a comparative study of aluminum and tungsten silicon schottky diodes

advertisement

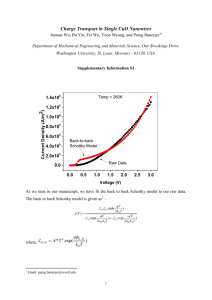

A COMPARATIVE STUDY OF ALUMINUM AND TUNGSTEN SILICON SCHOTTKY DIODES PABLO R. DE SOUZA, JACOBUS W. SWART AND JOSÉ A. DINIZ. Centro de Componentes Semicondutores (CCS) – and Faculdade de Engenharia Elétrica e de Computação (FEEC) – UNICAMP, C. P. 6061, CEP 13083-970, Campinas - SP. e-mail: pablo@led.unicamp.br ABSTRACT Power semiconductor devices have gained special attention in modern electronic systems, as the power required has been increased. An increase in efficiency in use of energy is crucial in the modern world, because energy, most party provided from natural resourses, is not unlimited for the human beings. Schottky diodes are important devices for these applications. This work presents a comparison between Schottky diodes fabricated with tungsten and aluminum as Schottky metal contact, to better understand and help to choose between materials that fulfill power electronics applications requirements. The results indicate superior characteristics for tungsten Schottky diodes compared to aluminum Schottky diodes. 1. INTRODUCTION Power semiconductor devices play a fundamental role in electronic systems. Besides controlling high power values, it is necessary that there is a good yield of these devices, increasing the power efficiency of the equipment for the best use of electric energy, because that is also a limited resource for the human beings. For voltages below 100V, the main applications are: power supplies for computers and telecommunications, automotive electronics, and so on (1). The volume of data processed by microprocessed systems, has been growing largely in last times, with these systems operating at high frequency. With the increase on frequency operation, current is drained more and more at each clock cycle, with the current levels rising at the same speed of frequency. To reduce power dissipation on devices, it is necessary to reduce the operating voltage, because as the power is proportional to the square of voltage, reducing this value to the half, the power dissipated is reduced to a quarter. Presently, it is common systems working with voltages below 2V, controlling loads of some hundreds of amperes, with tolerance of just some dozens of milivolts, like the last generation of Intel processors operating with more than 100 amperes of current in full load (2). With the proliferation of personal computers, the increase of power supplies efficiency is essential to reduce losses of energy, resulting on reduction of size and weight of the equipment, which is attractive to consumers. These sources operate in high frequencies due to the efficiency improvements and reduction in size of some components, as inductors and transformers for switched power supplies. Therefore, power semiconductor devices with low forward drop voltage and ability to operate at high frequency applications, is necessary to fulfill the requirements of these electronic systems. A Schottky rectifier has a low forward voltage drop, around 0.55V, reducing the power dissipated in on state operation. Besides, the Schottky diode has the advantage of high frequency operation, because no minority carriers are involved, and so does not present current transient delay, as in the case of a pn diode. For low voltage applications, below 100V, silicon Schottky diode is the most appropriate, due to the low cost of the manufacturing process robustness of silicon compared to other semiconductors. The forward voltage drop and leakage current of Schottky diodes, can be controlled with the right choice of the Schottky contact metal. Schottky barrier height is an important parameter of this device. Ideally, or in a first attempt, it can be determined by the diference of metal work function and the silicon electronic affinity, for n-type silicon substrate. The forward voltage drop can be reduced by choosing a low work function metal to form the Schottky contact. However, leakage current increases for low Schottky barrier height. Thus, it is necessary to establish a trade-off between direct and reverse IxV characteristics in the appropriated choice of the Schottky barrier metal. This work presents a study of static and dynamic characteristics comparing Schottky diodes made with aluminum and tungsten, as Schottky barrier metal, to determine what is the best material to use for power Schottky rectifiers. 