Measuring Instruments for Gear Testing

advertisement

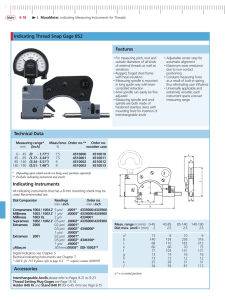

Chapter - page Measuring Instruments for Gear Testing Measurement of Tooth Span 8 - 2 Precision Micrometer 40 SM 8 - 2 Indicating Snap Gauge 840 FM 8 - 3 Tooth Span Formula, Tooth Span Table 8 - 4 Thread Micrometer 40 Z 8 - 5 Inside Thread Micrometer 44 FZ 8 - 5 Indicating Thread Snap Gauge 852 8 - 6 Anvils for 40 Z, 44 FZ and 852 8 - 7 Universal Measuring Instrument 844 T 8 - 8 Measuring Arms, Mounting Attachments and Anvils for Universal Measuring Instrument 844 T 8 - 9 Dial Bore Gauge for Inside Serrations 844 Z 8 - 10 8-1 Measuring Instruments for Gear Testing Measurement of Tooth Span Measuring tooth span enables indirect determination of the tooth thickness. Contrary to the specific measuring of tooth thickness, this procedure is performed totally without any reference points. Tooth span dimension Wk is measured over a specific number of teeth. The contact faces of the instrument are placed one on the lefthand flank and one on the righthand flank of the gear to be checked in the vicinity of the pitch circle (see sketch on left). The number of teeth k, the instrument is placed over, depends on the total number of teeth z and the pressure angle α. Use formula (see page 8-4) for the determination of the nominal dimension of tooth span Wk and number of teeth k . For spur gears with straight teeth there are tables for the determination of these two dimensions (for pressure angle αn= 20° see page 8-4). Wk Precision Micrometer 40 SM with disc-type anvils Features • For measurement of tooth spans as of module m= 0,8 mm • Chromium-plated steel frame • Maximum stability (for measuring ranges 0 - 95 mm) one piece frame and spindle guide • Measuring spindle hardened throughout and ground • Discs hardened and lapped • Scales with satin-chrome finish • Heat insulators • Ratchet stop with integrated coupler • Locking device • Standard accessories: Case (measuring ranges 0 - 95 mm), setting standard (as of measuring range 20 - 45 mm) Technical Data Measuring range mm 0 20 45 70 95 120 145 170 - 20 45 70 95 120 145 170 195 Readings mm 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 Span of error (DIN 863) fmax µm 4 4 5 5 6 6 7 7 Spindle thread pitch mm 0,5 0,5 0,5 0,5 0,5 0,5 0,5 0,5 Measuring face flatness parallelism µm µm ≤ ≤ ≤ ≤ ≤ ≤ ≤ ≤ 0,6 0,6 0,6 0,6 0,6 0,6 0,6 0,6 ≤ ≤ ≤ ≤ ≤ ≤ ≤ ≤ 4 4 4 4 5 5 5 5 Accessories Wooden case see page 1-25 8-2 Further applications see page 1-20 Order no. 4145000 4145001 4145002 4145003 4145004 4145005 4145006 4145007 Measuring Instruments for Gear Testing Indicating Snap Gauge 840 FM Marameter M with measuring jaws Features • Constant measuring force due to built-in spring; thus eliminating user influence • Highly versatile • Each gauge covers a large range. Within the respective limits, quickly and easily adjusted to any size and any type of measuring application. • Rugged, forged steel frame with heat insulators • Measuring spindle mounted in long guideway, levercontrolled retraction • Anvil spindle easily adjustable • Maximum wear resistance due to non-contact positioning in conjunction with carbide-tipped measuring faces • Measuring spindle and anvil spindle made of hardened stainless steel with extending carbide-tipped measuring jaws Indicating Instruments Any dial indicator featuring an 8 mm mounting shank may be used. Recommendations: Dial Comparators Readings Order