Lighting for Industrial Applications

L i g h t i n g f o r I n d u s t r i a l A p p l i c a t i o n s

T Derek Schouten | Dialight Corporation

303-514-1220 | dschouten@dialight.com

2

Industrial Lighting Factors

• Distinct approach and design needs

– Rough/harsh duty environments

– High/low ambient temperature conditions

– Corrosive environments

– Dirty/Dusty conditions

– Power quality variables to consider

– Fixture accessibility factors

– Long term solutions needed

– Safety regulations

– Human factors

• Lighting Requirements

– Industrial users often require mandated light levels for OSHA and other regulatory compliance based on specific tasks/locations.

150w Stanchion – LED Replacement

Industrial Lighting Factors

250w High Bay – LED Replacement

3

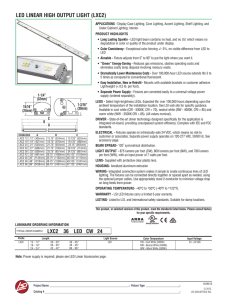

T8 Linear C1D2 – LED Replacement

400w High Bay – LED Replacement

70w Stanchion– LED Replacement

3

Issues With Existing Lighting Technologies

• Poor quality of light

• Excessive use of energy

• Safety & maintenance risks

• Sudden & unexpected light failures

• Restrike times of 2-20 min

• Audible noise produced

• Switching considerations

LED

High Pressure Sodium

High Pressure Sodium

LED

250w Low Bay– LED Replacement

5

Poor Light Quality - What you should know

• Inadequate or poor-quality lighting systems can create:

– Slips, trips, and falls

– Electric shocks and burns

– Inability to exit the space

• Poor lighting can affect the quality and productivity of work, specifically in situations where precision is required

• Poor lighting can be a health hazard - too much or too little light strains eyes and may cause eye discomfort (burning, etc.) and headaches.

5

6

Light Levels

• IES

(Illuminating Engineering Society) provides published, recommended light levels

– Specific Task, safety hazard, degree of activity, etc.

• Example:

– Walkway in a process area within a chemical facility:

• 5-10 foot candles

(50-75 lux)

70w Ceiling Mount – LED Replacement

6

7

Light Levels

• Example:

– Building exterior

• 3-5 foot candles

(30-50 lux)

70w Stanchion Mount – Retrofit LED Replacement

7

8

Why LED?

• Energy saving

– 60% + vs conventional efficient lighting

• Maintenance

– 10 year warranties

• Safety

– Full fixture output for >100,000h

• Reliability

– No need to replace bulbs or ballasts

• Control

– Instant on demand lighting – no restrike time

• Lifetime

– 10+ years of continual operation

400w High Bay – LED Replacement

LED Basics

• Solid State L ight E mitting D iodes

• The highest efficiency light source up to 200 lm/w from the chip

• Long lifetime –10 year warranties

• Sustained light output over life – L70

>100,000h

• CRI 75+

• Shock and vibration resistant

• Unaffected by switching cycles

• Instant on/off

• No hazardous materials

• Able to withstand extreme climates

– Up to 30% more efficient in cold environments

9

Structure of a white LED

Mixes down-converted yellow light with blue to produce light that appears white

10

Lighting Technology Comparison: LED vs. Traditional

Light source

High pressure sodium

Low pressure sodium

Mercury vapor

Metal halide

Fluorescent

CFL

Incandescent

Induction

LED

CRI

30

5

50

70-95

60-90

60-90

90-100

50-90

70-90

Lumens/watt

60-120

200

50

60-100

40-100

50-75

5-25

60-90

Up to 200

Lifetime in hours

10,000-24,000

10,000-24,000

10,000

6,000-20,000

6,000-45,000

6,000-15,000

1,000

60,000

100,000+

LED vs Traditional Lighting – Lumen Maintenance

12

Midpower LED

>100,000 hrs L70

100%

80%

LED L

70

400W High-Pressure

Sodium

~22,000 hrs L70

60%

40%

Median Lamp Life

Median Lamp Life

400W Metal-Halide

Lamp

~5,500 hrs L70

20%

0%

0 20000 40000 60000 80000 100000 120000 140000

Hours of Operation

12

Rated Life of Fixtures – Reports Used

• LM-79 measures total luminous flux, luminous intensity distribution, electrical power, efficacy (lumens per watt delivered), and color characteristics (CCT/CRI)

• IES developed two standards used to rate LED lifespans –

LM-80 and TM-21

– LM-80 measures lumen maintenance and depreciation in

LEDs.

• 6,000 – 10,000h real time test

• Three drive currents: High, Med, Low – Average used

• Operation at three case temperatures

• (55 ° C, 85 ° C and one selected by manufacturer)

– TM-21 takes the LM-80 data of an LED and uses calculations to predict total lifespan.

– TM-21 calculations and lifespans have become the industry standard for reporting.

• TM-21 is important as it creates a level playing field for

LED competitors using a universal mathematical algorithm.

13

13

Not all Lumens are Equal

• Traditional fixtures use

“Relative Photometry”

– The output of a fixture considering the lamp + reflector + accessories

– Lamp Lumens

– Most of the light that leaves a lamp is never “used”

• 60˚ Rules

– Light over 60 ° is considered

GLARE

– Not useful for general illumination.

