Chemical Engineering

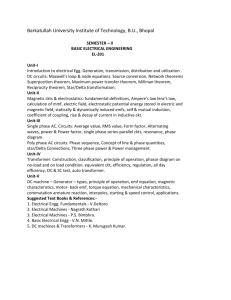

advertisement