Ultraminiaturized WLAN RF Receiver Module in Thin Organic

advertisement

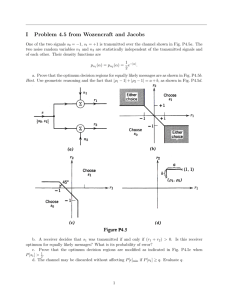

1276 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 4, NO. 8, AUGUST 2014 Ultraminiaturized WLAN RF Receiver Module in Thin Organic Substrate Srikrishna Sitaraman, Yuya Suzuki, Fuhan Liu, Nitesh Kumbhat, Sung Jin Kim, Venky Sundaram, and Rao Tummala, Fellow, IEEE Abstract— This paper presents the design, analysis, and demonstration of an ultra-thin wireless local area network (WLAN) RF receiver module with chip-last embedded actives and embedded passives in a low-loss organic substrate using systemon-package approach. The overall thickness of the module, including the embedded dies, is 160 µm– more than 3× thickness reduction compared to current wire-bond and flip-chip packages. The receiver module consists of gallium arsenide low-noise amplifier (LNA) dies, chip-last embedded in an ultrathin, lowloss organic substrate, and connected to a substrate-embedded three-metal-layer band-pass filter (BPF) in close proximity. Fullwave electromagnetic simulation was performed on a 3-D model of the designed receiver module to obtain its two-port scattering parameters (S-parameters) and to study noise coupling between the power-supply network and the signal path. The receiver module was then fabricated, tested for yield of the BPF, assembled and characterized, and the measured results were correlated with simulation. The BPF dimensions in the package were 1.5 mm × 2.9 mm × 0.15 mm, and its measured pass-band insertion loss was 2.3 dB with more than 15 dB return loss. The receiver module (LNA + BPF) dimensions were 5.5 mm × 2 mm × 0.16 mm, and it had a measured peak gain of 11 dB with more than 30 dB attenuation in the adjacent-band, indicating excellent performance in a miniaturized form-factor. Index Terms— Chip-last embedding, embedded passives, low-noise amplifier (LNA), organic substrate, system-on-package (SOP), wireless local area network (WLAN). I. I NTRODUCTION T HE growing demand for smart mobile systems drives the development of miniaturized electronic devices with increased functional density. System-on-package (SOP) [1] and system-on-chip (SoC) are two major approaches for system integration. For digital integration, SoC and through-silicon-via integration approaches have achieved miniaturization with improved performance and low cost. However, to miniaturize radio frequency (RF) components, SoC-based solutions [2], [3] suffer from very low Q-factor and Manuscript received October 26, 2013; revised March 20, 2014; accepted March 27, 2014. Date of publication June 26, 2014; date of current version July 31, 2014. Recommended for publication by Associate Editor A. Shapiro upon evaluation of reviewers’ comments. S. Sitaraman, F. Liu, N. Kumbhat, S. J. Kim, and V. Sundaram are with the Department of Electrical and Computer Engineering, Georgia Institute of Technology, Atlanta, GA 30332 USA (e-mail: srikrishna@gatech.edu; fliu@ece.gatech.edu; nitesh@gatech.edu; sungjin.kim@prc.gatech.edu; vs24@mail.gatech.edu). Y. Suzuki and R. Tummala are with the Department of Material Science Engineering, Georgia Institute of Technology, Atlanta, GA 30332 USA (e-mail: ysuzuki3@mail.gatech.edu; rao.tummala@ece.gatech.edu). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TCPMT.2014.2325592 Fig. 1. Components of a WLAN sub-system. high cost. Alternately, SOP approach effectively addresses the requirements of multifunctional wireless systems by enabling miniaturized high-performance RF and mixed-signal integration at low cost [1]. Traditional SOP-based integration of high-performance actives and passives for WLAN RF modules was demonstrated on low-temperature co-fired ceramics (LTCC) substrates [4]–[6]. Subsequently, to overcome the large thickness of LTCC substrates, RF integration on organic materials, such as liquid crystal polymer (LCP), was developed with surface mounted actives [7], [8]. Further, to address the requirement for low-profile form-factor and to improve RF performance, embedded integration approaches, such as chipfirst fan-out wafer level packaging [9], have been pursued [10]. However, they face the following barriers: 1) yield loss issues after die embedding causing loss of both substrate and dies; 2) technical challenges associated with embedding multiple heterogeneous components having dissimilar thicknesses; and 3) thermal dissipation issues among densely integrated