eric j. barth - Vanderbilt University

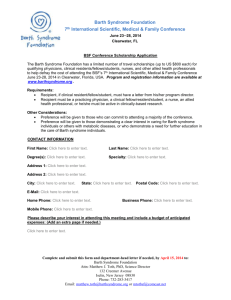

advertisement