2. EXPERIMENTS The devices were fabricated on n-type silicon substrates (orientation (100) and resistivity ranging from 0.008 – 0.020 Ω.cm) with an n-type epitaxial layer (thickness 3.6µm – 4.4µm and resistivity ranging from 1.09 – 1.11 Ω.cm). The samples were cleaned with H2SO4/H2O2 (1:5 at 85ºC), 10% HF solution, NH4OH/H2O2/H2O (1:5:5 at 85ºC) and HCl/H2O2/H2O(1:5:5 at 85ºC). For tungsten Schottky diodes, a tungsten film of 200nm thick was deposited by magnetron sputtering, and in addition, an aluminum layer of 1µm thick was deposited on top of the tungsten layer, by e-beam evaporation process. For aluminum Schottky diodes, an aluminum layer of 1µm thickness was deposited by e-beam evaporation process. Ohmic contact to the substrate was obtained depositing aluminum of 1µm thick on the backside of the wafers. The samples were sintered in forming gas by conventional thermal process at 450ºC during 30 minutes. Figure 1 illustrates the structure of the fabricated devices. The fabricated devices are squares with 4600µm of side, with rounded corner, to minimize the point effect. The square shape was chosen to maximize the use of the silicon wafer area. (a) (b) Figure 1 – Schematic of Schottky diode (a) with aluminum as metal Schottky contact and (b) with aluminum as metal Schottky contact. 3. RESULTS Figure 2 shows direct and reverse IxV characteristics of the fabricated Schottky diodes. Table I shows the parameters extracted from the curves of figure 2. Table I – Schottky diodes parameters extracted from Log(I)xV and reverse IxV curves of the Schottky diodes with W and Al as metal Schottky contact. Metal Schottky Rs VF(I=100mA) η Jr(V=-5V) Is φB contact (ohm) (V) (µA/cm2) (µA) W Al 2.70 2.64 0.50 0.70 1.05 1.04 63 121 2.96 2.30 (eV) 0.70 0.89 Both devices presented good characteristics, considering that they are conventional Schottky diodes that generally present poor reverse characteristics. The ideality factor (η) was close of the unit, indicating that the main process of current transport is due to the termionic emission. The aluminum Schottky diode presented a lower forward voltage drop, VF, (0.50V) and reverse current density, Jr, (63µA/cm2) comparing with the values obtained for aluminum Schottky diode (0.70V and 121µA/cm2). The lower forward voltage drop obtained with tungsten Schottky diodes is due the Schottky barrier height value (φB), that is lower than the Schottky barrier height for aluminum Schottky diode (0.70 eV for W/nSi and 0.89 eV for Al/nSi). However, the higher reverse current density (Jr) obtained for the aluminum Schottky diodes can be associated with aluminum spikes formed at the Schottky contact. These aluminum spikes concentrate high electric field, resulting in high leakage current. The barrier height of aluminum Schottky diodes, formed on n-type silicon wafers, can not be explained by the work function difference between aluminum and Silicon, and it is attributed to a thin p doped silicon layer formed at the Schottky interface. During the sintering process, for ohmic contact formation, some aluminum atoms diffuse into the Silicon surface and act as p-type dopants, forming this thin p type silicon layer (3). Thus, a pn junction is formed resulting in the rectifier behavior of aluminum on n-type silicon Schottky contact devices, resulting on higher breakdown voltage for aluminum Schottky diode. The low breakdown voltage observed for tungsten Schottky diodes can be due the lowering barrier height effects (4). The reverse characteristic of conventional Schottky diodes can be improved introducing a p guard ring to the device structure (5). -1 10 W Al -3 Log(I) (A) 10 -5 10 -7 10 -9 10 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 -10 0 V(V) (a) V(V) -70 