High-Speed Differential Line Driver/Receivers

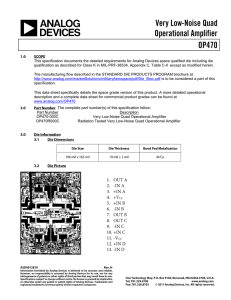

advertisement