industrial emergency lighting

advertisement

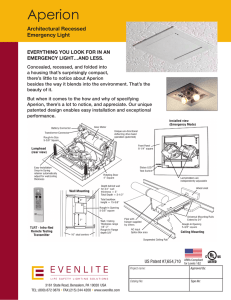

Now Available with NEMA 4X INDUSTRIAL EMERGENCY LIGHTING A P P L I C AT I O N G U I D E Table of Contents Applications ............................................................................ 2 Installation and Mounting..................................................... 3 Lamp Performance and Spacing........................................... 5 Remote Heads ......................................................................... 7 Maintenance Feature Options............................................... 9 Environmental Conditions Options ................................... 11 Available Option Packages ................................................. 13 Notes....................................................................................... 14 The Indura Series is specifically designed for industrial environments. Now with the addition of a NEMA 4X product, it is the industry’s broadest and most flexible product offering in emergency lighting unit equipment. This application guide is intended to provide detailed information that will aid you in effectively applying this product. Page 1 Applications Indura Indura 4X Indura is specifically designed for industrial and heavy commercial applications such as warehouses, parking garages, and manufacturing plants. The Indura 4X emergency lighting unit adds additional protection from hose-down or harsh environments where moisture, dirt, and dust would limit the life of ordinary emergency lighting units. • Weatherproof Housing - Overmolded lens adds protection from hose-down or harsh environments. • Gasket Design - Tongue-in-groove silicone gasket design prevents water and dust from entering housing. • Patented Mounting Bracket - 12-gauge steel mounting bracket finished with epoxy electrocoat to eliminate corrosion. • Lens - UV-stable polycarbonate lens protects lamp heads from environmental conditions, and wipes down easily. • Lamp Performance - Same superior lamp performance as standard Indura. • RT/SD - Remote test and self-diagnostics ease maintenance. • Vertical Design - Protects unit from moving equipment when pole- or column-mounted. • Reduced Installation - Mounting plate cuts installation time by 50% over old-style steel units. • Lamp Heads - Located on the bottom of housing to direct all light to the path of egress. Lamp heads can be adjusted 3600. • Superior Lamp Performance - Fieldadjustable beam spread assures optimal egress illumination in any application. • Hinged Cover - Allows for hands-free wiring once mounted. • RT/SD - Remote test and self-diagnostics ease maintenance. Warehouse Manufacturing Food Processing Mills and Refineries Installation and Mounting Indura Industrial Emergency Lighting Application Guide Easy Installation Four-Step Installation Process The Indura family is the industry's first easy install industrial emergency lighting unit, installing in half the time of old-style "box" units. Every Indura unit is shipped with a patented, universal, 12-gauge, epoxy-coated steel mounting bracket (Patent No. 6,135,624). The bracket eliminates the need for traditional mounting shelves that add additional cost to the installation. The mounting bracket can be secured to walls, columns, I-beams, poles, junction boxes or unistrut. Step 1: Attach the universal steel mounting bracket. Step 2: Slide housing onto mounting bracket until the snap-lock feature is engaged. Open front cover. Step 3: Remove the appropriate conduit/wiring entry hole plug and connect the AC input leads. Step 4: Close the front cover and screw in the fasteners. Snap-Lock Feature For Small Housing (100W or less) Wall Mounting Holes (Qty 4) J-Box Wire Route Holes (Qty 2) *Screw-Lock J-Box Mounting Holes (Qty 4) Pole-Mount Banding Slots (Qty 8) Uni-Strut Mounting Holes (Qty 4) Mounting Bracket *Note:Each Indura unit ships with a locking screw to "lock" the housing to the mounting plate through the inside of the back housing. With the snap-lock feature of the small Indura housing, this screw is not required. Page 3 Installation and Mounting Pole or Column Banding (ELA BS accessory) Pendant Mount (ELA IND PM accessory) For quick and easy strapping of the mounting bracket to a pole or column, order the banding strap accessory (ELA BS). Contains one 8.5 foot, 100% stainless steel band, three fasteners and one extender. Other banding may be utilized as long as the width is 3/4" or less. The Indura products in the small housing can be pendant-mounted. Order the ELA IND PM accessory to receive a metal support bracket to field-install around the top conduit entry hole in conjunction with the mounting bracket. Conduit entry holes on unit and pendant mount bracket are 7/8" in size. Conduit and canopy are not provided. 