User's Guide

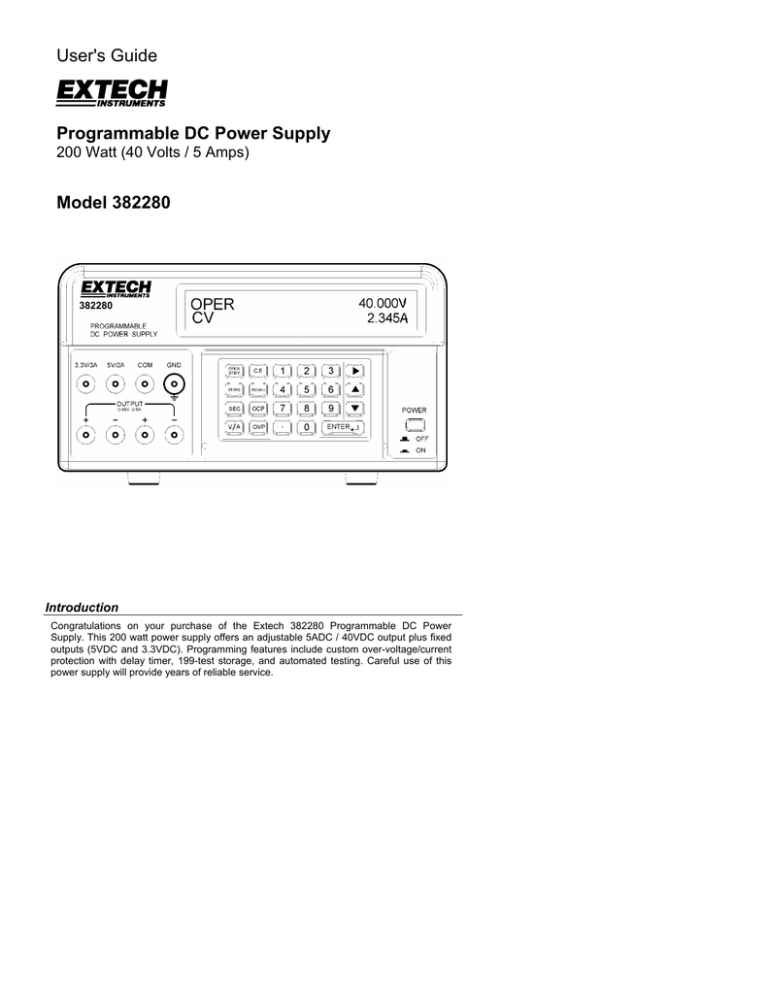

Programmable DC Power Supply

200 Watt (40 Volts / 5 Amps)

Model 382280

382280

Introduction

Congratulations on your purchase of the Extech 382280 Programmable DC Power

Supply. This 200 watt power supply offers an adjustable 5ADC / 40VDC output plus fixed

outputs (5VDC and 3.3VDC). Programming features include custom over-voltage/current

protection with delay timer, 199-test storage, and automated testing. Careful use of this

power supply will provide years of reliable service.

Specifications

Programmed Voltage and Current (after 5-minute warm-up)

Range

0 to 40V

0 to 5A

Voltage V (C.V.)

Current A (C.C.)

Resolution

1mV

1mA

Accuracy

0.05% ± 9mV

0.2% ± 9mA

Voltage and Current Display (Read back)

Range

0.1 to 40V

0.05 to 5A

Voltage V (C.C.)

Current A (C.V.)

Resolution

1mV

1mA

Accuracy

0.1% ± 12mV

0.2% ± 12mA

Display

Backlit Dot Matrix (2-line) Display

Programmable Voltage Output

0.000 to 40.000VDC

Programmable Current Output

0.000 to 5.000ADC

Resolution

1mV; 1mA

Fixed Outputs

5V (2A) and 3.3V (3A)

Memory

199 locations

Accuracy

Adjustable Voltage: 0.05% ±9mV

Adjustable Currrent: 0.2% ±9mA

Fixed 5V: ±0.25V; Fixed 3.3V: ±0.16V

Response Time

< 150 ms

Temperature Coefficient

< 100ppm / C

o

Load Regulation

< 1mV / Amp

Line Regulation

No effect if line voltage is within 90V and 130V for

115V power (200V to 240V for 220V power).

Ripple and Noise

(0 ~ 40V, 0 ~ 5A) < 3mVrms (C.V.) < 3mArms (C.C.)

