation volume/energy consumption), and the National Institute for Environmental Studies Greenhouse Gas Inventory Office of Japan(CO2 emissions). the Tokaido Shinkansen (Series N700 “Nozomi” ) Airplane (B777-200) (tons-CO2) 600,000 CO2 emissions 15,000 Transportation volume CO2 emissions 20,000 300,000 100,000 5,000 0 (FY) 51 300,000 34 200,000 10,000 58 Number of flights (round-trip/day) 400,000 18 18 18 16 19 21 23 23 27 38 40 44 62 61 57 55 55 46 29 20,000 15,000 5,000 ’90 ’91 ’92 ’93 ’94 ’95 ’96 ’97 ’98 ’99 ’00 ’01 ’02 ’03 ’04 ’05 ’06 ’07 ’08 ’09 ’10 ’11 0 (FY) Promoting railway use based on its characteristics of little burden on the global environment volume due to an increase in flights, and consequent CO2 emissions have virtually doubled. If, for argument’s sake, a calculation was made based on FY2011 transportation statistics that assumed that all transportation by airplane was handled by the Tokaido Shinkansen, it would show an actual overall emission reduction of approximately 370,000tons. This corresponds to the yearly CO2 emissions for 72,000 households. Railways have the outstanding characteristic of being highly energy efficient compared to other transport modes and having minimal adverse impact on the global environment. Even though railway accounts for 29% of the passenger transport volume in Japan, it is responsible for only 5% of CO2 emissions. We therefore believe that it is JR Central’s top priority to further improve the environmental superiority of railway in an effort to conserve the global environment and to increase domestic travelers who use railways by enhancing our level of service. Environmentally Superior Mode of the Tokaido Shinkansen Compared with an airplane (B777-200), the Tokaido Shinkansen(Series N700/N700A“Nozomi” ) consumes approximately one-eighth of the amount of energy per passenger seat of air when traveling between Tokyo and Osaka, and discharges about one-twelfth of the CO2 emissions of air.The data show that the Tokaido Shinkansen has overwhelming environmental superiority. Looking at the transportation volume and CO2 emissions for the Tokaido Shinkansen in the Tokyo-Osaka corridor in FY2011, we see that, comparedwith FY1990, CO2 emissions have decreased as a result of our efforts to improve energy efficiency though passenger volume much increased. By contrast, airplanes have shown an increase in transportation 40 40 Even more energy-efficient rolling stock: Series N700/N700A 20 20 ’90 ’91 ’92 ’93 ’94 ’95 ’96 ’97 ’98 ’99 ’00 ’01 ’02 ’03 ’04 ’05 ’06 ’07 ’08 ’09 ’10 ’11 ’12 ’13 (FY) 10,000 Source: Created based on the “Annual Aggregate Air Transportation Report (FY2011)” and the “Transportation Related Statistics” (Ministry of Land, Infrastructure, Transport and Tourism) Fundamental Policies for Engaging in Global Environmental Preservation 60 Energy-conserving rolling stock: Series 300, Series 700 0 Regenerative Braking System 25,000 Source: Created based on the FY2011 Inter-Regional Passenger Mobility Survey (Ministry of Land, Infrastructure, Transport and Tourism) JR Central believes that manifesting the superior qualities of railway, particularly with the Tokaido Shinkansen, results in a contribution to global environmental conservation. Our active approaches are the following two points. First, we reduce direct burden on the environment by developing energy-saving railway vehicles and increasing energy efficiency of railway operations. Second, we encourage many travelers to use railway whose burden on global environment is smaller than any other transportation mode by striving to provide more comfortable transportation services. We believe that such efforts enable us to suppress the environmental footprint of the whole transportation sector and eventually lead to preservation of the global environment. Series 0, Series 100 30,000 100,000 0 60 80 Reduction in Running Resistance (Cover-all hoods) Transportation volume (passenger-km) 100 80 0 (million passenger-kms) 35,000 500,000 25,000 200,000 22 75% CO2 emissions 30,000 Transportation volume (passenger-km) ’90 ’91 ’92 ’93 ’94 ’95 ’96 ’97 ’98 ’99 ’00 ’01 ’02 ’03 ’04 ’05 ’06 ’07 ’08 ’09 ’10 ’11 50 kg-CO2/seat (*2) −25% ● Changes in CO2 Emissions and Transportation Volume (Tokyo~Osaka)〈Airplanes〉 (million passenger-kms) 35,000 400,000 0 −19% About 1/12 of airplane 746 MJ/seat (*2) over FY1990 100 92% 4.2 kg-CO2/seat (*1) About 1/8 of airplane CO2 emissions 500,000 90 MJ/seat (*1) Changes in the Ratio of the Tokaido Shinkansen Energy-Conserving Model Rolling Stock and Unit Energy Consumption 32% improvement 270km/h 100% ● Comparison of CO2 Emission per Passenger Seat ● Comparison of Energy Consumption per Passenger Seat ● Changes in CO2 Emissions and Transportation Volume (Tokyo~Osaka)〈Shinkansen〉 (tons-CO2) 600,000 Comparison of Electric Power Consumption by the Tokaido Shinkansen Rolling Stock Type *1.Calculation based on running performance (JR Central