Reliable

Portable

Durable

Wireless

Introducing SINTERS’

Seat Electronics Tester

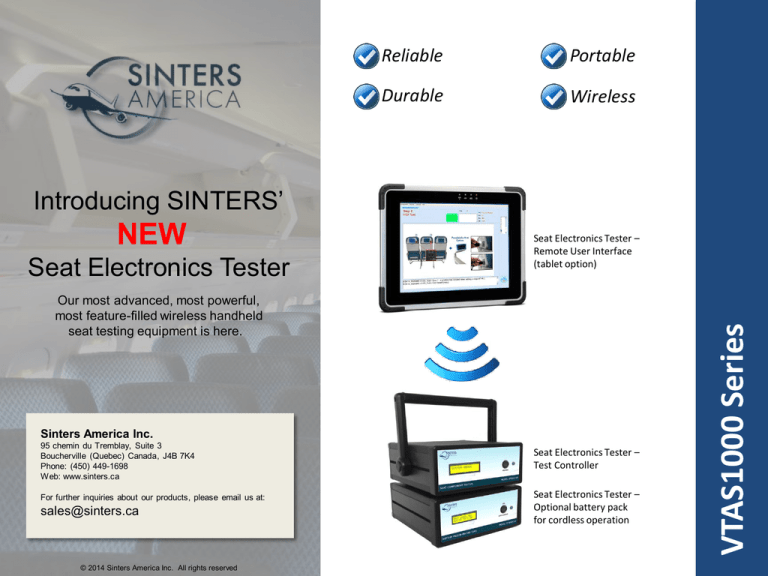

Seat Electronics Tester –

Remote User Interface

(tablet option)

Our most advanced, most powerful,

most feature-filled wireless handheld

seat testing equipment is here.

Sinters America Inc.

95 chemin du Tremblay, Suite 3

Boucherville (Quebec) Canada, J4B 7K4

Phone: (450) 449-1698

Web: www.sinters.ca

For further inquiries about our products, please email us at:

sales@sinters.ca

© 2014 Sinters America Inc. All rights reserved

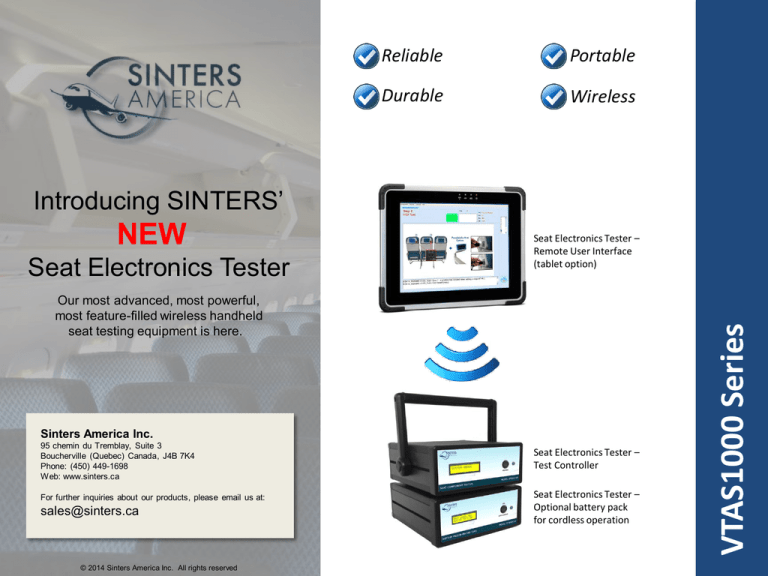

Seat Electronics Tester –

Test Controller

Seat Electronics Tester –

Optional battery pack

for cordless operation

VTAS1000 Series

NEW

VTAS1000 Series Seat Electronics Tester

Sinters’ new Aircraft Seat Electronics Tester provides completely new solution for aircraft seat testing. This new

product is portable and rugged perfect for use both on and off the aircraft.

Our modular hardware & software components are highly upgradeable and customizable to meet the

customer’s strict testing requirements for today and tomorrow.

The Seat Test Component Analysis Software provides a step by step user friendly interface that ensures

repeatable and measureable results during all phases of your testing.

© 2014 Sinters America Inc. All rights reserved

Key features and specifications

User interface

Option 2:

Portable, wired touchscreen with tabletop dock

Option 1:

Wireless remote control (tablet)

Lightweight rugged tablet combining form and function

Remote control of the test controller over Wi-Fi

Large, brilliant, multi-touch display

Weight: 2 pounds

Minimum 4 hours autonomy

Monitor with LED backlight and 4-wire resistive touch panel

Extra robust components and , high-quality pedestal

Single cable connection combining power, video and touch

Suitable for 24/7-operation

Weight: 1.3 pounds

Test Controller

All-in-one data acquisition system and embedded PC

Small enough to fit under the seat

Windows operating system for maximum software flexibility

(the test software runs on the controller)

