DISASSEMBLY ANALYSIS, MATERIAL COMPOSITION ANALYSIS

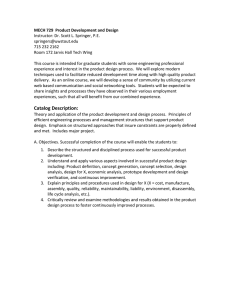

advertisement

DISASSEMBLY ANALYSIS, MATERIAL COMPOSITION

ANALYSIS AND ENVIRONMENTAL IMPACT

ASSESSMENT OF COMPUTER

DISK DRIVES

by

SUNIL MOHITE, B.E.

A THESIS

IN

INDUSTRIAL ENGINEERING

Submitted to the Graduate Faculty

of Texas Tech University in

Partial Fulfillment of

the Requirements for

the Degree of

MASTER OF SCIENCE

IN

INDUSTRIAL ENGINEERING

Approved

Hong -Chao Zhang

Chairperson of the Committee

Iris Rivero

John Kobza

Accepted

John Borrelli

Dean of the Graduate School

May, 2005

ACKNOWLEDGEMENTS

I would like to express my profound appreciation to Dr. Hong-Chao Zhang, my

advisor, for all guidance, inspiration and enthusiasm he has provided not only for this

research work but also throughout my term as a graduate student at Texas Tech

University. I am also deeply indebted to my advisory committee members, Dr. John

Kobza and Dr. Iris Rivero, for their helpful advice.

My gratitude goes to my beloved parents, Sadashiv Mohite and Vijaya Mohite,

and my brother Amit, for their love, guidance and motivation. I would like to thank my

friends’ Puneet Shrivastava, Rohit Kulkarni who have been of great help for my research

work. I would also like to thank Abhuday Desai, who has been a great inspiration to me,

for his guidance throughout my graduate degree program.

I also thank for Graduate School for providing summer thesis scholarship to

support this thesis research work.

ii

TABLE OF CONTENTS

ACKNOWLEDGEMENTS................................................................................................ ii

ABSTRACT …………………………………………………………………………......vi

LIST OF TABLES……………………………………………………………………….ix

LIST OF FIGURES ........................................................................................................... xi

LIST OF ABBREVIATIONS.......................................................................................... xiv

CHAPTER ......................................................................................................................... 1

I. INTRODUCTION ........................................................................................................... 1

II. LITERATURE REVIEW............................................................................................... 4

2.1

Environment Impact Analysis and Disassembly Analysis ................................. 4

2.2

Design for Environment...................................................................................... 7

2.3

Electronic Product Evaluation using Analytical Tool ........................................ 8

2.4

Company Initiative............................................................................................ 11

2.5

Eco Indicator Methods...................................................................................... 15

2.6

Government Policies......................................................................................... 17

2.7

Environmental Protection Agency.................................................................... 22

III. METHODOLOGY ..................................................................................................... 25

3.1

Description of the Product ................................................................................ 25

3.2

Disassembly Analysis ....................................................................................... 25

3.2.1

Disassembly Sequence.............................................................................. 26

3.2.2

Disassembly Procedure............................................................................. 26

3.2.3

Disassembly Tree...................................................................................... 27

iii

3.2.4

Comments on Disassembly....................................................................... 27

3.2.5

Component Relationship........................................................................... 27

3.2.6

Disassembly Time and Cost...................................................................... 28

3.3

Material Assessment and Component Weight.................................................. 28

3.4

Environmental Impact Assessment................................................................... 29

3.4.1

Eco-Indicator Calculation ......................................................................... 30

3.4.2

Saving in Eco-Indicator due to Recycling of the Product......................... 31

IV. RESULT AND ANALYSIS....................................................................................... 33

4.1

Hard Disk Drive Analysis................................................................................. 33

4.1.1

Product Description .................................................................................. 33

4.1.2

Disassembly Sequence.............................................................................. 33

4.1.3

Disassembly Procedure............................................................................. 34

4.1.4

Disassembly Tree of Hard Disk Drive...................................................... 36

4.1.5

Comments on Disassembly....................................................................... 37

4.1.6

Component Relationship........................................................................... 37

4.1.7

Disassembly Time and Cost...................................................................... 39

4.1.8

Material Analysis and Weight Distribution .............................................. 40

4.1.9

Environmental Impact Assessment........................................................... 41

4.1.10

Saving in Eco-Indicator due to Recycling ................................................ 45

4.2

Server CD-ROM Drive Analysis:..................................................................... 49

4.2.1

Product description ................................................................................... 49

4.2.2

Disassembly Sequence.............................................................................. 49

iv

4.2.3

Disassembly Procedure............................................................................. 51

4.2.4

Disassembly Tree for CD-ROM Drive:.................................................... 55

4.2.5

Comments on Disassembly....................................................................... 56

4.2.6

Component Relationship........................................................................... 56

4.2.7

Disassembly Time and Cost...................................................................... 58

4.2.8

Material Analysis and weight Distribution:.............................................. 60

4.2.9

Environmental Impact assessment............................................................ 61

4.2.10

Saving in Eco-Indicator due to Recycling ................................................ 65

4.3

Server Floppy Disk ........................................................................................... 70

4.3.1

Product Description .................................................................................. 70

4.3.2

Disassembly Sequence.............................................................................. 70

4.3.3

Disassembly Procedure............................................................................. 72

4.3.4

Disassembly Tree for Floppy Disk Drive: ................................................ 75

4.3.5

Comments on Disassembly....................................................................... 76

4.3.6

Component relationship ............................................................................ 77

4.3.7

Disassembly Time and Cost...................................................................... 78

4.3.8

Material Analysis and weight Distribution:.............................................. 80

4.3.9

Environmental Impact assessment............................................................ 81

4.3.10

Eco-Indicator Saving by Recycling .......................................................... 85

4.4

Laptop Floppy Drive......................................................................................... 90

4.4.1

Product Description: ................................................................................. 90

4.4.2

Disassembly Sequence.............................................................................. 90

v

4.4.3

Disassembly Procedure............................................................................. 92

4.4.4

Disassembly Tree:..................................................................................... 95

4.4.5

Comments on Disassembly....................................................................... 96

4.4.6

Component Relationship........................................................................... 96

4.4.7

Disassembly Time and Cost...................................................................... 98

4.4.8

Material Analysis and Weight Distribution: ............................................. 99

4.4.9

Environmental Impact Assessment......................................................... 100

4.4.10

Eco-Indicator Saving due to Recycling .................................................. 105

V. CONCLUSION AND FUTURE REASERCH.......................................................... 110

5.1

Contribution of this research........................................................................... 110

5.2

Future research................................................................................................ 111

BIBLIOGRAPHY........................................................................................................... 112

APPENDICES

A. ECOINDIACATOR VALUES OF MATERIAL ................................................... 118

B. STANDARD PRINTED CIRCUIT BOARD COMPOSITION............................. 119

C. CONTROL UNIT HARDDISK COMPONENET MATERIAL COMPOSITION 120

vi

ABSTRACT

This main objective of this thesis is to do the disassembly analysis of the

computer drives such as Hard Disk Drive of Desktop, Floppy Disk Drive of Server,

Floppy Disk Drive and CD-ROM drive of Server to identify the components and to

determine the Environmental Impact of these components and product as a whole.

