CND-CNF - Novenco Building and Industry

advertisement

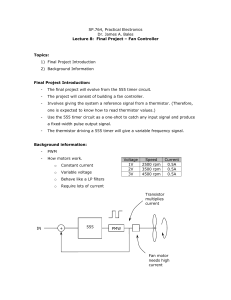

CND-CNF Centrifugal fans Product facts Product and use Motor installation size Centrifugal fans of type CND and CNF are light, compact low-pressure and medium fans with high efficiency, low sound level and good operating economy, designed for universal installation. Motor sizes for directly coupled fans. Centrifugal fans type CND and CNF are, due to the choice of material and finishing, well suited for ventilation in aggressive environments. Impeller diameter [mm] Motor size 315 400 450 500 560 630 710 80 - 112 80 - 132 80 - 132 80 - 132 100 - 160 100 -160 112 - 180 Motor sizes for belt driven fans. Coverage Air flow rates from 0.3 to 10 m3/s and pressure rises up to 4000 Pa. Installation sizes CND and CNF are produced in 7 standard sizes with impeller diameters of 315, 400, 450, 500, 560, 630 and 710 mm. Construction Fan housing with rectangular side panels for universal installation. The CND and CNF are available in both directly coupled and beltdriven motor versions. Temperature range The CND and CNF are designed for the temperature range -20 to +70 °C. Impeller diameter [mm] Motor size 315 400 450 500 560 630 710 80 - 132 80 - 132 80 - 160 80 - 160 100 - 160 100 -180 112 - 200 Materials Fan housing: Hot-rolled sheet steel, Domex 240, in a hot-dip galvanised version. Impeller: for types CND and CNF, the impeller is wide with backwardcurved blades. Steel quality Domex 500. The impeller is hot-dip galvanised after welding. Flange standard Motors Asynchronous standard motors. Directly coupled: Structural shape B5 (large flange) Belt-driven: Structural shape B3 (base motor) Dimension standard: IEC-72 Electrical standard: IEC-34 Insulation: Class F Inlet for type CND and CNF in accordance with Eurovent 1/2. Corrosion categories Centrifugal fans of type CND and CNF are, as standard, for operation in corrosion category C5-I (very high) in accordance with the standard DS/EN ISO 12944-2. C5-I produces lifetimes of 8-10 years with hot-dip galvanisation with 6080 µm layer thickness. Technical classification The outputs meet the requirements in accordance with BS 848, 1980 Part 1, installation type D. 2 CND-CNF Accessories • • • • • • • • Duct bosses Flexible connections Mating flanges Guard nets for inlet and outlet openings Anti-vibration mountings Inspection hatch Drain plug Brass inlet funnels Contents Product description 4 Dimensions 5 Position designations 7 Motors 8 Dimensioning curves 10 Accessories 17 Sound conditions 20 Regulation of air flow rate 21 Quality and service 22 Important Patents and trademarks This document is provided ’as is’. Novenco reserves the right to changes without further notice due to continuous product development. Novenco®, ZerAx®, Novenco A/S. The fan is designed for continuous operation. The following kinds of operation may cause fatigue break in the impeller and endanger people. The ZerAx® manufacturing processes, technologies and designs are patented by Novenco A/S. • Operation in stall area • Operation with pulsating counter pressure – called pump mode • Operation with repeated starting and stopping If in doubt, Novenco should be contacted to assess the suitability of the fan. and are registered trademarks of Other trademarks appearing in this document are the property of their respective owners. Quality and environment Novenco is certified in accordance with ISO 9001 and 14001. Copyright (c) 1966 - 2015, Novenco Building & Industry A/S. All rights are reserved. MU 14912 0315 CND-CNF 3 Product description The centrifugal fans type CND and CNF are light, compact low-pressure and medium fans designed for universal installation in compost plants and greenhouses as well as light industrial plants in aggressive environments. The fans are intended for continuous operation. The following types of operation can cause fatigue breakage of the impeller and thereby