no. Zentimess 1010 Compramess 1004 Millimess 1003 Supramess 1002 Extramess 2000 0,01 mm 5 µm 1 µm 0,5 µm 0,2 / 0,5 / 1 µm 4332000 4333000 4334000 4335000 4346000 Accessories Setting Discs 390 see chapter 10 Gauge blocks see chapter 10 Holder 840 Fk and Stand 840 Ff see page 6-10 Digital Dial Indicators “Millitast” see chapter 3 Electrical Indicating Instruments “Millitron” see chapter 4 Dial comparators in inch-version see chapter 3 Technical Data Measuring range mm 0 40 80 130 - 40 - 80 - 130 - 180 (inch) (0 (1.5 (3 (5 Measuring force N 1.5“) - 3“) - 5“) - 7“) 7,5 7,5 9 9 face mm 12 12 15 15 x x x x 12 12 17 17 Measuring face Tooth span flatness parallelism measurements µm µm as of module m ≤ ≤ ≤ ≤ 0,5 0,5 0,5 0,5 ≤ ≤ ≤ ≤ 2 3 3 3 0,5 0,5 1,0 1,0 Order no.* Order no. wooden case 4452000 4452001 4452002 4452003 4450011 4450012 4450013 4450014 * without indicating instrument Further applications see page 6-7 8-3 Measuring Instruments for Gear Testing Formula for Calculating Tooth Span used for calculation of nominal dimensions of tooth span and number of teeth The following relations are valid: Wk = mn • cos αn[(k-0,5) • π+z • inv αn]+ 2 • x • mn sin αn k=z• αn 180 + 0,5 x = profile displacement mn = standard module k inv αn = tan αn - αn(α in arch dimension) z = number of teeth of gear αn = number of teeth between measuring faces = standard pressure angle Table of Tooth Span for gears with straight teeth and without profile displacement Pressure angle αn = 20° module mn = 1 This table refers to module 1. In case of modules other than 1 the tooth span dimension Wk , which has been calculated, is multiplied by the module of the gear to be checked. If a profile displacement occurs, value + 2 • x • mn • sin αn is added to tooth span dimension Wk . In case of negative profile displacement, factor x must be designated as negative. Explanation of symbols: z = total number of gear teeth Wk = nominal dimension k = number of teeth in between measuring faces of measuring instrument z k Wk z k Wk 10 11 12 13 14 2 2 2 2 2 4,5683 4,5823 4,5963 4,6103 4,6243 45 46 47 48 49 5 6 6 6 6 13,9148 16,8810 16,8950 16,9090 16,9230 15 16 17 18 19 2 2 2 2 3 4,6383 4,6523 4,6663 4,6803 7,6464 50 51 52 53 54 6 6 6 6 6 20 21 22 23 24 3 3 3 3 3 7,6604 7,6744 7,6884 7,7025 7,7165 55 56 57 58 59 25 26 27 28 29 3 7,7305 3 7,7445 3 7,7585 4 10,7246 4 10,7386 30 31 32 33 34 4 4 4 4 4 35 36 37 38 39 40 41 42 43 44 8-4 z k Wk z k Wk z k Wk z k Wk 80 9 26,2135 81 9 26,2275 82 10 29,1937 83 10 29,2077 84 10 29,2217 115 116 117 118 119 13 13 13 14 14 38,5123 38,5263 38,5403 41,5064 41,5205 150 151 152 153 154 17 17 17 17 18 50,8110 50,8250 50,8390 50,8530 53,8192 185 186 187 188 189 21 21 21 21 21 63,1097 63,1237 63,1377 63,1517 63,1657 16,9370 16,9510 16,9650 16,9790 16,9930 85 86 87 88 89 10 10 10 10 10 29,2357 29,2497 29,2637 29,2777 29,2917 120 121 122 123 124 14 14 14 14 14 41,5344 41,5484 41,5625 41,5765 41,5905 155 156 157 158 159 18 18 18 18 18 53,8332 53,8472 53,8612 53,8752 53,8892 190 191 192 193 194 22 22 22 22 22 66,1319 66,1459 66,1599 66,1739 66,1879 7 7 7 7 7 19,9591 19,9732 19,9872 20,0012 20,0152 90 91 92 93 94 10 11 11 11 11 29,3057 32,2719 32,2859 32,2999 32,3139 125 126 127 128 129 14 14 15 15 15 41,6045 41,6185 44,5846 44,5986 44,6126 160 161 162 163 164 18 18 18 19 19 53,9032 53,9172 53,9312 56,8973 56,9113 195 196 197 198 199 22 22 22 22 23 66,2019 66,2159 66,2299 66,2439 69,2101 60 61 62 63 64 7 7 7 7 8 20,0292 20,0432 