For the disassembly analysis the computer drives were disassembled to the level

where further disassembly is not possible and the time for disassembly was noted down.

The best disassembly sequence was selected so that the disassembly is done in minimum

possible time. Disassembly tree was generated for the easier understanding of the

disassembly and to understand different levels of disassembly. Component relationship

was developed based on the mechanical relationship and electrical connection among the

components. Disassembly cost was calculated by taking into consideration only labor

expenses. Difficulty rate was calculated depending upon the operation performed to

disassemble the specific product.

For determining the environmental impact identification of material is necessary.

It is known that hazardous materials are present in the Printed Circuit Boards of the

computer drives. So the PCB’s from the computer drives were sent to ‘Noranda

Recycling Inc.’ for material analysis. The plastic used in the drives was identified by the

label present on the plastic components and the data for the metal components was taken

from the literature.

Environmental Impact Assessment was done by using Eco-Indicator 99

methodology. Environmental impact caused by components of the drive was calculated

vii

and environmental impact of the computer drive as a whole was also calculated. If these

components are recycled how much eco-indicator will be saved was determined by the

Environmentally

Weighted

Recycling

Quotes

Methodology.

Eco-Indicator

99

methodology is widely used methodology for determining the environmental impact of

the electronic products. Also it is very easy to use.

viii

LIST OF TABLES

1. Disassembly sequence ................................................................................................. 34

2. Component relationship ............................................................................................... 38

3. Disassembly time and cost.......................................................................................... 39

4. Component material and weight hard disk drive ......................................................... 40

5. Environmental impact assessment of hard disk drive.................................................. 42

6. Saving in Eco-Indicator due to recycling..................................................................... 46

7. Disassembly sequence CD-ROM drive ....................................................................... 50

8. Component relationships CD-ROM Drive .................................................................. 57

9. Disassembly time and cost........................................................................................... 58

10. CD-ROM material and weight.................................................................................... 60

11. Environmental impact assessment CD-ROM drive.................................................... 62

12. Eco-indicator saving due to recycling......................................................................... 66

13. Disassembly sequence ................................................................................................ 71

14. Component relationship server floppy disk drive....................................................... 77

15. Disassembly time and cost of floppy disk drive ......................................................... 78

16. Floppy disk drive material and weight....................................................................... 80

17. Environmental impact assessment of FDD................................................................. 82

18. Eco-Indicator saving due to recycling ........................................................................ 86

19. Disassembly sequence ................................................................................................ 91

20. Laptop floppy drive component relationship.............................................................. 97

21. Disassembly time and cost.......................................................................................... 98

ix

22. Laptop FDD material and weight ............................................................................... 99

23. Environmental impact assessment ............................................................................ 101

24. Eco-indicator saving due to recycling....................................................................... 106

x

LIST OF FIGURES

1. PCB ............................................................................................................................... 34

2. Top cover ...................................................................................................................... 34

3. Hard disk....................................................................................................................... 35

4. Pointer assembly ........................................................................................................... 35

5. Circular plate................................................................................................................. 35

6. Plastic assembly ............................................................................................................ 35

7. Disassembly cost of hard disk components ................................................................. 39

8. Component based EI score HDD.................................................................................. 45

9. Saving in eco-indicator due to recycling ...................................................................... 48

10. Bottom cover............................................................................................................... 51

11. PCB ............................................................................................................................. 51

12. CD motor .................................................................................................................... 51

13. CD optical reader ........................................................................................................ 52

14. Bottom cover............................................................................................................... 52

15. CD motor base plate.................................................................................................... 52

16. CD tray........................................................................................................................ 53

17. CD tray frame ............................................................................................................. 53

18. Motor for optical drive................................................................................................ 53

19. Plastic sub frame ......................................................................................................... 54

20. Motor for CD tray ....................................................................................................... 54

xi

21. Disassembly cost CD-ROM drive .............................................................................. 59

22. Component based eco-indicator CD-ROM drive ....................................................... 65

23. Saving in EI due to recycling...................................................................................... 69

24. Side clamp................................................................................................................... 72

25. Main PCB.................................................................................................................... 72

26. PCB ............................................................................................................................. 72

27. Top cover .................................................................................................................... 73

28. Motor........................................................................................................................... 73

29. Floppy reader .............................................................................................................. 73

30. CD insert cover ........................................................................................................... 74

31. Floppy insert flap and eject button.............................................................................. 74

32. PCB ............................................................................................................................. 74

33. Main frame.................................................................................................................. 74

34. Disassembly cost server floppy disk drive................................................................. 79

35. Component based EI score.......................................................................................... 84

36. Saving in EI due to recycling...................................................................................... 89

37. Bottom cover............................................................................................................... 92

38. Top cover .................................................................................................................... 92

39. Circuit board cover ..................................................................................................... 92

40. Main circuit board....................................................................................................... 93

41. Back cover .................................................................................................................. 93

42. Motor........................................................................................................................... 93

xii

43. Floppy insert cover ..................................................................................................... 93

44. Metal frame................................................................................................................. 94

45. Floppy reader assembly .............................................................................................. 94

46. Disassembly cost......................................................................................................... 98

47. Component based EI score........................................................................................ 104

48. Saving in EI due to recycling.................................................................................... 109

xiii

LIST OF ABBREVIATIONS

FDD

- Floppy Disk Drive

HDD

- Hard Disk Drive

RoHS

- Restriction on Hazardous Substance

WEEE

- Waste from electrical and electronics equipments

EPA

- Environmental Protection Agency

EOL

- End of Life

E-WASTE

- Electronic Waste

xiv

CHAPTER I

INTRODUCTION

Due to the technological advances today’s computers have very short product life

cycle. At the end of the useful life of the computer the question arises of its disposal. The

computer contains precious metals, hazardous substances, plastics etc. these days many

countries don’t allow to landfill the electronic waste due to the damage created by them

to the environment and also due to the shortage of landfills. And if the computers are land

filled the material of these computers can not be used again by doing recycling process.

In many countries there are different laws regarding the disposal of the electronic

products.

