Type RCF - Liberty Bell Components

advertisement

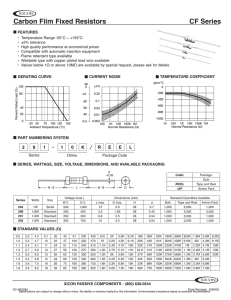

Zero Ohm and Jumper Wire Type RCF Zero Ohm and Jumper Wire Type RCF Series RCF25 - OR - M / RCF12 - OR - M ∆ Applications • Used when circuit path on a PC board needs to be crossed over. • Used for circuit tuning by changing point connections. d L H Fixed Component Resistors All Liberty Resistors uses the highest quality tin coated copper leads. The leads are rated at the below MAXIMUM soldering temperature and soldering time. D RCF25 - OR - W d MAXIMUM soldering temperature/time 350°C 3sec 235°C 2min L ∆ Specifications Construction Jumper Wire Ceramic (Metal Body) Ceramic (Metal Body) Ceramic (Metal Body) Ceramic (Metal Body) Ceramic (Metal Body) Part Number RCF24 * - OR - W RCF16 * - OR - C(M) RCF25 * - OR - C(M) RCF - 51 - OR - C(M) RCF - 100 - OR - C(M) RCF - 200 - OR - C(M) L 61.5 ± 1 3.8 ± 0.5 6.5 ± 0.3 9 ± 0.5 11 16 D 1.5 ± 0.2 2.5 ± 0.2 3.2 4.5 6 H (Min) d 0.6 ± 0.5 27 0.45 ± 0.5 27 0.6 ± 0.5 25 0.6 ± 0.5 30 0.8 ± 0.03 30 0.8 ± 0.03 Test Test Method Resistance Operating Temperature Max Current Max Working Voltage Max Overload Voltage Temperature Coefficient Short Time Overload Apply 2.5 times the rated voltage for 5 sec. 1000 hrs. at 70 ºC a direct voltage applied, cycles of 1.5 hrs on and Load 0.5 hrs off throughout test. 5 cycles of 30 min. duration at the extrements of temp. range, max. and min., measurements of ohmic value 4 hrs. after completion of Temperature Cycling test. Using a 90 ºC "V" shaped conductive block, applying 100V min., Dielectric Strength increasing 100V/sec. for 5 seconds Humidity 350 hrs. at 40 ºC, 90 to 95% Rh Solderability Dipped in Sn/Pb(60/40) at 235 ºC, 5 sec. 1.5 mm from the body. Vibration By MIL STD.202, 201A Traction, applied 2.5kg for 10 sec. Bends, 2 bends 90 ºC applying load Terminal Strength to terminals of 0.5kg. Twist 2 successive turn 180 ºC, 6mm from body. Trichlorethylene, TMC as the most aggressive for 60 sec. at boiling Resistance to Solvents point. Limits 0.01 ohm max. -55 ºC to +155 ºC 25amps @ +25 ºC (ZR25) 300Vdc 600Vdc (PPM/ ºC) 0 to -100 PPM No visible damage Δ R = 0.5% Δ R = 0.5% Δ R = 0.5% R = 0.5% 95% ø of tested surface covered No visible damage No visible damage 60 Liberty Bell Components, Inc. 11631 Seaboard Circle, Stanton, CA 90680 (888)820-8885 Fax: (888)820-8884 email: sales@libertycomponents.com website: www.libertycomponents.com Carbon Film Fixed Resistors Type RCF Carbon Film Fixed Resistors Type RCF Series Dimensions ∆ Features Resistance temperature coefficient is relatively high. Quick dissipation of heat and low temperature rise. Low price. Selected superior quality materials to ensure stability and reliability. Variety of packaging available: bulk, strip pack, tape and reel, etc. ∆ Applications • Easily used for various medical, telecom and consumer electronic equipment. d H L øD All Liberty Resistors uses the highest quality tin coated copper leads. The leads are rated at the below MAXIMUM soldering temperature