Stretchable Electronics for Smart Textiles

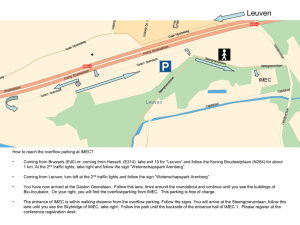

advertisement

Stretchable Electronics for Smart Textiles J. Vanfleteren IMEC – UGent/CMST Technology Park Building 914-A, B-9052 Gent-Zwijnaarde, BELGIUM http://tfcg.elis.ugent.be/ or http://www.cmst.be/ Jan.vanfleteren@elis.ugent.be Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 2 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 3 Introduction • Wearable and implantable systems require lightweight, comfortable, conformable versions of electronics and sensor systems conventional large rigid PCB’s are not acceptable (Philips) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 4 Introduction 2 facts to take into account for development of wearable and implantable circuits : • Fact #1 : In industrial environment : electronic circuits are produced and assembled on flat substrates (rigid or flex) • Fact #2 : Demand for complex systems requires the use of COTS (components-off-the-shelf) like commercial IC’s : microcontrollers, memory, display drivers, radio chips, etc. Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 5 Introduction – options for comfortable electronics Option#1 : Small area flat substrates Requires : • Miniaturisation & high density integration • Use of 3rd dimension of the substrate (multilayer, embedded & stacked Together with KULeuven components, folded flex) • Possible embedding in 3D shaped biocompatible material (Oticon) Implantable pressure sensor Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 6 Introduction – options for comfortable electronics Option#2 : non-flat substrates Case#2a : application allows/requires compact, non-flat assemblies : • from flat to cylindrical or conical shape : possible to use flexible circuits • 3D integration for surface minimization UTCP T. Torfs, FS2, App. Sess. 3 Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 7 Introduction – options for comfortable electronics Option#2 : non-flat substrates Case#2a : application allows/requires compact, non-flat assemblies : • from flat to any other shape (e.g. spherical : stretchable circuits necessary; e.g. spherical camera sensor, (J. Rogers group, Beckman Institute, U. Illinois) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 8 Introduction – options for comfortable electronics Option#2 : non-flat substrates Case#2b : application requires large area, distributed electronics, e.g. displays & signage, sensor arrays • at least flex cylindrical or conical shape • preferably stretchable circuit arbitrary shape Stretchable circuit = (compact) rigid/flex functional islands with stretchable interconnects Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 9 Introduction – options for comfortable electronics Unobtrusive circuits Flat substrates : small area UTCP Flex Non-flat substrates SMI Small area Stretch Large area Stretch Flex (Use as functional islands in stretchable circuits) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 10 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 11 Stretchable electronics • Start from conventionally packaged sensors and electronic components, not available in flexible / elastic format circuits with advanced functionality possible • Individual components or rigid/flexible component islands connected by stretchable wiring Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 12 Introduction - Stretchable wiring options • Conductive polymers : conductivity 3 orders of magnitude lower than metallic conductors – Intrinsic conductive polymers (PEDOT, PANI, Polypyrrole,…) – Stretchable insulating polymers with conductive fillers (e.g. Ag filled silicones) • Nanotechnology based materials : e.g. Metal Rubber™ of Nanosonic Inc. (www.nanosonic.com) : – Self-assembled nanocomposite material – Electrical resistance 5x10-6 Ω·cm (Cu : 1.7 x 10-6 Ω·cm) – Max. elongation : 200% – Still extremely expensive • Metallic conductors – Highest conductivity – Lowest cost – Standard use in PCB industry Our choice But : metals not intrinsically stretchable ?? Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 13 Stretchable wiring – out of plane deformation of metal interconnects • Deposition of Cr/Au conductors on pre-stretched Silicone (S. Lacour, Princeton University, New Jersey, USA) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 14 Stretchable wiring – out of plane deformation of metal interconnects • Lacour et al. (Princeton), IEEE Proceedings, August 2005) • Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 15 2D metallic springs – in plane deformation of metallic interconnects • Stretchability, while maintaining sufficient conductivity, obtained by meander-shaped fine-line metallic conductors - “2D springs” • Mechanical Modelling : Stress under deformation (stretching) dependent on : Wave shape (moderate) – Wave amplitude (moderate) – Line width (drastic) – “multitrack” “horseshoe” shaped conductors Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 16 2D metallic springs – in plane deformation of metallic interconnects Overmoulding of pattern plated Au tortuous wires (Source : D. Gray et al., Johns Hopkins University, Baltimore, MD, USA) expensive process (evaporated silver sacrificial layer, batch processing (no reel-toreel capabilities) “MID” = Moulded Interconnection Device Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 17 CMST’s MID based processes overview Acronym Full Name SMI Stretchable Mould Interconnect SCB Stretchable Copper Board Technology ID SMI-1 SMI-2 SMI-3 SCB-1 Properties Circuit fabrication and component assembly on sacrificial flex or rigid substrate; stretchability introduced at the end of the process Start from elastic substrate; circuit fabrication and component assembly on this substrate Name Plated conductor technology Peelable substrate technology Laser structured conductor technology Stretchable substrate technology Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 18 CMST’s MID (Mould Interconnect Device) processes overview Common technology properties : • Key features : – Meander shaped interconnections – Moulding technology – Stress relief (rigid/flex/stretch transistions) • Processes close to industrial printed circuit manufacturing use conventional leadfree solder assembly process (250-260 degC) • Completely embedded circuits – Washability – Implantability Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 19 SMI-1 : plated conductor technology (a) Flexible base material components Meander shaped wiring (b) Local stiffener Underfill, adhesive (c) Elastic carrier (d) (e) (f) • (a) pattern plating of meander shaped metal wiring on metallic sacrificial substrate (e.g. Au plating on Cu foil) • (b) mount components • (c) mold/cast stretchable substrate material (silicone / poly-urethane) • (d) remove sacrificial substrate (wet etch) • (e) optionally mount additional components • (f) apply second layer of stretchable material for complete embedding Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 20 SMI-1 : plated conductor technology • (a) Flexible base material components Meander shaped wiring (b) Local stiffener Underfill, adhesive (c) • • Elastic carrier (d) • (e) (f) • All processing (including component assembly (b)) is done on non-stretchable substrate, similar to flex assembly completely embedded circuits possible (immersion in liquids, implantation) potential to produce non-planar (e.g. cylindric) circuits (by bending Cu foil + components before moulding) Process applicable for • Any platable metal stack (Au, Ni/Cu/Ni/Au, Pt,..) • Any liquid, curable stretchable materials (silicones (Dow Corning), polyurethanes,...) Back-etch of Cu sheet not environmentally friendly Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 21 Stretchable materials selection Dowcorning type Way of application Sylgard 184 Sylgard 186 Silastic MDX-4210 Spinning Casting Moulding # components Remarks Cure Elongation (%) Young’s Modulus (MPa) Viscosity (Pa.s) 2 Used in literature as a stretchable dielectric 15’ @150°C 160 1,9 3,9 Designed for MEDICAL device encapsulation 15’ @100°C 470 base/curing agent 10:1 WL-5150 Spinning 1 WL-5351 JCR6224 Printing 1 Photopatternable Store @ -15°C BLACK Store @ -20°C 60 Extra products needed * Dowcorning 360 medical fluid =>lower viscosity Lowtemperaturecurable 60’ @150°C 37,6 160 0,45 7,4 370 0,1 3,0 270 • Suppliers of silicone materials : DOW Corning, Nusil • From stretchability point of view : Sylgard and Silastic are the most interesting DOW Corning materials Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 22 Moulding technology for polymer substrates a a) Injection of polymer to embed the first face of system on cupper foil b) Etching of the cupper substrate c) Injection of the bottom layer of polymer d) Unmolding the stretchable system b c d Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 23 Mould Design The areas where the components are, are thicker to make them locally less stretchable. Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 24 Use of solder mask for component assembly 1,5 mm Component Solder or ICA Solder Mask (not removed) 0,5 mm • • Plated stretchable interconnection Silicone component assembly compatible / identical to standard flex circuit assembly low level stress at component assembly sites 8 lead SMD packaged temperature sensor assembled using adhesives and embedded in PDMS (Dow Corning Silastic) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 25 SMI-1 Demonstrators Operating blue LED under 35% stretching Stretch test of operating elastic circuit Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 26 SMI-1 Demonstrators Stretchable thermometer Real-time temperature measurement Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 27 SMI-1 : plated conductor technology Drawbacks of SMI-1 : • Etching of (thick) uniform Cu sacrificial substrate • Shorts between component pads when mounting components : – Impossible to assemble charged battery – Impossible to check circuit functionality and to perform repair Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 28 SMI-2 : Peelable Substrate Technology • Elimination of conducting sacrificial substrate : use polyimide (PI) flex or FR4 type carrier subsrate instead of metal foil • No more plating of the conductors standard PCB Cu • Process close to PCB manufacturing and component assembly practices (use of lead-free solder) • Need for high-T temporary bonding adhesive (withstanding 250degC solder process) copper wax carrier PDMS, PU component Lamination Lithography + wet etch Assembly Embedding I Peeling Embedding II Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 29 SMI-2 demonstrators • Inductive link (with KULeuven/ESAT/MICAS) • 70micron Cu to ensure sufficient high Q-factor • Water-proof operation (> 2 months) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 30 SMI-3 : Laser structured conductor technology Standard flex PI + Cu copper PI wax ceramic silicone Laser cutting Removal of residues component • Very fast prototyping technology • Cu on polyimide carrier high reliability • Industrialization of residue removal step ? Seems difficult Assembly + Molding I Molding II After laser cutting After residue removal Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 31 SMI-3 demonstrators • Normally processed single-sided flex with laser cut stretchable interconnects • Fully functional stretchable wrist watch inlcuding • TI Microcontroller • Rigid 4 x 7 segment TN LCD • Pushbuttons • Battery • Passive components • Lifetime : 1 year (battery) Stretchable watch (master thesis T. Vervust) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 32 SMI-3 demonstrators 2nd Approach : • “perforated flex” : “stretchabilisation” of standard flexible circuit • No real stretchable interconnects • Less deformable, more reliable than 1st approach • 7 x 8 LED matrix, driven by single chip (charlieplexing) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 33 SCB-1 : Stretchable substrate technology (a) (b) (c) (d) (e) (f) copper photoresist Silicone component • Rough copper base substrate (18 μm thick) (a) • Spinning silicone (as thin as few 10s of microns) (b) • Patterning the Cu (c)(d) • Component assembly (now on stretchable substrate) (e) • Conventional PCB manufacturing and component assembly flow • use of high T stretchable material necessary to allow use of vapour phase reflow and SAC solder (260° C max.) for component assembly Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 34 SCB-1 demonstrators Copper TW-TW Spinned silicone Polyimide foil (no adhesion to cured silicone) Patterned meanders and functional island in copper (Ni/Au plating) Soldered components Final system Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 35 Comparison of the process flows Technology SMI-1 SMI-2 SMI-3 SCB-1 Technology SMI-1 SMI-2 SMI-3 SCB-1 Name Plated conductor technology Peelable substrate technology Laser structured conductor technology Stretchable substrate technology Name Plated conductor technology Peelable substrate technology Laser structured conductor technology Stretchable substrate technology Lab throughput speed Potential indutrial throughput speed Conductor thickness (micron) Min. conductor pitch (micron) slow (plating) slow (plating) 4 to 7 30 fast fast 17, 35, 70 100 very fast slow (laser structuring) 9, 12, 17, 35… 50 fast fast 17, 35, 70 100 Potential indutrial throughput speed Test before embedding Rework before embedding Rework after embedding slow (plating) not possible not possible not possible fast possible possible not possible slow (laser structuring) possible possible not possible fast possible possible, but more difficult not possible Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 36 Comparison of the process flows (2) Technology Name SMI-1 Plated conductor technology SMI-2 SMI-3 