European Union is almost ready to implement two new laws; the first one is

Directive on Waste of Electrical and Electronic Equipment (WEEE) and the second one

is Directive on restriction of the use of certain hazardous substances in electrical and

electronic equipment. According to this law by July 2006 electronic equipment should

not contain certain hazardous material above a specified threshold value. In United

States also certain states such as California does not allow to landfill the electronic

equipments at the end of their useful life. European Union has developed many ‘Eco

Labels’. The Eco-label is given to the electronic product if it meets certain material

criteria such as if the product contains less than the critical amount of hazardous material.

Many European countries, government is giving responsibilities to original equipment

manufacturers (OEM) for taking back their products at the end of their useful life.

1

OEMs usually don’t manufacture the computer peripherals such as CD-ROM,

Floppy Disk Drive or Hard Disk drive. But major portion of the computer is made-up of

these components and when they sell the computer it becomes OEM’s responsibility to

take care of the computer at the end of their useful life. The implementation of WEEE

directive will require manufacturers to provide disassembly information to the recyclers

to facilitate end of life treatment of the product. Further it’s necessary for the

manufacturers to give the information about components and material used in their

product and which components should be removed from the product so as to do separate

recovery or recycling operation.

If a Hard Drive, Floppy Drive or CD-ROM drive acquired from supplier contains

some hazardous material and it’s used as a part of computer manufactured by OEM, then

the OEM might have to take the product off the market due to fact that it won’t meet

specific criteria established by ROHS directive. So OEM should know the material

composition and environmental Impact caused by them. Environmental assessment tools

have been traditionally used to study Environmental Impact caused by these products. On

the basis of environmental analysis it will be possible for OEMs to choose right vendor

for these peripherals. Choosing right material would thus enable OEMs to develop better

recycling programs. The analysis of computer peripherals will be useful for OEMs in

determining the reusability and recycalabality of these components.

This study involves the assessment of Hard Disk Drive, Floppy Disk Drive and

CD-ROM drive from the perspective of disassembly, material analysis and environmental

Impact. In this study first disassembly analysis is done first, the next step followed in this

2

study is to determine the material of the components so as to detect the presence of the

hazardous material and finally environmental impact assessment was done using EcoIndicator 99 methodology.

In the disassembly analysis disassembly of Hard Disk Drive, Floppy Drive and

CD-ROM drive was done. The steps required to disassemble the whole product were

recorded until the further disassembly is not possible. Disassembly tree was generated for

the easier understanding of the disassembly and to establish the component relationship.

The time required for disassembly was recorded. Cost of disassembly was calculated by

taking into consideration time required for disassembly and the labor cost. Material

analysis was done for the components of the computer peripherals and weight of each

component was recorded. Type of plastic used for components was identified according

the description on the component. PCBs of all the Drives were sent to the material testing

lab to identify the composition. Literature information was used to identify the material

which could not be identified due to unavailability of means and resources. Eco-Indicator

99 method was used to analyze the Environmental Impact of the product as a whole and

Environmental Impact was also categorized according to the material and component

basis. Eco-Indicator values were taken from the Eco-Indicator 99 manual for designers.

Calculations were also done for saving in Eco-Indicator score due to recycling. It was

done on material basis and also on component basis. The factors in calculating saving in

Eco-Indicator were the recovery rate of recycling process and material grade of the

recycled product.

3

CHAPTER II

LITERATURE REVIEW

The research done for this thesis is mainly concerned with the disassembly

analysis of the computer drives and finding out the environmental impact of these drives.

So the literature review is done along the line of environmental impact analysis,

disassembly analysis for finding out what products were studied to determine their

environmental impact. Also what kinds of design for environment efforts are being done

so as to reduce the environmental impact of the product. Recycling analysis to get insight

of what is the current scenario regarding the recycling of electronic product. What are the

initiatives taken by the companies to reduce the environmental impact of the products

they produce and government policies, environmental protection agency’s efforts to

reduce the load of the electronic equipment on the environment. Different Eco-Indicator

methodologies were also studied.

2.1 Environment Impact Analysis and Disassembly Analysis

Huisman, J., Gijlswijk, R.V., and Ansems, A. [14] have made an attempt to

determine the flow of the heavy metals used in electronic product at the end of life so that

they can be reused. For this they have considered four end of life scenarios which are

controlled landfill, municipal Incineration, Dismantling/ mechanical separation with

smelting, recycling other material fractions and thermal treatment. Three electronic

products were selected for the presence of ten different heavy metals. The result shows

4

that different metals are emitted to the air for different options. For last three options Zinc

(Zn) and Lead (Pb) are the metals which constitute the most to the air emission.

Life cycle analysis of cassette tapes and mini disk was done by wantanbe, H.,

Satake, K., tomita, H., [22] to find out the environmental impact of these products. Their

research has showed that mini disk consume less energy for manufacturing than the

cassette tapes. They also observed that in cassette tapes the energy is mainly consumed

for the production of the material and in mini disk for the manufacturing process.

Potential recyclability of mini disk is 98% as compared to 71% of cassette tape. Oishi, S.,

Satake. K., of Sony Corporation have done the life cycle analysis of the CD-ROM drive

[42]. The main objective of their research was to find out about the emission of the

Carbon-di-oxide, Nitrogen Oxide and Sulfur Oxide. The authors have considered four life

cycle stages which were Production, Assembly, Transport and Use. The carbon-di-oxide

emission was used as the main environmental impact criteria because it’s the main cause

of global warming and it increases in relation with the energy consumption [42]. The

result showed that carbon-di-oxide emission was largest during the production stage

followed by the use stage. The carbon-di-oxide emission in assembly and transport stage

was minimal as compared to the production and use stage. Printed wiring boards were the

main constituent responsible for the carbon-di-oxide emission in the production stage at

about 50%. Another observation by the authors was although the metal parts constitute

about 50% of the weight; their share in the carbon-di-oxide emission was only 9% [42].

Pitts, G., Mizuki, C. of Microelectronics and Computer Technology Corporation

(MCC) [44] have stated the importance of the effective disposition of electronic products

5

in their research paper. They have mentioned the current recycling practices in the United

States. According to them there is dual infrastructure for the management of the solid

waste one deal with commercial waste and the other deals with consumer waste. Reasons

for ineffective disposition of the electronic products are also stated. In the second part of

the paper initiatives taken by different stats in the United States for successful disposition

of the electronic product are quoted and summary of European Recycling models is

given.

Sony had undertaken a disassembly evaluation workshop for the disassembly of

the TV sets [46]. During this workshop every step was clearly clarified and videotaped

for further documentation and interpretation. Cost of the disassembly was also calculated.