9/18" wide stainless steel fastener and housing assemblies 1/2" wide stainless steel banding 5/16" stainless steel attached hex-head screw Ceiling Mount (ELA IND CM accessory) The Indura and Indura 4X units listed below can be ceiling-mounted. The mounting bracket is still utilized by mounting the bracket to the ceiling or bar joist, then snapping and locking the unit in place. When the ELA IND CM accessory is ordered (see note below), a special battery bracket is provided to give extra support and safety. The screw-lock that secures the unit to the bracket should be used as an additional locking measure. Note: ELA IND CM1 - ceiling mount ELA IND CM2 - ceiling mount INDX654, INDX1236, INDX1254 ELA IND CM3 - ceiling mount ELA INDX CM2 - ceiling mount kit for IND618 kit for IND654, IND1236, IND1254 and kit for IND6100 kit for INDX 654, INDX1236, INDX1254 Page 4 Lamp Performance and Spacing Lamp selection and spacing between units is closely tied to mounting height. Once the mounting height of the application has been determined, use the chart below to select the lamp that optimizes the layout. The fixture spacing for each mounting height is given for both one footcandle average requirements and one footcandle minimum requirements, depending on your local code requirements. Composite Lamps Cat. # Volts Watts INDURA K0906 K0912 N1824 6 12 24 9 9 18 H1206 6 H2006 12'MH Type Fixture Spacing 16'MH 18'MH 14'MH 1 FC Avg. Min. 1 FC Avg. Min. 1 FC Avg. Min. 1 FC Avg. Min. 20'MH 24'MH 1 FC Avg. Min. 1 FC Avg. Min. Lumens Beam Kryp. Kryp. Inc. 180 190 289 Medium Medium Flood 26 24 36 ------- 26 24 36 ------- 23 22 34 ------- 20 22 34 ----15 20 22 32 ----15 10 20 28 ----15 12 Hal. 238 Spot Medium Flood 32 28 17 --16 --- 32 28 16 --16 --- 32 26 15 --16 --- 30 24 --- --18 --- 30 22 --- --18 --- 28 20 --- --15 --- 6 20 Hal. 402 Spot Medium Flood 46 35 22 16 22 15 46 34 21 16 24 15 45 33 20 16 24 15 43 31 18 16 23 15 41 29 17 16 22 --- 39 24 --- 16 18 --- H1212 12 12 Hal. 276 Spot Medium Flood 38 35 22 --16 --- 38 35 21 --17 --- 38 33 21 --19 --- 38 31 20 --20 15 37 30 18 --21 --- 33 26 --- 15 21 --- H2012 12 20 Hal. 314 Spot Medium Flood 38 26 15 --19 --- 38 26 15 --19 --- 36 23 --- --19 --- 36 23 --- --18 --- 34 21 --- --18 --- 30 17 --- 15 15 --- H2024 24 20 Hal. 300 Spot Medium Flood 38 38 23 ------- 38 38 23 ------- 37 37 22 --15 --- 35 35 20 --16 --- 33 33 18 --17 --- 30 29 15 --19 --- INDX K0906 K0912 N1824 6 12 24 9 9 18 Kryp. Kryp. Inc. 180 190 289 Medium Medium Flood 22 20 34 ------- 21 20 34 ------- 21 19 33 ------- 20 19 32 ----15 18 18 32 ----15 16 16 27 ----15 H1206 6 12 Hal. 238 Spot Medium Flood 25 25 17 --16 --- 25 22 16 --16 --- 25 22 14 --16 --- 25 20 13 --18 --- 25 19 12 --18 --- 25 15 10 --15 --- H2006 6 20 Hal. 402 Spot Medium Flood 38 35 26 16 22 15 38 33 24 16 24 15 38 33 22 16 24 15 38 32 20 16 23 15 38 31 18 16 22 --- 38 28 16 16 18 --- H1212 12 12 Hal. 276 Spot Medium Flood 30 28 18 --16 --- 30 27 16 --17 --- 30 25 15 --19 --- 30 24 14 --20 15 30 22 12 --21 --- 26 20 10 15 21 --- H2012 12 20 Hal. 314 Spot Medium Flood 33 26 15 --19 --- 33 26 15 --19 --- 33 23 --- --19 --- 33 23 --- --18 --- 33 21 --- --18 --- 29 17 --- 15 15 --- H2024 24 20 Hal. 300 Spot Medium Flood 34 35 29 ------- 34 34 26 ------- 34 34 25 --15 --- 33 34 22 --16 --- 32 33 21 --17 --- 30 31 18 --19 --- Sealed-Beam Lamps Cat. # Volts Watts Type INDURASealed Beam Lamps N5024S H3512S H5012S 24 12 12 50 35 50 Inc. Hal. Hal. 12'MH Lumens Beam 1 FC Avg. Min. Fixture Spacing 16'MH 18'MH 14'MH 1 FC Avg. Min. 1 FC Avg. Min. 1 FC Avg. Min. 20'MH 25'MH 1 FC Avg. Min. 1 FC Avg. Min. Fixture Spacing 420 706 940 11 X 5 9 X 4.5 7X5 65 75 80 ------- 60 