Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

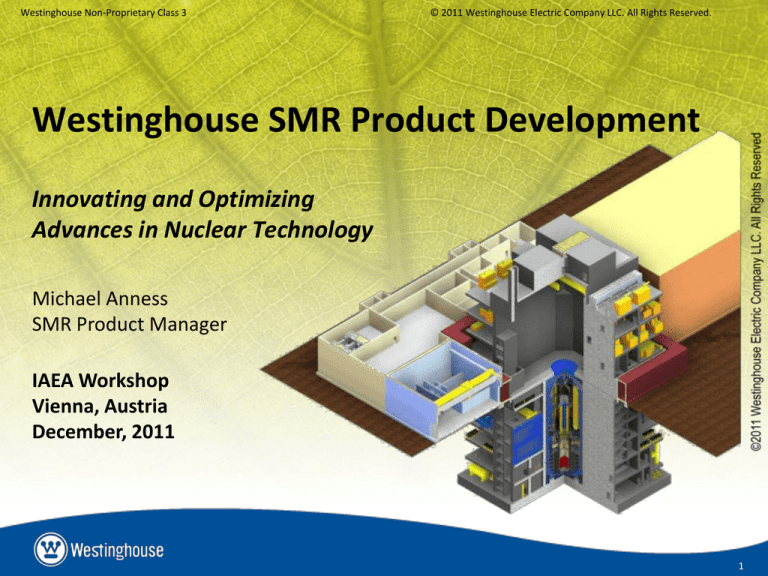

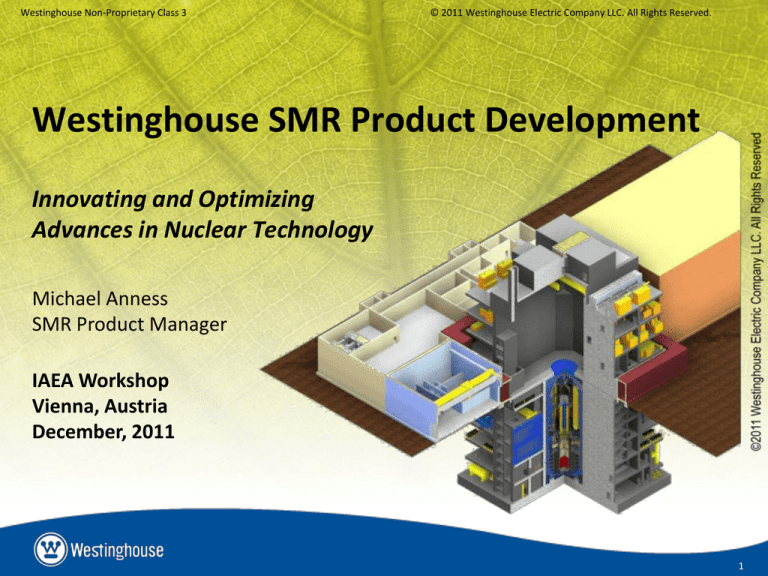

Westinghouse SMR Product Development

Innovating and Optimizing

Advances in Nuclear Technology

Michael Anness

SMR Product Manager

IAEA Workshop

Vienna, Austria

December, 2011

1

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Westinghouse’s Vision

Westinghouse will be the first to deploy a safe, economical SMR to meet

the many needs of existing and new to nuclear customers

Working within constraints

• Land, grid, cooling water, financing,

distributed service territory

Offering clean energy

• Offset owner costs for infrastructure

development: land, cooling, T&D

• Generation diversity

• Operational flexibility

Providing project certainty

• Reduced licensing risk

• Short-construction durations

• Cost predictability and certainty

New applications for nuclear…

Aging Fossil Plants

District Heating

Remote Markets

Small Grid Markets

Desalination

Process Heat

2

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SMR Product Philosophy

Best opportunity for cost competitiveness

•

•

•

•

Most power with the least amount of material

Fully-modular design

Plant modules that are installed, not constructed

Rail & truck transportable

Speed to market

• Proven ability to design, license & deploy reactors

• Existing technical skills, licensed technologies & supply

chain

• Designing to eliminate supply chain bottlenecks

• Leveraging AP1000® plant experience and lessons learned

3

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SMR Product Specifications

Specifications

Thermal Output

Electrical Output

Passive Safety Systems

Core Design

Reactor Vessel Size

Upper Vessel Package

Containment Vessel Size

Reactor Coolant Pumps

Steam Generator

Pressurizer

Instrumentation and Control

800 MWt

>225 MWe

No operator intervention required for 7

days

17x17 Robust Fuel Assembly

8.0 ft / 2.4 m Active Length

< 5.0% Enriched U235

89 Assemblies

Soluble Boron and 37 Internal CRDMs

24 month refueling cycle

Outer Diameter: 11.5 ft / 3.5 m

Height: 81 ft / 24.7 m

280 Tons / 254000 kg.

Outer Diameter: 32 ft / 9.7 m

Height: 89 ft / 27.1 m

Fully Modular Construction

8 External, Horizontally-Mounted Pumps

Sealless Configuration

Recirculating, Once-Through, Straight

Tube

Integral to Vessel

OVATION®-based Digital Control System

4

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SMR Plant Design