From the result of this disassembly evaluation of TV sets, general Disassembly

Evaluation was general disassembly methodology was developed and further specific

methodology was developed for specific products. Kuhn, M., and Hesselbach, J. have

developed assessment tool for recycling oriented design (AsTROid) [48]. The authors

have mentioned about what should be the optimal disassembly of product. The

disassembly time is divided into four categories which are handling time, separation time,

transition time and taking off time. The accumulated time for disassembly each

component can be calculated using the software developed by the authors. The software

also calculates environmental score of the product from design and recycling point of

view.

6

2.2 Design for Environment

Apple computers have done the analysis of their Power Mac G4 computer to

identify the environmental impact of the computer [9]. They have reviewed different

feature of the product so as to understand the environmental impact of that feature. To

reduce the environmental impact they have reduced the energy required for the operation

of the computer by integrating different design features such as platform integration,

silent sleep mode etc. because energy consumption during the use of the computer is the

main contributor to the environmental impact of the computer. Further they have reduced

the number of components required for logic board design, this has resulted in time,

resource and cost saving. They have stopped using flame retardants in their products

because it is environmentally hazardous when recycling or incineration is done. Stevels,

A., and Boks, C., [20] have made and attempt to do assessment of uncertainties which

arise at the end of life of electronic product and to prioritize them from design for

environment point of view. Their approach was to describe the all the factors which have

an effect on the end of life scenario of the product, finding out about the different factors

which change all the time such as changing material prices, changing legislation,

changing technologies etc., to compare the impact of these factor with each other,

weighting the different factor and prioritizing these factors. After this priorities can be

defined. From their research they have concluded that precious metal prices and their

concentration have the major effect on the end of life revenue generated by electronic

product.

7

Stevels, A., has studies the ISO standard 14001, ISO Technical report (draft)

14062, the European Environment Initiative and Eco labels to compare them for

effectiveness in environmental concern. He has reached to the conclusion that none of

them is gives completely satisfactory solution for environmental concerns. But if the best

elements of all are taken it provides a very good basis for further environmental standards

creation [28]. Segerberg, T., Bergendhal, C.G., [32] have mentioned the need for

development of the tool which can be used for environmentally conscious procurement.

And the authors have given the example of joint effort between the Swedish Institute of

Production Engineering Control and sixteen internationally operating manufacturers to

develop such kind of tool.

2.3 Electronic Product Evaluation using Analytical Tool

Biancaniello, J., Headley, L., Kingsbury, T., and Fisher, M. have published paper

regarding the plastics used in the electronics products [11]. The research paper gives the

information about the plastics which is recovered from consumer electronics. The

conclusions of this paper were plastic comprises 17% of end of life electronic products,

there are 12 types of plastics used electronic products, recycling equipment can detect

accurately more than 20 types of plastics, recycled plastics have favorable value to

recovery cost ratio [11], this research has shown the plastics used in electronics can be

recycled at the end of their useful life. American Plastic council (APC) has conducted

study of plastics which are being used in the Information Technology (IT) industry [31].

The main objective of the study were to find out about the Original Equipment

8

Manufacturer’s Recycling strategies, to identify the high volume, high value plastic used

in IT, characterize the recycling capabilities throughout the IT recycling supply chain

and finding out about the potential application of the recycled IT plastic. The study’s

primary focus was on the highly engineered resins. Recycling program was created by

Pitney Bowes Corporation and ‘wTe’ Corporation for recycling of the plastic in

Bridgeport, CT [33]. The research paper describes the steps taken by the company for

recycling the plastic which are procurement of the products, separating them according to

their model, disassembly procedure utilieszed and recycling process.

Wantanabe, H., Noguchi, t., kuromiya, M., Inagaki, Y. [34] of Sony Corporation

have developed a method which uses virgin and waste polystyrene to clean the waste

water. The method involves transformation of polystyrene into water soluble polymers

and then this water soluble polystyrene is used for waste water treatment. Tomita, H.,

Wantanbe, H., Ooki, H., Ichumira, M., Komine, T., of Sony Corporation have developed

method for recycling of the optical disk [41]. By using this method, the different layers of

optical disk (CD/CD-ROM) which are polycarbonate (PC) substrate, aluminum reflection

layer, protecting layer and label can be separated. The recovered polycarbonate substrate

can be used as recycled PC resin for other application. And recovered PC substrate can

again be used in the formation of new CDs. Busselle, L.D., Allred, R.E., of Adherent

Technologies, Inc. have described a recycling process which is being used at their plant

[35]. It is a low temperature catalytic process which can be integrated into continuous

recycling. For the experimental analysis of the system was done by feeding the system

with computers, computer cases, keyboard etc.

9

Langerak, E., [36] has discussed whether shredding of electronic component is

better for recycling or first disassembling it and then shredding it. The author has given

the example of the TV housing and computer keyboard for this purpose. And according

to the author it’s beneficial to shred the TV housing and then separates the materials. In

case of keyboard using automated disassembly machine to separate the components of

keyboards and then shredding it results in higher quality of material but economically it’s

not feasible. Study was done by Raucent, B., Delchambre, A., Lit, P., and Eglise. T., [37],

to propose viable recycling solution for the end of life electronic equipments. They have

considered the three scenarios, current state of Europe, European Commission work and

current situation in Brussels. They have visited the various recycling facilities in the

Europe to determine what kind of infrastructure would be useful for Brussels scenario.

After that simulation was done to determine the total cost and environmental benefits and

facility concept was developed. Biddle, M. B., Arola, D. P., [38] have compared the

business models used in the plastic recycling industry. The difference between two

business models is that first one uses manual plastic sorting and the other uses automated

plastic sorting. The advantages of manual sorting were mentioned as low capital

investment, no skilled workers, simple sorting method etc. and that of automated sorting

were higher volumes, enhanced sorting capacity etc. the authors have also observed that

properties of the plastic is the main issue regardless of whatever method is used.

Pitts. O. D., Kirby, J. R., Ching, S., of IBM Corporation have mentioned the

initiatives taken by IBM to recycle the PVC and PC/ABS material. They have selected

this material because it constitutes a large percentage of the IBM plastic usage [43].

10

Theo, L. [47] of Boliden Ltd. has given information about the recycling operations

performed by Ronnskar smelter, Bergsoe smelter and Norzinc smelter which are the

subsidiaries of the Boliden Ltd. The author has given information about the how much

material is recycled, what kind of material is recycled, what are the emissions to the air.

The author has also mentioned the general composition of printed circuit board.

2.4

Company Initiative

Ricoh Electronic Inc. has the policy of not sending any waste to the landfill [10].

For this they have established the system which creates employee awareness regarding

the environmental consciousness. They have identified the waste generation sources.