70 80 ------- 60 70 80 ------- 55 70 80 ------- 55 70 80 ------- 55 70 80 ------- Assumptions to arrive at these spacings: 6' wide path of egress in 15' wide aisle of 200'X200' open warehouse with reflectances = 10/10/10. One footcandle average requirement also meets .1 footcandle minimum and 40:1 max. to min. ratio as required by Life Safety Code. Visit our website at www.lithonia.com/indura for IES formatted files used to generate the spacing listed above. Page 5 Lamp Performance and Spacing Composite Versus Sealed-Beam Lamps Beam Pattern Adjustability Sealed-beam lamps have long been the specified lamp choice for optimum performance in the emergency segment of the lighting industry. In the past, composite lamps have offered reduced performance at an economical price. Indura composite lamps offer the best value by significantly exceeding the performance of sealed-beam lamps at the composite lamp price. High performance krypton composite lamps provide 20-37% more light output than the equivalent incandescent lamps. Halogen 12W50W lamps are available for applications where even higher mounting heights are required. In addition, the beam pattern for the composite lamps is field adjustable to a spot, medium or flood setting by simply adjusting the bezel of the lamp. The adjustability is somewhat analogous to the adjustability of a Mag-Light® (see picture at top right). The adjustibility of the lamps allows customers to optimize performance for different mounting heights and code requirements. The composite lamps can be adjusted by simply rotating the lamp bezel past the appropriate stop. After analyzing the spacing information for most composite halogen lamps, the spot position normally will work best for one footcandle average requirements, and the medium position normally will work best for one footcandle minimum requirements. The composite krypton lamp performs best in the medium position. The flood position normally will be reserved for composite incandescent lamps. Page 5 Remote Heads Advantages of Utilizing Remote Heads Remote heads reduce the number of units, minimizing the number of batteries on the job, resulting in lower maintenance costs. Remote heads are smaller and less obtrusive than a complete unit. This is important if aesthetics are a primary concern. In addition, remote heads can reduce initial product cost, especially in environments that require special ratings such as wet location or in areas where ambient temperatures can diminish battery capacity or life. In many instances, the unit with battery and electronics can be installed in a “normal” or controlled environment with the remote heads located in the areas that require special ratings. Advantages of Using Self-Contained Units If remote loads are not required, product cost can be reduced by using 6-volt self-contained (with battery) units. In most instances, a 6-volt product is less expensive than a 12-volt or 24volt product. Choose the capacity to operate the two lamps selected from the lamp chart (see page 4) that maximizes spacing. Selecting 6-, 12- or 24-Volt Units If remote heads are to be incorporated, first determine the number of remote lamps to be operated by each unit. Choose a 12-volt or 24volt product according to circuit run length and load requirements. Reference the voltage drop information supplied with this guide (see page 7). The length of run is increased approximately four times by using 12-volt instead of 6volt. It is increased another four times by using 24-volt instead of 12-volt. Terminal Blocks Terminal blocks are provided to simplify the connection of remote heads to the emergency unit. Units of 100-watt capacity or less (small housing) are equipped with one terminal block capable of accepting up to 10-gauge wire. Units of 150-watt capacity or greater are equipped with two terminal blocks capable of accepting up to 10-gauge wire. Fuses Per UL requirements, Indura units with battery capacities greater than 20 AH have fused DC output. Self-contained units diversify your emergency power sources. If a self-contained unit fails, it affects a much smaller area than if a unit running several remotes fails. In addition, self-contained units may reduce installation wiring costs by