danger of personal injury. • Operation in the stall area • Operation with pulsating counter pressure - pump mode • Operation with continued starting and stopping Novenco should, in case of doubts, be contacted in order to assess the suitability of the fan. Installation sizes Type CND is produced in 7 sizes with impeller diameters from 315 to 710 mm, air flow rates from 0.2 to 10 m3/s and total pressures up to approximately 2000 Pa. where the CND is partially welded, the CNF is all-welded and thus designed for higher operating RPMs. Bearing part with two dust-proof and waterproof deep groove ball bearings mounted in flanged bearing housings. The bearings have lifetime lubrication. Surface treatment All the fan parts are protected and treated with min. 60 µm hot-dip galvanisation (0.060 mm hot-dip galvanisation). Motors Choice of motor in accordance with specification. Requirement: B5 flange (large flange) for all motor sizes for directly coupled motors and B3 (base) for belt-driven motors. Environment All CND and CNF fans are designed for the temperature range -20 to +70°C. Type CNF is produced in 6 sizes with impeller diameters from 400 to 710 mm, air flow rates from 0.2 to 11 m3/ s and total pressures up to approximately 4000 Pa. The basic version is designed, with regard to the choice of material and finishing, to function in corrosion category C5-I (very high), see DS/ EN ISO 12944-2. Construction Accessories Centrifugal fans of type CND and CNF consist of the following main components. Duct boss - inlet Fan housing, constructed from two rectangular side panels and an allwelded casing. Is fitted as standard on CND/CNF. Loose duct bosses are available for connection of ducts with flexible connections. Flexible connections Inlet funnel, mounted in the front side panel with a boss for duct connection and designed to conduct the air with as little loss as possible to the impeller. For duct boss and outlet flange. Versions (materials) for both circular (inlet) and square (outlet) connections. Impeller type CND and CNF with 8 backward-curved blades designed and produced with the same geometry and material. However, For installation on the fan outlet. The mating flanges consist of welded steel frames and are finished 4 CND-CNF Mating flange with min. 60 µm hot-dip galvanisation. Inspection hatch CND and CNF are available with an inspection hatch located in the casing of the housing. Inspection hatches are available in 2 sizes, depending on the fan size. When ordering, please state the location of the inspection hatch in relation to the outlet direction. Drain plug Please also state the location of the drain plug in the side panels of the fan housing in relation to the outlet direction on order. Guard nets Guard nets for the inlet (circular) and outlet (square) respectively. Anti-vibration mountings Types CND and CNF are available with anti-vibration mountings. The location and choice of antivibration mountings are shown in the installation instructions. Brass inlet funnel The inlet funnel is available in brass for both CND and CNF fans for use in environments with increased security. Dimensions H K S 45 B1 B øD L S F T A1 C A Sizes 315 400 450 500 560 630 710 S E G S For anti-vibration mountings øJ A A1 B B1 C dia. D E G H dia. J K L approx. S T F1 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] 690 800 891 1000 1121 1246 1405 410 485 543 600 673 760 869 595 700 760 850 953 1063 1135 345 400 445 500 560 622 672 252 312 347 392 437 482 537 315 400 450 500 560 630 710 280 340 375 420 465 510 577 ML-24 ML-24 ML-29 ML-29 ML-29 ML-26 ML-31 297 357 392 443 488 533 595 525 585 655 690 795 840 910 11.5 11.5 14 14 14 14 14 335 430 480 535 595 665 750 1040 1120 1175 1255 1440 1525 1620 100 100 125 125 125 125 125 475 540 610 670 780 825 940 1. Dimensions: ML means Motor Length (see motor catalogue) Weights Sizes Weight, directly coupled, excl. motor [kg] Weight, belt-driven, excl. motor [kg] 315 400 450 500 560 630 710 40 59 77 84 113 153 187 62 78 100 118 165 206 255 CND-CNF 5 Outlet flanges G P stk. x øR C F A Connection ducts are made with the same internal dimensions as the fan outlet opening (A x B). MxK NxT Mating flanges with the same bolt holes as the outlet flanges are available as accessories. See dimensioned drawing. B Sizes A [mm] B [mm] C [mm] F [mm] G [mm] K [mm] M [mm] N [mm] T [mm] P [qty.] R [mm] 315 400 450 500 560 630 710 315 400 450 500 560 630 710 220 280 315 350 395 440 497 30 30 30 35 35 35 40 347 432 482 536 596 666 750 252 312 347 386 431 476 537 110 140 125 125 125 170 150 1 1 2 2 2 2 3 2 2 2 3 3 3 4 142.5 185 185 155 155 200 170 10 10 12 14 14 14 18 7 7 7 7 7 7 10 6 CND-CNF Position designations RD 0 RD 90 RD 180 RD 270 LG 0 LG 90 LG 180 LG 270 LG/1 LG/2 LG/3 LG/4 RD/1 RD/2 RD/3 RD/4 Directly coupled and low motor bracket for belt drive. Belt drive with motor mounted on fan housing. Positions in accordance with Eurovent seen from motor side Impeller positions Pos. LG Pos. RD CND-CNF 7 Motors Motor size1 Sizes 315 400 450 500 560 630 710 - 80 - 90 - 100 - 112 - 132 - 160 - 180 * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * 1. The motor flange B5 is a large flange and for all motor sizes. The motor junction box must be coordinated with the fan motor cover. Max. RPM for CND/CNF Fan types CND and CNF are designed and produced with the same geometry and material, but where the CND is partially welded, the CNF is all-welded and thus designed for higher operating RPMs. Sizes 315 400 450 500 560 630 710 8 CND-CNF Steel quality: Domex 500 Surface treatment: Hot-dip galvanisation, approximately 60 µm zinc. Max. RPM CND CNF 4618 3426 2957 2592 2249 2086 1797 5874 4090 3365 2927 2464 2387 1994 Motor installation The tables show the maximum motor sizes that can be installed directly on the fans. Motor on the side – vertical motor panel Motor installation sizes for directly coupled motors Fan sizes 315 400 450 500 560 630 710 Motor sizes Motor on the top – horizontal motor panel Belt-driven motor on the top Belt-driven motor on the side Fan sizes –315 –400 –450 –500 –560 –630 –710 80-112 80-132 80-132 80-132 100-160 100-160 112-180 Max. motor Type Weights [kg] 112 112 112 132 132 132 132 40 40 40 70 70 70 70 Fan sizes –315 –400 –450 –500 –560 –630 –710 Max. motor Type Weights [kg] 112 112 112 132 132 132 160 40 40 40 70 70 140 140 Low-mounted motor bracket for large motors Large motors are mounted on low motor brackets bolted to the fan housing. The low centre of gravity and the large distances between the installation points produce stable installation for large motors. Required motor position and fan position Z W Shaft end t b ød l Fan sizes ød [mm] I [mm] b [mm] t [mm] –315 –400 –450 –500 –560 –630 –710 28h6 28h6 38h6 38h6 48h6 48h6 65h6 30 30 50 50 70 70 70 8 8 10 10 14 14 18 31 31 41 41 51 51 69 CND-CNF 9 Dimensioning curves CND-315 CNF-315 Max. Ipt Max. Ipt = 5874 RPM = 0.0951 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 4618 RPM = 0.0951 kg x m2 6000 60 70 65 If the fan is used in the shaded area, it is necessary to consider in particular whether the necessary power can be achieved with the max. standard motor size. 70 74 74 Pt, Pa 65 5000 109 dB 4000 60% Max. speed 618 4 CND 106 dB 3000 4 000 103 dB 0 350 2000 300 500 100 dB 0 97 dB 2 0 0 2 0 Pd 0 Pd + P2 0 P1 30 20 3 m3/s m/s 2.5 2 1.5 W 0 10 4.5 v 4 0 1 0.5 3 qv 5 0 2.2 1.5 0 7.5 91 dB 6 88 dB 9k 1000 94 dB 40 1000 500 1000 500 50 1500 100 Symbols Basis for chart (Arr. D) 10 CND-CNF pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet Pa Pa Pa CND-400 CNF-400 Max. Ipt Max. Ipt = 4090 RPM = 0.2440 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 3426 RPM = 0.2440 kg x m2 CNF CND 5000 60 Pt, Pa If the fan is used in the shaded area, it is necessary to consider in particular whether the necessary power can be achieved with the max. standard motor size. 75 70 65 77 75 