figures) Series N700 “Nozomi” (Tokyo~Shin-Osaka) *2.Calculated by JR Central while referencing ANA’s Annual Report 2011 B777-200 (Haneda~Itami・Kansai Airport) Transportation volume Transportation volume Railway Rolling Stock Ratio (%) Distribution of Transportation Volume, Energy Consumption and CO 2 Emissions Unit energy consumption (Ratio using a FY1990 basis) (QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQHWF Environmental Action Guidelines 1. Provide comfortable transportation services to promote further use of railways which offer superior global environmental preservation 2. Promote technological development that contributes to global environmental preservation 3. Efficiently utilize fuel and energy 4. Promote waste control and recycling 5. Appropriately manage chemical substances 6. Procure environmental friendly goods and materials 7. Contribute to society and raise awareness for preservation of the global environment Efforts on the Tokaido Shinkansen (1) Introduce Energy Saving Rolling Stock We are proactively developing and introducing energy-conserving rolling stock in our effort to further reduce Shinkansen energy consumption. Series 300 train, which started to operate in March 1992, improved its energy consumption by approximately 30% compared with the first Series 0 train (in the case of 220km/h operation). We have continued introducing energy-saving rolling stock since then. By the time Shinagawa Station opened in October 2003, we had replaced all rolling stock with high-speed and energy-conserving Series 300 and Series 700 trains. We introduced 80 sets of Series N700 trains from 2007 to 2011 and 13 sets of N700A trains by FY2013, and will introduce another 18 sets of N700A trains from FY2014 to FY2016. Data of current electric power consumption demonstrate a remarkable improvement in energy efficiency. In terms of energy consumption needed Series 300 (1992) Series 700 (1999) Series N700/ N700A (2007) (2013) *Simulated run from Tokyo to Shin-Osaka at the maximum speed of 270km/h. ▲Series 300 (Not Equipped with Cover-All Hood) to operate between Tokyo Station and Shin-Osaka Station, our main Shinkansen train of Series N700/N700A consumes approximately 25% less than Series 300 train which ran 270km/h and terminated commercial operation in March 2012. The result is that our energy consumption per unit (*) at the end of FY2013 improved by approximately 32% compared with that of FY1990 (in the case of 270km/h operation). We are striving to further reduce energy consumption by replacing Series 700 trains with N700A whose energy-conserving performance is the same as that of Series N700 train. *Energy Consumption per Unit: JR Central recognizes that total rolling stock kilometers is the value that is most relevant with our business and defines Energy Consumption per Unit as the amount of energy consumed when running 1 railway carriage for 1 kilometer. (2) Energy-Saving Technology on Series N700 and N700A trains Series N700 and N700A trains have been highly improved in energy efficiency by the introduction of technologies mentioned as follows. ① Reduction in Running Resistance Series N700 and N700A train has an aerodynamically superior nose shape to reduce specific running resistance. Exterior uniformity was also enhanced by introducing flush windowpanes, which have no unevenness between the outside panel and windowpane, and cover-all hoods between all railway cars. ② Reducing Rolling Stock Weight Reducing the weight of rolling stock greatly contributes to improving its energy efficiency. A simpler bolster-less bogie and a lighter aluminum alloy for the body frame is adopted for Series 300 train and later developed Series 700 and Series N700, N700A trains. Furthermore, all rolling stock after Series 300 train employed a high performance and small traction motor, made possible by improvements in semiconductor technology. These efforts have made it possible to reduce the total weight of the Shinkansen train. ③ Introduction of Body Inclining System The body inclining system is introduced to increase the speed at curves currently subject to speed restriction. This system makes it possible to increase speed while maintaining comfort, shorten travel hours and realize energy saving due to a decrease of the frequency of speed acceleration and deceleration. Brake (Generation) Propulsion (Electric power consumption) The motor is used as a generator during braking to produce electricity and return it to the overhead wires. The electricity that is returned to the overhead wires is recycled by other trains during acceleration. ▲Series N700 / N700A (Equipped with Cover-All Hood) ④ Expansion of Regenerative Braking System Regenerative braking system convert kinetic energy into electric energy by using electric motors as generators during braking and then channeling the generated power to the overhead wire for use by other trains. JR Central