SiC @ Infineon

An insight in the analysis for SiC

André Kabakow

Infineon Technologies AG

andre.kabakow@infineon.com

Copyright © Infineon Technologies 2011. All rights reserved.

Content

General information

Examples of analysis

Summary and Outlook

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 2

Content

General information

Examples of analysis

Summary and Outlook

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 3

Purpose

Infineon is one of the key player in SiC power technology.

Understanding the material is essential to keep this role.

SiC is about 30 years behind Si (taking wafer size as a basis ).

fundamental research is still ongoing

6/19/2013

Page 4

Material properties

very hard

high temperature stability

high thermal conductivity

excellent chemical and radiation resistance

more than 250 known polytypes

4H structure - ABCB

most common structures: 6H, 4H and 3C

only 4H SiC used for IFX power devices

100 mm (4-inch) wafers available today

150 mm wafers available since August 2012

6/19/2013

Page 5

Physical and electrical properties

wide energy bandgap (eV)

4H-SiC: 3.26

Si: 1.12

high breakdown electric field [V/cm]

4H-SiC: 2.2 x 106

Si: 2.5 x 105

high thermal conductivity (W/cm · K @ RT)

4H-SiC: 3.0-3.8

Si: 1.5

high saturated electron drift velocity [cm/sec (@ E ≥ 2 x 105 V/cm)]

4H-SiC: 2.0 x 107

Si: 1.0 x 107

SiC is very suitable for power devices

6/19/2013

Page 6

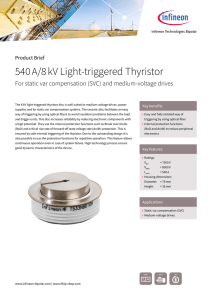

SiC market and potential

SiC power technology has the potential to

start to play a major role next to conventional

Si in the current decade

estimated worldwide annual sales 100-150 Mio. €

estimated growth rate 30-40% p.a.

key applications

hybrid and electric vehicles

renewable energies (wind energy plants and solar

converter)

switching power supplies

uninterruptable power supplies

drives

key drivers

efficiency

low system costs

power density

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 7

SiC related issues

defect density (104-105 cm-2) affects the performance and

reliability of SiC devices

influence of crystal defects on functionality and reliability of

SiC devices is barely understood

characterization and analysis necessary to develop failure

mechanisms

formation of a MOS structure not as easy as for Si

new challenges for FA

6/19/2013

Page 8

Content

General information

Examples of analysis

Summary and Outlook

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 9

Electrical characterization

in principle as for Si power devices

high current measurements

High Power Curve Tracer (pulsed measurement)

¬ avoids overheating of the device

partial backside opening of the device for

further characterization

¬ BS contact with probe needle not necessary

¬ ensures a good BS contact

die

solder

leadframe

package

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 10

Emission Microscopy - EMMI

SiC is transparent not only to IR, but also

to the visible light spectrum

SiC merged pn-Schottky-Diode

Schottky diode for normal current

pn diode for surge current

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 11

Emission Microscopy - EMMI

higher Vf after extreme stress at high current densities beyond

specification

EMMI shows a reduced effective area

EMMI signature points to extensive crystal defects

reference

6/19/2013

fail

Copyright © Infineon Technologies 2011. All rights reserved.

Page 12

Bipolar Degradation

current density [A/cm2]

Stacking faults can grow at high current densities triggered by

electron hole recombination.

forward

400 characteristics

before and

after stress

300

p+

BPD

n- drift layer

n+ substrate

200

cathode

growth of stacking faults triggered

by electron-hole-recombination

100

0

0

6/19/2013

1

2

3

voltage[V]

4

J.P. Bergmann et al., Mat. Sci. For. Vols. 353-356 (2001), pp 299-302

Copyright © Infineon Technologies 2011. All rights reserved.

Page 13

Crystal defect etching

etching in molten KOH at 500°C under a fume hood

Ni wire

Ni foil

tube furnace at IFX

bigger Ni cup

smaller Ni cup with

molten KOH

Ni cage with the

sample

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 14

crystall defect etching

size and shape of the etch pits depend on the defect type

no easier procedure is known to decorate crystal defects till now

threading edge

dislocation

basal plane

dislocation

threading screw

dislocation

Yukari Ishikawa et al., Mat. Sci. For. Vols. 645-648 (2010), pp 351-354

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 15

SEM to visualize p doped areas

mechanical cross section is required

saves further investigation with e.g. SCM (Scanning

Capacitance Microscopy)

misaligned p doping of a JFET

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 16

Content

General information

Examples of analysis

Summary and Outlook

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 17

Summary and outlook

FA methods, well-known for Si, still applicable for SiC

some work better:

“p doped areas under SEM”

some work worse:

“crystal defect etching”

Analysis, with all of its methods, can contribute to a better

understanding of the material and its failure mechanisms.

What is the correlation between the EMMI signature of “bipolar

degraded” devices and the triggered crystal defects?

Find an easier method for defect etching

6/19/2013

Copyright © Infineon Technologies 2011. All rights reserved.

Page 18

Picture credits

page 4:

http://www.nature.com/nature/journal/v430/n7003/images/430974

a-f1.2.jpg

http://atecom.en.alibaba.com/viewimg/picture.html?picture=http://

i00.i.aliimg.com/photo/v2/525568278/EPI_Ready_Polish_Wafer_4H

_6H_Silicon.jpg

page 5:

https://apecconf.org/2012/images/PDF/2012/Industry_Sessions/is1.5.5.pdf

http://upload.wikimedia.org/wikipedia/commons/1/15/Toyota_Prius

_Plug-In_Hybrid_IAA_2009.jpg

http://www.quantrimang.com.vn/photos/image/032011/29/Usnasa-columbia.jpg

http://www.greenology.co.za/images/windturbine.jpg

6/19/2013

Copyright © Infineon Technologies 2009. All rights reserved.

Page 19