GaAs-Based Surface Mount Wafer Scale Package MMICs

for DC to 45 GHz Applications

White Paper

By: Henrik Morkner

I. Introduction

Packaging has always been the “Achilles Heal” of extracting the maximum microwave performance out of any IC

technology. The inherent parasitic capacitance and inductance associated with bond wires, lead frames, and

encapsulating dielectric materials dominate the final

products high frequency performance. One way to solve

this problem is to eliminate parasitic causing factors and

make the IC become the package. This is the basis of WSP

(Wafer Scale Packaging).

While a relatively simple concept, WSP can be hard to

implement. Problems that must be addressed include

cracking, environmental protection, solder tolerance and

cost.

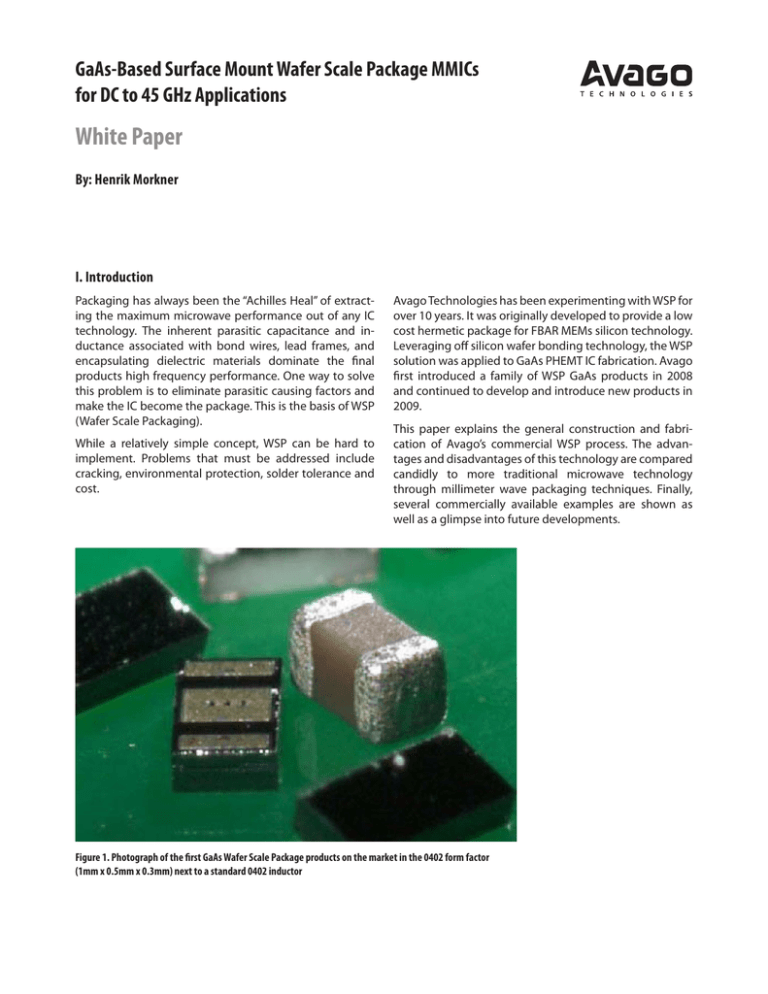

Avago Technologies has been experimenting with WSP for

over 10 years. It was originally developed to provide a low

cost hermetic package for FBAR MEMs silicon technology.

Leveraging off silicon wafer bonding technology, the WSP

solution was applied to GaAs PHEMT IC fabrication. Avago

first introduced a family of WSP GaAs products in 2008

and continued to develop and introduce new products in

2009.

This paper explains the general construction and fabrication of Avago’s commercial WSP process. The advantages and disadvantages of this technology are compared

candidly to more traditional microwave technology

through millimeter wave packaging techniques. Finally,

several commercially available examples are shown as

well as a glimpse into future developments.