puts the regenerative braking system for practical use for the Shinkansen with Series 300 for the first time and has continued to incorporate it with Series700 and Series N700 and N700A. While 12 of the 16 cars in one set of Series 700 are regenerative, 14 of the 16 cars in one set of Series N700 and N700A are regenerative. The generative brakes on 14 cars provide all of the full-time braking power for the entire 16 cars in normal braking. This has further raised energy efficiency and contributes to increase energy saving of the Shinkansen train. ⑤ Lighter, Smaller Blower-less Power Converter JR Central has put the blower-less power converter, which uses the wind from running for air cooling, into practical use for the first time on a limited number of motor cars for Series N700. Power Converter is a main power control unit by which electricity from the contact lines is converted for the motors during acceleration, and electricity from the motor conversely returns to the contact lines during deceleration. For N700A, they were made 17% smaller and lighter, and installed on all motor cars. ⑥ Saving energy consumption of cabin lighting In the cabins of regular cars on N700A, lighting has been optimized in accordance with the bright seat colors. LED lights with dimmer switches have been employed in the toilets and powder rooms. These measures have resulted in achieving a reduction in energy consumption of lightning by 20% compared with Series N700. ⑦ Eco-friendly Materials Approximately 90% of the waste generated by scrapped Shinkansen rolling stock is recyclable. With regard to N700A, 100% recyclable polyester has been used for seat cushions, and conventional FRP (fiber reinforced plastic) bogie skirts, which cover bogie to lower running noise and air resistance, have been replaced with stainless steel ones. 23 (QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQHWF (QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQ Comparison of Electric Power Consumption and Diesel Fuel Consumption of Conventional Line Car (Electric Car and Diesel Car) ● Comparison of Electric Power Consumption by Conventional Line Electric Car Type Conventional rolling stock Series 117 ● Changes in the Number of Conventional Line Electric Rolling Stock Introduced (Base) 345 300 (Cars) 664 868 136 221 988 1,000 800 69 ● Changes in the Number of Conventional Line Diesel Cars Introduced 554 1,200 (Cars) 100 (110km/h) New energyconserving rolling stock Series 313 Changes in Energy-Conserving Rolling Stock (Electric Car and Diesel Car) 244 250 779 254 221 200 642 (120km/h) *Based on simulated test runs between Toyohashi and Ogaki (rapid operation) 600 150 ▲SCMAGLEV and Railway Park (solar power generation system) 139 ▲JR Gate Tower (Skystreet, 15th floor / image of courtyard) 420 ● Diesel Fuel Consumption Comparison by Conventional Line Diesel Car Model 400 100 Rolling stock with conventional engine 200 50 Rolling stock with new model engine 56 100 (Base) 0 71 *Based on performance when running the Kiha 40 with the new and old engines (Conventional engine: DMF15HS; New engine: C-DMF14HZ) 127 ’93 ’98 Energy-conserving model ’08 0 ’13 (FY) Conventional model *Figures indicate the number of rolling stock as of the end of each fiscal year (March) and may include retained trains. including some event trains and retained trains. Efforts on Conventional Lines (1) Progress in Committing to Energy-saving Rolling Stock JR Central has been striving to conserve energy of rolling stock on conventional lines. Just as with the Shinkansen, we have made an effort with conventional line electric cars to improve their energy efficiency by introducing higher efficiency power control conversion methods and regenerative braking system which convert kinetic energy into electric energy by using electric motors as generators during braking, as well as reducing car weight. For conventional line diesel vehicles, we have strived to introduce vehicles having greater energy conserving capability by reducing vehicle weight, as well as introducing lighter and higher energy efficient diesel engines. As a result of our continual introduction of new energy saving rolling stock, 100% of rolling stock on conventional lines became energy-conserving by the end of FY2013. (2) Future Plans JR Central has decided to electrify the Taketoyo Line (19.3km, between Obu and Taketoyo), used by commuters and students in the Nagoya metropolitan area, by the spring of 2015. This electrification will decrease the burden on the environment with a reduction in CO2 emission by 2,900 tons annually (57% reduction from present). Compliance of Related Laws JR Central sets a system to adhere to the related environmental laws. ① Management of Chemical Substances Based on the “PRTR Law (Pollutant Release and Transfer Register Law)”, we report the amount of emission and transfer of relevant substances to local governments and manage those