2.5Gbps Laser Diode Driver

ments, fast product turn-around time dominates

the customer’s decision-making process in vendor

selection. The exponential growth in optical technology due to this high bandwidth demand, along

with competition in optical components, makes

customers more demanding and specific about

product requirements.

High-Bandwidth Demand

The increasing demand for high-bandwidth in

different applications related to the Internet,

telecommunications, data communications, fiber

channel, etc., has created a tremendous need for

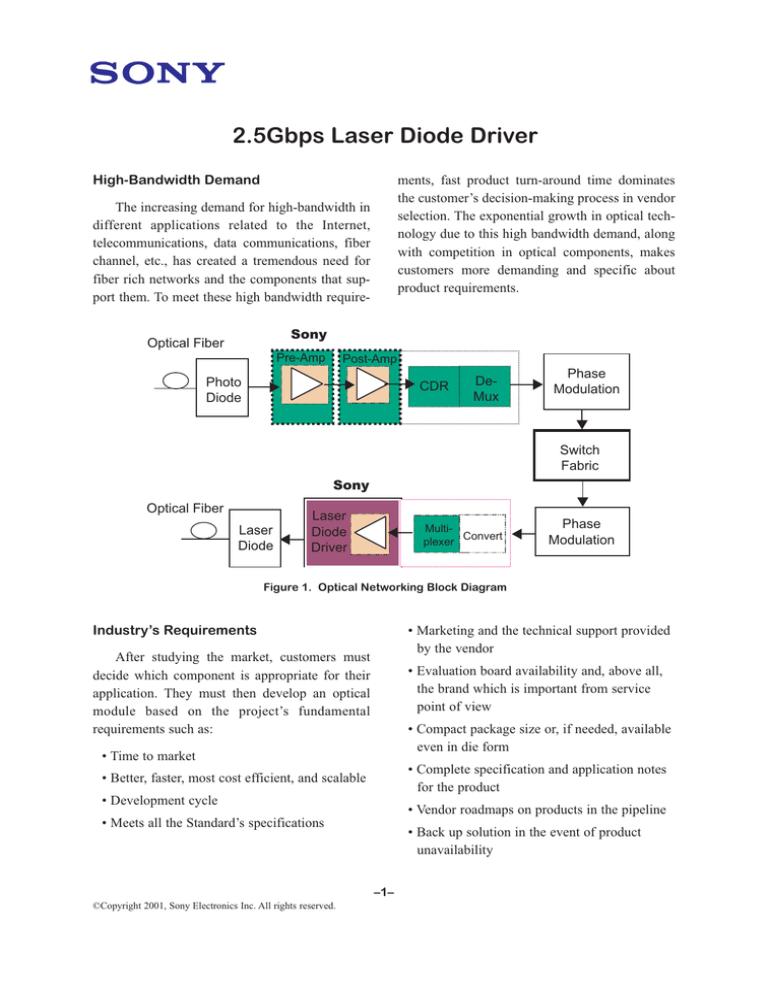

fiber rich networks and the components that support them. To meet these high bandwidth requireSony

Optical Fiber

Pre-Amp

Post-Amp

Photo

Diode

CDR

DeMux

Phase

Modulation

Switch

Fabric

Sony

Optical Fiber

Laser

Diode

Laser

Diode

Driver

Multiplexer Convert

Phase

Modulation

Figure 1. Optical Networking Block Diagram

Industry’s Requirements

• Marketing and the technical support provided

by the vendor

After studying the market, customers must

decide which component is appropriate for their

application. They must then develop an optical

module based on the project’s fundamental

requirements such as:

• Evaluation board availability and, above all,

the brand which is important from service

point of view

• Compact package size or, if needed, available

even in die form

• Time to market

• Complete specification and application notes

for the product

• Better, faster, most cost efficient, and scalable

• Development cycle

• Vendor roadmaps on products in the pipeline

• Meets all the Standard’s specifications

• Back up solution in the event of product

unavailability

–1–

©Copyright 2001, Sony Electronics Inc. All rights reserved.

Qualifying Tests

About Sony’s Laser Diode Driver

Qualification of these devices is time consuming. The customer needs to perform multiple tests,

including:

The CXB18128 is a single high-speed monolithic Laser Diode Driver with positive referenced

emitter coupled logic (PECL) and current mode

logic (CML) input level.

• Electro-optical test, requiring several weeks

CXB1828 has built-in Automatic Power

Control Circuitry (APC) for bias current and a

Signal Duty Correction Circuit. The key function

for this device is to provide the bias output current

and the modulation output current, which is

between 3mA and 50mA. It is available in a compact package and also in a wafer form. The overall characteristics make the Laser Diode Driver

better, faster, more cost efficient and scalable.

Typical applications include fiber optics-based

communications and Gigabit Ethernet.

• Life time tests, taking a few months

• Fulfillment of all standards (ITU / Bellcore)

specifications

• Check AC / DC characteristics and power consumption

• Confirm vendor-provided temperature characteristics and package qualification

Why Sony’s Laser Diode Driver

Sony has a line of optical communication

products and a promising road map including

10Gbps follow-on products. Based on the criteria

and concerns already mentioned, one of these

high-performance optical networking products is

the Laser Diode Driver (LDD). An ideal product

for fiber optics applications, CXB1828 high speed

LDD with Automatic Power Control (APC) is part

of Sony’s family of 2.5 Gbps optical networking

ICs for use in high-performance optical transmitter and receiver functions. The CXB1828 possesses design flexibility while meeting the need for

high performance, reliability, and low cost. It

comes in a compact 32pin VQFN plastic package

with a fine lead pitch of 0.4mm and is proven in

fiber optics applications. A typical SONET application fully utilizing this product is an OC-48

module, producing a data rate of 2.488 Gbps.