and soldering time. MAXIMUM soldering temperature/time 350°C 3sec 235°C 2min Fixed Component Resistors • • • • • ∆ Specifications Performance -55°C ~ +155°C T.C.R. Type -150 -150 ± 150 -1,000 -700 Under 1.1K Ω - 51K Ω Temp Coefficient 0.125W 1K Ω 47K Ω 510K Ω (ppm/°C) Under 1.1K Ω - 160K Ω 0.25W 1K Ω 150K Ω 2.2M Ω 0.5W & Under 24K Ω 510K Ω Over 1K Ω 470K Ω 2.2K Ω Noise Type 0.1 0.3 0.6 0.125W Under 11K Ω Noise (μV/V) 10K Ω 100K Ω 0.25W & Under 110K Ω - 560K Ω Over 100K Ω 510K Ω 2.2M Ω Dielectric Withstanding No evidence of flashover or breakdown Resistance to Solvents Permanent marking no physical or electrical Short Time Overload ∆Rmax ≤ ± (1% ± 0.05Ω) Resistance to Soldering ∆Rmax ≤ ± (1% ± 0.05Ω) Heat Test Method JIS C 5202 MIL-STD-202 - Requirements Operating Temp. Range Temperature Cycling Vibration Moisture R>100KΩ Resistance R≤100KΩ R>100KΩ Load Life R≤100KΩ ∆Rmax ≤ ± (0.5% ± 0.05Ω) ∆Rmax ∆Rmax ∆Rmax ∆Rmax ∆Rmax ≤ ± (0.5% ± 0.05Ω) ≤ ± 5% ≤ ± (3% ± 0.05Ω) ≤ ± 3% ≤ ± (2% ± 0.05Ω) -150 -1,300 560 Ω 1M Ω 2.4M Ω 5.1M Ω 2.4M Ω 10M Ω 5.2 Method 304 1.0 Over 110K Ω Over 110K Ω 5.9-11 Method 308 5.7-A 5.5-A 6.4, 350°C 3 Sec. 7.4, 55°C / 85°C 6.3.3-A Method 301 Method 215 Method 204 7.9,40°C 90-95% RH 1000Hrs Method 106 7.10, 70°C 1000Hrs Method 108 damage or Method 210 Method 107 61 Liberty Bell Components, Inc. 11631 Seaboard Circle, Stanton, CA 90680 (888)820-8885 Fax: (888)820-8884 email: sales@libertycomponents.com website: www.libertycomponents.com Carbon Film Fixed Resistors Type RCF Carbon Film Fixed Resistors Type RCF Series ∆ Dimensions POWER RATING (W) 1/8W 1/4WS 1/4W 1/3W 1/2WS 1/2W 1W 2W 3W Type Fixed Component Resistors RCF-16 RCF-20 RCF-25 RCF-33 RCF-52 RCF-50 RCF-100 RCF-200 RCF-300 L±0.5 3.7 3.7 6.5 8.5 6.5 9.0 11.0 16.0 17.0 Resistance Range ±2 %(G) ±5%(J) 10Ω - 470K 0.1Ω - 47M 10Ω - 470K 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 1M 0.1Ω - 47M 10Ω - 470K 0.1Ω - 47M Max. Max. D±0.5 H (Min) D±0.03 (mm) Working V. Overload V. 1.6 27 0.46 200V 400V 1.6 27 0.46 200V 400V 2.5 27 0.58 250V 500V 2.8 25 0.58 300V 600V 2.5 27 0.58 250V 500V 3.2 25 0.58 350V 700V 4.5 30 0.80 500V 1000V 5.0 30 0.80 500V 1000V 6.0 30 0.80 650V 1200V Derating Curve Surface Tem p Rise CR300S 100 CR200S Surface Temp (°C) Load (%) 80 60 40 20 80 CR100S 60 CR50S CR33S 40 CR25S 20 CR16S 0 0 40 80 120 160 0 25 Am bient Tem p (°C) Current Noise 75 100 Tem perature Coefficient 3.2 0 1.0 -200 TC of R(PPM / °C) Noise Voltage (μV/V) 50 Load (%) 0 .10 .032 .010 -400 -600 -800 -1000 .003 1K 10K 100K 1M 0 Nom inal Resistance (Ω) 100 1K 10K 100K 1M Am bient Tem p °C ∆ Part Numbering RCF 25 Series Code Power Rating TR Packaging TR=Tape Reel 16=1/8W 20=1/4WS 25=1/4W 51=1/2W 52=1/2WS 100=1W 200=2W J 100 Resistance Code D50=0.50Ω 1D0=1.0Ω 100=10Ω 101=100Ω 102=1000Ω 103=10000Ω 104=100000Ω 105=1000000Ω Tolerance: J = ± 5% 62 Liberty Bell Components, Inc. 11631 Seaboard Circle, Stanton, CA 90680 (888)820-8885 Fax: (888)820-8884 email: sales@libertycomponents.com website: www.libertycomponents.com