20,0572 20,0712 23,0373 95 96 97 98 99 11 11 11 11 11 32,3279 32,3419 32,3559 32,3699 32,3839 130 131 132 133 134 15 15 15 15 15 44,6266 44,6406 44,6546 44,6686 44,6826 165 166 167 168 169 19 19 19 19 19 56,9254 56,9394 56,9534 56,9674 56,9814 200 201 202 203 204 23 23 23 23 23 69,2241 69,2381 69,2521 69,2661 69,2801 10,7526 10,7666 10,7806 10,7946 10,8086 65 66 67 68 69 8 8 8 8 8 23,0513 23,0653 23,0793 23,0933 23,1074 100 101 102 103 104 12 12 12 12 12 35,3500 35,3641 35,3781 35,3921 35,4061 135 136 137 138 139 15 16 16 16 16 44,6966 47,6628 47,6768 47,6908 47,7048 170 171 172 173 174 19 19 20 20 20 56,9954 57,0094 59,9755 59,9895 60,0035 205 206 207 208 209 23 23 23 24 24 69,2941 69,3081 69,3221 72,2882 72,3022 4 4 5 5 5 10,8226 10,8367 13,8028 13,8168 13,8308 70 71 72 73 74 8 8 8 9 9 23,1214 23,1354 23,1494 26,1155 26,1295 105 106 107 108 109 12 12 12 12 13 35,4201 35,4341 35,4481 35,4621 38,4282 140 141 142 143 144 16 16 16 16 16 47,7168 47,7328 47,7468 47,7608 47,7748 175 176 177 178 179 20 20 20 20 20 60,0175 60,0315 60,0456 60,0596 60,0736 210 211 212 213 214 24 24 24 24 24 72,3163 72,3303 72,3443 72,3583 72,3723 5 5 5 5 5 13,8448 13,8588 13,8728 13,8868 13,9008 75 76 77 78 79 9 9 9 9 9 26,1435 26,1575 26,1715 26,1855 26,1995 110 111 112 113 114 13 13 13 13 13 38,4422 38,4563 38,4703 38,4843 38,4983 145 146 147 148 149 17 17 17 17 17 50,7410 50,7550 50,7690 50,7830 50,7970 180 181 182 183 184 20 21 21 21 21 60,0876 63,0537 63,0677 63,0817 63,0957 215 216 217 218 219 24 24 25 25 25 72,3863 72,4003 75,3664 75,3804 75,3944 Measuring Instruments for Gear Testing Checking of Pitch Circle Diameter Measuring of the roller dimension MdR or ball dimension MdK of gears enables indirect determination of tooth thickness. This procedure is chosen mainly for narrow gears with helical teeth or gears with large helix angles on which tooth span checks cannot be performed. A measuring ball or roller is placed in two tooth spacings which are opposite each other. The diameter of the measuring ball or roller is such that it contacts the tooth flank in the vicinity of the pitch circle where the involute error is at its minimum and hardly influences the measuring results. MdR MdK DM Md - 2 DM Md + 2 DM MdR/MdK DM DM = Roller dimension of gear = Ball dimension of gear = Roller or ball diameter = Setting dimension for gears with external teeth = Setting dimension for gears with internal teeth DM MdR/MdK Thread Micrometer 40 Z Inside Thread Micrometer 44 FZ Features Features • Rugged steel frame with heat insulators. One piece frame and spindle guide up to and including 100 mm, for maximum stability • Measuring spindle hardened throughout, ground and provided with locking lever • Adjustable anvil • Spindle and anvil with mounting bores for accommodating interchangeable anvils • Flat end surface of anvil rests on hardened steel ball in bottom of mounting bore • Scales with satin-chrome finish Technical Data Readings Mounting bores for anvils Spindle thread pitch Thimble dia. Measuring range mm 0 25 50 75 100 125 150 175 - 25 50 75 100 125 150 175 200 • Lightweight, rigid tubular construction • Measuring spindle hardened throughout and ground • Two mounting bores for interchangeable anvils • One anvil holder adjustable DM • As of 100 mm, heat insulation and locking lever • Anvil shank rests on hardened steel ball in bottom of mounting bore • Delivered in case Technical Data 0,1 mm Readings Mounting bores for anvils