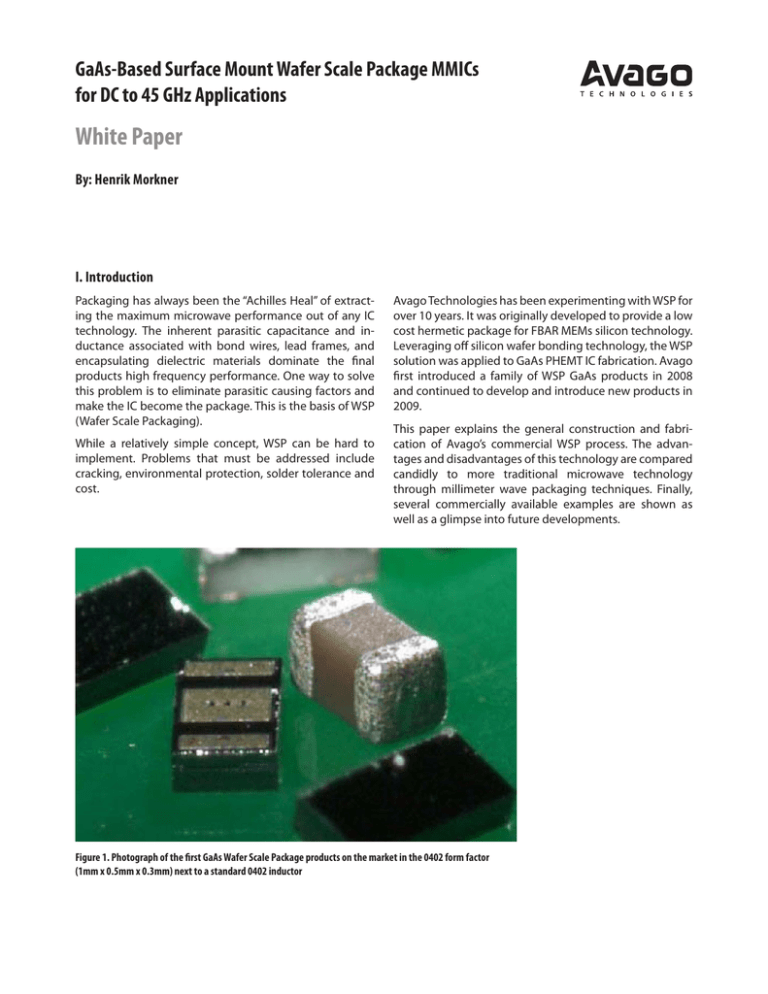

Figure 1. Photograph of the first GaAs Wafer Scale Package products on the market in the 0402 form factor

(1mm x 0.5mm x 0.3mm) next to a standard 0402 inductor

II. Basic WSP Manufacturing processes and construction

WSP starts with a standard GaAs wafer that is processed

to create a MMIC. At Avago either depletion mode or enhancement mode PHEMT wafers can be used. The wafer is

left thick, that is no vias are present, for the WSP process.

To keep yields high, wafer performance can be typically

verified with coplanar Process Control Monitor probing

before entering the WSP process.

Starting from a standard GaAs wafer, the first step in

creating a WSP is to apply a gasket material. This material

is selected for its malleability and adherence to topside

nitride and metal. Proprietary patterns and voids are made

in the gasket to ensure an air cavity forms over critical

microwave elements, such as FET fingers and transmission

lines. The height and size of the gasket and consequential

air cavities is critical since unwanted modes of microwave

propagation can form due to dielectric discontinuities

and reflections.

Figure 2. Wafer Scale Package construction and cross section

2

Once the gasket is formed another GaAs wafer, the cap,

is bonded on top. Using a GaAs wafer as the cap material

offers several advantages. It has the same thermal

expansion coefficient as the base wafer and fits into the

bonding and alignment system. It also provides a uniform

sawing medium for singulation. The actual bonding is

performed by Avago proprietary equipment built for

FBAR and GaAs wafers.

After bonding both the top side and bottom are ground

down to final package height specifications. Then a via

pattern is aligned to the bottom side to connect not only

ground but all “hot” – signal via transitions. A proprietary

metal stack is applied to the bottom side to create the

pads that can withstand a standard reflow solder process.

The bottom side metal is also patterned to relieve stress

that can form cracks.