eliminating the low voltage circuit required to connect the remote heads. Page 7 Remote Heads Example 1: Voltage Drop Tables The following information is provided to assist in planning layouts for emergency lighting systems. The National Electrical Code limits voltage drop to a maximum of 5 percent of nominal. Thus, circuit runs must be of sufficient size to maintain operating voltage when remote fixtures and/or exit signs are connected to the emergency lighting equipment. The table below shows the length of wire run based on system voltage, wire gauge and total wattage on the run. Formula: As per National Electrical Code standards, VD = 2 x L x I x R 1000 A 12-volt system using a 10-gauge wire will operate four 12-watt lamps. Total watts on the wire run is 48, length of run from table is 70 feet. Longer Wire Runs If loads are uniformly spaced along circuit path (equal watts, equal distances), lengths in the table can be increased by certain values. Example 2: Remote heads from Example 1 will be uniformly spaced. Multiplier is 1.6 for four fixtures. Maximum permissible length of wire run is 70' x 1.6 or 112'. Number of fixtures Multiplier Where: L I R VD = = = = length of run in feet current resistance of material at 750C voltage drop 2 3 4 5 1.33 1.5 1.6 1.67 To determine multiplier for six or more fixtures, use the following formula: Number of fixtures = n Multiplier = 2n n+1 6-VOLT SYSTEM Total watts 8 10 12 13 14 16 18 20 21 24 25 30 35 36 40 48 50 54 60 75 100 125 150 175 200 225 250 300 400 450 12 67 53 44 41 38 33 30 26 25 22 21 18 15 15 13 11 10 10 9 8 6 4 3 3 2 2 2 1 1 1 Wire size 10 8 6 length of wire run (feet) 106 169 268 85 135 214 70 112 178 65 110 165 60 96 153 53 84 134 47 75 120 42 67 107 40 64 102 35 56 89 32 54 86 28 45 71 24 39 62 24 38 61 21 33 53 17 28 44 17 27 43 16 26 41 14 22 36 11 18 29 9 14 22 6 10 17 5 9 14 4 7 12 4 6 10 3 6 9 3 5 8 2 4 7 2 3 5 1 3 4 12-VOLT SYSTEM 4 350 280 234 216 200 175 156 140 134 117 112 93 80 97 70 58 56 65 47 37 28 22 19 16 14 12 11 9 7 7 Total watts 8 10 12 13 14 16 18 20 21 24 25 30 35 36 40 48 50 54 60 75 100 125 150 175 200 225 250 300 400 450 12 267 213 178 165 152 133 110 106 101 89 85 71 61 61 53 44 42 40 35 29 21 17 14 12 10 9 8 7 5 4 Wire size 10 8 6 length of wire run (feet) 425 675 1,073 339 540 858 283 450 715 260 415 660 242 385 613 212 337 536 190 300 475 169 270 429 161 257 408 141 225 357 136 215 340 112 180 285 97 154 245 97 154 244 84 135 214 70 112 178 68 108 170 64 102 163 52 90 140 45 72 114 34 54 86 27 43 68 23 36 57 19 30 49 17 27 43 15 24 38 14 21 34 11 18 28 8 13 21 7 12 19 24-VOLT SYSTEM 4 1,707 1.366 1,138 1,050 975 853 760 683 650 569 540 455 390 388 341 284 275 259 225 182 137 109 91 78 68 60 55 45 34 30 Total watts 8 10 12 13 14 16 18 20 21 24 25 30 35 36 40 48 50 54 60 75 100 125 150 175 200 225 250 300 400 450 12 Wire size 10 8 6 length of wire run (feet) 1,068 1,698 2,701 4,293 854 1,358 2,161 3,435 712 1,132 1,801 2,862 660 1,040 1,668 2,640 610 970 1,543 2,453 534 849 1,350 2,146 440 760 1,200 1,900 427 679 1,080 1,717 407 647 1,029 1,635 356 566 900 1,431 340 544 860 1,360 284 448 720 1,140 244 388 616 980 242 386 614 976 213 339 540 858 178 283 450 715 168 272 432 680 162 257 410 651 140 208 360 560 116 180 288 456 84 136 216 344 68 108 172 274 56 92 144 228 48 77 123 196 40 68 108 172 37 60 96 152 32 52 84 136 26 44 72 112 21 34 54 85 19 30 48 76 4 6,830 5,464 4,553 4,200 3,902 3,415 3,040 2,732 2,601 2,276 2,160 1,810 1,560 1553 1,366 1,138 1,100 1,035 900 728 548 437 364 312 272 242 220 180 136 120 Page 8 Maintenance Feature Options Standard Control Panel Self-Diagnostics (Available with the Select, Premium and Ultimate Option Packages) A status LED and test switch are provided on all units. To begin a test, press the test switch and the lamps will come on. The status LED indicates that the AC power is applied and the unit is charging. The color of the status LED indicates the charging state of the unit. LED Indicator State OFF Green Red Condition Unit is in emergency mode Unit is in normal mode Unit is in high charge mode Control Panel The NFPA 101 - Life Safety Code requires emergency lighting to be tested for 30 seconds every 30 days and 90 minutes once a year. While the annual