Spindle thread pitch Thimble dia. 3,5 mm 0,5 mm 17,5 mm Span of error fme (DIN 863) Order no. Order no. wooden case 4 µm 4 µm 5 µm 5 µm 6 µm 6 µm 7 µm 7 µm 4170000 4170001 4170002 4170003 4170004 4170005 4170006 4170007 4170010 4170011 4170012 4170013 4170014 4170015 4170016 4170017 Dimensions and accessories see page 7-2 Measuring range mm 75 100 125 150 175 - 100 125 150 175 200 0,1 mm 3,5 mm 0,5 mm 17,5 mm Span of error fme (DIN 863) 5 µm 6 µm 6 µm 7 µm 7 µm Order no. 4179000 4179001 4179002 4179003 4179004 Interchangeable anvils see page 8-7 resp. page 7-6 for threads Dimensions and accessories see page 7-5 8-5 Measuring Instruments for Gear Testing Indicating Thread Snap Gauge 852 Features • Rugged, forged steel frame with heat insulators • Mounted in long guideway, lever-controlled retraction • Anvil spindle easily adjustable • Measuring spindle and anvil spindle made of hardened, stainless steel with mounting bores for interchangeable anvils • Adjustable center stop for automatic alignment • Max. wear resistance due to non-contact positioning • Constant measuring force due to built-in compression spring; thus measuring results independent of user influence • Highly versatile. The gauge covers a large range Indicating Instruments Technical Data Measuring range* mm (inch) 0 45 85 140 Measuring Order no.** Order no. force N wooden case (0-13/ - 45 4“) - 85 (13/4-33/8“) - 140 (33/8-51/2“) - 190 (11/2-71/2“) 7,5 7,5 9 9 4510000 4510001 4510002 4510003 * depends on anvils used ** without indicating instrument 4510010 4510011 4510012 4510013 Any dial indicator featuring an 8 mm mounting shank may be used. Recommendations: Indicating instrument Dial Indicator 810 Zentimess 1010 Compramess 1004 Millimess 1003 Extramess 2000 Readings Order no. 0,01 mm 0,01 mm 5 µm 1 µm 0,2 / 0,5 / 1 µm 4311110 4332000 4333000 4334000 4346000 Digital Dial Indicators “Millitast” see chapter 3 Electrical Indicating Instruments “Millitron” see chapter 4 Indicators in inch-version see chapter 3 Accessories Interchangeable Anvils see page 8-7 resp. page 7-9 for threads Holder 840 Fk and Stand 840 Ff (for 0-45 mm) see page 6-10 Dimensions see page 7-7 0,5 0,5 Measuring Range +10mm 8-6 Measuring Instruments for Gear Testing Anvils for 40 Z / 44 FZ / 852 Interchangeable Ball Anvils For measuring gears and for special applications. Carbide ball. With cylindrical mounting shank and retainer ring. For mounting into mounting bores of thread micrometers 40 Z, 44 FZ and 852. Shank dia. Shank length Accuracy of ball dia. Module 0,6 0,7 0,9 1 1,25 1,5 1,75 2 2,5 2,75 3 3,25 3,5 H 3,5 mm 15,5 mm ± 2 µm Dia. mm Dimension mm Order no. 1 1,25 1,5 1,75 2 2,5 3 3,5 4 4,5 5 5,5 6 5,5 5,8 6,0 6,3 6,5 7,0 7,5 8,0 8,5 9,0 9,5 10,0 10,5 4170550 4170551 4170552 4170553 4170554 4170556 4170557 4170558 4170559 4170560 4170561 4170562 4170563 Further sizes on request (material: steel) Roller Blades For measuring gears and for special applications. Measuring roller made of carbide. For mounting in mounting bores of thread micrometers 40 Z, 44 FZ and 852. Shank dia. Shank length Accuracy of ball dia. Module 0,6 0,7 0,9 1 1,25 1,5 1,75 2 2,5 2,75 3 3,25 3,5 H 3,5 mm 15,5 mm ± 2 µm Dia. mm Dimension H mm Order no. 1 1,25 1,5 1,75 2 2,5 3 3,5 4 4,5 5 5,5 6 5,5 5,8 6,0 6,3 6,5 7,0 7,5 8,0 8,5 9,0 9,5 10,0 10,5 4510200 4510201 4510202 4510203 4510204 4510206 4510207 4510208 4510209 4510210 4510211 4510212 4510213 Further sizes on request (material: steel) 8-7 