Superconducting transformers - Power Delivery, IEEE Transactions on

advertisement

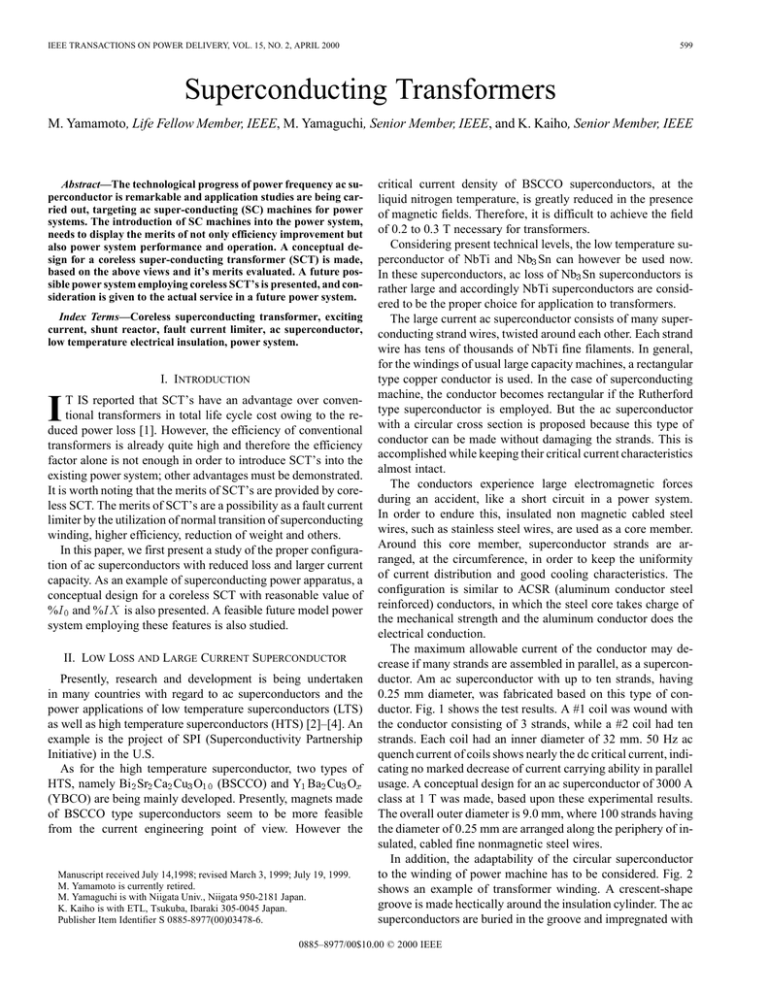

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 15, NO. 2, APRIL 2000 599 Superconducting Transformers M. Yamamoto, Life Fellow Member, IEEE, M. Yamaguchi, Senior Member, IEEE, and K. Kaiho, Senior Member, IEEE Abstract—The technological progress of power frequency ac superconductor is remarkable and application studies are being carried out, targeting ac super-conducting (SC) machines for power systems. The introduction of SC machines into the power system, needs to display the merits of not only efficiency improvement but also power system performance and operation. A conceptual design for a coreless super-conducting transformer (SCT) is made, based on the above views and it’s merits evaluated. A future possible power system employing coreless SCT’s is presented, and consideration is given to the actual service in a future power system. Index Terms—Coreless superconducting transformer, exciting current, shunt reactor, fault current limiter, ac superconductor, low temperature electrical insulation, power system. I. INTRODUCTION I T IS reported that SCT’s have an advantage over conventional transformers in total life cycle cost owing to the reduced power loss [1]. However, the efficiency of conventional transformers is already quite high and therefore the efficiency factor alone is not enough in order to introduce SCT’s into the existing power system; other advantages must be demonstrated. It is worth noting that the merits of SCT’s are provided by coreless SCT. The merits of SCT’s are a possibility as a fault current limiter by the utilization of normal transition of superconducting winding, higher efficiency, reduction of weight and others. In this paper, we first present a study of the proper configuration of ac superconductors with reduced loss and larger current capacity. As an example of superconducting power apparatus, a conceptual design for a coreless SCT with reasonable value of %I0 and %IX is also presented. A feasible future model power system employing these features is also studied. II. LOW LOSS AND LARGE CURRENT SUPERCONDUCTOR Presently, research and development is being undertaken in many countries with regard to ac superconductors and the power applications of low temperature superconductors (LTS) as well as high temperature superconductors (HTS) [2]–[4]. An example is the project of SPI (Superconductivity Partnership Initiative) in the U.S. As for the high temperature superconductor, two types of HTS, namely Bi2 Sr2 Ca2 Cu3 O10 (BSCCO) and Y1 Ba2 Cu3 Ox (YBCO) are being mainly developed. Presently, magnets made of BSCCO type superconductors seem to be more feasible from the current engineering point of view. However the Manuscript received July 14,1998; revised March 3, 1999; July 19, 1999. M. Yamamoto is currently retired. M. Yamaguchi is with Niigata Univ., Niigata 950-2181 Japan. K. Kaiho is with ETL, Tsukuba, Ibaraki 305-0045 Japan. Publisher Item Identifier S 0885-8977(00)03478-6. critical current density of BSCCO superconductors, at the liquid nitrogen temperature, is greatly reduced in the presence of magnetic fields. Therefore, it is difficult to achieve the field of 0.2 to 0.3 T necessary for transformers. Considering present technical levels, the low temperature superconductor of NbTi and Nb3 Sn can however be used now. In these superconductors, ac loss of Nb3 Sn superconductors is rather large and accordingly NbTi superconductors are considered to be the proper choice for application to transformers. The large current ac superconductor consists of many superconducting strand wires, twisted around each other. Each strand wire has tens of thousands of NbTi fine filaments. In general, for the windings of usual large capacity machines, a rectangular type copper conductor is used. In the case of superconducting machine, the conductor becomes rectangular if the Rutherford type superconductor is employed. But the