test has to be manual, the monthly test is allowed to be an electronic selftest (a monthly visual inspection is still required). One benefit of the automatic test is lower maintenance cost because maintenance personnel no longer need to use ladders and lifts to manually test the units on a monthly basis. Only units that indicate a failure will need to be inspected. A second benefit is greater performance and reliability of the units because manual testing is rarely performed. Self-diagnostics assures that units are tested and problems are identified. Manual Test To manually test, press the test button, lamps will come on and a 30-second diagnostic test will start. The status LED indicates the units charging state if diagnostic failures are not detected during the test. Note: Unit must have adequate charge level to run test. If the unit indicates inadequate charge when the test button is pressed, the unit will need to be charged longer before a manual test can be performed. LED Indicator State Condition OFF Green Green flashing Red Unit is in emergency mode Unit is in normal mode Unit is in test mode Unit is in normal high charge mode Battery failure Lamp failure Electronic failure Temporary inadequate charge Red flashing (single pulse) Red flashing (double pulse) Red flashing (triple pulse) Red/green flashing Control Panel with Self-Diagnostics Page 9 Maintenance Feature Options Self-Test Schedule The unit automatically performs a five-minute self-diagnostic test every 30 days. The unit also automatically performs a 30-minute selfdiagnostic test every six months. Self-Test Rescheduling If a self-test occurs at a time when it is desired that the lamps not be on, the automatic selftest can be delayed for eight hours by pressing the test switch once during the self-test. Remote Test (Available with the Extra Option Package) When remote test is ordered, the unit is equipped with a radio frequency receiver that is designed to activate a 30-second test from up to 35 feet away with the use of the hand-held remote transmitter (ELA RTT). This eliminates time spent climbing ladders or riding lifts to test equipment. The ELA RTT must be ordered as a separate accessory. A minimum of one per job location is required. Automatic Load Learning Feature All self-diagnostic units are capable of automatically determining the total connected lamp current during the first scheduled selftest. After the unit saves this information, a lamp failure will be indicated anytime a greater than 10 percent reduction in total load current is detected. The load learn function can also be initiated manually by pressing and holding the test switch for 15 seconds, during this period the lamps will be on. The unit will signal that the total lamp current has been saved by turning off the lamps at the end of the 15 second period. This manual load learn feature should be used whenever the total connected lamp load to the unit is changed. ELA RTT Note: Manual load learn functions will not function if there is inadequate charge on the battery. If this is the case, wait until the battery enters trickle charge mode and then initiate manual load learn function. Clearing Failure Indications Once the failed component has been replaced, press the test button once to clear the failure indication. Page 10 Environmental Condition Options Now available with a NEMA 4X rating, Indura 4X provides protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, hose-directed water, corrosion, and the damage caused by the external formation of ice on the enclosure. Discharge Capacity versus Temperature 100 Capacity (%) NEMA 4X 80 60 40 20 0 What is NEMA 4X? NEMA is an organization responsible for setting enclosure standards. UL has adopted these standards; thus the term "NEMA 4X." UL provides a UL50, 4 and 4X listing based on the product passing the below tests: 1. Hosedown test - a 1" diameter hose delivers 65 gallons of water per minute at a distance of 10-12 feet. 2. Corrosion resistance - the product itself is subjected to a salt spray for 200 hours. 3. Icing Test - the product is put in temperatures of -6.70C and sprayed down, thus causing ice to develop on the lens and housing. Product is acceptable if while ice laden, the product is operable and remains undamaged. 