Open Circuit (OCP) detection

Current > 0.05A

(5V/2A, 3.3V/3A) 10mVrms ~ 20mVrms

C.V. or C.C. detection

Current > 0.05A

Short Circuit Protect

When the 5V or 3.3V output is less than 1V

(shorted), one of the preceding alert symbols will be

shown on the LCD

Power Source

110/220VAC 50/60Hz

Dimensions

12.2 x 9.9 x 5.3” (310 x 250 x 135mm)

Weight

8.4 lbs. (3.8kg)

Safety Symbols

Please read the statement thoroughly to prevent injury or loss of life, and

to prevent damage to this product.

Earth Ground Terminal

2

Version 1.6 7/04

Front Panel Description

1. OPER/STBY: Operation/Standby button. Press to enable/disable the output. When the

supply is in the STANDBY mode the output is 0 volts.

2. RECALL: Press to call up stored output sets or to activate Automatic Test Sequencing.

3. STORE: Press to save the present V/A output set to memory. Use the numeric keys (not

the arrows) to select a storage location from 000 to 199 and then press ENTER.

4. SEC (Seconds): Press to enter time in seconds. Use the ENTER key to confirm entries.

5. V/A: Press to toggle between voltage (V) and current (A) on the display.

6. OCP (Over-Current Protection): Press to enable/disable OCP.

7. OVP (Over Voltage Protection): Press to program the OVP value (defaults to 40V).

8. Numeric keypad and period button.

9. ENTER: Press to confirm entries.

10. ▼ (DOWN Arrow): Press to decrease a programming value.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

▲ (UP Arrow): Press to increase a programming value.

(RIGHT Arrow): Press to move the cursor to a new location in a row.

POWER ON/OFF: Press to turn the supply on or off.

Rubber feet.

Dot matrix display.

GND: Ground terminal (connected to the chassis of the unit).

COM: Common terminal for the 5V and the 3.3V output.

3.3V/3A: Positive terminal for the 3.3V output. If more than 3A is drawn, the output will

be lower than the 3.3V specified.

5V/2A: Positive terminal for the 5V output. If more than 2A is drawn, the output will be

lower than the 5V specified.

Positive Terminal for the 40VDC / 5ADC output. This terminal is physically connected to

terminal 22. Use terminal 21 (not COM) as the negative terminal for best accuracy. Note

that terminal 21, 23, and COM are connected.

Negative terminal for 40VDC / 5ADC (terminal 20) output.

Positive Terminal for the 40VDC / 5ADC output. This terminal is physically connected to

terminal 20. Use terminal 23 (not COM) as the negative terminal for best accuracy.

Negative terminal for 40VDC / 5ADC (terminal 22) output.

CE (Cancel Entry): Press to cancel a programming entry.

3

Version 1.6 7/04

Operation

Preparation for use

1. Place the supply on a flat level surface.

2. Select the input voltage using the switch on

the rear of the supply (see diagram above).

3. Make sure the sides and the back of the unit

are not blocked. Leave at least 2” (5 cm) of

space for good ventilation.

Line Voltage

Selector Switch

Basic Test Setup Diagram

Setting and Outputting Voltage and Current

NOTE: The 3.3V and 5V fixed outputs are always active when power is turned on.

NOTE: The power supply enters the STBY (stand-by) mode when the power is turned on.

The output values, time delay, and OVP are the same as they were before the power

was turned off.

1. Connect the power supply output to the circuit or device under test before pressing the

OPER/STBY button.

2. Check that the displayed voltage and current output settings are as desired.

3. To change the values of voltage or current use the V/A button to move the underline

cursor to first digit of the voltage or current display, enter the value directly from the

numeric keypad and then press ENTER or:

a.

Move the underline cursor to voltage or current with the V/A button,

b.

Use the RIGHT arrow button to select the digit to change,

c.

Use the UP/DOWN arrow buttons to change the digit value

d.

Press the ENTER button to select the value.

4. To clear any programming entries, press the CE button.

5. Press the STBY/OPER button to enable the power supply output.

Note: If the output goes to zero, the current or voltage limit may be set too low.

6. To change the output values during operation, use the RIGHT & UP/DOWN buttons.

7. The user can monitor the output voltage by connecting a DMM as shown above.

Warning: When the unit is placed in STBY mode, the output is 0V; however the

output terminals are still physically connected to the internal circuit.

