Industry 4.0 - On the way to a Smart Factory

Dr. Andreas Wittmann

Industry 4.0 @ Infineon

n Infineon Technologies – Company Overview and Market

n Industry 4.0 – On the way to a Smart Factory

n Challenges on the way to Industry 4.0

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 2

Industry 4.0 @ Infineon

n Infineon Technologies – Company Overview and Market

n Industry 4.0 – On the way to a Smart Factory

n Challenges on the way to Industry 4.0

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 3

Infineon at a Glance

The Company

n Infineon provides semiconductor and system solutions, focusing

on three central needs of our modern society:

Energy Efficiency, Mobility and Security

n Revenue in FY 2013: € 3.843 billion

n Around 29.000 employees worldwide (as of June 2014)

n Strong technology portfolio with more than 18,650 patents and

patent applications (as of September 2013)

n 21 R&D locations; 12 manufacturing locations

n Germany's largest and Europe's second largest

semiconductor company

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 4

We Focus on Three Central Needs

of Modern Society

Energy Efficiency

Mobility

Security

Automotive

Industrial Power Control

Power Management & Multimarket

Chip Card & Security

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 5

Infineon Holds Top Positions in All Major

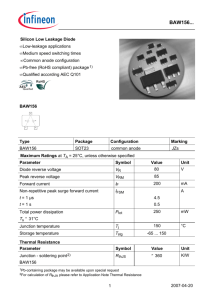

Product Categories

Automotive

semiconductors

Power

semiconductors

total market in 2013:

$25.1bn

total market in 2012:

$15.0bn

Renesas

13.3%

Infineon

STMicro

Freescale

NXP

9.6%

7.9%

Infineon

Toshiba

Smart card ICs

total market in 2013:

$2.48bn

11.8%

NXP

7.0%

Infineon

Mitsubishi

6.5%

21.7%

6.9%

STMicro

7.4%

32.3%

STMicro

5.6%

Fairchild

5.6%

Samsung

17.9%

16.5%

Automotive semiconductors incl.

semiconductor sensors.

Discrete power semiconductors

and power modules.

Microcontroller-based smart

card ICs.

Source: Strategy Analytics,

April 2014.

Source: IHS, December 2013.

Source: IHS, July 2014.

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 6

Our CO2 Balance: Emission Reduction

Enabled by Our Products and Solutions

More than

15.8

million

tons

1.2

million

tons

CO2 burden1)

Ratio

1:13

CO2 savings2)

Net ecological benefit :

more than 14.6 million tons of CO2 emission reduction

1) including manufacturing, transport, material, chemistry, emissions, water, waste and waste water, energy

consumption; values are based on internal figures as well as official data for one year.

2) considering only automotive products, lighting, PC power supply, regenerative energy production (photovoltaic, wind)

and drives, calculation based on average lifetime and Infineon market-share.

July 30, 2014

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 7

Industry 4.0 @ Infineon

n Infineon Technologies – Company Overview and Market

n Industry 4.0 – On the way to a Smart Factory

n Challenges on the way to Industry 4.0

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 8

Microelectronics are enablers for Industry 4.0

Brain =

Microprocessor

Eyes, Ears =

Sensors, MEMS

Mouth =

Communication

Components

Muscles =

Power

Semiconductor

Immune System =

Hardware–based

Safety & Security

concept

Source: Dr. Ploss 2014

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 9

„Smart Factory“ - The Central Element of

Industry 4.0

In the Smart

Factory people,

machines and

resources

communicate

naturally as in a

social network.

n In a Smart Factory intelligent products are clearly identifiable

and locatable at any time.

n The Smart Factory links value chain networks in real time.

n The Smart Factory manages complexity of intelligent systems,

increases efficiency of production and and is also robust against

disturbances.

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 10

Industry 4.0 contributes to achieve the

following Operational Targets of Manufacturing

react quickly to

changes because

of transparent

procedures

competitive strength, as

efficiency can be increased

through integration of

production, data and people

Enhance

Flexibilty

innovative

business models

are developed

Shorten

Time to Market

2014-09-17

Industry 4.0

Increase

Efficiency

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 11

One of the most complex production

system is a Semiconductor Frontend Fab.