77 70 Max. speed 4090 n= CNF 65 4000 Max. speed 426 3 CND 3000 300 60% 106 dB 0 103 dB 2000 250 100 dB 0 97 dB 0 200 1000 Pd 0 Pd + P2 0 P1 200 40 30 300 400 500 600 500 20 10 m3/s m/s 4 3 20 100 kW 0 10 6 v 2 1 5 4 0 3 qv 2 0 1 Pd 0 10 9 0 8 7.5 7 150 94 dB 91 dB 30 700 800 900 80 90 1000 40 50 60 70 Pa Pa Pa Symbols Basis for chart (Arr. D) pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet CND-CNF 11 CND-450 CNF-450 Max. Ipt Max. Ipt = 3365 RPM = 0.4218 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 2957 RPM = 0.4218 kg x m2 CND CNF 4000 Max. speed = 33 n CNF pt, Pa 65 65 70 60 75 77 77 70 75 65 106 dB Max. speed 957 2 CND 3000 260 60% 0 103 dB 2000 220 100 dB 0 97 dB 0 180 1000 91 dB 0 10 140 94 dB qv 0 v 0 Pd 0 Pd + P2 0 P1 1 2 kW 8 6 5 4 0 3 2 1 0 3 3 5 m /s 4 m/s 10 20 100 200 30 300 10000 10 20 400 500 20000 30 40 40 600 700 30000 50 60 12 CND-CNF pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = Pa Pa 70 Symbols Basis for chart (Arr. D) Pa volume flow RPM efficiency in % power demand, impeller sound power level, outlet CND-500 CNF-500 Max. Ipt Max. Ipt = 2927 RPM = 0.6430 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 2592 RPM = 0.6430 kg x m2 CND CNF 4000 pt, Pa Max. speed CNF n 92 =2 7 60 65 75 70 79 79 75 70 106 dB 3000 2 Max. speed 259 CND 65 103 dB 220 2000 60% 0 100 dB 180 150 1000 97 dB 94 dB 0 91 dB 0 9 k 11 120 0 Pd 0 Pd + P2 0 P1 4 W 0 3 7 v 2 6 0 1 5 qv 4 0 3 2 1 0 5 6 m3/s m/s 10 20 100 200 30 300 400 500 Pa 600 500 10 20 30 700 1000 40 50 60 Pa Pa 70 Symbols Basis for chart (Arr. D) pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet CND-CNF 13 CND-560 CNF-560 Max. Ipt. Max. Ipt. = 2464 RPM = 1.0212 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 2249 RPM = 1.0212 kg x m2 CNF CND 60 65 70 80 75 81 81 80 75 Max. speed 4 246 CNF n= 3000 pt, Pa Max. speed 9 CND 224 70 65 2000 190 0 60% 106 dB 160 1000 130 0 103 dB 0 100 dB 97 dB 94 dB 0 91 dB Pd 0 Pd + P2 0 P1 W 0 9 v 3 8 0 2 7 6 qv 5 4 3 1 0 2 1 0 k 11 10 100 4 7 m3/s 6 5 m/s 30 20 10 100 200 300 400 20 600 Pa 10000 5000 10 500 Pa 30 40 50 Pa 60 Symbols Basis for chart (Arr. D) 14 CND-CNF pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet CND-630 CNF-630 Max. Ipt Max. Ipt = 2387 RPM = 2.2571 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 2086 RPM = 2.2571 kg x m2 CNF CND 4000 Max. speed 387 n=2 CNF pt, Pa 60 65 70 75 83 80 75 Max. speed 2086 CND 3000 80 83 109 dB 1800 70 65 106 dB 2000 60% 1600 103 dB 1400 1000 100 dB 97 dB 1200 94 dB 1000 0 Pd 0 Pd + P2 0 P1 4 3 kW v 2 18 0 1 16 qv 14 12 0 10 8 6 4 2 0 5 7 6 3 9 8 m /s m/s 10 30 20 100 200 300 400 500 600 40 50 60 500 10 20 30 Pa 700 Pa 1000 Pa 70 Symbols Basis for chart (Arr. D) pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet CND-CNF 15 CND-710 CNF-710 Max. IVent Max. IVent = 1994 RPM = 3.6479 kg x m2 δ = 1.20 kg/m3 (at 20° C) = 1797 RPM = 3.6479 kg x m2 CND CNF 94 Max. speed 19 = CNF n 60 65 70 75 84 84 80 75 80 3000 pt, Pa 109 dB Max. speed 1797 CND 106 dB 1600 65 2000 60 % 103 dB 1400 100 dB 1200 1000 97 dB 1000 94 dB 20 kW 18 16 14 12 10 8 6 4 2 0 0 0 v 0 Pd 0 Pd + P2 0 P1 10 20 100 3 m /s 10 5 qv 200 m/s 30 300 400 500 Pa 600 500 10 20 30 700 1000 40 50 60 70 Symbols Basis for chart (Arr. D) 16 CND-CNF pt pd p1 p2 v = = = = = total pressure dynamic pressure, outlet connection loss, inlet connection loss, outlet air speed, outlet qv = n = η = kW = dB = volume flow RPM efficiency in % power demand, impeller sound power level, outlet Pa Pa Accessories Duct bosses The bosses are available as loose supplies and used for connection of ducts with flexible connections. They are standard on both CND and CNF. Material: Steel Surface treatment: Hot-dip galvanised, approx. 