actives. To mitigate such concerns in miniaturizing high-performance modules, SOP approach using chip-last embedding was pioneered by and is currently being pursued at Georgia Tech Packaging Research Center (GT-PRC) [11]. Chip-last embedded SOP has six essential advantages over SoC and chip-first approaches: 1) ability to embed multiple heterogeneous actives with minimal substrate yield loss; 2) intermediate-testability of substrates and components before assembly; 3) shorter interconnections between components, enabling superior electrical performance; 4) accessibility of the die backside, facilitating improved thermal performance; 5) flexible choice of substrate materials to address the requirements of different components; and 6) low-cost manufacturability for market affordability. A typical WLAN RF receiver module consists of an LNA and a BPF, as represented in Fig. 1. Using chip-last SOP, functional WLAN RF receiver modules were demonstrated in ultrathin six-metal-layer and three-metal-layer organic substrates [12], [13]. This paper extends on [13] by including the following: 1) extraction of S-parameters of the low-noise amplifier (LNA) dies from 2156-3950 © 2014 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission. See http://www.ieee.org/publications_standards/publications/rights/index.html for more information. SITARAMAN et al.: ULTRAMINIATURIZED WLAN RF RECEIVER MODULE IN THIN ORGANIC SUBSTRATE Fig. 2. 1277 Stack-up structure of the three-metal-layer substrate. the LNA module [no band-pass filter (BPF)] measurement; 2) 3-D full-wave electromagnetic (EM) simulation and characterization of the embedded BPF; and 3) 3-D full-wave EM simulation and analysis of the WLAN receiver module (LNA + BPF) design. The receiver module demonstrated here is more than 3× miniaturized in thickness compared to current wire-bond and flip-chip packages [14]. This paper is organized into six sections. Section I is the introduction. Section II details the design of the LNA module and the receiver module (LNA + BPF). Section III presents the simulation and analysis of the receiver module. Section IV discusses the fabrication, assembly, and characterization results. Correlation between the simulation and measurements is presented in Section V, followed by the conclusion in Section VI. II. WLAN R ECEIVER M ODULE D ESIGN Fig. 3. LNA module design top view. Fig. 4. Simulated performance of the BPF. Miniaturization of RF components involves electrical design of miniaturized high-gain actives and high-Q passives, and interconnecting these components with minimal substrate losses and interconnection parasitics. While superior performance of RF actives can be achieved through optimal design of GaAs and GaN dies, miniaturizing high-Q passives requires substrate materials having high permittivity (Dk) and lowloss tangent (Df); and short interconnections with reduced parasitics. For this paper, the dies were obtained from TriQuint Semiconductor, Inc., [15]. A. Substrate Material, Stack-Up, and Design Rules To realize miniaturized high-Q passives, ZEONIF ™ XL (X-L)–a low-loss organic material–has been employed in this paper. X-L, developed by Zeon Corp, is a halogen-free glass–fiber-reinforced polymer laminate. The cross section of the stack-up is illustrated in Fig. 2. The substrate stack-up consists of a core layer and a build-up film. To achieve this stack-up, a 100 μm-thick X-L prepreg (Dk = 6.5, Df = 0.0035) was laminated onto one side of an X-L copperclad laminate (CCL) core (Dk = 6.2, Df = 0.0031) of thickness 35 μm. B. Design of LNA Module and Receiver Module For this demonstration, two modules were designed, fabricated, and characterized: 1) an LNA module, designed with only the LNA dies and without the filter– for comparison with the original package from which the dies were sourced, and 2) a receiver module, designed by integrating the LNA dies and an embedded BPF–to demonstrate miniaturization with improved performance over the original LNA package (no filter). 