SCB-1 Peelable substrate technology Laser structured conductor technology Stretchable substrate technology Special features / issues very fine pitch possible battery integration difficult lots of waste (Cu substrate back-etch) need for high-T temporary bonding adhesive to avoid process instability during solder assembly Cu meanders still on PI carrier; high reliability expected limited to high-T elastic carrier materials Favourite technology, in terms of the state of technology development and potential industrialisation : SMI-2 : Peelable substrate technology (SMI-3 (“perforated flex”) also used for fast prototyping) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 37 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 38 Reliability tests : uniaxial stretching 2 types of « stretchability » tests : • 1-time stretchability (stretch until failure, i.e. loss of electrical connection) • Cyclic stretching (more relevant for actual use) Relevant cases : • Reliability of stretchable interconnects • Reliability of transition component / component island to stretchable interconnect Measurements • Electrical resistance Reliability test vehicle (with or without interposer) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 39 1-time stretchability W : track width 3 L : track period 0 3 type of “horseshoes” : H = 0 => H0 H = 30deg => H30 H = 45deg => H45 R = 900 µm SMI-3 technology W <= R/10 Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 40 Elongation Reliability tests : Cyclic uniaxial stretching 20% cycle 10s Time • 3000 cycles until conductor break for Ω – – – – – SMI-3 technology (laser cut Cu on PI) Track width W = 100µm Meander length L = 800µm Horseshoe angle = 30 20% elongation • SMI-2 (pure Cu) behave worse Instron 5543 Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 41 Reliability tests : Cyclic uniaxial stretching • • • • Cyclic uniaxial stretch tests on SMI-2 samples Meander radius = 700m, metal track width = 100m Period of stretch & release cycle = 2s Monitoring of electrical continuity of stretchable interconnection lines Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 42 Measurements End of life SMI-3 (Cu on PI) Ag filled PDMS shunt Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 43 Reliability tests : Cyclic uniaxial stretching Lifetime of a stretchable interconnect Ongoing experiment Interconnect lifetime (# cycles) 1000000 100000 10000 1000 y = 2E+06x-3.061 100 1 • • • • 10 % strain 100 Lifetime decreases with % strain to the power 3 At 10% strain : lifetime of 2500 cycles At 2.5% : 500 000 cycles exceeded, test still ongoing At lower strains (< 5%) : lifetime exceeds this law Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 44 Reliability : failure modes and solutions 1) Crack formation and propagation avoid plastic deformation by use of other metals optimize meander design, based on FEM modeling reduce crack propagation with PI support 2) Buckling : reduce width of meander track (planned) Support meander with PI Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 45 Reliability enhancement : Multitrack design “Twirl” shape Reliability enhancement by providing bridges Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 46 Reliability enhancement : Multitrack design Non-lethal break 20% deformation 60% deformation Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 47 Reliability enhancement : component and meander support for SMI-2 Straight tracks on component island: when stretched, a lot of stress is induced in the copper wiring, which breaks. Components on pads of stretch interconnects: when stretched, a lot of stress is on the solder joints and pads, which break. metal metal Polyimide supporting the component island protecting the straight tracks and soldered joints B Polyimide supporting the stretchable copper conductors support metal support Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 48 Reliability enhancement : component and meander support for SMI-2 Temporary support during process Strong and flexible Polymer Flexible support for functional Islands and meanders Temporary adhesive during process. Melts when heated. Standard PCB process Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 49 Reliability enhancement : component and meander support for SMI-2 Flexible functional island Rigid carrier Stretchable interconnection Wax Adhesive layer Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 50 Reliability enhancement : component and meander support for SMI-2 Completely embedded in stretchable material Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 51 Reliability