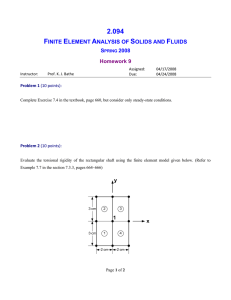

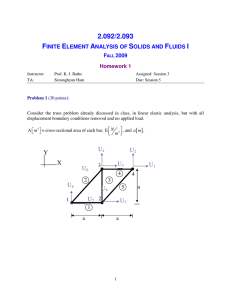

2.094 Finite Element Analysis of Solids and Fluids

advertisement

MIT OpenCourseWare http://ocw.mit.edu 2.094 Finite Element Analysis of Solids and Fluids Spring 2008 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms. 2.094 — Finite Element Analysis of Solids and Fluids Fall ‘08 Lecture 17 - Incompressible fluid flow and heat transfer, cont’d Prof. K.J. Bathe 17.1 MIT OpenCourseWare Abstract body Reading: Sec. 7.4 Fluid Flow Sv , Sf Sv ∪ Sf = S Sv ∩ Sf = 0 17.2 Heat transfer Sθ , Sq Sθ ∪ Sq = S Sθ ∩ Sq = 0 Actual 2D problem (channel flow) 71 MIT 2.094 17.3 17. Incompressible fluid flow and heat transfer, cont’d Basic equations P.V. velocities � � � � v i ρvi,j vj dV + τij eij dV = v i fiB dV + V V V S S v i f fi f dSf (17.1) Sf Continuity � pvi,i dV = 0 (17.2) V P.V. temperature � � � � θρcp θ,i vi dV + θ,i kθ,i dV = θq B dV + V V V S θ q S dS (17.3) Sq F.E. solution xi = � hk xki (17.4) vi = � hk vik (17.5) θ= � hk θk (17.6) p= � h̃k pk (17.7) ⎛ ⇒ F (u) = R 17.4 ⎞ v u = ⎝ p ⎠ nodal variables θ (17.8) Model problem 1D equation, ρcp v dθ d2 θ =k 2 dx dx (17.9) (v is given, unit cross section) Non-dimensional form (Section 7.4) Pe dθ d2 θ = 2 dx dx (17.10) 72 MIT 2.094 Pe = 17. Incompressible fluid flow and heat transfer, cont’d vL , α α= k ρcp (17.11) θ∗ is non-dimensional � � exp PeLx − 1 θ − θL = exp (Pe) − 1 θR − θ L (17.10) in F.E. analysis becomes � � dθ dθ dθ θPe dV + dV = 0 dx V V dx dx (17.12) (17.13) Discretized by linear elements: h∗ = θ(ξ) = � � ξ ξ 1 − ∗ θi−1 + ∗ θi h h h L (17.14) For node i: −θi−1 − Pee Pee θi−1 + 2θi − θi+1 + θi+1 = 0 2 2 (17.15) where Pee = vh α � � h = Pe L (17.16) This result is the same as obtained by finite differences � 1 � θ�� � = 2 (θi+1 − 2θi + θi−1 ) i (h∗ ) � θi+1 − θi−1 � θ� � = 2h∗ i 73 (17.17) (17.18) MIT 2.094 17. Incompressible fluid flow and heat transfer, cont’d Considered θi+1 = 1, θi−1 = 0. Then θi = 1 − (Pee /2) 2 (17.19) Physically unrealistic solution when Pee > 2. For this not to happen, we should refine the mesh—a very fine mesh would be required. We use “upwinding” dθ �� θi − θi−1 � = dx i h∗ (17.20) The result is (−1 − Pee ) θi−1 + (2 + Pee ) θi − θi+1 = 0 Very stable, e.g. � θi−1 = 0 θi+1 = 1 ⇒ θi = (17.21) 1 2 + Pee (17.22) Unfortunately it is not that accurate. To obtain better accuracy in the interpolation for θ, use the function � x� exp Pe L −1 (17.23) exp (Pe) − 1 The result is Pee dependent: This implies flow-condition based interpolation. We use such interpolation functions—see references. References [1] K.J. Bathe and H. Zhang. “A Flow-Condition-Based Interpolation Finite Element Procedure for Incompressible Fluid Flows.” Computers & Structures, 80:1267–1277, 2002. [2] H. Kohno and K.J. Bathe. “A Flow-Condition-Based Interpolation Finite Element Procedure for Triangular Grids.” International Journal for Numerical Methods in Fluids, 51:673–699, 2006. 74 MIT 2.094 17.5 17. Incompressible fluid flow and heat transfer, cont’d FSI briefly Lagrangian formulation for the structure/solid Arbitrary Lagrangian-Eulerian (ALE) formulation Let f be a variable of a particle (e.g. f = θ). Consider 1D � ∂f ∂f � f˙� = + v (17.24) ∂t ∂x particle where v is the particle velocity. For a mesh point, � ∂f ∂f � f ∗� = + vm ∂t ∂x mesh point (17.25) where vm is the mesh point velocity. Hence, � � ∂f � � f˙� = f ∗� + (v − vm ) ∂x particle mesh point (17.26) Use (17.26) in the momentum and energy equations and use force equilibrium and compatibility at the FSI boundary to set up the governing F.E. equations. References [1] K.J. Bathe, H. Zhang and M.H. Wang. “Finite Element Analysis of Incompressible and Compressible Fluid Flows with Free Surfaces and Structural Interactions.” Computers & Structures, 56:193–213, 1995. [2] K.J. Bathe, H. Zhang and S. Ji. “Finite Element Analysis of Fluid Flows Fully Coupled with Structural Interactions.” Computers & Structures, 72:1–16, 1999. [3] K.J. Bathe and H. Zhang. “Finite Element Developments for General Fluid Flows with Structural Interactions.” International Journal for Numerical Methods in Engineering, 60:213–232, 2004. 75