Measuring Instruments for Gear Testing Universal Measuring Instrument 844 T Multimar Features • External and internal serrations • Rugged, ground and hard chromium-plated column • Movable arm holder mounted in precision ball guide to eliminate play and friction • Stationary arm holder can be moved on column for rough setting • High sensitivity and maximum accuracy by maximum freedom and stability of movable arm holder • Constant measuring force due to built-in compression spring • Reversable measuring force direction for external and internal measurements • Measuring arms can be reversed to extend measuring range Technical Data Measuring range* mm (inch) 25 100 250 600 - 110 - 260 - 610 - 1010 (1 - 4.33“) (4 - 10.24“) (10 - 24.02“) (24 - 39.76“) Extended measuring range mm (inch) 25 100 250 600 - 185 - 335 - 685 - 1085 Travel of movable anvil mm (1 - 7.28“) (4 - 13.18“) (10 - 26.96“) (24 - 42.71“) * These ranges apply to inside measurements. For outside measurements they are decreased by 25 mm. Extension of measuring range by 180° reversal of measuring units. All measuring ranges depend on measuring anvils used. ** without indicating instrument Indicating Instruments Any dial indicator featuring an 8 mm mounting shank may be used. Recommendations: Indicating Instruments Readings Order no. Dial Indicator 810 0,01 mm Zentimess 1010 0,01 mm Compramess 1004 5 µm Digital Dial Indicator “Millitast“ 1083 1 µm Digital Dial Indicator “Millitast“ 1085 1 µm 4311110 4332000 4333000 4336800 4336301 Electrical Indicating Instruments “Millitron” see chapter 4 Indicators in “inch“-version see chapter 3 8-8 10 10 10 10 Order no.** 4500001 4500002 4500003 4500004 Order no. wooden case 4500010 4500011 4500012 4500013 Measuring Instruments for Gear Testing Measuring Arms, Mounting Attachments and Anvils for Universal Measuring Instrument 844 T Measuring Arms 844 Te For outside and inside diameters. With bore dia. 3,5 mm for accommodation of Interchangeable Anvils 844 Tk. Throat depth a Order no. 25 mm 50 mm 100 mm 4500020 4500021 4500022 Ball Anvils 844 Tk 844 Te Module mm 0,6 0,7 0,9 1 1,25 1,5 1,75 Dia. mm Order no. Module mm Dia. mm Order no. 1 1,25 1,5 1,75 2 2,5 3 4500350 4500351 4500352 4500353 4500354 4500356 4500357 2 2,5 2,75 3 3,25 3,5 3,5 4 4,5 5 5,5 6 4500358 4500359 4500360 4500361 4500362 4500363 DM a Made of carbide. With cylindrical mounting shank and retainer ring which ensures locking but permits rotation in bore of measuring arms 844 Te. Shank dia. 3,5 mm Shank length 6 mm Accuracy of ball dia. ± 2 µm 844 Tk 844 Tm l Mounting Attachment 844 Tm DM Accommodates Cylindrical Measuring Pins 844 Tz for checking of external and internal gears. Order no. 844 Tz 4500030 Cylindrical Measuring Pins 844 Tz Further Accessories for Universal Measuring Instrument 844 T Made of steel, with shank fitting into bore of arms 844 Tm. For Module mm 0,6 0,7 0,9 1 1,25 1,5 1,75 2 2,5 2,75 3 3,25 3,5 Dia. mm Length l mm Order no. 1 1,25 1,5 1,75 2 2,5 3 3,5 4 4,5 5 5,5 6 6 6 6 10 10 10 15 15 15 20 20 20 20 4500500 4500501 4500502 4500503 4500504 4500506 4500507 4500508 4500509 4500510 4500511 4500512 4500513 - inside and outside dimensions external and internal threads registers small collars recesses and grooves inside and outside tapers external and internal threads see page 1-7 8-9 Measuring Instruments for Gear Testing Dial Bore Gauge for Inside Serrations 844 Z Features • For rapid and precise measurement of dimension