Additional SafeLite® Information

advertisement

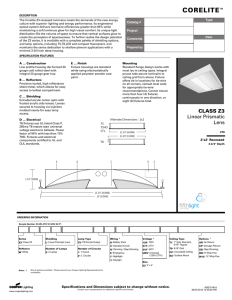

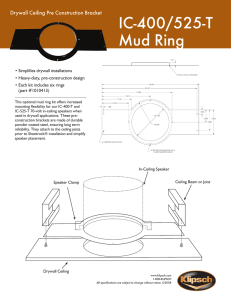

SafeLite The only UL Listed fixture protection enclosure with fire tested designs for: can lights, 2 x 2’, 2 x 4’, and 20” x 60” fixtures (including vented) for a range of construction assemblies and fire ratings up to 3 hours Patent / U.S. Patent Registration No. 7,627,999 B2 New improved spiral fasteners 2.14 SafeLitePosterRevision.pub UL/ULC & Code Requires Fixture Protection UL fire rated suspended and gypsum ceiling designs require that penetrations be protected. Items such as recessed light fixtures & speaker high hats must be protected with specified materials. Code requires membrane penetrations in fire rated floor/ceiling assemblies be protected to maintain the assembly fire rating. IBC 2009 & 2012 713.4.1.2 Membrane penetrations. Penetrations of membranes that are part of a horizontal assembly shall comply with Section 713.4.1.1.1 or 713.4.1.1.2. Where floor/ceiling assemblies are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced. Typical Tile / Drywall Enclosure Results As reported by inspectors and contractors, tile enclosures don’t hold up. Nails offer little holding power in the edge of 5/8” tile or drywall. Cover notched to accept power cable Considerable material and labor expense is required to cut, construct and install these fragile covers. IMPORTANT: Installers, owners and architects can face liability exposure for premature assembly failures. Drywall Enclosure 2 layers of 5/8” fire rated gypsum to be attached to a steel frame. Joints & penetrations to be fire caulked or taped and spackled. * CAUTION: Drywall (gypsum) product limitations state “avoid exposure to sustained temperatures of 125 F” (Dries out chemically bound water that provides fire resistance). * Light fixture ballasts and especially can lights generate considerable heat in unconditioned ceiling cavity space. * Field constructed drywall enclosures are subject to variations in quality and therefore performance. • Suspension wire & electrical cable notches may render the enclosure ineffective if not properly addressed. • Covers are heavy and labor intensive to construct and install. Now Winroc-SPI Typical SafeLite UL Listed Design (UL P267) 14B. Fixture Protection – Luminaires, Luminaire Assemblies and Luminaire Enclosures Classified for Fire Resistance* — SUPERIOR PLUS CONSTRUCTION PRODUCTS CORP — SafeLite® dba Specialty Products & Insulation (Winroc-SPI) New York City Approval The material used in the fabrication of SafeLite has been found acceptable for use by NYC Department of Buildings, Report of Materials and Equipment Acceptance Division MEA 210-82-M Vol. 2 Prescribed Test(s): RS 5-5 (ASTM E84), Toxicity Laboratory: Underwriters Laboratories, Inc. SafeLite Physical Properties Maximum service temperature: 1200F Melt Point: > 2000F Fire Performance: Non-combustible per ASTM E-136 Flame Spread 25, Smoke 0 per ASTM E-84 R Value 4.2 per inch per ASTM C-518 (effective R value 5.25 at 1 ¼” thick. helps reduce heating/cooling energy costs) Acoustical Performance per ASTM C-423 NRC 1.00 at 2” thick, CAC data follows Ceiling Attenuation Class (CAC) CAC is important and controls sound transmission and speech privacy between closed adjacent spaces. Ceiling CAC Performance CAC, A measure for rating the performance of a ceiling system as a barrier to airborne sound transmission through a common plenum between adjacent closed spaces such as offices or classrooms. Ceiling spec. NRC .70, CAC 40 A CAC less than 25 is considered low performance. * Suspended or drywall ceiling CAC 40 * Note: penetrations through the ceiling membrane increase noise transmission to adjacent space and floors above. Wall w/ R11 STC = 44 UL listed SafeLite provide documented sound blocking performance. This is especially important in health care and education environments for speech privacy, speech intelligibility and concentration. High Performance Acoustical Ceiling (penetrations can make up 10 - 20% of the ceiling area) SafeLite covers restore ceiling sound blocking (CAC) performance. Recessed lights, speakers, HVAC diffusers, sprinkler heads etc. significantly compromise drywall or suspended ceiling performance. CAC – Two Room Transmission Loss – AL20 (TM418) ASTM E 1414 Armstrong high CAC #1811 Fine Fiss. tile without light fixtures, CAC 44 Armstrong #1811 tile with 2 – 2 x 4 light fixtures, CAC 41 Armstrong #1811 tile with 2 – 2 x 4 fixtures with SafeLite covers. CAC 45 Conclusion: Just 2 light fixtures had a significant impact on ceiling acoustical performance. The 4 db (decibel) CAC improvement shown with SafeLite is significant. A 3 db change sounds as if the noise level doubled. This type of documented performance is critical for any sound proofing effort. SafeLite Can Light Covers for Sound Blocking Architects specify SafeLite to stop sound transmission through assemblies and into adjacent space. A ceiling thermal image scan reveals missing insulation. Uncovered recessed fixtures represent similar energy loss areas. Non combustible SafeLite reduces fixture energy losses. 1 ¼” thick SafeLite light covers provide an R Value of 5.25. 2009 IECC Mandatory Requirements – Recessed Lighting (502.4.8) All recessed luminaries installed in the building envelope * Type IC rated and sealed with gasket or caulk between housing and interior wall or ceiling covering * Type IC rated and labeled in accordance with ASTM E 283 to allow ≤ 2.0 cfm of air movement from conditioned space to ceiling cavity • “Code establishes the minimum requirement” SafeLite provides additional energy saving enhancement, contributing to reduced green house gas emissions and LEED Credits Note: your specific code may allow non-IC fixtures SafeLite Elements 1. 1 ¼” thick main cover with pre grooved easy fold side panels. 2. End caps 2 1 1 2 4 3 3 4 3. Spacer peel and stick insulation pin w/ washer to secure cover and maintain air space. 4. Spiral Fasteners for improved end cap attachment. SafeLite Can Light and Speaker Installations Are Similar Unprotected Can Light SafeLite Protected Can Light SafeLite base board is produced from natural materials which are made from up to 90% recycled content and can contribute to LEED credits. SafeLite = Labor Savings Installers typically report 1 or 2 heavy and awkward drywall or fragile fire rated ceiling tile enclosures field cut, fabricated and installed per man hour. SafeLite enclosures can be installed at 10-12 per man hour. One contractor documented $10,000 savings on his first job using SafeLite versus field fabricating gypsum board enclosures. Common SafeLite Applications (For Fire/Sound Blocking and Energy Savings) – Hospitals and medical facilities – Classrooms, music rooms – Office space, conference rooms and corridors – Performance space – Mixed function space SafeLite Users Acoustical ceiling and drywall contractors General contractors that self perform Institutional facilities, especially maintenance departments at hospitals and retirement facilities Electrical contractors Firestop specialty contractors Modular construction factories Key SafeLite Benefits Maintains assembly fire ratings for life safety and liability protection. Demonstrated sound blocking improves room to room confidentiality, provides a better learning environment. An effective R value of 5.25 reduces fixture energy losses saving energy and reducing greenhouse gas emissions. Made from natural materials with high recycled content contributes to LEED credits. Light weight covers install in about 5 minutes, reducing labor costs. Standard Fluorescent Light Dimensions 23 3/4” 5 1 1/4” 7/8” 4 5/8” 3 5/8” 21 1/4” Standard SafeLite fluorescent covers are available 24 and 48” long. Other fluorescent, can light and speaker high hats are made to order. SafeLite covers are available to fit virtually any fixture size. Installing SafeLite is Quick n Easy! Tools Needed Main Panel End caps New Spiral Anchors “V” grooved panel for quick fold and pin installation Installation On A Standard 2’ x 2’ Light Fixture Step 1 Power cable Apply peel n stick pin with spacer near center of light, but away from ballast Main Panel Installation Step 2 Fold down cover side panels and position on light. Mark cover to accept BX (armored) cable. Slit & Pull Cable into SafeLite, Align Edge with Fixture. Step 3 Lock washer on Spacer pin(s) keep cover in place. (Snip off excess pin) SafeLite easily slits to accommodate power cable and suspension wire. Install End Caps Step 4 End caps secured with improved spiral fasteners. Standard cover sizes include 6 fasteners. Contractors typically report installation in 5-6 minutes.