substances appropriately. We also reduce the amount of chemical usage by promoting the use of substitutes if possible. ② Measures against Soil Contamination In 2012, specific hazardous substances were detected exceeding the standard value from the results of soil surveys in which samples were taken from the mound between Zenshoji Station and Hida-Hagiwara Station on the Takayama Line. We reported to relevant administrative 24 ’03 ▲“Eco Business Trips” Poster 6 0 ’93 ’98 Cars with new model engines ’03 0 ’08 0 ’13 (FY) Cars with conventional engines *Figures indicate the number of rolling stock as of the end of each fiscal year (March) and include retained trains. as well as inspection trains. ▲General Training Center (rooftop gardening) agencies and removed the specific hazardous substances from the sites. Introduction of Natural Energies and Energy-Saving Equipment Effective Use of Resources JR Central strives to leverage natural energies, such as solar power generation systems, and introduce energy-saving equipment when renovating facilities and building new ones. As we conduct our business activities to promote ridership of railway, a mode of transportation with minimal impact on the global environment, we are proactively working to effectively utilize resources, such as engaging in the 3R activity; Reduce, Reuse, and Recycle. Specifically, we are committed to using non-painted stainless steel for conventional line rolling stock, reducing emissions of waste materials during construction, recycling tickets, commuter passes and uniforms, reusing rolling stock, implementing a system utilizing well water, reusing rainwater for irrigation, as well as collecting and separating rubbish. In addition, we establish the “JR Central Green Procurement Guidelines”. In the procurement of materials for construction and engineering work, we are advancing our commitment which gives even greater consideration to global environmental conservation. The Proposal of “Eco Business Trips” JR Central proposes the idea of “Eco Business Trips” as part of our endeavor to prevent global warming. “Eco Business Trips” refer to “business trips that contribute to environmental conservation”, or the mindset of “selecting transportation and business trip methods that will emit small amount of greenhouse gas when traveling mid to long distances (business trips)”. We believe that the idea of “Eco Business Trips” and activities based on the idea will contribute to further preventing global warming. We actively announce the idea of “Eco Business Trips” through advertisement campaigns to spread it in the society. (1) SCMAGLEV and Railway Park At the SCMAGLEV and Railway Park, which opened in March 2011, we introduced a solar energy generation system on the expansive roof as one facet of our commitment to global environmental conservation. The system has a generation capacity of approximately 500kW, or roughly 620,000kWh annually, which can cover about 30 percent of the Railway Park’s energy needs. (2) General Training Center JR Central combined our two training centers in Aichi Prefecture and Shizuoka Prefecture in September 2011 and established the new “General Training Center” taking into account environmental performance. We are actively reducing energy consumption by introducing a ventilation system which uses ice storage achieved from the utilization of nighttime electricity service as its heat source, utilizing well water and reclaimed water, adopting LED illumination and so on. Furthermore, we designed the building to use natural energy effectively by improving insulation efficiency externally by arranging a rooftop garden and sun louvers and taking natural wind and light from the courtyard at the maximum. The result has been demonstrated in our acquisition of the “rank S”, the highest assessment level under “Comprehensive Assessment System for Built Environment Efficiency (CASBEE)”, a widely used system for evaluating the environmental performance of buildings. High-efficiency transformer facilities, boilers and other equipment will be introduced in an effort to increase energy savings by about 10 percent. (4) Nagoya Workshop JR Central started to conduct anti-earthquake measures and upgrade equipment from February 2014 in the Nagoya Workshop where general overhauls and important equipment inspections of conventional line vehicles are conducted. We try to reduce 20% of electric power use needed for operation in the workshop by introducing high ceiling LED lightings and transforming equipment as energy saving measures. (5) JR Gate Tower Project One concept adopted in our plans for the JR Gate Tower is the formation of a comfortable urban space that considers reducing the burden on the environment through the use of natural energy. More specifically, energy consumption for the entire building is reduced by installing regional air-conditioning systems, adopting LED lighting, mounting