1) LNA Module Design: The LNA module consisted of two embedded LNA dies along with RF signal transmission lines and DC power supply rails. The RF transmission lines were designed for 50 impedance. EM simulation of the transmission lines was performed using SONNET [16]. The dies were embedded in a cavity formed in the 100 μmthick build-up layer and were connected to landing pads on metal layer M2 with very short (15 μm height) copper–copper 1278 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 4, NO. 8, AUGUST 2014 Fig. 5. WLAN receiver module. (a) Schematic cross section and 3-D view. (b) Top view. Fig. 6. Simulation flow used for analyzing the receiver module layout. interconnections using thermo-compression bonding [17]. Since the separation between the active side of the die and the ground plane (M3) was only 45 μm, the copper on M3 was etched away under the dies to avoid eddy-current losses in the on-chip inductors. Metal patches were added to the power-supply rails on M1 to facilitate surface assembly of the decoupling capacitors. The LNA module occupied an area of 2.6 mm × 2.1 mm, as shown in Fig. 3. However, the coupon for this module was designed bigger to accommodate additional structures that aid in characterization. The thickness of this module was 160 μm. 2) Receiver Module Design: The receiver module design essentially integrated the LNA module with an embedded band-pass filter. The circuit schematic of the filter was simulated using Agilent ADS [18]. Based on the schematic, the layout of the filter was designed and optimized using SONNET EM simulator [16]. To achieve the highest capacitance density, the capacitors were designed between metal-layers M2–M3 across the thinner dielectric layer. The inductors were designed as two-layered structures across M2–M3 as well to increase the mutual inductance. The metal on layer M1 was assigned as the filter ground plane. To minimize the effect of ground parasitics, all the capacitors on M2–M3 were designed as stitched capacitors [19]. The filter occupied an area of 1.5 mm × 2.9 mm and its simulated response is shown in Fig. 4. For the receiver module design, this BPF was integrated with the LNA module design, such that the BPF connected the antenna to the LNA. For the characterization of this module, the antenna was replaced with a set of RF-probe pads. Fig. 7. Top view of the WLAN receiver 3-D model. The schematic cross section, 3-D view and top-view of the receiver module layout, is shown in Fig. 5. Its dimensions were 5.5 mm × 2 mm × 0.16 mm. III. F ULL WAVE 3-D EM S IMULATIONS The entire receiver module layout was simulated using HFSS, a 3-D full-wave EM solver. The simulation flow shown in Fig. 6 was employed. The receiver module layout design was imported into HFSS and set up for simulation. Setting-up the model included the following: 1) specifying the substrate dimensions and assigning stack-up materials; 2) creating tapered, conformallymetalized vias similar to the ones in the fabricated sample; 3) defining metal types and thicknesses; and 4) assigning ports. The metal thickness was set as 10 μm on all the layers. Since EM models of the dies were not available, the input and output terminals of the dies were replaced with lumped ports. Further, to include the effect of the die on the package resonances, a perfect electric conductor (PEC) sheet was introduced at the location of the die active surface. To capture any noise coupling from the power supply network to the receiver module input, a lumped port was located at the DC pads as well. The simulation was set-up for a driven terminal solution. A frequency sweep from 100 MHz to 20 GHz was defined in steps SITARAMAN et al.: ULTRAMINIATURIZED WLAN RF RECEIVER MODULE IN THIN ORGANIC SUBSTRATE 1279 Fig. 8. Characteristics of output RF signal path. Fig. 11. Complete package model created in Agilent ADS indicating signal flow. Fig. 9. Coupling from DC pad to RF signal path. Fig. 12. Complete receiver model simulated using HFSS and Agilent ADS. Fig. 10. Agilent ADS set-up to extract the LNA die S-parameters. of 100 MHz. The top view of the 3-D model in HFSS is shown in Fig. 7, with the die cavity, the BPF, and the ports indicated. This model was simulated and its S-parameters were obtained. The signal loss in the input and output RF paths and the coupling from the DC pads to the RF signal paths are studied. The input signal path contains the BPF which has a loss of 1.7 dB, as observed from Fig. 4. The insertion loss of the output signal path is shown in Fig. 8. It can be seen that the insertion loss at 2.4 GHz was 0.3 dB and return loss 15 dB. Additionally, the noise coupling from the power supply network to the signal input and output paths was also obtained, as shown in Fig. 9. Very low-noise coupling at the input is critical, since the input signal level is low and any additional Fig. 13. Image of the