Battery Terminals - Automotive Components Limited

advertisement

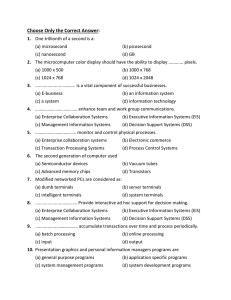

Battery Terminals AU S T R A L I A N E N G I N E E R I N G E X C E L L E N C E ACL Total Quality Management System ACL is absolutely committed to the highest standards of manufacturing excellence guided by our rigorous Total Quality Management System. This is recognised by accreditation to international standards for Quality Management (ISO/TS 16949: 2009) and Environmental Responsibility (AS/NZS 14001:2004). The quality management system ensures that: All organisational, commercial, engineering and processing decisions are made with a view to improving value to our customers. All systems and processes are dedicated to maintaining and continuously improving; the highest product quality standards, a safe yet challenging workplace for our employees and minimising our environmental footprint. Battery Terminals Product Information ACL manufacture a range of battery terminals utilising the powder metallurgy process which is the commercial process for manufacturing components from ferrous and non-ferrous metal powders. The precise surface finish and tapered bore geometry of ACL battery terminals results in optimum contact with the battery terminal post, eliminating the potential for corrosion which can occur between poorly fitting connections. ACL battery terminals are manufactured in high quality pure brass material and feature a material structure of fine interconnected porosity. ACL manufactures its own range of non-ferrous powders, which includes brass powder, utilising the water atomising production process. To increase the effective life of the battery terminals, each battery terminal is vacuum impregnated with corrosion inhibiting fluid. ACL battery terminals are manufactured using precision tooling, resulting in a component free from burrs and irregular shape which is predominant with battery terminals made from other processes. 1. American Society of Testing and Materials - B282 (Class A). ACL’s high quality pure brass material conforms to the following specifications: 2. Society of Automotive Engineers - 890. 3. Military - MIL-B-12128C. Battery Terminals RT4 RT15N & RT16P A side entry, double action quick fix terminal. Light duty lug connection type terminals. The bolt clamps the cable and then the nut is tightened to clamp the terminal to the battery post. Positive and negative terminals for marine, radio and industrial applications. RT11 RT17N & RT18P A solderless, saddle type universal terminal. Heavy duty lug connection type terminals. Easy to install with the cable tightly clamped by the saddle ensuring good contact. Positive and negative terminals for marine, radio and industrial applications. RT14N & RT14P RT32 Solderless lead attachment terminals for marine and radio applications. A solderless quick fix universal terminal. Manufactured to fit positive and negative pole sizes, this avoids incorrect attachment of leads thereby preventing damage to polarity sensitive equipment. Metal Terminals Powders Battery Easy to install with the cable securely held to the terminal by the set screw Manufacturing Process What is Powder Metallurgy? Powder Metallurgy is a commercial process for manufacturing production quantities of components from ferrous and non-ferrous metal powders. The process to manufacture a powder metallurgy component requires elemental or alloy powders to be mixed and blended and then compacted to a near net shape known as a ‘green’ component. This ‘green’ component is then sintered in a controlled atmosphere furnace at a temperature below the melting point of the material, resulting in the powder particles being metallurgically bonded which is known as ‘sintering’. The powder metallurgy process is both cost effective and efficient and is used to manufacture complex and simple parts to final dimensions in production rates which can range from a few hundred to several thousand components per hour. Battery Terminals ACL Bearing Company A Division of Automotive Components Limited Tel: +61 (0)3 6324 4600 Fax: +61 (0)3 6326 6666 www.acl.com.au 07/2012 ©rethink environmental print 47508 253-293 George Town Road, Rocherlea, Tasmania 7248 Australia