ac superconductor with a circular cross section is proposed because this type of conductor can be made without damaging the strands. This is accomplished while keeping their critical current characteristics almost intact. The conductors experience large electromagnetic forces during an accident, like a short circuit in a power system. In order to endure this, insulated non magnetic cabled steel wires, such as stainless steel wires, are used as a core member. Around this core member, superconductor strands are arranged, at the circumference, in order to keep the uniformity of current distribution and good cooling characteristics. The configuration is similar to ACSR (aluminum conductor steel reinforced) conductors, in which the steel core takes charge of the mechanical strength and the aluminum conductor does the electrical conduction. The maximum allowable current of the conductor may decrease if many strands are assembled in parallel, as a superconductor. Am ac superconductor with up to ten strands, having 0.25 mm diameter, was fabricated based on this type of conductor. Fig. 1 shows the test results. A #1 coil was wound with the conductor consisting of 3 strands, while a #2 coil had ten strands. Each coil had an inner diameter of 32 mm. 50 Hz ac quench current of coils shows nearly the dc critical current, indicating no marked decrease of current carrying ability in parallel usage. A conceptual design for an ac superconductor of 3000 A class at 1 T was made, based upon these experimental results. The overall outer diameter is 9.0 mm, where 100 strands having the diameter of 0.25 mm are arranged along the periphery of insulated, cabled fine nonmagnetic steel wires. In addition, the adaptability of the circular superconductor to the winding of power machine has to be considered. Fig. 2 shows an example of transformer winding. A crescent-shape groove is made hectically around the insulation cylinder. The ac superconductors are buried in the groove and impregnated with 0885–8977/00$10.00 © 2000 IEEE 600 IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 15, NO. 2, APRIL 2000 possible not tc increase the %I0 so much by means of having more winding turns, taking advantage of conspicuously low loss superconductor, as compared with copper wires which is described later in the conceptual design. For example, it is possible to set the exciting current %I0 at about 1/3 of the rated current. This current can then be used for the substitution of the shunt reactor to compensate for the capacitive component of power transmission lines and/or cables. It is natural that %IX will increase but this will be restrained within acceptable levels for power system operation as shown by the conceptual design. However, the coreless SCT uses a plastic tank instead of stray loss, due to a leakage flux, decreases enabling a high %IX . B. The Advantage of not Using Iron Core Magnetic Nonlinearities Fig. 1 50 Hz ac quench current of coils and dc critical currents of strand The third harmonic current does not exist as a result of the coreless construction not requiring tertiary winding at the receiving side transformer. The rush current does not occur due to magnetic saturation and the mistaken operation of relays does not occur. C. Weight Reduction The weight of core and clamps occupies about one half of the total weight of conventional transformers. Therefore, the weight of SCT’s can be reduced by about 50% without the iron core, though precise difference will depend on construction. D. Quenching Phenomena Fig. 2 Multi-concentric cylindrical coil, epoxy resin impregnated epoxy resin. By employing this configuration, the mechanical strength is raised and reliability of electrical insulation is also raised. This is a result of that the gaps between conductor and insulation cylinders are impregnated with epoxy resin and the possibility of a partial discharge is reduced. III. MERITS OF CORELESS SCT A consideration is made on the merits provided by coreless SCT’s employing the technically feasible