test vehicle mask layout. interference would lower the signal-to-noise ratio (SNR) at the input. It can be observed that even the worst-case noise coupling at the input is as low as −40 dB up to 10 GHz. Thus the low insertion loss of the signal path and low-noise coupling inside the package indicate that the noise added by the package is very low. Next, to obtain the S-parameter model of the LNA dies, the set-up shown in Fig. 10 was used. First, the S-parameters of the package interconnections of the LNA module (no filter) were obtained through the 3-D EM simulations 1280 Fig. 14. IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 4, NO. 8, AUGUST 2014 Fabrication process steps. Fig. 16. RF receiver module after assembly. (a) Top view. (b) X-ray image. Fig. 15. Images of (a) substrate prior to assembly. (b) Top view of die cavity. using HFSS. Following this, the LNA module (no filter) was fabricated and characterized. Then, the simulated S-parameters of the package interconnections were de-embedded from the characterized results of the LNA module. This yielded the S-parameter model of the LNA dies. To simulate the complete receiver package along with the dies, the simulated S-parameter model of the receiver package, and the de-embedded S-parameter model of the LNA dies were imported into Agilent ADS, as shown in Fig. 11. The die model was connected to its corresponding input–output port locations on the receiver package model. This set-up was then simulated in Agilent ADS to obtain the S-parameters of the complete package, as shown in Fig. 12. IV. FABRICATION , A SSEMBLY, AND C HARACTERIZATION A. Fabrication The module layout was panelized and integrated into a testvehicle for fabrication. The top-view image of the test vehicle layout is shown in Fig. 13. The fabrication process steps are depicted in Fig. 14. To achieve a good yield especially for the copper features with 30 μm spacing, semi additive process was employed for the metal patterning. The first step of substrate fabrication was the drilling of through-vias in the XL CCL using laser ablation to obtain vias of diameter 50 μm. Next, electro-less plating was performed to metalize the vias with a seed layer of 1 μm (steps 1–2). This was followed by the photoresist lamination on the top side and photo-lithography to pattern the photoresist, such that only the regions where the copper needs to be retained are exposed (step 3). Subsequently, electrolytic plating was performed to increase the thickness of the exposed copper (step 4). Once the thickness of the plated copper was close to 10 μm, the photoresist was stripped away and the seed layer removed through microetching (step 5). Then, the prepreg material was laminated on the top side of the core (step 6) followed by blind via drilling and metal patterning through subtractive etching (steps 7–8). Finally, cavities were formed on the build-up layer for die embedding, and nicked-gold surface finish was applied to the copper traces (step 9). An image of the substrate just before assembly is shown in Fig. 15 along with an image of the top view of the cavity containing copper traces and die landing pads. B. Assembly The ability to perform intermediate testing with chip-last approach helped to determine the yield of the BPFs through characterization, prior to die assembly. SITARAMAN et al.: ULTRAMINIATURIZED WLAN RF RECEIVER MODULE IN THIN ORGANIC SUBSTRATE Fig. 17. Cross-section view of the receiver module. Fig. 18. Measured response of the LNA module. Fig. 19. Measured response of the RF receiver module. Fig. 20. The two LNA dies and the decoupling capacitors were assembled on tested known-good coupons. The top view of the assembled receiver module and its X-ray image [13] are shown in Fig. 16. The ground planes on the backside of the dies were wire-bonded to each other and to the ground islands on the substrate. Multiple wire-bonds were used to achieve a low-inductance short between the substrate ground and the dies’ ground. After assembly, the modules were characterized using a vector network analyzer (VNA) to study the model-tohardware correlation. A cross section of the fabricated receiver module is shown in Fig. 17. C. Characterization After assembly, the LNA and receiver modules were characterized using the following set-up. 1281 Comparison of filter response simulation versus measurement. Fig. 21. Comparison of receiver performance simulation versus measurement. GSG RF