Their strategy for sending zero percent waste to landfill was the use of the ‘5Rs’ method

and green purchasing. ‘5Rs’ method consists of refusing to buy anything which would

become waste, return the material to suppliers, reducing the waste at source, reusing

anything which is possible and recycling waste which is left after practicing the first four

‘Rs’.

Brady, T. A., and O’Connell, S. describe the steps taken by the Intel Corporation

to meet with the environmental regulations and laws regarding the material content in

electronic products [13]. They have followed the material declaration guide developed by

‘Electronic Industries Alliance’ (EIA). This guide divides the material used in electronic

products into three categories which are a) controlled material (legally prohibited or

banned) b) restricted (prohibited in certain application) and c) material of interest. For

first and second category Intel has developed ‘Environmental product content

11

specification for suppliers and outsourced manufactures’ to define environmental

requirements for Intel Corporation [13]. For the material of interest category Intel does

the material test by inductively coupled plasma atomic emission spectroscopy per

USEPA method 200.7. [13]. after these tests are done material declaration datasheet are

developed. Deagher, A., of Hewlett- Packard (HP) company has written about the HP’s

take back program of electronic products in her research paper [15]. She has described

how HP’s take back program works, what are the different aspects of it. HP has different

take back programs developed for different products such as Electronic Hardware

program, Laser Jet program and Inkjet program. The author has mentioned the difficulties

in successful operation of HP’s take back program due to different laws in different

countries, even in United States; different states have different laws, controlling cost and

insufficient customer participation. To reduce the environmental impact of their computer

product ‘Digital Equipment Corporation’ has developed a product stewardship group at

each of their facilities. One product integration manager is selected from this group to

raise the awareness of product stewardship with the key function within the business such

as marketing, engineering, manufacturing, logistic etc. [16] the following approach was

taken by ‘Digital Equipment Corporation for successful achievement of product

stewardship, getting support of the management, selecting the product, determining the

product requirement, support activities for the design teams to meet this requirement and

making sure that these product requirements are met.

At International Machines Corporation (IBM) systematic approach has been

adopted to collect and document environmental information about products [17]. For

12

collection of environment information following aspects considered are product design,

regulatory requirements regarding that product, shipping and transportation, marketing

and customer support and product disassembly operation. After this information is

collected it’s documented as ‘Product Environmental Profile’ (PEP). This information is

collected by the IBM product manager and product development team. This PEP consists

of product identification and description, product energy information, product

composition information, product consumable and packaging information, environmental

design, attributes information and standard compliance, emission information. Yehle. L.,

Nobs, C., Keene, R., Grencheus, E. [57] of IBM corporation have described the working

principles of its asset recovery center. Initially the asset recovery center was designed to

dismantle the products and proper environmental disposal of the product. And later parts

recovery operations were incorporated in the asset recovery center. The authors have

also mentioned what changes occurred in the asset recovery center through the years.

Vanderstraeten, J.C., Orolandella, F., Lueckefett, H.J., Korpalaski, T., and

Dirksen, T. [23] have said in their paper that manufacture’s self declaration about the

environmental aspect of the products is better than the currently available eco labels.

They have mentioned the problems and issues with the eco labels such as large number of

eco labels, diversity of criteria to be met for each eco label, unscientific criteria, number

of test procedures to be done etc. Authors say that self declaration concept is better than

eco labels in the following areas such as simple reporting of environmental parameters,

standard test protocols, in house test reduces the delay, standard test and reporting etc.

authors have given example of the Hewlett- Packard’s about what principles they have

13

followed for the self declaration of environmental parameters for their products. At

Panasonic corporation environmental control policy was created in 1991 [25] so as to

make Panasonic products environmentally friendly. Further in 1997 Corporate

Environmental Affairs Division was established. The main objective of this Corporate

Environmental Affairs Division was to do the product assessment, develop energy

conservation technologies so that product will be energy efficient, constrain the variation

of the plastics used in the electronic products so that recycling process is not complicated

and eliminate the presence of toxic substance in the products. Staggs, D., Turk, L.,

Minter, J., Wanielista, M. [30] of Dell Computer Corporation have discussed the Dell’s

Business model and have explained what were the driving factors behind acquisition of

TCO 95 eco label and Blue Angel certification. At IBM corporation Systematic

Environmental Assessment (SEA) methodology is used to develop and report the

environmental evaluation of the product [40]. The SEA is used when decisions regarding

the material, processes and technologies need to be taken. The SEA methodology consists

of defining the goal of assessment , technological parameters needed to be studied are

defined, life cycle analysis of different designs is done by taking into consideration

appropriate environmental aspects, weighting factors are assigned and finally ranking is

determined based on the analysis.

AT & T Company has its own program for the end of life management of the

personal computers [45]. Life management program at AT & T Company deals with the

issues, such as procurement of the computer, installation of the computers, fixing the

computers and end of life disposal/recycling of the computer.

14

2.5 Eco Indicator Methods

In 2001 attempt has been made by Luo, Wirojanagud and Caudill [1] to compare

the four major environmental performance metrics and how those metrics can be applied

to electronic products. The authors have compared Eco-Indicator 95, Eco-indicator 99,

Ecological Footprint and EcoPro methodologies. The methodologies of these four

environmental performance metrics are described. The differences between the weighting

techniques of these methodologies are described. Environmental performance of three

products is calculated using above four mentioned methodologies. The products were two

laptops from different manufacturers having same material content, two telephones from

different manufacturer having different energy usage and economic value and the third

product was a subassembly of a part where one part was made up from aluminum and the

second part was made from plastic.

Stevels, A., Boks, C., and Huisman, J., [2] suggest that, their approach for

calculating

recycling

quotes

which

is

‘Environmentally

Weighted

Recycling

Quotes’(EWRQ) is more accurate than the current weight based material recycling

efficiency. The paper discusses about how to calculate the actual weighted environment

impact. The authors say that the actual weighted environmental impact is the sum of

weighted environmental impact of end of life treatment, weighted environmental impact

of substitution of material, weighted environmental impact of landfill and weighted

environmental impact of incineration. The environmental impact calculated by this way

gives the total environmental impact of end of life stage of a product. Then minimum

environmental impact and maximum environmental impact of the product is calculated.

15

And normalizing these values the EWRQ is calculated. The authors have calculated the

EWRQ of cellular phone for showing how the methodology works. Stevels, A., Huisman,

J., and Middendorf, A. [3] have tried to compare the results of EWRQ methodology by

using different environmental impact assessment tools such as Eco-Indicator 95, Ecoindicator 99 and Toxic Potential Indicator. And further these results are compared with

the traditional weight based recycling quotes. Environmental assessment of nine different

products such as TV, VCR, Walkman, Fax etc was done by using those two

methodologies. They have observed that products which have higher percentage of metal

and Glass have higher material recycle efficiency. The differences between the two

approaches are shown by the example of the electronic product ‘Fax Machine’.