enhancement : rigid-flex-stretch transition improvements – Flexible supporting islands: – Better transition between rigid interposers and stretch connections – Better transition between SMD components and stretch connections – Better transition from flex to stretch: patterning supporting polyimide and copper – Stretchable conductors: – Support of stretchable conductors by polyimide Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 52 Reliability enhancement : rigid-flex-stretch transition improvements – Molding improvement: – Gradual transition (fillet) between thicker and thinner parts Less local stress concentration at interface Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 53 Reliability enhancement : rigid-flex-stretch transition improvements Interposer integrated Single layer: multilayer interposer can be mounted Rigid-flex-stretch transition Molding improved Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 54 Reliability enhancement : rigid-flex-stretch transition improvements 4 samples TM1-v1 5 samples TM1-v2 # Cycles to failure • cyclic strain of 10% @ 1% strain rate • supported component islands • non-supported meanders Large spread Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 55 Reliability enhancement : rigid-flex-stretch transition improvements • Failure mechanisms : breaking of supporting PI layer, Cu plastic deformation • Combination meander narrowing / thickness transition to be optimised Failure modes : Position on crossection: Meanders (m): M T W B Interposer connection: - Base (B): - Thin buckle (T) - Wide buckle (W) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 56 Polyimide as mechanical meander support Photodefinable polyimide significantly improves lifetime Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 Thin-film based SMI with double-sided PI meander support Cyclic strain : 10% Strain rate : 10%/s Lifetime > 500’000 cycles (4 tracks, 2 with PI and 50nm TiW/200nm Au same pattern, 2 with wider PI support) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 58 Meander circuit design Theoretical stretchability in meander direction Theoretical stretchability perpendicular to meander direction • Meanders designed as “horseshoes” = connected circular segments • Best stress distribution along the line • Theoretical stretchability determined by α Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 59 Meander circuit design W : track width L : track period Preliminary design rules : • W/R < 0.1 • Practical stretchability 0.1*theoretical stretchability (H=0…45deg) • W : determined by technology, determines also minimum R • Application determines required practical stretchability, this determines horseshoe angle Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 60 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 61 Textile integration Interconnection: Principle Copper pad, free of silicone Stretchable test sample with interconnection pads Interconnect different stretchable modules with: stitched conductor, embroidered wire, conductive ribbon,… Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 62 Textile integration: procedure Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 63 Textile integration: Screenprinting PDMS gluing layer PDMS type Viscosity (centipoise) 9601 280000 9600 184 186 490000 4575 66700 Dow Corning 9600 textile glue Screenprinting done @ Centexbel Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 64 Textile integration: Screenprinting PDMS gluing layer Silicone Viscosity (centipoise) 186 9601 66700 280000 No silicone on backside Lamination of silicone sheet (186) on textile via silicone layer of 9601 Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 65 Textile integration: Demonstrators 7x8 led matrix on a T-shirt Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 66 Technology extensions – textile integration Molding allows creation of breathable zones (textile integration) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 67 Textile integration: Interconnection Stitched conductive yarn (done @ Centexbel Verviers) Stitched conductive yarn : Shieldex (PA + Ag) Stitched contactpad Sealed with silicone (Mechanical and water protection) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 68 Textile integration: Interconnection Soldered electric wire Soldered Electric wires Sealed with silicone Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 69 Textile integration: Interconnection Soldering + sealing Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 70 Textile integration: Interconnection Finished samples Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 