Electrohydraulic Discharge and Nonthermal Plasma for Water

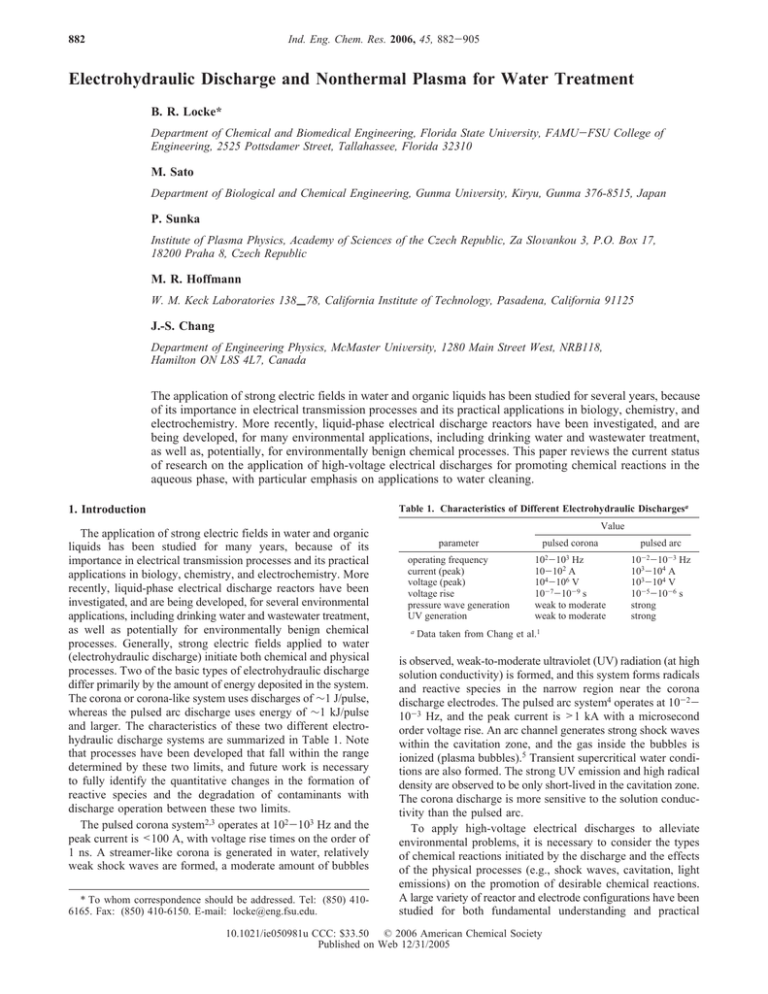

advertisement