solar power generation panels, and creating green areas in the 15th floor courtyard and on roofs of low-rise buildings as part of our commitment to reduce the load on the environment. Our aim is to achieve “Rank S” environmental performance, the highest rank on the “CASBEE” scale. We plan to reduce the building’s CO2 emission by about 25 % compared to buildings modeled on the CASBEE 2008 standard. (3) Hamamatsu Workshop In July 2010, we began on renovating the Hamamatsu Workshop where general overhauls are conducted of Tokaido Shinkansen rolling stock. In conjunction with this overhaul, we plan to install energy-saving equipment and utilize renewable energy sources. Specifically, the roof of the workshop will be used for installing solar power generation system with the capacity to generate approximately 300kW or about 300,000kwh annually. 25 (QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQ Table1 Environmental Accounting Classification Main Efforts • Introduction of energy-conserving rolling stock Global • Improved energy-savings at stations environmental and office buildings conservation • Installation of non-CFC type equipment etc. Principal Effects of Environmental Conservation ・Energy-conserving rolling stock ratios:100% (Shinkansen), 100% (conventional line electric cars), 100% (conventional line diesel cars) ・Non-CFC rectifiers: 45 in operation INPUT Electric power 2.79 billion kWh (2.02 billion kWh) Fuel 34 millionℓ(16 millionℓ) 7.0 Development of energy-conserving rolling stock Research and •• Development related to environmental development conservation along railway etc. 0.5 89.6 ・Energy-conserving efficiency of Series N700: −25% (compared to Series 300) Water 3,445 thousand m3 • Proper disposal and recycling of station and train refuse • Proper disposal and recycling of items generated by workshops and engineering work etc. 1.1 36.1 ・Recycling rate for refuse and waste: 70% ・Recycling rate for construction waste: 71% *Figures in parentheses are for operations (reprinted) Environmental • Countermeasures for noise and vibration conservation along • Proper management of environmental load substances etc. railway lines 30.4 18.0 ・Protection of surrounding environment by noise-blocking wall, embankment rising, improvement of roadbeds and shaving of rail surface, etc. OUTPUT CO2 emissions 1,529 Refuse and waste 341 (Station, train & office refuse 18) (Construction waste products 312) (Rolling stock scrap 12) Unit: thousand tons Of this, (Amount of converted crude oil) Management activities • Environmental advertising • Environmental management education etc. 0.0 0.0 ・Acquisition of ISO14001 certification in Technology Research and Development Department Social activities • Support and cooperation for organizations and other groups undertaking environmental conservation 0.0 0.0 ・Participation in Environmental Partnership Organizing Club (EPOC) 493.6 151.0 Total *2 &RRSHUDWLRQZLWK-5&HQWUDODQG/RFDO&RPPXQLWLHV Figure1 Environmental preservation cost (100 million yen)*1 Investment Expenditures 461.4 Resource recycling (QJDJHPHQWLQ*OREDO(QYLURQPHQW3UHVHUYDWLRQHWF *1. Fractions of ¥10,000,000 are omitted [Approach to Environmental Accounting Tabulation] *2. Totals do not add up due to rounding ● Compilation is applicable only to JR Central. ● The applicable period is April 1, 2013 to March 31, 2014. ● “Environmental Accounting Guidelines 2005,” a publication of the Ministry of the Environment, was consulted with regard to aspects of style. ● Depreciation is not included in the calculations for expenditures. ● In the event of multiple-purpose expenditures, the full amount of the higher environmental conservation effect is included in the calculation. Environmental Accounting The investments, costs, and their principal effect involved in environmental conservation activities during FY2013 are estimated on the Table1. Environmental Impact of Operations The main resources and energy utilized as well as waste generated during JR Central’s business activities for FY2013 are indicated on the Figure1. Environment Achievement Level JR Central strives to achieve “Implementation Plan of Low Carbon Society” in which our energy consumption per unit at the end of FY2020 will be improved by 25% compared with that of FY1995. So far we set the Voluntary Plan in which the energy consumption per unit at the end of FY2010 would be improved by 15% compared with that of FY1995 and the Plan has been achieved. JR Central has also continued to develop and introduce energy saving Shinkansen trains. We will flexibly set train services based on the 10 Nozomi Timetable to meet the demand of passengers, enhance transportation service by Speed-up Project in which Shinkansen’s maximum speed will be increased from 270km/h to 285km/h, and continue the introduction of energy saving rolling stock. * The electricity and fuel CO2 emission coefficient is based on a report