NbTi superconductors. The most obvious points of difference between the SCT and the conventional one are the possibilities to adopt a coreless construction and to utilize the quenching phenomena of a superconducting coil. These two points produce certain advantages as will be discussed below. A. Coreless Construction and Exciting Current It is not practical to remove the core of conventional transformers since the %I0 will become several times larger than the rated current. On the other hand, in the case of the SCT it is There are two possibilities concerning the quenching phenomena of SCT [5]. One is the active utilization of coil quench in parallel operation with conventional transformers. The other possibility is not to let coil quench on the occurrence of a fault due to high %IX of the coreless SCT. In the first case, letting SCT quench at an occurrence of a line short circuit, regardless of whether core or coreless type, the load current is transferred to the conventional transformers and naturally it will be overloaded. The load ratio is seldom over 75% at the usual operations, so it is reasonable to consider the overload value of 150%. The life of transformers will be slightly reduced after a few hours operation at 150% overload according to the transformer overload allowance of ANSI/IEEE rule C57-92. Then, SCT can be recovered to the superconducting state from the normal state with enough time. It is worth noting that the reactance of transformers is less, considering the whole power system, thus having less influence upon the stability of the power system. The second case is that the operation of superconducting power systems must not be interrupted due to coil quench of the coreless SCT, in an accident. Currents in the superconducting power system will not greatly exceed the level of about 1 pu against the fault outside a superconducting power system in a proposed power system, described below (Fig. 5). As a result the total %IX of coreless SCT with high reactance, generator and cable is close to 100%, accordingly there is no overcurrent bringing about the coil quenching of the SCT. YAMAMOTO et al.: SUPERCONDUCTING TRANSFORMERS 601 TABLE I TEST RESULTS OF A MODEL CORELESS AUTO-SCT Fig. 4 An example of an interleaved winding arrangement (a) L-H-L (b) L-H-L-H 2) Auto-transformer V1 = j! (LS + LC + 2M )I0 LC + M V LS + LC + 2M 1 (5) L +M L 0 M )I2 : j!( S LC + M C (6) V2 = Fig. 3 Coil connection and dimensions of a model coreless auto-SCT (a) Coil connection (b) Coil dimension (radius in mm) IV. CHARACTERISTICS OF CORELESS SCT A. Coreless SCT Generally, in transformers having a core, the ratio of the number of turns of each winding coincides with the voltage ratio since the main magnetic flux passes through the core. However, in the case of the coreless transformer, both ratios do not agree because the main magnetic flux is distributed in the windings and winding bores. Table I and Fig. 3 show the test results and coil dimensions for the model SCT. As for the coreless transformer under this situation, it is necessary to estimate the voltage ratio, %I0 and %IX based on self inductance of primary and secondary windings; L1 and L2 and their mutual inductance M , using the following equations [6]. 1) Two windings transformer Primary voltage V1 and secondary voltage V2 at no-load is given by V1 = j!L1 I0 V2 = j!MI0 = M V L1 1 (1) (2) Short circuit voltage of primary side, V1s is expressed by, V1s = j! L1 L2 0 M 2 I2 M (3) V1S = (4) Here, LS and LC are self-inductance of series and common winding, respectively, and M is the mutual inductance between the windings. A model sc transformer was made to confirm the above analyzes. The calculated induced voltage, %I0 and %IX agreed approximately with test results as shown in Table I. A conceptual design study was made on a coreless SCT with an actual rating as described below, based on the above equations. In the design, we employed the same insulation distance as an oil immersed insulation system. That is, we assumed