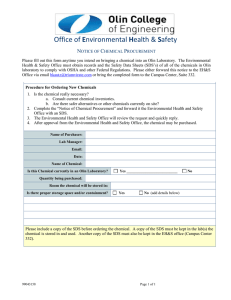

SDS compliance checks

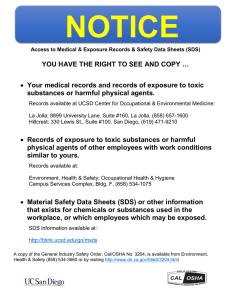

advertisement