of laws (Energy Saving Act) concerning the streamlining of energy use. 240 recycled ▲SCMAGLEV and Railway Park ▲Nagoya Central Hospital (including intracompany reuse) ■ Evaluation for our activities JR Central was awarded in December 2013 the Environmental Minister’ s commendation in the Technology Development and Commercialization Category of the Minister of the Environment’ s 2013 Commendation for Global Warming Prevention Activity. This is because our activities for environment load reduction were highly evaluated; the environmental friendly system of N700A and the development and introduction of energy saving rolling stock. We were awarded the same commendation twice in 2003 and 2007. We were also awarded the Gold Prize of the Aichi Environmental Commendation in February 2014. *Winning past awards of the Minister of the Environment’s Commendation for Global Warming Prevention Activity ■ FY2003 Category: Technology dissemination and Introduction Name of Activity: Development and introducing energy saving rolling stock for the Tokaido Shinkansen and others and accomplishment of saving CO2 emission. ■ FY2007 Category: Technology Development and Commercialization Name of Activity: Development of N700A trains achieving both speed-up and energy saving. Cooperation with JR Central and local communities (1) Contribution to Community Development Railway stations serve as a gateway to communities. Fulfilling the role better, JR Central cooperates with the requests of local governments to establish new stations, improve station buildings, develop plazas in front of stations and facilitate railway elevation projects, thereby contributing to community development. Based on related laws, such as the Barrier-Free Law, JR Central as well as central and local governments cooperate to renovate facilities for all passengers, including disabled and elderly passengers, to use our service safely and comfortably. In particular, in accordance with the fundamental government policy, we will continue to renovate stations with governments and municipalities by setting elevators and escalators at stations used by more than 5,000 passengers a day, as well as stations used by more than 3,000 and less than 5,000 passengers after March 2011 when the new policy was defined by government. In addition, to prevent passengers from falling off the platform, we install new moving platform fences at the Shinkansen stations, replace normal blocks with braille blocks that indicate where platform edges are located, which completed its replacement at all Shinkansen Stations, and establish spaces dedicated for passengers getting off trains on the platform. (2) Setting General Hospitals for Local Communities JR Central established the “Nagoya Central Hospital” in Nakamura Ward, Nagoya, whose mission is to provide advanced and high quality acute medical care. The hospital offers patient-centered care by introducing cutting-edge medical equipment and so on. The institution also positively provides preventive medicine and thorough medical examination in association with other medical professions at the medical examination center. The hospital continues to contribute to the local community as a core hospital of the Nagoya area by offering high-quality, advanced and safe medical services certified by Japan Council for Quality Health Care. (3) Engaging programs for vitalizing local communities (SCMAGLEV and Railway Park) We opened the SCMAGLEV and Railway Park in March 2011 in Nagoya in response to a request from the City of Nagoya to participate in the “Monozukuri (manufacturing) Culture Exchange Area Project”. At the SCMAGLEV and Railway Park, we introduce the “progress of the high-speed railway technology” through displays of rolling stock for the Tokaido Shinkansen, conventional lines and Superconducting Maglev. In July 2013, the number of visitors reached the 2.5 million mark. We are making an effort to improve the general public’s understanding of railway and contribute to the promotion of industrial tourism by planning events, advertising the Park, and offering products linked with Nagoya region tourism to attract even more visitors. International Exchange JR Central undertakes a wide range of international operations, such as gathering up-to-date railway information from around the world via the company’s network of overseas offices (Washington D.C., London and Sydney), participating in international conferences to exchange technological and management information with railway operators in the world and issuing press releases to overseas as part of our PR activities. We also participate in cooperation over railway technologies in response to government requests, and contribute to human resource development by accepting interns from overseas universities and international organizations. ▲The Minister of the Environment’s 2013 Commendation for Global Warming Prevention Activity. 26 27