probes: 500 μm pitch. DC supply: 3.3 V, 14 mA [15]. Two-port VNA. Short open load thru (SOLT) calibration to isolate the parasitics of the coaxial cables and probes. The measured response of the LNA module is shown in Fig. 18. The peak gain at 2.4 GHz was 14.13 dB with more than 15 dB return loss. It is noteworthy that the measured gain of the LNA module is comparable with its datasheet performance [15], despite the fact that the LNA dies were designed and optimized for a wire-bond package. The measured response of the RF-probe design is shown in Fig. 19. The peak gain of the receiver module was 11 dB, and the gain at 2.4 GHz was 9.2 dB with more than 25 dB adjacent band rejection (at 5.2 GHz). The isolation of GSM 1) 2) 3) 4) 1282 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 4, NO. 8, AUGUST 2014 band at 1.9 GHz was 32.35 dB. The shift in peak gain was attributed to the pass band of the BPF shifting to 2.6 GHz, reducing the gain of the receiver module at 2.4 GHz. V. A NALYSIS A comparison between the performances of the 3-D fullwave EM simulation of the BPF and its measurement is shown in Fig. 20. A slight drift in the performance toward the higher frequencies was observed and is attributed to process variations that potentially cause a reduction in the capacitor or inductor values. Good correlation between the complete receiver package simulation and its measurement can be observed from Fig. 21. VI. C ONCLUSION This paper demonstrates a chip-last embedded WLAN receiver module in a low-loss organic substrate. The LNA module with dimensions 2.6 mm × 2 mm × 0.16 mm is more than 3× smaller in volume compared with current packages [14]. It has a measured peak gain of 14 dB. The receiver module has a gain of 9 dB at 2.4 GHz. By comparing the performance of the LNA and the receiver modules, very good rejection of the adjacent frequency bands is observed in the receiver module, validating the efficacy of the BPF. The measured response of the receiver module correlates well with the results of the 3-D EM simulations. The dimensions of the receiver module are 5.5 mm × 2 mm × 0.16 mm. Compared with current wire-bonded LNA packages without a filter [14], this receiver module, including the filter, is more than 1.5× smaller in volume. The receiver module thus demonstrated is the thinnest known RF receiver organic package for WLAN applications, demonstrated to date. R EFERENCES [1] R. R. Tummala and J. Laskar, “Gigabit wireless: System-on-a-package technology,” Proc. IEEE, vol. 92, no. 2, pp. 376–387, Feb. 2004. [2] R. Vaidya, D. Gupta, M. Bhakuni, and R. Prince, “A miniature low current fully integrated front end module for WLAN 802.11b/g applications,” in Proc. IEEE CSIC Symp., Oct. 2007, pp. 1–4. [3] H. Morkner, M. Karakucuk, G. Carr, and S. Espino, “A full duplex front end module for WiFi 802.11.n applications,” in Proc. EuWiT, Oct. 2008, pp. 162–165. [4] J. Ji, Y. Li, J. Fang, and Y. Fei, “Modeling and realization of a wideband LNA based on LTCC technology,” in Proc. ICMMT, vol. 1. Apr. 2008, pp. 378–381. [5] B. C. Ham et al., “A GPS/BT/WiFi triple-mode RF FEM using Siand LTCC-based embedded technologies,” in IEEE MTT-S Int. Microw. Symp. Dig., Jun. 2012, pp. 1–3. [6] M.-C. Wu and S.-J. Chung, “A small SiP module using LTCC 3D circuitry for dual band WLAN 802.11 a/b/g front-end solution,” in Topical Meeting Silicon Monolithic Integr. Circuits RF Syst. Dig. Papers, Jan. 2006, p. 4. [7] S. Dalmia, V. Govind, J. Dekosky, V. Sundaram, G. White, and M. Swaminathan, “Design and implementations of RF systems and subsystems in LCP-type multilayer technology,” in Proc. 56th Electron. Compon. Technol. Conf., 2006, p. 5. [8] T. Kamgaing, E. Davies-Venn, and K. Radhakrishnan, “A compact 802.11 a/b/g/n WLAN front-end module using passives embedded in a flip-chip BGA organic package substrate,” in IEEE MTT-S Int. Microw. Symp. Dig., Jun. 2009, pp. 213–216. [9] M. Brunnbauer, E. Furgut, G. Beer, and T. Meyer, “Embedded wafer level ball grid array (eWLB),” in Proc. 33rd IEEE/CPMT IEMT Symp., Nov. 2008, pp. 1–6. [10] C. Durand et al., “High performance RF inductors integrated in advanced fan-out wafer level packaging technology,” in Proc. IEEE 12th Topical Meeting SiRF, Jan. 2012, pp. 215–218. [11] B.