– small contribution to groundlevel intensity.

– Visually uncomfortable to human observer.

Red shaded area = Glare Zone

14

Precise Optics With LED

• LED fixtures use “Absolute Photometry”

– The light output given is what is coming out of the fixture

– Additional optical control is still needed to maximize useable light

• Initial Fixture Lumens

– Some manufacturers report initial fixture lumens. This corresponds with most test data

– Some manufactures may report LED lumens, not taking into account a fixture's lens and other losses associated

15

HID Lumens vs LED Lumens

• HID

– Light is dispersed in every direction

– Reflectors and glass do not direct light energy perfectly

– 30%+ of light is “trapped” within the luminaire

– Lamp lumens depreciate much quicker than LED

• LED

– LED lumens are directional

– Use of optics is critical

– Every photon is directed towards the working area

– LED lumens depreciate very slowly

400W

Metal Halide

44,000 lm

112W

LED

14,000 lm

16

HID Lumens vs LED Lumens

• HID

– 44,000 lm

– 465W Metal Halide

– 20’x20’x15’

– LLF 0.65

– 19.5 fc avg

• LED

– 14,000 lm

– 112W LED

– 20’x20’x15

– LLF 0.65

– 22 fc avg

17

Designing LED Fixtures for Industrial Applications

Not all fixtures are built the same

• Fixture architecture different than commercial or residential products

– Diverse power quality considerations

• LEDs are a solid state device (circuit board)

• Large motor loads or other components within facility

– Demanding environments

• High/low temperatures

• Corrosive environments

• Ingress protection

• Dust and debris in the application

• Classified rated areas

– Fixtures need to perform flawlessly for the rated life in these environments

400w High Bay – LED Replacement

18

18

Designing LED Fixtures for Industrial Applications

Mechanical Considerations

– Robust housings using materials suited for industrial environments

– Corrosive resistant materials may be a factor in design

• Polycarbonate, acrylic, epoxy based paints, stainless steel

– Thermal management for longevity as well as T-ratings

• Heat is the enemy of any LED

– Light weight and compact for installation considerations

Metal

Halide

HPS

Industrial

LED

Maximum

Surface Temp

450°C (842°F)

300°C (572°F)

280°C (536°F)

260°C (500°F)

230°C (446°F)

215°C (419°F)

200°C (392°F)

180°C (356°F)

165°C (329°F)

160°C (320°F)

135°C (275°F)

120°C (248°F)

100°C (212°F)

85°C (185°F)

NEC 500 – Table

500.8 (B)

T3B

T3C

T4

T4A

T5

T6

T2C

T2D

T3

T3A

T1

T2

T2A

T2B

19

19

Designing LED Fixtures for Industrial Applications

Component Considerations

– Internal thermal sensors to regulate fixture output under high ambient conditions

– Algorithms to monitor for sine wave anomalies

– Oversized MOV’s to handle surge/transient/harmonic events

– Different soldering techniques

– Complete solid state design for high vibration applications

– Potted power supplies

• Moisture, shock, thermal reasons

– Factory sealed construction

20

20

Designing LED Fixtures for Industrial Applications

Thermal Effects on Lumen Maintenance

– If a manufacturer puts more current into the LED chip, more light output is achieved, but fixture life is significantly reduced.

= 700mA drive current

= 1000mA drive current

L70

21

21

LED Fixture Install Advantages

Hard to reach locations are ideal for LED use

– Eliminate expensive lift rentals and scaffolding installation to change lamps/ballasts

Often these factors lead to neglected fixtures resulting in poor lighting conditions and hazards

Turbine Deck - 1000w HID LED Replacement

22

22

LED Cost Savings Example

• Project Information

– Turbine Deck

– 24/7 lighting operation

– Energy Cost: $0.10 /kWh

•

• Existing Fixtures & Cost Assumptions

– (20) 1000W HPS high bays

– Annual energy costs: $20,093

– *Avg annual maint costs: $491

LED Fixtures & Cost Assumptions

– (20) 480W LED High Bay – 1000W equal

• Summary

– Initial spend: $30,760

– Initial cost: $30,760

– Annual energy costs: $8,387

– Annual maintenance cost: $0/fixture

– Annual energy savings: $11,706

• % Energy reduction: -58.3%

• 100,000 hr savings: $133,633

– Payback 2.53 years

• With rebates: <2 years

23

23

LED Lighting Technology Adoption

“If all U.S. lighting installations were replaced overnight with the best LED technologies available in 2014, our nation would save 4,896 trillion Btu of energy. Energy savings would result in an annual figure of about $49 billion.

”

- July 2015 LED Adoption Report - DOE

150w Low Bay – LED Replacement

*Annual source energy savings from

LEDs in 2014 was approximately

143 trillion Btu, which is equivalent to an annual energy cost savings of about $1.4 billion.

LED makes up 3% of total INDOOR lighting market and 10% of OUTDOOR

Lighting market by end of 2014.

24

24

LANXESS Rubber Plant - Singapore

T h a n k Yo u !

T Derek Schouten | 303-514-1220 dschouten@dialight.com