III. Modelling and Design: WSP PCB to IC Transition

There are several physical constraints as well as electrical

issues that need to be solved in the design of the WSP

PCB to IC transition. The physical constraint is the physical

tolerance of the PCB that the WSP is mounted on. Typically,

a 100 µm gap and 200 µm pad is required for PCB to WSP

transition. The WSP must take this pad layout and transfer

the microwave energy through a relatively lossy GaAs

dielectric (DR = 12.7) up and to the inner surface. The

typical design goal is for a 50 Ω impedance (better than

-20 dB return loss) during this transition.

0

-5

-10

-15

-20

-25

-30

-35

-40

-45

-50

RL

IL

0

10

20

30

40

Frequency (GHz)

50

Figure 4. Simulated Return Loss and Insertion Loss

3

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

Insertion Loss (dB)

Return Loss (dB)

Figure 3. 3D Simulation Structures (HFSS) of simple thru structure

60

70

To design this transition, Avago employed several EM

simulators (HFSS and Microwave Office). EM simulation is

required due to the lack of ideal elements or traditional

transitions. Each simulator offered different advantages

and results. Differences between modelled performance is

often caused by how the boundaries and vertical dimensions are calculated as well as grid array restrictions. In the

end all results were heavily matched against measured

results. Figure 3 shows the EM simulation deck. Figure 4

shows simulated results to 60 GHz for a GaAs WSP on a

Rogers 4350 laminate PCB.

IV. Comparison to Traditional Packaging

WSP lowers parasitic loss, capacitance and inductance

WSP offers two significant advantages over conventional

microwave package technology.

WSP solutions do not have a lead frame, bond wires,

a cumbersome lid or plastic encapsulation that adds

parasitic loss, inductance, or capacitance. This gives WSP

an inherent bandwidth and high frequency performance

advantage. While most packages struggle to achieve low

loss performance above 20 GHz, WSP has demonstrated

excellent performance to 80 GHz in standard SMT and PCB

environments.

WSP simplifies the assembly process

As Figure 5 shows there are fewer steps in a WSP assembly

process. Also, these steps can be performed in a clean

automated fabrication facility. Wafers do not travel to

assembly contractors where they can be subjected to uncontrolled ESD and environmental forces.

Figure 6 shows a conventional package with its associated

loss factors.

Typical assembly processes

MMIC Wafer

Die Singulation

Die Attach Assembly

Wire bond Assembly

MMIC Wafer

Packaging Assembly

Bonded with Cap Wafer

Packaging Singulation

Figure 5a. Typical plastic package assembly process

Input Bond Wire adds Noise

and parasitic Inductance

Singulation

Figure 5b. WSP equivalent process

Plastic increases capacitance

and lower bandwidth

Output Bond Wire decreases

power and adds Inductance

MMIC wafer

RF in

Parasitic pad capacitance

decreases bandwidth

Figure 6. Typical parasitics in other SMT technologies

4

Lead frame increases

thermal resistance

RF out

V. Released–to–Market WSP product examples

The first WSP products in the market were simple. This was

necessary to keep the number of variables at a minimum

and to provide a reliable and consistent product. As with

any new technology, the goal was to build confidence and

experience. Avago introduced the VMMK-1226 e-PHEMT

FET on a 0402 (1.0 x 0.5mm) WSP in the spring of 2008.

The VMMK-1226 features DC–26 GHz performance equivalent to that of more expensive ceramic devices. The

VMMK-1226 has three leads with a complete air cavity

over the active FET. The topology is extremely simple with

no on-chip matching. Figure 7 shows the bottom leads

and inside layout.

Avago Technologies’ second generation of WSP products

use the same size and pad layout as the VMMK-1226 but

with a more complicated integrated circuit. Figure 8 shows

the VMMK-2x03 series of sub –12 GHz parts that were introduced in 2009.