-W. Lee et al., “Chip-last embedded active for system-on-package (SOP),” in Proc. 57th ECTC, May/Jun. 2007, pp. 292–298. [12] V. Sridharan et al., “Ultra-miniaturized WLAN RF receiver with chiplast GaAs embedded active,” in Proc. IEEE 61st ECTC, May 2011, pp. 1371–1376. [13] Y. Suzuki et al., “Low cost system-in-package module using next generation low loss organic material,” in Proc. IEEE 62nd ECTC, May/Jun. 2012, pp. 1412–1417. [14] BGA622 Datasheet: Silicon Germanium Wide Band Low Noise Amplifier, Infineon, Neubiberg, Germany, 2008. [15] TQM3M7001 802.11a/b/g Dual-Band, Low Noise Amplifier Module, TriQuint, Hillsboro, OR, USA, 2004. [16] Sonnet EM Suite, Sonnet Software Inc., Onondaga, NY, USA, 2013. [17] A. Choudhury et al., “Low temperature, low profile, ultra-fine pitch copper-to-copper chip-last embedded-active interconnection technology,” in Proc. 60th ECTC, Jun. 2010, pp. 350–356. [18] Advanced Design System (ADS), Agilent EEsof EDA, Agilent, Santa Clara, CA, USA, 2009. [19] S. Min et al., “Filter integration in ultra thin organic substrate via 3D stitched capacitor,” in Proc. Electr. Design Adv. Packag. Syst. Symp., 2009, pp. 1–4. Srikrishna Sitaraman received the B.E. degree in electronics and communications engineering from Anna University, Chennai, India, in 2010, and the M.S. degree in electrical and computer engineering from the Georgia Institute of Technology, Atlanta, GA, USA, in 2012, where he is currently pursuing the Ph.D. degree with the 3-D Systems Packaging Research Center. He was with Intel Corporation, Phoenix, AZ, USA, as a Packaging Engineering Intern in 2012. His current research interests include modeling, design, and demonstration of ultraminiaturized high-performance wireless LAN radio frequency packages using 3-D organic and glass substrates. Yuya Suzuki received the degree from the University of Tokyo, Tokyo, Japan, in 2007, focusing on polymer solar cell. He was with Zeon Corporation, Tokyo, where he was involved in polymer science. He is currently with the Packaging Research Center, Georgia Institute of Technology, Atlanta, GA, USA, as a Visiting Engineer. His main interests are polymer synthesis, polymer processing, and organic–inorganic hybrid materials. His current research interests include the development of glass interposer and passive embedded RF module using low-loss polymer material. Fuhan Liu is an Associate Program Manager of Multilayer RDL Research with the 3D Systems Packaging Research Center, Georgia Institute of Technology, Atlanta, GA, USA. He is currently involved in the research and development of systemon-a-package integrations, ultrafine pitch redistribution layer low-cost glass interposer and package, low-cost organic interposer and package, low-cost low-CTE ultrathin high I/Os chip-embedded fan-out package, and embedded actives, passives, and optoelectronics integration technologies. He has developed and demonstrated various pioneer and leading edge technologies, including 1.5–5-um copper circuit traces multilayer RDL on glass, organic, and silicon packages using low-cost PCB and packaging facilities and processes, 1–2 metal layer low-CTE (2–4 ppm/0 C) package substrate with more than 500 I/Os chip assembly with overall package thickness less than 100 um, chip-last embedded IC chip in high-performance organic package for 1–110-GHz multiband applications, high-bandwidth integrated optoelectronics systems with optical interconnect and high-density electrical interconnect, and multispectral imaging using CMOS imager with mosaic filter for bio application. He has been involved in the area for more than 18 years. SITARAMAN et al.: ULTRAMINIATURIZED WLAN RF RECEIVER MODULE IN THIN ORGANIC SUBSTRATE Nitesh Kumbhat received the B.Tech. degree in metallurgical and materials engineering from IIT Roorkee, Roorkee, India, and the M.S. degree in materials science and engineering with a specialization in microelectronics packaging from the Georgia Institute of Technology (Georgia Tech), Atlanta, GA, USA, in 2003 and 2005, respectively. He was with Intel, Phoenix, AZ, USA, from 2005 to 2007, as a Package Technology Development Engineer, where he was involved in cutting-edge flip-chip mobile chipset package technology development. He was with the Packaging Research Center at Georgia Tech as a Research Engineer from 2008 to 2012, where he led the interconnections research. He joined Avago Technologies, Singapore, in 2012, and has been involved in the area of MEMS packaging. He has experience with substrate fabrication and chip-embedding technologies, finite element analysis, flip-chip assembly, and reliability analysis. He has several publications