In 2001 Persson, J. [4] has written a paper about the need of the eco-indicators in

the product development stage. The author has explained the concept how eco-indicators

can be developed for different needs and hoe the scales can be selected. The paper also

describes the criteria set by ‘Organization for economic Co-operation and Development’

for generation of eco-indicators. Environmental Impact assessment of a component at

Truck Manufacturing Company is carried out for the development of Eco-Indicators for

the specific part and later these Eco-Indicators will be used for the components which

belong to the same part family.

Analysis of desktop monitor, control unit and keyboard was done by Frey, S. D.,

Harrison, D. J., and Billet, E. H. [5] using Ecological Footprint methodology. The main

factors in the analysis were land space resource consumption by PC system, land space of

resource consumption by life cycle, land space of energy form materials by life cycle and

16

land space of energy consumption from processes by life cycle. They have observed that

the use phase is the main contributor to the energy consumption. Their research has

concluded that the desktop monitor has the highest ecological footprint followed by

control unit in second place and the keyboard is in third place.

2.6 Government Policies

Lueckefett, H. J., Orlandella, F., Holbrook, L. [6] have discussed different

environmental legislations proposed by the European countries in their research paper.

European Union makes the legislation to achieve environmental goals but it depends on

each individual country how to achieve those goals. The regulations are made so that the

environmentally hazardous materials are not used in the electronic products. The authors

have provided the list of the specific materials which are prohibited for use in products in

specific countries. They have also mentioned the example of Hewlett-Packard Company

about how that company makes its product environmentally safe according to various

regulations and laws.

Stevels, A., [7] has discussed the directive on Waste of Electrical and Electronic

Equipment (WEEE) for assessing whether it is eco-efficient or not. He has mentioned the

objectives of the take back system for electronic products. He has described how different

categories are defined in the WEEE directive. In WEEE no clear definition of the

required recovery and recycling quotes are given [7]. The author says that recycling

targets should be set according to the environmental impact of the material and not

according the weight of the material, which is the case in the WEEE directive. He has

17

proved this by comparing recycling of gold and palladium which are precious metals with

the recycling of plastics. Dowdell, D.C., Noel, R., Adda, S., Laurent, D., Glazebrrok, B

and Kirkpatrick, N.[8] have compared the current disposal methods in the United

Kingdom, 100% landfill of all the electronic product and end of life results by proposed

WEEE directive. They have compared eight different electronic products such as

refrigerator, TV, personal computer, washing machine, telephone etc. they studied life

cycle analysis of the electronic products after it becomes waste. Cost benefit analysis for

three different methodologies was also done. It’s been concluded that current United

Kingdom processing and disposal routes have more environmental impact than the

proposed WEEE directive. For the some products revenue generated is higher if WEEE

guidelines are followed for disposal and for some products revenue generated is less as

compared to the current United Kingdom processing and disposal routes.

Raymond, M., [12] has described the electronic recycling laws regarding the take

back policy in her research paper. She has observed that every country has different laws.

According to the WEEE directive, the European Union is making laws which will require

all the electronics to be recycled at the end of their useful life and restricts certain

hazardous substances in electronics. The author has given the example of the different

European countries and the practice followed in those countries regarding the take back

policy. For example in Germany and Austria manufacturers are directly responsible for

collection of used packaging. Norway government charges manufacturers to pay the fees

to two collection organizations which collect the electronic product at the end of their

useful life and the fees is collected at the time of the import of electronic product in the

18

country. Hieronymi, K., of Hewlett-Packard Company has described the Waste of

Electronics and Electrical Equipment legislation from its major elements, their

implementation and finance point of view [18].his research paper describes how the

WEEE legislation can be implemented and what steps should be taken for successful

finance management while implementing the WEEE legislation. In 2003 attempt has

been made by Stevels, A., and Huisman, J. [19] to calculate the financial advantages of

take back program and recycling of electronic products. They have compared different

end of life options for products from environmental gain and monetary point of view.

‘REMPRODUSE’ is a project which started in Europe in 1997. The main

objective of this project was closing the recycling loop for copper through redesigning of

the copper rich electronic products such as electric motor. This project was started due to

realization that in motors steel and cooper are attached hard to each other and these two

metals are not compatible with each other and they should be totally separated [24]. The

objective of this project is to make copper rich electric motors and disassembly oriented

recycling system adapt each other. In 1999 Jordan R. C., Korfmacher, H.A., and Suoss,

B. [26] have discussed the laws that exits in Germany regarding the packaging directives

of electronic product. Further they have mentioned the discussed the principles of

directive for waste from electrical and electronic equipment (WEEE). They also

mentioned the difficulties in recycling of the plastics prior to 1998 because of the labels

which describe them. These labels are not recycling compatible with the plastics. This

problem was solved when ‘3M’, a major label manufacturer developed labels which are

fully recycling compatible with the plastics. Mausi, K., Nilsson, J., Boks, C. [27] have

19

compared the end of life scenarios of electronic products and legislation regarding

electronic products in Japan, Europe and United states. According to them Europe is

leading in environmentally conscious processing end of life electronic products. Japan is

rapidly following the suit of European countries to develop laws and regulation regarding

the end of life of electronic products. And United States is taking wait and see approach.

Johnson, E.P., of Atlantic Consulting [29] has defined the concept of Eco-labels.

Further he has discussed European Union eco-label stating its need, the criteria which

should be used for its development. According to the author eco label can be developed

in four steps which are feasibility study which includes determining eco label efficiency,

determining the capability of eco-label in making difference in ecology etc. the next step

is to do market research study to determine the product group, product manufacturer,

what is the environmental performance of different products and what difference can ecolabel make in these products. The next step is to do the life cycle analysis of these

products. After this criteria for eco-labels are proposed. The author has given the example

of the personal computer and explained how eco-labels were developed for the personal

computer. Wendschlag, H., Urbach, H.P., Hermann, F. [39] have compared the different

eco labels from ISO point of view. They have categorized different eco labels into type 1,

type 2 and type 3 based on the ISO characterization. The authors have also described the

different issues involved in these three types of eco label. Conclusion of this comparison

was most of the eco labels have the same criteria but there are too many differences also.

IT Industries stand about these eco label is mentioned.