4. Gasket test - gasket must maintain strength of not less than 75% when subjected to circulating air in a temperature of 69-700C. Cooler Temperatures Lower Discharge Capacity Lead-calcium batteries are designed for dry locations with temperature ranges from 60°90°F. Since the battery is the main temperaturesensitive element and many industrial environments experience varying temperature ranges, it is important to know the effects on battery life and capacity. Lead-calcium batteries operate on a electrochemical reaction, which converts chemical energy to electric energy. The electrochemical reaction is reduced as the temperature lowers. Thus, the available discharge capacity in a battery is reduced at lower temperatures. 20 40 60 80 100 Temperature (oF) Temperature 770F 320F 50 F Capacity* 100% 80% 65% * Based on the 90-minute rate Cold Weather Condition (Available with the Ultimate Option Package) To prevent this from happening, Indura offers the Ultimate option package which includes a high-temperature nickel-cadmium battery or high-ambient lead-calcium battery rated for temperatures between -400F (-400C) and 1310F (550C). These special batteries are available on the IND618, IND1236, IND12100 and INDX618, INDX1236, and INDX12100 products. A battery blanket and heater are used to accomplish this rating without de-rating battery capacity. Hotter Temperatures Reduce Battery Life, Not Capacity While lower temperatures reduce capacity with no adverse effect on battery life, warmer temperatures have no adverse effect on capacity, but they do diminish battery life. The life of standard lead-calcium batteries is greatly reduced when temperatures are consistently above 900F. The Indura Premium Option package utilizes a high-performance nickel-cadmium battery or high ambient lead-calcium battery especially designed for environments with extreme fluctuation in temperature. The Premium option is UL listed from 32oF (0oC) to 131oF (55oC). While battery life is still affected at higher temperatures, a good battery life can still be achieved with these batteries. The following chart reflects battery life at given temperatures assuming exposure to this temperature 24 hours a day, 7 days a week and 365 days a year. Page 11 Environmental Conditions Options Exposure to a given temperature 24/7/365 is extremely unlikely for an unconditioned space. Unconditioned facilities generally experience the same temperature fluctuations as outdoor applications, except tempered to the warm side to varying degrees, depending on the ventilation of the facility and the height inside the facility at which the temperature is being measured. Below are examples of how to calculate the life of the high temperature batteries, depending on the amount of time during a year that it is exposed to a given temperature. For each application, it is important to obtain the average temperature for each season of the year and measure the temperature variation at the desired mounting height of the fixture to be able to apply these calculations. Example 1: May - Oct (Day) May - Oct (Evening) Nov - April (Day) Nov - April (Evening) Average Temperature 1300F (550C) 860F (300C) 0 Life Expectancy 1.6 yrs. 9 yrs. 13 yrs. 13 yrs. 0 75 F (25 C) 500F (100C) % of time in Temperature 25% 25% 25% 25% Total Life Range Expectancy 0.40 2.25 3.25 3.25 9.15 years Example 1: The average temperature during six months of the year (May-October) from 8 a.m. - 8 p.m. in a warehouse is 1300F (550C). At this temperature, the life expectancy would be 1.6 years. The average evening temperature in these same months in the same warehouse application from 8:01 p.m. - 7:59 a.m. is 860F (300C). At this temperature, the life expectancy would be 9 years. For the months of November through April during daytime hours, the average temperature is 750F (250C) in the warehouse. The life expectancy at this temperature would be 13 years. While in the evening, the average temperature is 500F (100C) and the life expectancy is 13 years. If we look at an entire year, it is 1300F for 25% of the time, 860F for another 25% of the year, 750F for another 25% and 500F for the remaining 25%. If we average out the life expectancy for each quarter, this will give us a total life expectancy of 9.15 years. Life Expectancy of High Ambient Batteries with 24/7/365 Exposure Life Expectancy (yrs) 14 12 10 Damp Location Conditions For moist or humid areas, a damp location listing is needed. All Indura units come standard UL listed for damp locations. 