Furnace

IMPLANT

Defect Densitiy

ETCH

Wet Etching

Metrology

Lithography

PVD / MCVD

(Physical Vapor

Deposition)

Start

CMP (Chemical

Mechanical

Polishing)

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

CVD (Chemical

Vapor Deposition)

Page 12

Essential Fields of Action to deploy Industry

4.0 into Manufacturing

Source: WZL/Frauenhofer IPT

Logistics

Automation

Ergonomics

IT

Technical Infra

HR System

Info & IT Security

Energy Efficiency

Production Planning &

Control

Quality Management

Engineering

Maintenance

!!no claim to completeness!!

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 13

Verticale Integration

Industry 4.0

State of the Art FrontEnd factories realized

elements of a „Smart Factory“.

Manufacturing

Information

The most complex

production

system is a

semiconductor FrontEnd

in Real fabrication.

time

Paperless Manufacturing

Clearly identified

and located

Collaborative Human-Maschine

Interaction

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 14

The potential of Industry 4.0 is immense –

e.g. Energy Efficiency

Transformation Ability / Mutability

§ From Mass Production to Lot size 1

§ Fast Product Ramp Up

§ Time to Market

Resilient Factory

Robustness

§ Stable production

§ Fast adaptation in case of

disturbances

§ Strong defense against hackers

Energy Efficiency

Resource Efficiency

Example from Aachener Werkzeugmaschinenkolloquium 2014

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 15

Potentials with Industry 4.0 for an energy

efficient production

n A semiconductor manufacturing consumes

Production Infineon

100 GWh and more per year 1).

n More than 60% of the energy consumption is

related to process tools, chillers and supply

air fans

n This potential can only be developed by

having robust and demand oriented

steering mechanisms!

De-Ionized

Water

5%

Support

3%

Process Tools

35%

Supply Air

Fans

19%

„Subfab“ – Medium supply

Exhaust Air

Fans

7%

Sources:

Example from Aachener Werkzeugmaschinenkolloquium 2014

2014-09-17

Liquid Nitrogen

Plant

7%

Process

Cooling Water

4%

Chiller

20%

1) EPA. 1997. Proceedings of the Semiconductor Energy Efficiency Opportunities

Workshop. San Jose, CA, November 13-14. Washington, DC: U.S. Environmental

Protection Agency

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 16

Energy Efficiency Potentials through

Industry 4.0

Today

Industry 4.0

n Robust media supply for

challenging process tools and

manufacturing processes

n Robust and demand oriented

media supply for the

challenging process tools and

manufacturing processes

n Limited transparency of

energy and media

consumption of the single

equipment, e.g. pumps are

running with constant speed

n Only a few machines share

the same supply aggregates

n Real-time Information of

energy consumption for

supply aggregates (e.g.

chiller)

n Retrofitting of existing e.g.

chillers with the ad-hoc

connectivity capability and

demand oriented steering

mechanisms

n new Services could develop

„pay per use“ e.g. cooling

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 17

Industry 4.0 @ Infineon

n Infineon Technologies – Company Overview and Market

n Industry 4.0 – On the way to a Smart Factory

n Challenges on the way to Industry 4.0

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 18

Industry 4.0 offers immense potentials for us, for us

as semiconductor supplier and for our factories!

However: Several challenges need to be solved to move towards Industry 4.0

Smart Factories need to be stable and beneficial.

Know-how needs to be secured successfully.

Company 1

Company 2

Tool 1

Security

Tool 2

Tool 3

Tool 4

Manufacturing tools are linked together internally and

externally. Therefore they need to be protected from

manipulation.

The Smart Factory needs to be able to control

complexity and to be robust against dysfunctions.

Deployment of Industry 4.0 will only be successful within

collaboration networks: e.g. Politics, Institutions,

Research, SMEs

2014-09-17

Copyright © Infineon Technologies AG 2014. All rights reserved.

Page 19