60 µm Duct bosses Flexible connections The connections are available for duct bosses and outlet flanges. Versions in different materials are available for both flame-proof flexible connections and incombustible flexible connections. Material quality: Perl E 6 Temperature range: -30 to +80 °C Material quality: Alpha Maritex Temperature range: -36 to +260 °C Flexible connections Inlet Outlet Mating flanges The flanges are for installation on the fan outlets. The constructions are welded steel frames. Material: Steel Domex 240 Surface treatment: Hot-dip galvanised, approx. 60 µm Mating flanges CND-CNF 17 Guard nets The nets are for the inlet (circular) and outlet (square) respectively. Material: Steel wire Surface treatment: Electro-galvanised, approx. 20 µm Finish treatment: Passivated Guard nets for inlet and outlet openings Anti-vibration mountings The CND and CNF are available with anti-vibration mountings. Refer to the installation instructions for location and choice of anti-vibration mountings. Anti-vibration mountings Base plate for anti-vibration mountings The CND and CNF are available with base plates for fixing anti-vibration mountings to the foundation. Material: Domex 240 Surface treatment: Hot-dip galvanised, approx. 60 µm Base plate for anti-vibration mountings 18 CND-CNF Inspection hatches Material: Domex 240 Surface treatment: Hot-dip galvanised, approx. 60 µm 300 200 The CND and CNF are available with inspection hatches located in the fan housing. Inspection hatches are available in 2 sizes and depend on fan size. Please state the location of the inspection hatch in relation to the outlet direction on order. The location of the inspection hatch and drain boss is given in relation to the outlet direction. 100 200 120o 180o Inspection hatch/Access door Drain plug Inspection hatch Drain plug The location of the drain plug in the fan housing side panels must be stated on order. The position is in relation to the outlet direction. Material: Stainless steel and hot-dip galvanised fittings respectively Connection: 3/4” RG Drain plug Brass inlet funnels Inlet funnels made of brass for use in environments with increased safety is available for CND and CNF. Material: Half-hard brass Brass inlet funnel CND-CNF 19 Sound conditions Fans in operation generate sound. It is partly electrical and also mechanical sounds from the motor, bearings and other mechanical parts. Sound from air flows through fan add to the sound picture as well. The sound generation is minimised by correct design and careful production of fan parts, in particular the inlet funnel and impeller, which contribute greatly to the overall sound generation. Poor installation conditions, for example a sharp duct bend immediately before the inlet opening, may add considerably to the sound generation. Electrical and mechanical generated sound and the part of sound from the air flow that passes out through the fan housing, can only be dampened by enclosing the fan in a casing or with walls of low-vibration materials. Sound generated in the impeller spreads through the inlet and outlet openings to the duct system and on to the ventilated rooms. Calculation of the sound conditions in the duct system and the ventilated rooms, including dimensioning of any silencers in the system, is only possible on the basis of the sound power level in the fan inlet and outlet openings. In connection with all considerations concerning sound, a sharp distinction must be made between the two terms sound power level and sound pressure level. Sound power level is an expression of the energy emitted through the fan inlet and outlet openings and forms the basis for any calculation concerning the sound conditions in Octave band [Hz] the connected duct systems and in the rooms served by the fan. from the total sound power level found. Sound pressure level is a measure of the sound impression perceived by the ear at a given location in the environment. It can be measured using a sound meter with a microphone mounted at the location. The correction values depend on the blade frequency z×n ----------- , where 60 z = number of blades n = fan speed in RPM Sound pressure level depends