that the liquid helium insulation dielectric strength, without partial discharge, is the same as or more than that of an oil insulation system [7]–[9]. The tap voltage was omitted as a feasibility study. B. Step-up Coreless SCT A study is made to obtain reasonable value of %I0 , %IX and total loss for the coreless SCT which provides the possibility of less total loss and smaller size. The large capacity generators in the normal power system have synchronous reactance Xd of 150 to 200%. On the other hand, the superconducting generators have a small Xd value of 1/3 compared with the conventional generators. Therefore, the stability of the power system can be ensured even if %IX of step-up transformers is about 50%. A conceptual design is now made, assuming 33% of %I0 and 50% of %IX . For the purpose of a decrease in %IX , it is effective to divide LV (low voltage) and HV (high voltage) windings to plural coils and interleave each coil concentrically. The greater the number of coil divisions, the lower %IX , however, 602 IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 15, NO. 2, APRIL 2000 TABLE II CONCEPTUAL DESIGN OF A STEP-UP AND STEP-DOWN CORELESS SCT Fig. 5 An example of an SC and a conventional hybrid power system the winding arrangement shown in Fig. 4 is considered to be practical. Table II is an example of a conceptual design of 3-50 Hz-1000 MVA-22 kV-138 kV step-up coreless SCT. The L-H-L winding arrangement of Fig. 4(a) satisfies the condition of %I0 and %IX described above and if required, it is possible to lower %IX to about 25% with the arrangement of L-H-L-H as shown in Fig. 4(b). The total loss of this transformer is about 2000 kW, assuming the superconductor’s ac loss of 25 kW/m3 at 1 T, 50 Hz, and 1/600 of refrigerator efficiency. This loss is considerably smaller than the approximately 3000 kW loss of conventional 345 to 550 kV transformers. Further, there is the advantage of omitting a shunt reactor, owing to the large %I0 . C. Step-Down Transformer Generally, the auto-transformers are used on the receiving side of large scale transmission lines. The self capacity of the auto-transformer is reduced by the ratio; (V1 0 V2)=V1 with regard to the rated capacity (V1 I1 or V2 I2 ) of the transformer, where V1 and V2 are the terminal voltage of HV and LV. The less the difference of V1 and V2 , the smaller it becomes. The voltage drop, due to the load current, appears only in the series winding and it also becomes smaller with the reduction of the voltage difference of two windings. Namely, both %I0 and %IX of the auto-transformer tend to have smaller values compared with normal transformers with two windings, enabling a coreless type without difficulty. As an example, a conceptual design of the coreless auto-SCT of 3-50 Hz-1000 MVA-132/69 kV was made, as shown in Table II. The windings were arranged concentrically, placing the series winding inside and the common winding outside. With this arrangement the achievement of 33% of %I0 and 25% of %IX was possible. V. FUTURE POWER SYSTEM An example for a future power system is shown in Fig. 5, where a hybrid system composed of conventional and superconducting systems are employed. We took into account that superconducting machines would be installed in the existing power system step by step [10]. The combination of both power systems, having different electrical parameters, is performed at the receiving side. In the superconducting power system, SCT’s using NbTi superconductors are cooled with liquid helium, while superconducting power cables made of high Tc superconductors are cooled with liquid nitrogen (LN2 ) and insulated with plastic sheet. YAMAMOTO et al.: SUPERCONDUCTING TRANSFORMERS The electrostatic charging current of the power cable, transmission and/or distribution lines is compensated by the exciting current of the coreless SCT, here assuming the %I0 of the coreless SCT to be about 1/3 of the rated current, though it can be widely varied by the design as required. In addition, a further