Drain

Source

Gate

Parameters

Specifications

Frequency

DC – 26GHz

Operating Condition

1.5V @ 10 mA

Gain

12dB @ 12GHz

NF

0.5dB @ 12GHz

OIP3

22dBm @ 12GHz

P1dB

10dBm @ 12GHz

Figure 7. The first Avago WSP products were 200 µ and 400 µ

Float

Vdd

Size: 1.1mm x 0.6mm (0402 component)

Amp

Input

Bias-Tee

Input

Pad

Ground

Pad

50_Ohm line

Output

Output

Pad

50_Ohm line

VMMK-2103

VMMK-2203

VMMK-2303

VMMK-2403

VMMK-2503

0.5 – 6 GHz

1 – 10 GHz

0.5 – 6 GHz

2 – 4 GHz

1 – 12 GHz

Bias

5V/25mA

5V/28mA

1.8V/20mA

5V/50mA

5V/60mA

Gain

14 dB

16 dB

13 dB

15 dB

14 dB

NF

2.4 dB

2.3 dB

< 2.5 dB

2.5 dB

3.7 dB

OIP3

23 dBm

15 dBm

23 dBm

32 dBm

28 dBm

P1dB

NA

NA

10 dBm

20 dBm

17 dBm

Freq Range

Figure 8. 2009 Avago second generation WSP introductions

5

Bias-Tee

VI. WSP applications and simulation

Avago WSP products in the 0402 format are intended to

be basic building blocks in a variety of systems. While

there certainly are military applications (small size and a

near hermetic package) the main targets are commercial

and consumer applications such as DBS satellite, GPS and

radar detectors.

One of the challenges to wide WSP use involves simulation and performance verification. Avago has dedicated

much effort to this. Avago now provides both traditional sparameter and x-parameter data. The x-parameters follow

a new standard introduced by Agilent. Additional information is available at: (http://www.home.agilent.com/

agilent/application.jspx?nid=-34017.0.00&US&lc=eng)

Figure 9 shows an example WSP application along with

x-parameter data.

Avago WSP application with x–parameters

The advantages and key features of x-parameters are

widely quoted:

“X-parameters can help you overcome a key challenge in

RF engineering, namely that nonlinear impedance differences, harmonic mixing, and nonlinear reflection effects that

occur when components are cascaded under large signal

operating conditions. This means that there is a nonlinear,

and as such, non-trivial relationship between the properties

of the individual cascaded components and the composite

properties of the resulting cascade. This situation is unlike

that at DC; where one can (for example), simply add the

values of resistors connected in series. X-parameters help

solve this cascading problem: if you measure the X-parameters of a set of components individually, you can calculate

the X-parameters and hence the nonlinear transfer function

of any cascade made from them1.”

40

20

0

-20

-40

-60

-80

-100

-120

-140

Figure 9 a. A 0402 VMMK part mounted on a PCB

dBm(Vout[::,1])

dBm(Vout[::,5])

dBm(Vout[::,4])

dBm(Vout[::,3])

dBm(Vout[::,2])

-20 -18 -16 -14 -12 -10 -8 -6 -4 -2 0

Pin

2

4

6

8 10 12

Figure 9 b. 1st, 2nd, 3rd, 4th, and 5th Harmonic from x-par

Vdd

0.1uF

Graphical Extrapolation of the IP3 Point

60

40

100pF

20

Size: 1.1mm x 0.6mm (0402 component)

0

-20

Input

Input

Pad

Ground

Pad

-40

Output

Amp

-60

Output

Pad

50_Ohm line

Figure 9 c. Typical VMMK bias network

-80

Bias-Tee

-100

50_Ohm line

-25

-20

-15

-10

-5

0

5

extended_range

10

15

20

25

1.5

2.0

2.5

Figure 9 d. Output IP3 as calculated using x-parameters

Transmitted Spectrum

0

Spectrum_in

Spectrum_out

-20

-40

-60

-80

-100

-120

Figure 9 e. Typical VMMK demonstration board

6

-2.5

-2.0

-1.5

-1.0

-0.5 0.0 0.5

freq, MHz

Figure 9 f. ACPR as calculated using x-parameters

1.0

VII. Conclusion and future developments

WSP technology as implemented at Avago Technologies

provides a viable and reliable solution to future microwave

through millimeter needs. It has better performance than

traditional packaging by eliminating bond wires, lead

frames, and laminate or plastic encapsulates. It provides a

complete sealed environment (passing MSL level 2) for the

active components yet provides a low dielectric constant

(air) cavity above the chip. Users find assembly is easy and

as volume increases existing automation equipment will

drive their costs lower.

