Mask Integrity Test Accessory (MITA ) Model 8120 Operator`s Manual

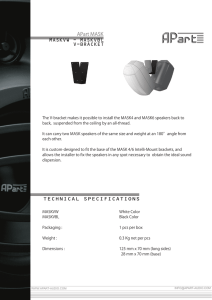

advertisement