Provides power to seat electronics for functional testing

All inputs and outputs concentrated into one 156-pos

Zero Insertion Force connector on the rear of the unit

External power input for shop use

Battery power input for on-aircraft use

Dimensions: 8W x 3.5H x 9D inches

Weight: approx. 5 lbs

© 2014 Sinters America Inc. All rights reserved

Key features and specifications (continued…)

Battery pack (optional)

The battery clips onto the bottom of the controller to form a single, portable and cordless test equipment

Battery characteristics: 24V, 10Ah (240Wh)

Battery autonomy: 3h (based on an standard economy class 3-seat group with in-seat IFE)

Charge time: 6h (charger included)

Dimensions: 8W x 3.5H x 9D inches

Weight: approx. 12 lbs

Kit

Includes one Wireless Controller, one tablet, one 240Wh battery pack, one charger and one plug-in power supply

Test Executive Software

Custom cable harness manufactured to aircraft seat specification

1 carrying case below maximum airline carry-on dimensions

© 2014 Sinters America Inc. All rights reserved

How can the Seat Electronics Tester help you?

The system allows you to do a full functional check of the electronic components of a seat or seat row,

including the IFE and other components such as PCU, headphone jacks and power ports, both AC and

USB.

The system is composed of an embedded PC along with data acquisition cards and signal conditioning

components, all of which are packaged into a lightweight and portable box.

In a shop environment, an external 100-240VAC->24VDC power supply powers not only the seat tester but

also the seat or seat row.

Onboard the aircraft, a matching battery pack (24VDC, 10Ah) allows you to go cordless and perform a few

hours of testing without the need for APU or ground power.

The system can be fixed of mobile.

• The unit has VGA and USB outputs to which can be connected a display and keyboard and mouse.

• Also offered as means of user interface is a touchscreen or tablet for portable applications.

Uses:

Manufacturing

Validate wiring and functionality before delivery (EOL testing).

Line maintenance

Debug one or more faulty seat rows / components (between flights or overnight)

Heavy maintenance

After seat repair or refurbishment, validate wiring and functionality before reinstallation into aircraft

© 2014 Sinters America Inc. All rights reserved

How can the Seat Electronics Tester help you? (continued…)

Available inputs and ouputs:

•

•

•

•

4 + 4 stereo audio inputs and outputs

16 digital outputs

8 x 28V/open digital inputs

8 x GND/open digital inputs

•

•

•

•

•

2 analog outputs

8 analog inputs

2 x Ethernet

4 x USB

Optional CAN, I2C, SPI

Software

Easy to use test executive (or test manager) into which all the test procedures are scripted. The user /

owner has full access to the test scripts and, with a minimum of programming background, can program

and execute new test functionalities in very little time.

Being Windows based (XP embedded to be more precise) you can also install proprietary test software

onto the machine and run it side by side with the Seat Tester software.

© 2014 Sinters America Inc. All rights reserved

Test Executive Software

Easy to learn and user-friendly test executive (or test manager) into which all the test procedures are

scripted. The user / owner has full access to the test scripts and, with a minimum of programming

background, can program and execute new test functionalities in very little time.

Being Windows based (XP embedded to be more precise) you can also install proprietary test software onto

the machine and run it side by side with the Seat Tester software.

© 2014 Sinters America Inc. All rights reserved

Test Executive Software (continued…)

On the preceding slide is a screenshot of the test executive’s GUI, loaded with a sample 2-seat row

configuration.

The left side of the screen shows the seat row structure, including 2 seats and their respective monitors

(identified ans SVDUs, short for Seat Video Display Unit), audio ports, PCU, USB and power ports.

The test structure (tree) is configured using an XML file. To each tree element is associated a test script

programmed to validate the individual component. The second column of the tree will show the results of

each individual as they are executed.

Test control is done using the button bar in the right-mid section. Run selected will run the test associated to

the selected tree item. Run all will run the test scripts for all the seat (row) components, starting from the top.

Stop allows you to stop execution of a test at any time. The Report button displays the test report (user

configurable, HTML format) and allows saving to disk/network or printing.

Test scripts can be programmed to display instructions and prompts (buttons or text input) in the dark blue

area above the button bar. The right top area is there for the test scripts to display images (graphical

instructions for example).

Finally, the black area is a “log” area where the test scripts can display status or progress information

(optional).

© 2014 Sinters America Inc. All rights reserved

About SINTERS AMERICA inc.

Headquartered in Montreal (Québec), SINTERS AMERICA INC. is an Automated Test Equipment integrator

providing end-to-end solutions to the aerospace industry.

From concept to final production, engineering to manufacturing, SINTERS AMERICA INC. ,an AS9100

company, has since 2002 developed unique solutions and products for Airlines, MROs and OEMs such as

Air Canada, United Airlines, Airbus, ATR, Boeing, Bombardier, CAE, Pratt & Whitney and Safran.

© 2014 Sinters America Inc. All rights reserved