The WSP starts as a standard processed GaAs wafer. The

backside vias and I/O pads serve as the lead-frame of the

wafer scale package. The backside metal is thick enough

to ensure adequate coverage in the bottom of the vias

without inhibiting the use of standard solder paste in

assembly. The pad size and separation are adequate to

ensure that no special package footprint concessions

need to be made by customers and their board houses.

Lead-free solder paste is the recommended adhesive, as it

will help the parts self-align on the board.

There are some drawbacks to this technology. The first

is that GaAs is inherently fragile, thus the metal backing

of the WSP must be carefully controlled to prevent stress

cracks during application. Secondly, the die is inherently

larger in a WSP application versus a pure chip and wire

assembly. Real estate wise it is more expensive.

Figure 10. Prototype WSP 3 x 3mm DC–50GHz TWA

7

The largest hurdle to wide customer adoption is that the

technology is new. Most microwave through millimeter

wave IC users are conservative and slow to adopt new

ideas into their mainstream manufacturing. The need for

compact solutions and better performance are strong

driving forces that counter this conservatism.

Development continues at Avago to expand and diversify

the WSP portfolio. In 2009 there will many new products

released to market using the 0402 format to make basic

microwave building blocks, including amplifiers, detectors,

switches and mixers. Also during 2009, sampling and reliability qualification will start on larger package formats

that allow more functions. This will include 1 x 2 mm, 2 x

2 mm, and 3 x 3 mm packages with QFN compatible footprints. These new products will have heights of only 0.4

mm. Applications for the more complex and larger WSP

products include Ka and Ku band 2 W power amplifiers,

38 GHz down-converters and up-converters, and e-band

products. Figure 10 shows a prototype DC–50 GHz TWA in

a 3 x 3 mm WSP.

Design and construction of GaAs based WSP is relatively

straightforward once certain hurdles are passed. The

fabrication hurdle is to bond two wafers together while

forming a perfect air gap over critical active areas of the IC.

The design hurdle is to properly model the 3-dimension

transitions with minimal parasitic losses or unwanted

mode creation. The last hurdle is customer adoption and

usage, which requires applications where the advantages

of WSP far outweigh any risks.

References

[1] K. Phan, J. Kessler, H. Morkner, M. Vice, L. Nguyen, J. Roland, “A Miniaturized Wafer-Scale Package Demonstrated

with Three Enhancement Mode Amplifiers”, EuMC 2008, October 2008

[2] S. Kumar, J. Kessler, H. Morkner, ”6-24 GHz Mixer Using 0.25um Enhancement Mode PHEMT Technology in a Low

Cost Chip Scale Package”, EuMC 2008, October 2008

[3] K. Phan, H Morkner, “A High Performance Yet Easy to Use Low Noise Amplifier in SMT Package for 6 to 20GHz Low

Cost Applications,” European Microwave Conference, 12th GaAs Symposium, Amsterdam pp. 603-606, 2004.

[4] K. Phan, K. Fujii, H. Morker, “Two High Dynamic Range mmW Amplifiers in SMT Package with ESD Protection,“ 37th

European Microwave Conference, Munich, pp. 1209-1212, 2007

[5] K. Kobayashi, “Improved Efficiency, IP3-Bandwidth and Robustness of a Microwave Darlington Amplifier using

0.5um ED PHEMT and a New Circuit Topology,” IEEE CSIC Digest, pp. 93-96, 2005

[6] S. Kumar, M. Vice, H. Morkner, W. Lam, “Enhancement mode GaAs PHEMT LNA with linearity Control (IP3) and Phase

matched Mitigated Bypass Switch with Differential Active Mixer,” IEEE 2003 International Microwave Symposium,

[7] H. Morkner, M. Frank, S. Yajima, “A Miniature PHEMT Switched-LNA for 800MHz to 8 GHz Handset Applications”,

IEEE 1999 RFIC Symposium, June 1999, Session TUE1-2

1 Agilent Technologies.

For product information and a complete list of distributors, please go to our web site:

www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2009 Avago Technologies. All rights reserved.

AV02-2103EN - September 16, 2009