8 6 For areas requiring wet location, the NEMA 4X listing on Indura 4X covers these requirements. 4 2 0 60 77 86 104 122 131 Battery Temperature (oF) Temperature 600F (200C) 770F (250C) 860F (300C) 1040F (400C) 1220F (500C) 1310F (550C) Avg. Life (yrs) 13.0 13.0 9.0 5.0 2.5 1.6 Page 12 Available Option Packages Time Delay Audible Failure Indication (Available with all Option Packages) (Available with the Select, Premium and Ultimate Option Packages) HID fixtures normally require a time period of 5 to 20 minutes to re-strike after momentary power interruptions or brownouts significant enough to cause the HID lamp to lose its arc. Therefore, it is necessary to light the path of egress during the re-strike time period. This may be especially critical in areas that experience frequent power interruptions or brownouts. The time delay option meets this requirement by maintaining emergency operation for an additional 20 minutes after normal power is restored. In units equipped with Audible Failure Indication, failure indications are accompanied by a 15-second-long alarm tone every 15 minutes. The tone stops when the failure indication is cleared or the AFI board is disabled. Other possible solutions to this application are to order the HID fixtures with a QRS (Quartz Re-Strike System) option or QRSTD option. The QRS option automatically switches the 120-volt quartz lamp on if there is a power interruption or brownout significant enough to cause the HID lamp to drop out. The 120-volt quartz lamp stays on until the HID fixture restrikes. QRS does not energize during cold start of HID luminaires. Wiring for the quartz lamp is internal to the ballast assembly; the 120 volts required to operate the quartz lamp is supplied by the ballast. Wattage of the quartz lamp (supplied by others) should not exceed that of the HID source. The QRSTD option functions the same as the QRS, except for the quartz lamp which energizes under hot and cold starting conditions. The quartz lamp will come on when a luminaire is energized and will remain on for two minutes after start-up or re-strike. Both the QRS and QRSTD options are significantly more expensive than the TD option, especially when you add in the price of the quartz lamp. However, depending on the illumination requirements, the fixture, and the fixture mounting height requirements, it is possible that the QRS option would be required. Evaluate each particular job to determine which option provides the best performance. Note: QRS does not provide emergency illumination in the case of a power failure. Indura and Indura 4X Option Packages The Extra Option Package features remote test and time delay. (10°C to 40°C). The Select Option Package features selfdiagnostics, time-delay, and audible failure indication. (10°C to 40°C). The Premium Option Package features high temperature nickel-cadmium battery or high ambient lead-calcium battery. This package also includes self-diagnostics, time delay and audible failure indication. UL listed for 0° to 55°C. The Ultimate Option Package features high temperature nickel-cadmium battery or high ambient lead-calcium battery with heater, thermostat and battery blanket. This package also includes self-diagnostics, time delay and audible failure indication. UL listed for -40° to 55°C. * Damp location comes standard on all Indura products, while the hosedown NEMA 4X listing comes standard on all Indura 4X products. ** For more information on the above features listed within each package, please reference the previous pages containing descriptions of each. For Additional Information Visit our website at www.lithonia.com/indura Page 13 Lithonia Lighting © 2001 Acuity Lighting Group, Inc., Rev. 5/04 Form No. 680.185 REF-120 680.185.pmd Acuity Lighting Group, Inc. Emergency Lighting Systems One Lithonia Way, Decatur, GA 30035 Phone: 800-334-8694 In Canada: 160 avenue Labrosse, Point-Claire, P.Q. H9R 1A1 www.lithonia.com