shortage of compensation win be filled by SVC (static var controller), etc. Type A systems and Type B systems are considered in the above power system. The superconducting cable features the capability of large power transmission at relatively low voltage. In the B system, the step-down transformer could be omitted by connecting the power cable directly with a bus at the receiving side and consequently it will be of benefit to lower cost as well as reduced total loss as a power system. VI. CONCLUSION Of these studies, SCT with core was first studied and it was made clear that this type of SCT has less total loss than conventional transformers. However, its core size requires about the same size of conventional transformer, in order to obtain the appropriate %IX . In addition, the construction of a cryostat becomes rather complicated because of the need to place the core at room temperature. Thus, it is difficult to describe the advantages of applications of superconducting technology. It is concluded that the coreless SCT has the potential to provide many advantages, namely reduced power loss, weight reduction, application as a fault current limiter, no necessity of tertiary winding at the receiving side transformer and for the substitution of the shunt reactor if considered in the total power system. But to achieve this, further developments are necessary. These developments include the low loss and large current superconductors, liquid helium insulation system so as to cope with 110 to 132 kV power system, adaptable cryostat and such. 603 [3] K. Funaki, M. Iwakuma, M. Takeo, and K. Yamafuji et al., “Preliminary tests of a 500 kVA-class oxide cooled by subcooled nitrogen,” IEEE Transactions on Applied Superconductivity, vol. 7, no. 2, pp. 824–827, 1997. [4] H. Yamaguchi et al., “Loss characteristics of air-core superconducting transformer,” IEEE Transactions on Magnetics, vol. MAG-28, no. 5, pp. 2232–2234, 1992. [5] M. Yamamoto et al., “Feasibility study on a superconducting transformer,” IEEE Transactions on Magnetics, vol. MAG-22, no. 5, pp. 418–420, 1986. [6] K. Kajikawa and K. Kaiho, “Usable ranges of some expressions formainly culation of the self-inductance of a circular coil of rectangular cross section,” Cryogenic Engineering, vol. 30, no. 7, pp. 324–332, 1995. [7] M. Yamamoto, I. Ishii, H. Yoshida, and M. Yamaguchi, “Cryogenic liquid insulation system for electrical machines,” in Proc. 6th Int. Symposium on High Voltage Engineering, 1989, 31- 08, pp. 1–5. [8] R. J. Meats et al., “Pressurized helium breakdown at low temperature,” proceedings of IEE, vol. 119, no. 6, pp. 760–765, 1972. [9] B. Fallou et al., “Insulation components for high voltage cryogenic equipment,”, CIGRE Report, 15-04, 1974. [10] M. Yamamoto, K. Kaiho, and T. Ishigohka, “Fully superconducting power system,” Cryogenics, vol. 34, pp. 761–764, 1994. Mitsuyoshi Yamamoto was born in 1923 in Tokyo Japan. He received the Doctor of Engineering from Tokyo University in 1961. He joined Toshiba Corporation in 1949 and was engaged in developing electrical machines. After retirement, he was Professor of Saitama University and Takushoku University. Mitsugi Yamaguchi was born in 1942 Sapporo Japan. He received the Doctor of Engineering from Hokkaido University in 1970. He joined Toshiba Corporation in 1970 and was engaged in developing superconducting devices. He retired to join Niigata University in 1996 and is currently Professor at the Graduate School of Science and Technology, Niigata University. REFERENCES [1] H. Riemersma et al., “Application of Superconducting to Power Transformer,” IEEE MAG-20, no. 7, pp. 3398–3405, 1981. [2] A. Fevrier et al., “220 kVA superconducting transformer,” in Proceedings of ICEC 11, 1986, pp. 474–478. Katsuyuki Kaiho was born in 1942 in Tokyo Japan. He received the Doctor of Engineering from Tokyo University in 1976. In 1996 he joined Electrotechnical Laboratory. From then to now he is engaged mainly in research and development on applications of superconducting magnets.