0.0 -60 -50 -40 -30 -20 I(A) -5.0m -10.0m -15.0m W Al -20.0m (b) Figure 2 - (a) Log(I)xV and (b) reverse IxV characteristics of tungsten and aluminum Schottky diodes. Table I shows the parameters extracted from the curves of figure 2. Table I – Schottky diodes parameters extracted from Log(I)xV and reverse IxV curves of the Schottky diodes with W and Al as metal Schottky contact. Metal Schottky Rs VF(I=100mA) η Jr(V=-5V) Is φB contact (ohm) (V) (µA/cm2) (µA) W Al 2.70 2.64 0.50 0.70 1.05 1.04 63 121 (eV) 0.70 0.89 2.96 2.30 Table II shows the extracted parameters of voltage and current transient curves in figures 3 and 4 respectively. The input signal used for voltage transient measurements was a square wave with voltage levels +5V to –5V and frequency of 200kHz. For the current transient measurements the square wave frequency was changed to 500Hz. Table II – Schottky diodes parameters extracted from current and voltage transient curves of Schottky diodes with W and Al as metal Schottky contact. Metal Schottky VF (V) IF (mA) IR (µA) tr (ns) tf (µs) contact W Al 0.26 0.55 7.39 7.04 65.58 167 360 450 1 1 Figures 3 and 4 shows that both devices presented very similar switching characteristics, with similar values obtained for rise (tr) and fall (tf) times. It is important to observe that for aluminum Schottky diode, even with the presence of the p-type silicon layer in the Schottky junction, the amount of injected holes is very small, not interfering on switching characteristics of this device. Comparing the on state voltage (VF) and the leakage current (IR) for both devices, we can conclude that tungsten is the proper choice for power Schottky diodes, due the smaller forward voltage drop and lower leakage current. The peaks in the voltage curve are due to the resonant circuit formed by the series resistance of the diode, junction capacitance and parasitic inductance of the circuit used for the measurements. W Al 1 0 V(V) -1 -2 -3 -4 -5 -4.0µ -2.0µ 0.0 2.0µ 4.0µ t(s) Figure 3 – Curves of transient of voltage for the devices with tungsten and aluminum. 40.0m W Al 30.0m 20.0m I(A) 10.0m 0.0 -10.0m -20.0m -30.0m -40.0m 1.016m 1.018m 1.020m 1.022m t(s) Figure 4 – Curves of transient of current for the devices with tungsten and aluminum. 4. CONCLUSION Comparing the characteristics obtained of the fabricated devices, with tungsten and aluminum as metal Schottky contact, tungsten schottky diodes presented better parameters for power electronic applications, mainly for its lower forward voltage drop. However this device presented a low breakdown voltage (-20V). This parameter can be improved by introducing a guard ring in the device structure. The obtained results support the model of the formation of a pseudo pn junction at the Al/Si contact, explaining the larger barrier height than expected when considering work function differences only. In addition, the Al/Si contact is known to produce spikes in the Si surface. This explains the larger leakage currents observed for these diodes. ACKNOWLEDGEMENTS The authors would like to thank support of the staff of CCS for device fabrication. This work received financial support from FAPESP (Fundação de Amparo à Pesquisa do Estado de São Paulo). REFERENCES 1 – B. J. Baliga, “Trends in power semiconductor devices”, IEEE Transactions on Electron Devices, Vol. 43, nº10, pp. 1717-1730, october 1996. 2 – A. Lidow, D. Kinzer, G. Sheridan and D. Tam, “The semiconductor roadmap for power management in the new millennium”, Proceedings of the IEEE, pp. 803-812, june 2001. 3 – T.M. Reith, J. D. Schick, “The electrical effect on Schottky barrier diodes of Si crystalization from Al-Si metal films”, Applied Physics Letters, Vol.25, nº. 9, pp.524526, 1974. 4 – J. M. Andrews, M.P. Lepselter, “Reverse current-voltage characteristics of metalsilicide Schottky diodes”, Solid State Eletronics, Vol. 13, p.p. 1011-1023, 1970. 5 – B. W. Liou, C. L. Lee, “Characteristics of high breakdown voltage Schottky barrier diodes using p+ polycristaline silicon diffused guard ring”, Solid State Electronics, 44, pp.631-638, 2000.