20

Information about the ‘Directive on Waste Electrical and Electronic Equipment’

(WEEE) and ‘Directive on the Restriction of Use of Certain Hazardous Substances’

(ROHS) is published by ‘Envirowise’ which is a government sponsored program in

United Kingdom [54]. In the publication list of the electronic equipments is given, their

manufacturers will be covered under these regulations. A proposed limit of hazardous

substances in the electronic equipment is mentioned and all the electronic equipment

should comply with this limit after July 2006. How functioning of ‘WEEE’ will

financially sustain is also explained. What are the responsibilities of Electronic

equipment manufacturer are elucidated. Official journal of European Union gives the

information about the ‘directive of waste electrical and electronic equipment’ (WEEE)

[55]. The article gives information about the objective, scope of the WEEE. Definition of

WEEE is elucidated. Different legislation regarding to product design, collection of the

electronic equipment at end of their life, how they should be treated, how much

percentage material should be recovered from equipment in different categories are

explained. Details about the financing aspect of the WEEE are also elaborated. Electronic

equipment manufacturer responsibilities regarding their end of life are described.

Electronic equipment product categories are defined such as large household appliances,

small household appliances, IT and telecommunication equipment, consumer equipment

etc. All the equipments are categorized into ten categories. Information about directive on

restriction of the use of certain hazardous material in electrical and electronic equipment

is published by official journal of European Union [56]. List of materials is provided

which should not be used by the electronic manufacturers in their equipment after 1st July

21

2006. Also concentration values for hazardous material which would be allowed are

published. Steveles, L. N., and Meinders, H.C., [21] of Philips Electronics have described

the different policies of ISO 14001 which are being followed at the company for

successful implementation of eco design in company’s product. The authors have

mentioned the sections of the ISO 14001 and how they are being implemented at the

Philips Electronics.

2.7 Environmental Protection Agency

Useful information about the electronic reuse and recycling can be found in

Environmental Protection agencies technical assistance periodical called as ‘waste wise

update’. The electronic reuse and recycling periodical is published in October 2000 and

the information is given about information required before donating the used electronics,

recommendation for improving future electronic acquisition, methods for managing used

electronics, what are the opportunities for the manufacturers to minimize the electronic

waste and government policies regarding the end of life of electronic products [49].

Information about the regulation regarding the CRT disposal is given such as household

monitors, monitors which are donated for continuous use are not considered as hazardous

waste [49]. End of life management facility does not come under the federal regulation if

the amount electronic waste managed by that facility does not exceed 100 kilogram per

month and if this 100 kilogram per month limit is exceeded, federal laws are applicable to

that facility [49]. Guidelines for purchaser of electronic equipment are also given so that

in the future recycling of this electronic equipment is easy. ‘Aspen Skiing Company’ and

22

‘Public Service Enterprise Group’ have donated their old computers to schools and other

educational facilities; this can be the one way of managing used electronics. Further

information is also given about determining when to donate the old electronic equipment

and what precaution should be taken before donating them. The example of United State

Postal Service’s (USPS) end of life management of electronic products is given. USPS

sends its electronic equipment to the recycler and if the recycler sells it, USPS shares the

revenue with the recycler. How computers are recycled is also explained in the report.

Strategies for manufacturers about how to minimize the electronic waste are also

explained which include standardization of the material used in the electronic product,

using recycled material, using refurbished parts, remanufacturing of the used electronic

product and taking care that material used in the electronic product is recyclable [49].

Actions taken by the government to manage the electronic waste are also elaborated in

the report.

EPA has published periodical which deals with the extended product

responsibility. Design for environment, supply chain and industry partnership, leasing

and take back are the main topics discussed in the periodical. DFE example is illustrated

by Allergen pharmaceutical company which has initiated different strategies in their

company so as products are environmentally friendly. Allergen identified the waste

sources and the options were identified to reduce them or eliminate them [50]. They have

started using environmentally friendly material in their products instead of using

hazardous materials etc. supply chain and industrial partnership is illustrated by the

example of Public Service Electric and Gas Company. They have developed strategy by

23

which they reduced the number of suppliers from 270 to just 9 and further they have

implemented take back policy with the suppliers. Leasing contract is made between the

Dell Computer Corporation and Monsanto. According to this agreement Monsanto leases

high end computer from Dell and returns them after 24-36 months. Dell re-leases this

computer to the companies which don’t need high end computers. Rechargeable Battery

Recycling Corporation (RBRC) is formed by Matsushita Electric Corporation, Sanyo

Energy Corporation, Eveready, SAFT America and Varta batteries Inc. for collecting and

recycling used Nickel-Cadmium batteries. Example of XEROX Corporation is also given

to illustrate the implementation of Take Back policy.

Environmental management system (EMS) is a set of policies and procedure that

defines how an organization evaluates, manages and tracks its environmental impact [51].

EMS is nothing but the Plan-Do-Check-Act model. In the plan phase organization

discovers it’s all environmental aspects. Then critical aspects are recognized and

environmental goals are set for these aspects. Next these goals are achieved through

employee education and operational control. Organizations performance is evaluated in

the next phase to check whether the goals are achieved or not. And if the goals are not

achieved the corrective action is taken. Federal government has given orders to its all

facilities to implement EMS by the end of 2005 [51]. Facts about the recycled products

are explained in closing the loop periodical by EPA [53]. Examples of different

companies and government offices are given who have started buying the recycled

products [52]. Cradle to cradle concept is explained by the EPA in their technical

assistance periodical [53].

24

CHAPTER III

METHODOLOGY

The main aim of this thesis is to carry out disassembly analysis, material

assessment and to find out about the environmental impact caused by the components

used in the computer drives. The products analyzed were for this study were CD-ROM

drive of Server, Floppy Disk Drive of Server, Hard Disk Drive of Desktop and Floppy

Disk Drive of Laptop. The following steps were taken to do the analysis of the product.

For disassembly analysis disassembly sequence was determined, disassembly steps are

elaborated in disassembly procedure, disassembly tree is generated. After disassembling

the computer drives material assessment was done. And based on the weight and material

of the components Eco-Indicator score is calculated. The approach taken for this study is

explained in detail as follows

3.1 Description of the Product

The information regarding the product such as Manufacturer of the product,

Model number, Serial number, Total weight of product and Product specification was

recorded.

3.2 Disassembly Analysis

In this section methodology followed for the disassembly analysis is explained

25

3.2.1

Disassembly Sequence

Disassembly sequence was generated based on the actual disassembly of the

product. Disassembly sequence was generated because for recycling of the product

components disassembly of the product is the first step and of the identification of the

components used in the products to determine their material and weight. Different

disassembly sequences were considered and the best possible disassembly sequence was

generated which would facilitate disassembly of the product in minimum possible time.

Disassembly procedure is tabulated in a table. The table consists of operation number;

description of the part disassembled, disassembly procedure followed, time taken for the

disassembly operation of that part and brief description of procedure such as how many

screws were removed and whether any other action was taken for the disassembly of that

part such as pulling the sub frame from the main frame of the component. The time for

removing the screws or other direct operation such as pulling the cables between the two

components, for e.g. as disconnecting cable between main circuit board and motor, was

considered as the time for disassembly. The time for set up of the experiment or changing

of the tools between two operations was not considered to contribute to the disassembly

sequence. Disassembly of the product was done until no further disassembly is possible

due to unavailability or resources.