4

Version 1.6 7/04

Over Voltage Protection (OVP)

Over Voltage Protection (OVP) allows the user to set a maximum permissible output voltage

If the voltage limit is exceeded, the unit will display “OVP” and revert to the STBY mode.

Setting the Over Voltage Protection (OVP) value

1. In the STBY mode, press the OVP key, “?_” appears in the display.

2. Enter a value from the keypad (range of 0.001 to 40V).

3. Press the ENTER key to store the value.

Viewing the Over Voltage Protection (OVP) value

The OVP value can be viewed when the supply is switched from the OPER mode to the

STBY mode. When switched, “OVP” will briefly appear in the upper display line and the

value will briefly appear in the middle of the lower line of the display.

Over Current Protection (OCP)

Over Current Protection (OCP) allows the user to set a maximum permissible current. If the

current limit is exceeded, the unit automatically reverts to the STBY mode.

Setting the Over Current Protection (OCP) value

1. In the STBY mode, press the V/A key to move the underline cursor to the A display.

2. Press the OCP key and enter the value from the keypad (0.001 to 5A)

3. Press the ENTER key to store the value.

Enabling the Over Current Protection (OCP)

Press the OCP button to enable/disable the OCP function. “OCP” will appear in the

display when the function is enabled.

Over Current Protection (OCP) Time Delay

The OCP shutdown can be delayed up to 600 seconds using the SEC function.

1. Press the SEC key. “?” will appear in the display.

2. Enter the value from the keypad (0.01 to 600 seconds) and press the ENTER key.

5

Version 1.6 7/04

Automated Testing

Storing Test Setups

1. Set the Voltage and Current values as desired.

2. Press the SEC button and set the time in seconds. This time will be associated with the

step if the automatic step output function is selected.

3. Press the STORE button to save the values. “STRxxx?” will appear in the display

(where “xxx” (0 to 199) will be the memory location).

4. Press ENTER to store the value in the displayed location or enter a new location

number from the keypad and press ENTER. If a three digit number is entered, pressing

ENTER is not necessary.

Recalling Test Setups

1. Press the RECALL button to view the setup in a memory location. “RCLxxx” and the

stored values will appear in the display (where “xxx” (0 tp 199) will be the memory

location).

2. To view the setup in any other location, enter the setup number and press ENTER. If a

three digit number is entered, pressing ENTER is not necessary.

3. Press RECALL to exit the display.

Automatic Test Sequencing (ATS)

In ATS mode, the unit automatically cycles through a series of stored test setups. The first

and last steps are programmable and the sequence will include all steps between the first

and last steps. Each test setup memory location represents one step. The duration the step

is programmable from 1 to 60 seconds and is programmed when the steps are stored.

Note: Initial setup and sequencing should be performed in the STBY mode to verify proper

operation without an active output.

Setup and Operation of Automatic Test Sequencing (ATS)

1. To set the LAST and FIRST step of the sequence:

a.

Press the RECALL button.

b.

Use the numeric keypad to enter the three digit test setup location number for the

last step (RCL018, for example) and press ENTER.

c.

Use the numeric keypad to enter the three digit test setup location number for the

first step (RCL001, for example) and press ENTER.

d.

Press RECALL

2. The time duration for each step is stored with each step in the storing process.

3. To begin the test sequencing, press and hold the RECALL until the beeper sounds and

the stair-step icon appears. The sequencing will automatically begin a single cycle

through the programmed steps.

4. Observe the output for proper operation.

5. Press the OPER/STBY key to activate the output

6. Press the OPER/STBY to return to the standby mode or press CE to exit the sequencing

mode

Note: The ATS session will be terminated if any command is received via the RS-232c

interface.

Note: For continuous cycling, hold the RECALL button while turning power on.

6

Version 1.6 7/04

RS-232 PC Communications Interface

RS-232 data format

Baud rate

9600

Parity

none

Data bits

8

Stop bits

1

Flow control

none

RS-232 Connection

Connect the supplied communications cable to the rear of the

power supply and to the communications port of the PC.

3

5

9

1

7

Power Supply

PC

Pin 2 ------------------------------ Pin 2 RX

Pin 3 ------------------------------ Pin 3 TX

Pin 4 ------------------------------ Pin 4 DTR

Pin 5 ------------------------------ Pin 5 GND

RS-232 Commands

The command format is as follows: Command Parameter <Carriage Return (cr)>

For example: V 20.5 (sets output to 20.5VDC)

An ASCII code for <Carriage Return> must be sent together with the command or

commands. Commands will not be processed until a <Carriage Return> is received. Note

that the unit can process up to 50 characters. If more than 50 characters are received, the

unit will clear the entire command buffer.

