BUCK-BOOST DC-DC CONVERTER with INPUT PROTECTION

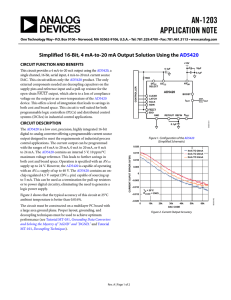

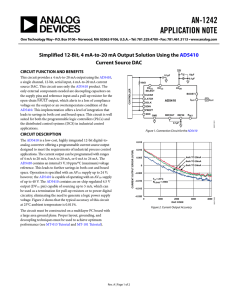

advertisement