3.2.2

Disassembly Procedure

Step by step explanation of the disassembly of the product is described in the

disassembly procedure. This is essentially same as the disassembly sequence; the only

26

difference here is after every step of the disassembly, picture is shown so that it would

facilitate easier understanding for the person reading it.

3.2.3

Disassembly Tree

Disassembly procedure was also explained in terms of disassembly tree so that one

could understand different levels of disassembly. Disassembly tree is generated based on

the disassembly steps followed for this experiment. Disassembly tree would also facilitate

understanding of what steps required to be taken to reach to a specific component of the

product.

3.2.4

Comments on Disassembly

After studying the disassembly sequence remarks on the disassembly are made in

this section. Discussion regarding the structure of the component is made. Why specific

disassembly steps are taken is discussed. What are the difficulties involved is also

discussed.

3.2.5

Component Relationship

Component relationship was established according the mechanical relationship

between the products and electrical connection of the product. Such as whether two

components are connected mechanically by screws, snap fit or by electrical connection

by means of cable. This relationship is tabulated in the table. The table consists of part

27

name, the identified material of that part and to which other part it is connected either

mechanically or electrically.

3.2.6

Disassembly Time and Cost

Disassembly time was recorded. Only the time required for direct disassembly

operation such as removal of screw, removing snap fit or disconnecting cables was

recorded. The time for change of tools or disassembly set up was not considered as the

disassembly time. For calculating the cost of disassembly only cost of labor is

considered. Wage rate of $10/hr is considered in the calculation of the disassembly cost.

Other direct or indirect costs are not considered for the calculation of the disassembly

cost.

Disassembly cost for component in cents = (time for disassembly of that

component * 5/18)

The factor 5/18 = 1000 cents/ 3600 sec. which is equal to $ 10/ hr.

The disassembly time was recorded in seconds so time for disassembly was

multiplied by the factor 5/18 which would give the cost in cent for the disassembly time

considered.

3.3 Material Assessment and Component Weight

Environmental performance of the product is determined by the material used in the

product. Environmental impact of a component is increased if the product contains

hazardous materials. The main component which contains the hazardous material is PCB.

28

So PCBs of Hard Disk Drive, CD-ROM drive and Floppy Drive were sent to the

‘Noranda Recycling Inc.’ for material analysis. The results of that test were used to

determine the material of the PCBs. The plastic material used in the Hard Drive, Floppy

Drive and CD-ROM drive was determined by the label on the plastic components present

in those products. And the data regarding the metals was taken from the literature. The

weight of the every component is recorded

The test result from ‘Noranda Recycling Inc.’ for the material analysis of PCB did

not detect the presence of some materials such as Gold, Aluminum, Epoxy, Glass,

Ceramics etc. but from the information available in literature it is known that these

materials are also present in the PCB. So weight of this material present in the PCB is

approximated by the information available in the literature.

3.4 Environmental Impact Assessment

For Environmental Impact assessment Eco-Indicator 99 (EI-99) methodology is

followed. The Eco-Indicator 99 database provides weighted environmental impact scores

for several common materials and their associated processes. EI-99 involves a procedure

where-in the environmental burden of a material or process is weighted based on three

impact categories viz.

− Human health

− Ecosystem quality

− Resources

29

In the default weighting structure 40% weightage is given to human health, 40%

to ecosystem quality and 20% to resource consumption. These values are provided in

terms millipoint per kilogram for materials.

For purpose of analysis in this research just the production phase of material lifecycle was considered. Later for the end-of life scenario, saving in Eco-Indicator due to

recycling is computed using a different hypothesis. If a certain amount of material is

recycled, the environmental impact of reproducing that exact of amount of material is

avoided. So a certain amount of Eco-Indicator saving is associated with the recycling of

any material. This methodology is explained in detail later.

3.4.1

Eco-Indicator Calculation

Once the material analysis of each product is complete, the eco-indicator value for

each enlisted material is found from the EI-99 score database. The weight based ecoindicator for each material is calculated by simply multiplying the material eco-indicator

with the weight of the material in the product as shown below.

Weight Based EI (mPt) = Material EI (mPt/kg) * Weight of Material

Adding up all the weight based EI of all materials in a particular component the

net eco-indicator for that component is calculated.

Net Component Eco-Indicator = Σ (Weight based material EI)

30

3.4.2

Saving in Eco-Indicator due to Recycling of the Product

If the material is recycled the environmental impact of reproduction of same

amount of that material will be avoided. This is due to the fact that recycled material can

be used in products instead of extracting materials from their ore. Environmentally

Weighted Recycling Quotes (EWRQ) methodology established by Ab Stevels [2], gives a

clear outlook of the end-of-life scenarios of a product. This method evaluates the

recyclability score of a product based on various end-of-life scenarios of different

material fractions of a product. The end-of-life routes considered in this research are:

- Substitution by recycling

- Incineration

- Landfill

Recycling EI is calculated by following formula [2]

EI (actual) = ∑ {(EI (end of life treatment) + EI (substitution) + EI (landfill)

+ EI (incineration)}

But the scope of this thesis is only limited to the recycling (substitution) scenario.

Although the environmental impact is avoided by recycling there are some factors to be

considered for computing the avoided environmental impact. One factor is the recovery

rate of the material in a recycling process. The second factor is the grade of the recycled

material which dictates the application of recycled material. Saving in Eco-Indicator due

to recycling is calculated in terms of eco-indicator values for the materials. The recovery

rate and recycled material grade are represented as percentages or fractions. The

calculations are shown below:

31

EI Saving by Recycling = Weight based EI * Recovery Rate * Material Recycle

Grade

Material Recovery rate and Material Recycle Grade data was obtained from the

‘Noranda Recycling Inc.’ for the metals and for the plastics the data for the recovery rate

and recycle grade was taken from the literature.

32

CHAPTER IV

RESULT AND ANALYSIS

4.1 Hard Disk Drive Analysis

4.1.1

Product Description

Hard-Drive

Model:

Western Digital

Model No.:

WD100BB – 75AUA1

Serial No.:

WMA6Z10216664

Total Weight:

575 grams/ 20.235 oz

Model Specification:

IDE Hard Drive 10 GB

4.1.2

Disassembly Sequence

Following table gives the description of the disassembly steps followed for the

disassembly of the Hard Disk Drive. The total disassembly was done in 4 minutes and

twenty-nine seconds. Disassembly procedure gives the detailed explanation of the

disassembly where pictures are also included for the easier understanding.

33