Summary of Commands

STBY <cr>

OPER <cr>

V xx.xxx <cr>

A x.xxx <cr>

SEC xxx.xx <cr>

OVP xx.xxx <cr>

OCP 0 <cr>

OCP 1 <cr>

STORE xxx <cr>

RECALL xxx <cr>

STEP <cr>

? <cr>

V? <cr>

A? <cr>

OCP? <cr>

OVP? <cr>

SEC? <cr>

STATUS? <cr>

(place the unit in standby mode)

(place the unit in operating mode)

(set the voltage output)

(set the current output)

(enter time in seconds)

(enter desired voltage value for over-voltage protection)

(disable the over-current protection)

(enable the over-current protection)

(store the present output values to memory location xxx)

(recall an output setup from memory location xxx)

(enable the ATS Auto Test Sequencing function)

(retrieve all data)

(retrieve the voltage value)

(retrieve the current value)

(retrieve the status of OCP)

(retrieve the voltage value for OVP)

(retrieve the time value in seconds)

(retrieve the STBY/OPER, OCP, OVP, & 5V/3.3V fixed output status)

Note: All commands are case insensitive.

7

Version 1.6 7/04

Example of an RS-232C Program

V 20.5 <cr>:

program 20.5V

A 1.25 <cr>:

program 1.25A

V 30 A 2 SEC 20 <cr>:

program 30V, 2A, for 20 seconds

OVP 35 <cr>:

set 35V for the over voltage protection

SEC 60 <cr>:

enter 60 seconds

OCP 0 <cr>:

disable OCP (Open circuit protection)

OCP 1 <cr>:

enable OCP

STORE 120 <cr>:

store current V/A values in memory location 120.

RECALL 100 <cr>:

recall V and A values stored in memory location 100.

RECALL 110 <cr>:

recall V and A values stored in memory location 110.

Step <cr>:

enable ATS function. Starting step is 100 (recalled first in the

previous statement) and the ending step is 110 (recalled after

step 100).

? <cr> (Inquire all data)

V 40.000 40.000 CV

A 01.000 00.999 CV

OCP 10.00 ENABLE

OVP 40.000

5V OK 3.3V OK

OPER CV

V? <cr> (obtain the voltage value)

V 40.000 40.000 CV

A? <cr> (obtain the value of current)

A 01.000 00.999 CV

Note: The first set of data following the character V or A is the programmed value, while the

second set of data is the read back A/D value. The third set of data is the status (CV, CC) of

the unit. If the third set of data shows 0V, the unit is placed in the STBY mode. The unit

sends out a <new line> and <carriage return> after each line of data.

8

Version 1.6 7/04

TM

Using Windows

Terminal or HyperTerminal program for PC Communication

The Terminal or the HyperTerminal program is included in all Windows

Typically it is located using the following path:

TM

operating systems.

START Menu > Programs > Accessories > Communications > Terminal or HyperTerminal

When in the Terminal or HyperTerminal program, go to PROPERTIES and configure as

follows:

1. In the CONNECT TO field, select COM1 or COM2 (depending on which port is being

used).

2. In the CONFIGURATION section, select the following data format: Baud rate 9600, no

parity, 8 data bits, 1 stop bit, and no flow control.

3. In the ASCII SETUP section, click on “echo typed characters” and “Send line ends with

line feeds”.

After Terminal or HyperTerminal is setup, type in the commands as described in the

previous examples.

9

Version 1.6 7/04

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty

applies to sensors and cables). If it should become necessary to return the instrument for

service during or beyond the warranty period, contact the Customer Service Department at

(781) 890-7440 ext. 210 for authorization or visit our website www.extech.com for contact

information. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and

proper packaging to prevent damage in transit. This warranty does not apply to defects

resulting from action of the user such as misuse, improper wiring, operation outside of

specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific

purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set

forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also

provides NIST certification for most products. Call the Customer Service Department for

information on calibration services available for this product. Extech recommends that

annual calibrations be performed to verify meter performance and accuracy.

Support line (781) 890-7440

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Copyright © 2004 Extech Instruments Corporation

All rights reserved including the right of reproduction in whole or in part in any form.

10

Version 1.6 7/04