on the fan sound power level, the distance from the fan and the silencing properties of the environment. When the fan sound properties are characterised by stating a sound pressure level, it is necessary also to give a precise description of the conditions under which the stated sound level occurs. When comparing the sound properties of two fans, make sure not to compare the sound power level with the sound pressure level. Do only compare sound pressure levels with the same distances from the fan and with the same silencing in the environment. For a correctly designed fan, the sound power level depends primarily on the supplied air flow rate and the total fan pressure. It can be read on the graphs for the individual fans in section “Dimensioning curves” beginning on page 10. The sound power level is stated in dB with a reference value of 10-12 W, and applies within the normal working range of the fan. The tolerance is ±5 dB. If the sound power level needs to be divided into octave values, the sound power level in the different octave bands is determined by deducting the correction values in the table below 63 125 250 500 1k 2k 4k 8k 7 11 13 15 4 7 11 13 7 4 7 10 12 7 4 6 17 12 7 4 22 17 12 7 27 22 17 12 32 27 22 18 Octave band [Hz] 63 125 250 500 1k 2k 4k 8k Sound power level [dB] 89 93 96 93 88 83 78 73 CND/CNF Blade frequency 90-180 Hz 180-360 Hz 360-710 Hz 710-1400 Hz 20 CND-CNF The CND and CNF have 8 blades each. Example A centrifugal fan of type CND-500 has an output of 3 m³/s at 1600 Pa and 2323 RPM. Blade frequency: 2323 8 × ------------ ~ 310 Hz 60 On the graph on page 13, the total sound power level is 100 dB. The correction value for 250 Hz is 4 dB. The sound power level for this octave band is thus 100 dB - 4 dB = 96 dB The full octave analysis is shown in the below table. Regulation of air flow rate The fan capacity can be regulated in several ways, depending on the operating requirements. • By changing poles between 2 fixed RPMs in the ratio 3: 2 (motor with 2 separate windings) or 2:1 (Dahlander winding motor) • By frequency regulation • By a combination of the above Changing poles In connection with time-related variations in the air flow rate demand, for example night-time and daytime operation, it is recommended that the fan is fitted with a change-pole motor. When the fan is changed to a different RPM, the fan efficiency is unchanged. The change can be timer-controlled. If other operating points are required, than can be achieved by changing poles, other regulation methods must be used. Frequency regulation Fan efficiency remains virtually unchanged throughout the regulation range and no sound is generated as a result of the regulation. CND-CNF 21 Quality and service Rest assured Warranty The Novenco CND-CNF centrifugal fans are produced in accordance with Novencos well-known quality standards. Novenco is ISO 9001 certified and all fans are inspected and tested, before leaving the production. The fans are offered with options for technical guidance on installation, test of function and training of personnel. Novenco provides according to law a standard 12 months warranty from the product is sent from the factory. The warranty covers materials and manufacturing defects. Wear parts are not covered. Extended warranties can be agreed upon. CND-CNF 22 MU 14912 0315 Novenco develops and manufactures ventilation systems that are marketed worldwide through subsidiaries and agents. The company was founded in Denmark 1947 and has become one of the world-leading suppliers. Novenco symbolises quality and environmentally responsible operation and is certified according to ISO 9001 and ISO 14001. The company headquarters are located in Naestved, Denmark. and are Novenco, ZerAx, registered trademarks of Novenco A/S. Read more about Novenco on the internet. Novenco Building & Industry A/S · Industrivej 22 · 4700 Naestved · Denmark Phone: +45 70 77 88 99 · www.novenco-building.com