Behavioural Safety

advertisement

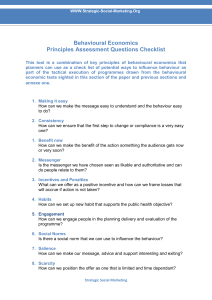

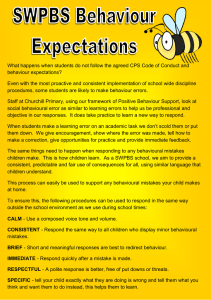

Behavioural Safety Management Safety Team Observation Program Doug Ward WSM Safety Management Consultancy WSM Behaviour Based Safety • Based on findings of an insurance executive report in 1951. • 73% of accidents reported by managers attributable from “man failures” • Re-classified to include an additional 15%. • DuPont evaluated 96% of accidents triggered or caused by unsafe acts and 4% unsafe condition • Introduction of the STOP program WSM What is Behaviour Based Safety • Focuses on at-risk behaviors that can lead to injury • Focuses on safe behaviors that can contribute to injury prevention • BBS is an injury prevention process WSM Why is Behavioural Safety used • Most accidents are reportedly caused by inappropriate behavior. • Good vehicle for management and employee engagement. • BBS determines the performance of your safety management systems. • Improve the visibility of your managers. • BBS influence the culture of your organisation through attitudes and perceptions. WSM How do we change behaviour? • • • • • Strong health and safety culture Lead from the top No blame Employees given appropriate information All employees trained in need for safety and application of organisation policies • Employees consulted on all important issues WSM Unsafe behaviour WSM Unsafe Behaviour “Spiderman” WSM Total Safety Culture WSM Total Safety Culture There Are 3 types of at Risk Behavior •Conscious behaviour. •Habitual behaviour. •Unintentional behaviour. BBS is about unintentional behavior and habitual behavior. To be more specific, it's about how to prevent mistakes or errors you never wanted to make in the first place. WSM Total Safety Culture 1 FATAL 30 MAJORS (Disabling Accidents) 300 RECORDABLE ACCIDENTS (Off Work, limited work and no lost time) 3,000 NEAR MISSES OR FIRST AID 30,000 HAZARDS Unsafe acts-Unsafe conditions WSM Total Safety Culture • What can cause or Contribute to “Critical Errors”. • Inexperience • Change of environment • Eyes not on Task • • • Mind not on Task Increase work load Familiar routine (New Start) (unfamiliar) (Rushing) (Frustration) (Fatigue) (Complacency) WSM Behavior Based Safety Journey Process Improvement Action Plan Employee ownership Data collection Observation Training Pre-Task/JSA Training Behavior Awareness Training Observations/Feedback JSA SafeStart WSM Process of Behaviour Based Safety • • • • • • • Advanced Safety Awareness Training. Safe Start (Risk Assessments). Job Task Analysis/Job Safety Analysis (JSA) Hazards Identified in Risk Assessments. Behavioural Observations. Observe job task looking at safe and at risk actions Complete STOP form enter into data base and action plans developed. • Communicate findings and implement action program. • Audit and evaluate progress. WSM Behavioural Observation Sheet WSM Behaviour Change STOP Feedback • • • • • • Remember participations is voluntary. Listen to disagreements. Respect their position and find points you can agree on. You may not have all the answers? Don’t act like you do. Prioritise and act upon findings. Communicate actions. WSM Behavioural Safety Program Resistance/Pitfalls • • • • • • • • Top Management – buy in. Controlled outside the organisation. Big brother blame culture. Just another management initiative program. Discipline of everyone. Poor communication. Start and finish. Failed program loss of credibility. WSM Behavioural Safety The Meerkat Way Video on inter-dependent safety WSM Heading text Thank you for listening WSM