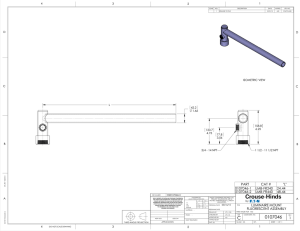

hazardous location products-nec

advertisement