• Containment Vessel Below

Turbine Building

Grade

• All Safety Systems Protected

by Reactor Building

Annex

Maintenance Hall

Radwaste

Grade

Nuclear Island

5

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Containment Vessel (CV) Overview

Compact, High-Pressure Design

• Water-covered

• Penetrations designed for

refueling and outage

– Large external and internal

pressure

• Removable top head

• Accommodates modular

installation

Containment

Vessel

Pressurizer

Core Makeup

Tank

Steam

Generator

Reactor

Coolant

Pumps

Internal

Control Rod

Drives

Reactor Core

6

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Integral Reactor Overview

• Reactor Vessel (RV)

– Includes Pressurizer (PZR) and Steam

Generators (SG)

– Reactor Coolant Pump (RCP) mounted

to RV shell

– Support pads welded to lower shell

– Intermediate flange

– Traditional bolted flange

Pressurizer

Steam

Generator

RCPs

7

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Recirculating Steam Generators

• Straight-tube steam generator

– Flow from top to bottom of

tubes

• Hot leg located in center of tube

bundle

– Transfers hot water to the

upper tube sheet

• Main steam and feedwater piping

connections

• Recirculating steam generator with

steam/water mixture delivered to

steam drum outside containment

Tubesheet

Tubes

Tube supports

Wrapper

Hot Leg

Transition Cone / Cold

Leg

8

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SG Internals

Tubesheet

Containment Wall

Steam Generator

External Steam Drum

Steam Nozzle to

Turbine

Steam and Feed

Nozzles

Tubes

Tube supports

Feedwater

Nozzle

Secondary

Separators

Primary

Separators

Wrapper

Sludge Collector

Hot Leg

Recirculation

Nozzle

Transition Cone / Cold

Leg

Wet Steam

Nozzle

9

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Steam Drum Design

Dry Steam Flow Path

•Wet Steam Nozzle

•Lower Deck Plate

•Primary Separators

•Secondary Separators

•Steam Outlet Nozzle

Recirculating Liquid Flow Path

•Wet Steam Nozzle

•Lower Deck Plate

•Primary Separators

•Lower Drum

•Recirculation Nozzle

Typical Design Features

Elevated Feedring with Spray nozzles

Primary Separators

Feedwater Flow Path

•Feedwater Nozzle

•Lower Drum

•Recirculation Nozzle

Secondary Separators

10

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Fuel Assembly Overview

181.71 Inconel Top Grid Elevation

Non-mixing Vane Grid

Mixing Vane Grid (Total 8)

