Outcomes and evidence requirements

advertisement

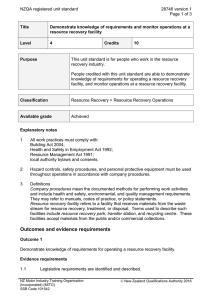

NZQA unit standard PortsNew7 version 1 Page 1 of 3 Title Operate heavy machinery in a port operation Level 4 Credits 30 Purpose People credited with this unit standard are able to start-up, operate, shut down and demonstrate operator maintenance checks for port heavy machinery. Classification Stevedoring and Ports Industry > Cargo Operations Available grade Achieved Explanatory notes 1 Legislation and formal requirements relevant to this unit standard may include the following Acts/Regulations and any supersessions: – Health and Safety in Employment Act 1992; – Code of Practice for Health and Safety in Port Operations (Wellington: – Occupational Safety and Health Service, Department of Labour, 2004) available at http://www.osh.govt.nz/order/catalogue/380.shtml. – General Harbour (Ship, Cargo, and Dock Safety) Regulations 1968, IMDG Code, Part 24a Maritime Rule, and port bylaws. 2 Definition Company policies and procedures refers to relevant workplace documents which are current and accessible to candidates, trainers, and assessors, and which comply with legal requirements. 3 Unit Standard Ports New5 Carry out pre operational checks, identify faults and follow reporting procedures for heavy port machinery is a recommended pre or co requisite to this unit standard. 4 Conditions – Competence in this standard or in the operation of any machine is not a licence to operate and machine specific licencing and induction is always required. – This standard is for machinery that exceeds 10 tonne working load capacity. – Evidence is required for a minimum of two machines. Outcomes and evidence requirements Outcome 1 Start-up port heavy machinery. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2015 NZQA unit standard PortsNew7 version 1 Page 2 of 3 Evidence requirements 1.1 Protective equipment is worn in accordance with machine operational safety requirements and company policies and procedures. 1.2 Safe methods are used to enter the machine control position. 1.3 Machine is started in accordance with safe operating practices and machine specifications. Range includes but is not limited to – seating, controls, location of personnel. 1.4 Gauges and warning symbols are checked during warm-up in accordance with machine specifications. 1.5 Controls are tested as functioning before being operated in accordance with machine specifications. Outcome 2 Operate port heavy machinery. Evidence requirements 2.1 Machine safety procedures are adhered to in accordance with manufacturer’s specifications and company policies and procedures. 2.2 Gauges and warning devices are monitored. 2.3 Operation of machine is controlled and is in accordance with manufacturer instructions and/or company policies and procedures. 2.4 Communication with other personnel is maintained in accordance with company policies and procedures. 2.5 Machine operations are completed efficiently in a minimum number of cycles. 2.6 Operation avoids unnecessary wear and damage to machine. Outcome 3 Shut down port heavy machinery Evidence requirements 3.1 Machinery is demobilised in preparation for shut down in accordance with manufacturers specifications and/or company policies and procedures . 3.2 Power source is idled down and switched off in accordance with manufacturer instructions and/or company policies and procedures. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2015 NZQA unit standard 3.3 PortsNew7 version 1 Page 3 of 3 Machinery is shut down and isolated/secured in accordance with manufacturer instructions and company policies and procedures. Outcome 4 Demonstrate operator maintenance checks for port heavy machinery. Performance criteria 4.1 Operator maintenance schedule is followed in accordance with manufacturer instructions and/or company policies and procedures. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 N/A Consent and Moderation Requirements (CMR) reference 0145 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2015