in journals, conferences, and magazines. His current research interests include interactions between MEMS devices and packages. Sung Jin Kim received the B.S. and M.S. degrees from Kookmin University, Seoul, Korea. He has over 18 years of experience in the packaging industry as a Researcher, Developer, and Team Manager with Amkor Technology, Gwangju, Korea, the Vice President at UTAC Corporation, Hsinch, Taiwan, the Managing Director at Daeduck Electronics Company, Ltd., Ansan, Korea, and the Business Unit Head at Foxconn Advanced Technology, Taipei, China. He built four factories in Asia from the scratch to full production for packaging, IC substrate, and embedded technology. He developed and delivered the world’s first 0.48-mm thickness multichip stacked lead frame package for NAND flash memory applications in 2004, lead system-in-package (SiP) development for system miniaturization, and Rmask substrate (no solder mask type substrate) development for JEDEC L-1 reliability packages in 2003, and directed board-on-chip package development using liquid elastomer die attach material with liquid encapsulation for DRAM applications in 2001. He is the inventor of many international patents for plastic BGA, stacked CSP, and SiP fields. He is currently with 3D Systems Packaging Research Center, Georgia Institute of Technology, Atlanta, GA, USA, where he is developing and commercializing leading-edge research programs with industry partners. He also teaches packaging courses and mentors graduate students. 1283 Venky Sundaram received the B.S. degree from IIT Bombay, Mumbai, India, and the M.S. and Ph.D. degrees in materials science and engineering from the Georgia Institute of Technology (Georgia Tech), Atlanta, GA, USA. He is the Director of Research and Industry Relations with the 3D Systems Packaging Research Center at Georgia Tech. He is the Program Director for the Low-Cost Glass Interposer and Packages industry consortium with more than 25 active global industry members. He is a globally recognized an expert in packaging technology and the Co-Founder of Jacket Micro Devices Inc., Decatur, GA, USA, an RF/wireless startup acquired by AVX. He holds more than 15 patents and more than 100 publications. His current research interests include system-on-a-package technology, 3-D packaging and integration, ultrahigh-density interposers, embedded components, and systems integration research. Dr. Sundaram is the Co-Chairman of the IEEE CPMT Technical Committee on High Density Substrates, and is in the Executive Council of IMAPS as the Director of Education Programs. He was a recipient of several best paper awards. Rao Tummala (F’93) received the B.S. degree from the Indian Institute of Science, Bangalore, India, and the Ph.D. degree from the University of Illinois at Urbana-Champaign, Champaign, IL, USA. He is a Distinguished and Endowed Chair Professor, and the Founding Director of the National Science Foundation’s Engineering Research Center at the Georgia Institute of Technology (Georgia Tech), Atlanta, GA, USA, where he is involved in Moore’s law for system integration. Prior to joining Georgia Tech, he was an IBM Fellow, involved in the first plasma display and multichip electronics for mainframes and servers. He has authored about 500 technical papers, holds 74 patents and inventions, and authored the first modern Microelectronics Packaging Handbook, the first undergrad textbook Fundamentals of Microsystems Packaging, and the first book introducing the system-on-package technology. Prof. Tummala is a member of the National Academy of Engineering and the Past President of the IEEE Components, Packaging, and Manufacturing Technology Society and the International Microelectronics and Packaging Society. He was a recipient of many industry, academic, and professional society awards, including the Industry Week’s Award for improving U.S. competitiveness, the IEEE’s David Sarnoff Award, the IMAPS’ Dan Hughes Award, the Engineering Materials Award from the American Society for Microbiology, and the Total Excellence in Manufacturing Award from SME. He was also a recipient of the Distinguished Alumni Awards from the University of Illinois, the Indian Institute of Science, and Georgia Tech in 2011. He was also a recipient of the Technovisionary Award from the Indian Semiconductor Association and the IEEE Field Award for contributions in electronics systems integration, and cross-disciplinary education.