71 Textile integration : washability Complete embedding creates potential for washability Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 72 JL-73 Textile integration : washability Purpose: Reliability of solder contacts of SMD components on flexible islands Mechanical test: washing 10cm - On flexible substrate (lasercut) - Daisy chain of 0 Ohm resistors: 0603 and 0402 package - Dummy IC’s with daisy chain: TSSOP 28 and QFN 32 - Contact pads P1 to P43 to detect broken contacts in the chain - Contact pads are accessible for measurement trough openings in silicone Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 73 JL-74 Textile integration : washability Sample details: package types & measurement points Reference sample Optimized sample FR4 stiffeners underneath TSSOP and QFN components Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 74 JL-75 Textile integration : washability Testsamples and test overview = For every test, 6 samples (5 optimized + 1 reference sample) Test effect of using protective bag during washing Test reproducability of results Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 75 JL-76 Textile integration : washability 1) Chain status after 25 cycles (woven, in bag) – reference sample: 2) Chain status after 25 cycles (woven, no bag) – reference sample: Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 76 JL-77 Textile integration : washability Failure analysis of reference sample: Crack in solder & copper Delamination Failure on TSSOP leads Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 JL-78 Textile integration : washability 1) Chain status after 25 cycles (woven, in bag) - Optimized design: Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 78 JL-79 Textile integration : washability 1) Woven, in bag Both for optimized design Better with protective bag ! 2) Woven, no bag - Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 79 JL-80 Textile integration : washability 1) Woven, in bag Both for optimized design 3) Woven, in bag Reproducible Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 80 JL-81 Textile integration : washability Failure analysis of optimized design: Corners of flex sticking out of PDMS encapsulation Cracks in flex of resistor chains Folding of flex (dummy IC islands) - Partner restricted Jan Vanfleteren COLAE ++ Seminar PTW OCT. 2011 - HUMAN Gent, April 25, 2012 © imec/restricted 2012 81 JL-82 Textile integration : washability 1) Chain status after 25 cycles (knitted, in bag) - Optimized design: No measurements at t=0 early failures might be due to assembly No failures after 25 washing cycles ! Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 82 JL-83 Textile integration : washability 1) Chain status after 25 cycles (knitted, not in bag) - Optimized design: No failures after 25 washing cycles ! Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 83 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 84 Stretchable electronics applications Stretchable electronics useful only if • Application requires large surface with electronic components or modules, distributed over the area or • Circuit is too large and must be partitioned in single flex/rigid modules which are then connected with stretchable interconnects Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 85 Stretchable electronics applications Examples : • Lighting, and especially LEDs – Wearable signage : leisure (party shirt), safety (signage in jackets for road workers, bikers,…), advertising (the modern sandwich man), – advanced lighting : atmospheric lighting in interior (upholstery, curtains, walls, etc.) • Large area arrays with distributed sensors – Pressure sensors in mattress • Body area sensor networks, and especially movement sensors – Fall detection – orientation tracking, body posture tracking for : gaming & entertainment (advanced Wii), music & dance performances, revalidation, sports, medical applications (epileptic seizure detection) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 86 Stretchable electronics applications Philips EC-STELLA demonstrator: fitness monitor Smooth flex-stretch transition Flexible islands for interposers PI + copper Soldermask applied Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 87 Stretchable electronics applications Philips Activity Monitor Functional boards mounted on flexible islands Functionality of circuit tested before molding Developed in EU Project Stella Molded demonstrator using Sylgard 186 PDMS Fully Functional demo, The system includes a wireless link, a rechargeable battery circuit and accelerometers for activity detection. Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 88 Stretchable electronics applications Verhaert EC-STELLA demonstrator: baby monitor Smooth flex-stretch transition Temporary flex connector Polyimide Copper Soldermask Flexible island Smooth flex-stretch transition Respiration sensor connections Buzzer connections Embedded in Sylgard 186 by casting Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 89 SMI Demonstrators Verhaert Baby breathing demonstrator The demonstrator contains 79 components, 2 rubbery rulers and a buzzer. The rubbery rulers are integrated in the moulded device acting as sensors for the breathing detection. Developed in EU Project Stella Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 90 SMI Demonstrators Party Shirt (5x10 full color led matrix) Including wireless communication Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 91 SMI Demonstrators Party Shirt (5x10 full color led matrix) Fully integrated in T-shirt Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 92 Contents • Introduction – options for comfortable electronics • Stretchable Mould Interconnect (SMI) technologies • Reliability / technology improvement • Textile integration and washability • Applications • Conclusions and outlook Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 93 Conclusions and outlook • Stretchable circuits were developed, based on meander shaped high-conductance Cu interconnects and liquid injection moulding technology • The technology is to a large extent compatible with standard PCB circuit fabrication and assembly technology • The feasibility of stretchable circuitry was proven by mechanical reliability tests and functional demonstrators • Textile integration is feasible; washability up to 25 cycles proven for test samples on knitted substrates Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 94 Conclusions and outlook • Industrialisation of the technology requires a chain of companies with various competences : • Printed Circuit Board Manufacturers • Electronic assembly companies • Polymer processing specialists (moulding, …) • Textile integrators (confection) • End users • Technology has reached the level of maturity to start building this chain Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 95 Acknowledgements • • • • • • EC-IST-FP6-IP-”STELLA” (STretchable ELectronics for Large Area applications) (contract nr. 028026) (http://www.stella-project.eu/) EC-IST-FP7-CA-”Systex” (co-ordination action on intelligent textile systems (since 05/2008) (http://www.systex.org/) Flemish IWT-SBO-”BioFlex” : Biocompatible Flexible and Stretchable Electronics circuits (http://tfcg.elis.ugent.be/projects/bioflex/) Belgian TAP2-”SWEET” : Stretchable and Washable Electronics for Embedding in Textiles (http://tfcg.elis.ugent.be/projects/sweet/) EC-IST-FP7-IP-Place-It – “Platform for Large Area Conformable Electronics by InTegration” (since 02/10) (http://www.place-it-project.eu/) EC-IST-FP7-IP-PASTA – “Integrating Platform for Advanced Smart Textile Applications” (starting 10/2010) Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 96 Recent publications • J. Fjelstad et al. “Stretchable Circuits”, in “Flexible Circuit Technology”, 4th edition, BR Publishing, Seaside, USA, Chapter 13, pp. 478-513, November 2011. • J. Vanfleteren et al., “Printed circuit board technology inspired stretchable circuits” MRS Bulletin, Vol.37, pp.254-260 , March 2012. • T. Vervust et al., “Integration of stretchable and washable electronic modules for smart textile applications”, J. Textile Institute, 05 Mar 2012, 12 pages. • Y.-Y. Hsu et al., "The effects of encapsulation on deformation behavior and failure mechanisms of stretchable interconnects", Thin Solid Films, Vol. 519, No. 7, pp. 2225-2234, Jan. 2011. • R. Verplancke et al. “Thin-film stretchable electronics Technology based on meandering interconnections: fabrication and mechanical performance”, J. Micromech. Microeng., Vol.22, No1, published online December 8, 2011. • Y.-Y. Hsu at al., “Polyimide-Enhanced Stretchable Interconnects: Design, Fabrication, and Characterization”, IEEE Trans. Electr. Dev., Vol. 58, No. 8, pp. 2680-2688, August 2011. • Patents / patent applications : #US 7,487,587 B2 (February 10, 2009), #EP 1 746 869 B1 (July 27, 2011), #US 2009 0107704 A1 (April 30, 2009), #WO 2010/086416 A1 (August 5, 2010), #WO 2010/086033 A1 (August 5, 2010), #WO 2010/086034 A1 (August 5, 2010), Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 97 Thank you for your attention Questions ? Jan Vanfleteren COLAE Seminar Gent, April 25, 2012 © imec/restricted 2012 98