164.39 Mid Grid Elevation

Based on proven 17x17 RFA design

J=1

153.73IFM Elevation

IFM Grid (Total 4)

Upper Core Plate

144.09 Mid Grid Elevation

Top Mounted Core

Instrumentation

WSMR

LM0001

Inconel Top Grid

RFA2 Mid-Grid

Grid

EnhancedNon-mixing

strengthVane

188.800

Enhanced fretting margin

Mixing

Grid (Total 8)

ZIRLO®

grid Vane

material

IFM Grid (Total 4)

Opt. ZIRLO® Cladding

Westinghouse Integral Nozzle (WIN)

133.43IFM Elevation

No potential for loose parts

J=5

123.79

Gridcasting

Elevation

OneMid

piece

113.13IFM Elevation

181.71 Inconel

Top Grid Elevation

Skeleton

structure

103.49 Mid Grid Elevation

Enhanced dimensional stability

164.39

Mid Grid

Elevation

ZIRLO®

thimble

tubes

92.83 IFM Elevation

Thick thimble tubes

J=3

153.73IFM

Elevation

83.19

Mid Grid

Elevation

Tube-in-tube

dashpot

design

Anti-bowing

design prevents IRI

144.09

Mid Grid Elevation

62.89 Mid Grid Elevation

IFBA, ZrB2 Integral Fuel

Burnable Absorber

133.43IFM Elevation

42.59 Mid Grid Elevation

123.79 Mid Grid Elevation

23.97 Mid Grid Elevation

113.13IFM Elevation

Inconel Bottom Grid

188.800

Non-mixing Vane Grid

Oxide Coated

Cladding

Protective

Grid

Bottom Nozzle

Stand-off

Plenum

103.49 Mid Piece/Bottom

Grid Elevation

6.66 Inconel Bottom Grid Elevation

92.83 IFM Elevation

3.223 Inconel Protective Grid Elevation J = 3

83.19

Mid GridGrid

Elevation

Protective

(P-Grid)

Base Line Elevation (0.0)

Low Profile Debris

Filter

Lower Core

Plate

Bottom Nozzle (LP DFBN)

J=2

62.89 Mid Grid Elevation

J=1

42.59 Mid Grid Elevation

23.97 Mid Grid Elevation

6.66 Inconel Bottom Grid Elevation

11

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

CRDM Design

• Latch assemblies, controls, and

interfaces with fuel are all based on

existing, proven designs

• AP1000® CRDM (including latch

assembly and coil stack) already

tested to 8 million steps in a 610°F

Test Loop

• Component testing underway

12

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Containment Vessel - How Small is Small?

25 Westinghouse SMR

Containment Vessels fit in a

single AP1000® Containment

Vessel

13

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Site Layout

• Required Land Area: 16 Acres

– Excavation depth 105 feet

• Multiple Units: Separation

– Security-based separation assumes a unit is operating adjacent to a unit

under construction

– Spacing prevents seismic interaction between units

• Reactor building (100’x100’) 6 levels below grade (105’ deep)

– Separate contaminated and clean areas

– Multiple safety trains separated for flooding, fire and access

• Turbine building contains BOP and

non-safety equipment only

14

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SMR Safety: “Seven Days”

15

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

SMR Product Features

• All the advancements of the

•

•

•

•

AP1000® reactor at a much smaller

scale

Licensed passive safety system

Simplified and standardized design

Modular

Most power from least

amount of material

16

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

Thank You!

17

Westinghouse Non-Proprietary Class 3

© 2011 Westinghouse Electric Company LLC. All Rights Reserved.

AP1000 and ZIRLO are registered trademarks in the

United States of Westinghouse Electric Company LLC,

its subsidiaries and/or its affiliates. These marks may

also be used and/or registered in other countries

throughout the world. All rights reserved.

Unauthorized use is strictly prohibited.

Ovation is a trademark of Emerson Electric Co. Other

names may be trademarks of their respective owners.

18