over balls, roundness and conicity of internal gears in any position and at any depth. Gauge consists of a few modular units for quick conversion of the gauge to another gear size within the large total measuring range. Measuring range Holder 844 Kg with clamping device for indicator. Diameter of mounting bore 8 mm Order no. 4470851 26 - 300 mm Extension 844 Kv for extra-deep bores; length 64 mm Order no. 4470070 Modular Units: Measuring Head 844 z1 for dimensions over balls MdK 26 - 125 mm for screwing-in of Floating Ball Anvil 844 z3 Ball Anvils 844 z5 - 844 z8 Extensions 844 z9 - 844 z12 Order no. 4485000 Lifting Knob 954 Measuring Head 844 z2 Wooden case Facilitates insertion of measuring instrument in serration; thus measuring spindle of indicator is lifted. Order no. 4372030 for dimensions over balls MdK 48,5 - 300 mm for screwing-in of Floating Ball Anvil 844 z4 Ball Anvils 844 z5 - 844 z8 Extensions 844 z9 - 844 z13 Order no. 4485001 Order no 4485013 Floating Ball Anvil 844 z3 for dimensions over balls MdK 26,0 - 125 mm measuring range 3 mm in connection with measuring head 844 z1 954 Floating Ball Anvil 844 z4 for dimensions over balls MdK 48,5 - 300 mm measuring range 3 mm in connection with measuring head 844 z2 844 Kg Ball Anvils 844 z5 - 844 z8 for Measuring Heads 844 z1 and 844 z2 with carbide ball Type 844 844 844 844 z5 z6 z7 z8 Length in mm 2,5 5,0 7,5 10,0 844 Kv Extensions 844 z9 - 844 z13 844 z1 for extending measuring range Type 844 844 844 844 844 z9 z10 z11 z12 z13 844 z5 Length in mm Order no. 10 20 40 80 100* 4486501 4486502 4486503 4486504 4486505 844 z9 844 z3 844 z10 844 z6 23,5-26,5mm 844 z11 844 z7 844 z2 844 z8 844 z4 844 z12 844 z13 46-49mm *only for 844 z2 8-10 Measuring Instruments for Gear Testing Dial Bore Gauge for Inside Serrations 844 Z Selection of the modular units Determination of the setting value Example: Desired-measurement over balls Mi 85,530 mm and assignment of ball diameters to module Selecting of Measuring Head: Measuring Head 844 z2 + Floating Ball Anvil 844 z4 /. 46,000 mm 39,530 mm Selecting of Extensions: 39,530 mm 844 z9 + 844 z10 /. 30,000 mm 9,530 mm Selecting of Ball Anvils: 9,530 mm 844 z7 /. 7,500 mm Remaining value* 2,030 mm Mi + 2 DM Mi DM DM *Remaining value must be within measuring range of Floating Ball Anvil 844 z3 or 844 z4. When ordering, please state ball diameter of the modular units 844 z3-844 z8. It depends on module of serration and can be determined from right-hand table. = Ball diameter of the ball anvil DM Mi = Measurement over balls = Setting value Mi + 2 DM (length of the gauge block required for setting) Measuring range 83,5 - 86,5 mm 844 z7 7,5 844 z2 844 z9 + 844 z10 30 844 z4 Module m 0,3 0,35 0,4 0,45 0,5 0,55 0,6 / 0,65 0,7 / 0,8 0,9 1 1,25 1,5 1,75 2 46-49 Mi Indicating Instruments Ball dia. DM (mm) 0,5 0,6 0,7 0,75 0,85 0,9 1 1,25 1,5 1,75 2 2,5 3 3,5 Module m 2,25 / 2,5 2,75 3 3,25 3,5 3,75 4 4,5 5 5,5 6 7 8 9 Ball dia. DM (mm) 4,0 4,5 5,0 5,5 6,0 6,35 6,5 7,5 8,5 9,0 10,0 12,0 13,5 15,0 Further ball diameters on request. Any dial indicator featuring an 8 mm mounting shank may be used. Recommendations: Indicating Instruments Dial Indicator 810 Zentimess 1010 Compramess 1004 Millimess 1003 Extramess 2000 Readings Order no. 0,01 mm 0,01 mm 5 µm 1 µm 0,2 / 0,5 / 1 µm 4311110 4332000 4333000 4334000 4346000 Digital Dial Indicators “Millitast” see chapter 3 Electrical Indicating Instruments “Millitron” see chapter 4 8-11