The CXB1828 is a complete 2.448Gbps laser

diode driver powered with single +3.3V supply

and the control of the diode bias current is

achieved through the automatic power control circuitry. An APC circuit is provided to maintain

constant laser power in transmitters that use a

monitor photodiode.

The CXB1828 accepts differential PECL and

CML data inputs and provides output currents.

PECL is input to the data buffer at a maximum

data rate. The shutdown and input alarm circuit

disables both the modulation current driver and

laser diode bias generator under various conditions. The shutdown has TTL input to disable output current. This chip also provides an on-chip

input termination of 50 Ohms.

–2–

Features

Application

• Directly drives laser diode

Typical applications for the LDD are:

• Low cost IC fabricated in bipolar process

• Maximum data rate of 2.5Gbps

• SONET /SDH transmission systems and

modules

• Power on Reset function

• OC-48 fiber optic modules

• Automatic Power Control (APC) for bias

control

• SONET/SDH: 622Mbps, 2.5Gbps

• Gigabit Ethernet: 1.25Gbps

• Built in Shutdown, Input Alarm and Reset

circuitry

• Acceptable PECL and CML inputs

• Internal duty cycle correction circuit

• Activity error detector function

• Typical rise time is 100ps

• Low power consumption of 48mA

• Available in both in wafer form or in 32 pin

VQFN package

• On-chip input termination

• Compact package size of 4.8mm X 4.8mm

• Industry standard interface

• Single +3.3V supply voltage

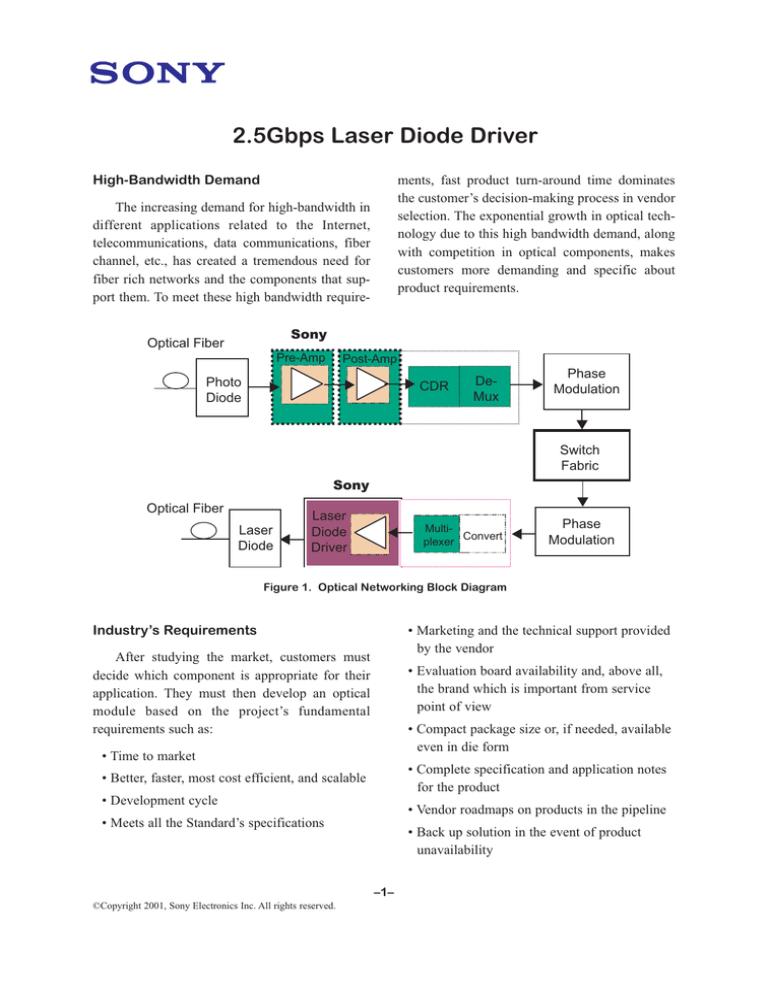

Laser

Diode

Laser Diode Driver

Multiplexer Convert

Phase

Modulation

Figure 2. Typical Transmitter Unit for SONET/SDH Fiber System

As fiber optics data communication products

are growing at a rapid pace, higher speed, compact sizes and increased functionality is imminent. Even though greater integration is possible

(though not desirable in all cases), this provides

the customer more room for flexibility.

Conclusions

Benefits

• Directly drives laser diode

• Low power consumption

• Internal duty cycle correction circuit

Embracing this growing market trend, Sony

will provide more integrated devices with highspeed optical components that reach up to

10Gbps. These devices will be available in wafer

form as well as traditional packaging. Sony’s

product roadmap potentially includes products

such as Post-Amp, Laser Diode Driver (LDD),

Clock & Data Recovery (CDR), SERDES and

Pre-Amp.

• Built in Shutdown, Input Alarm and Reset circuitry

• TTL / PECL/ CML Inputs acceptable

• Compact package size 4.8mm x 4.8mm

–4–